Telescopic chassis structure used for excavator

An excavator and chassis technology, which is applied in the field of retractable chassis structure, can solve the problems of inability to adjust the distance between the main frame and the left and right traveling frames, large volume and weight, and potential safety hazards, and achieves simple structure, low manufacturing cost, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

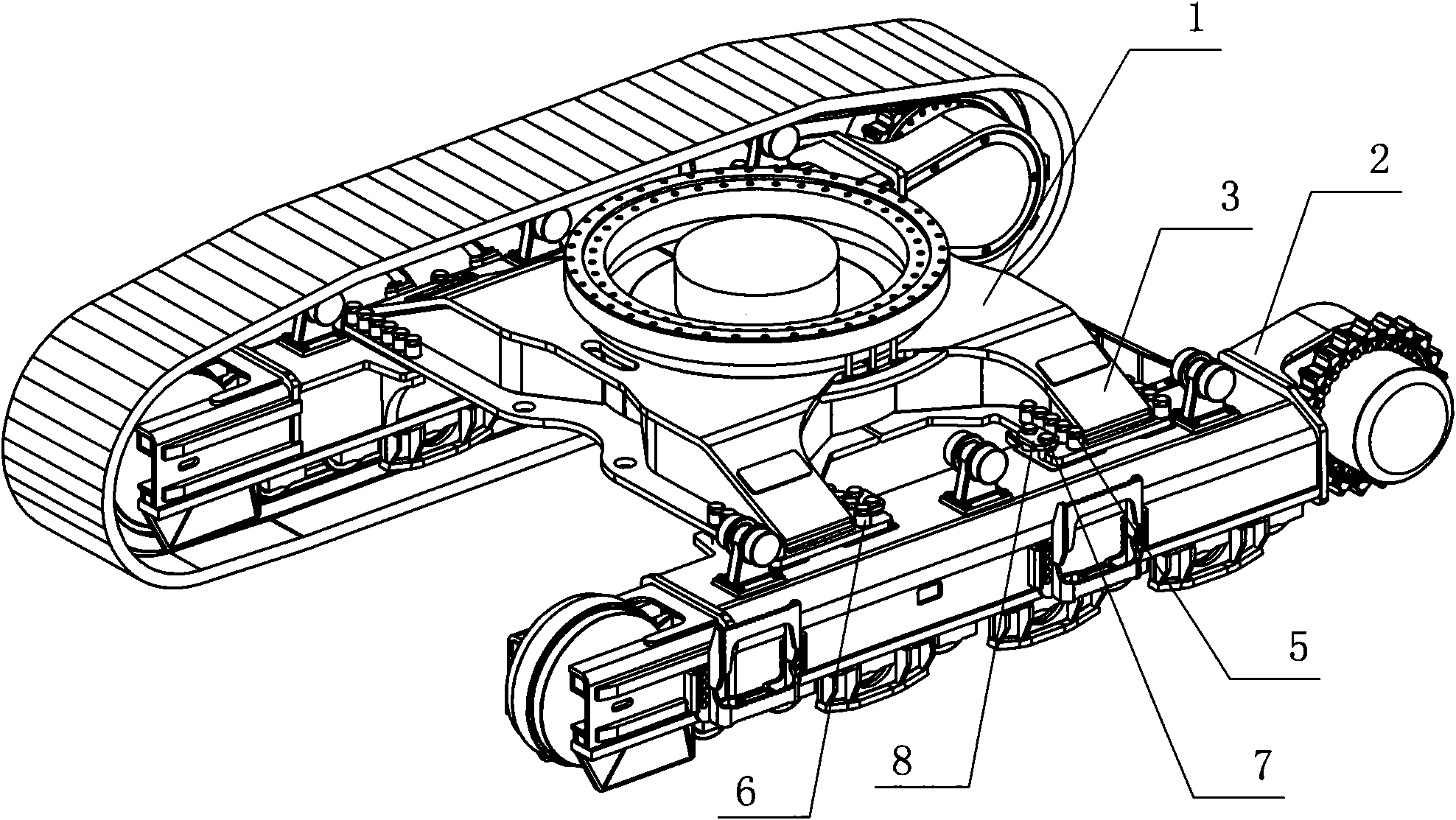

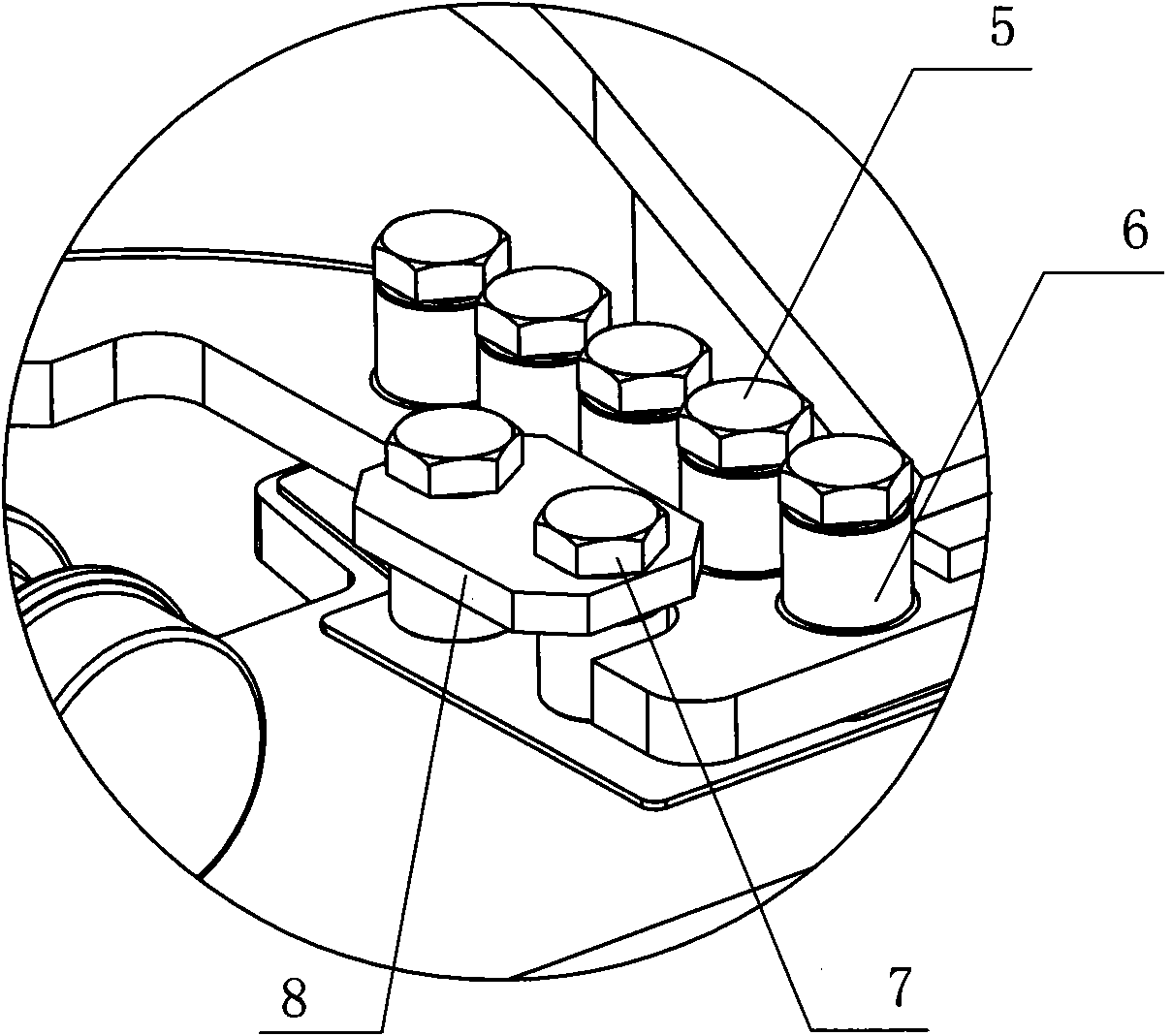

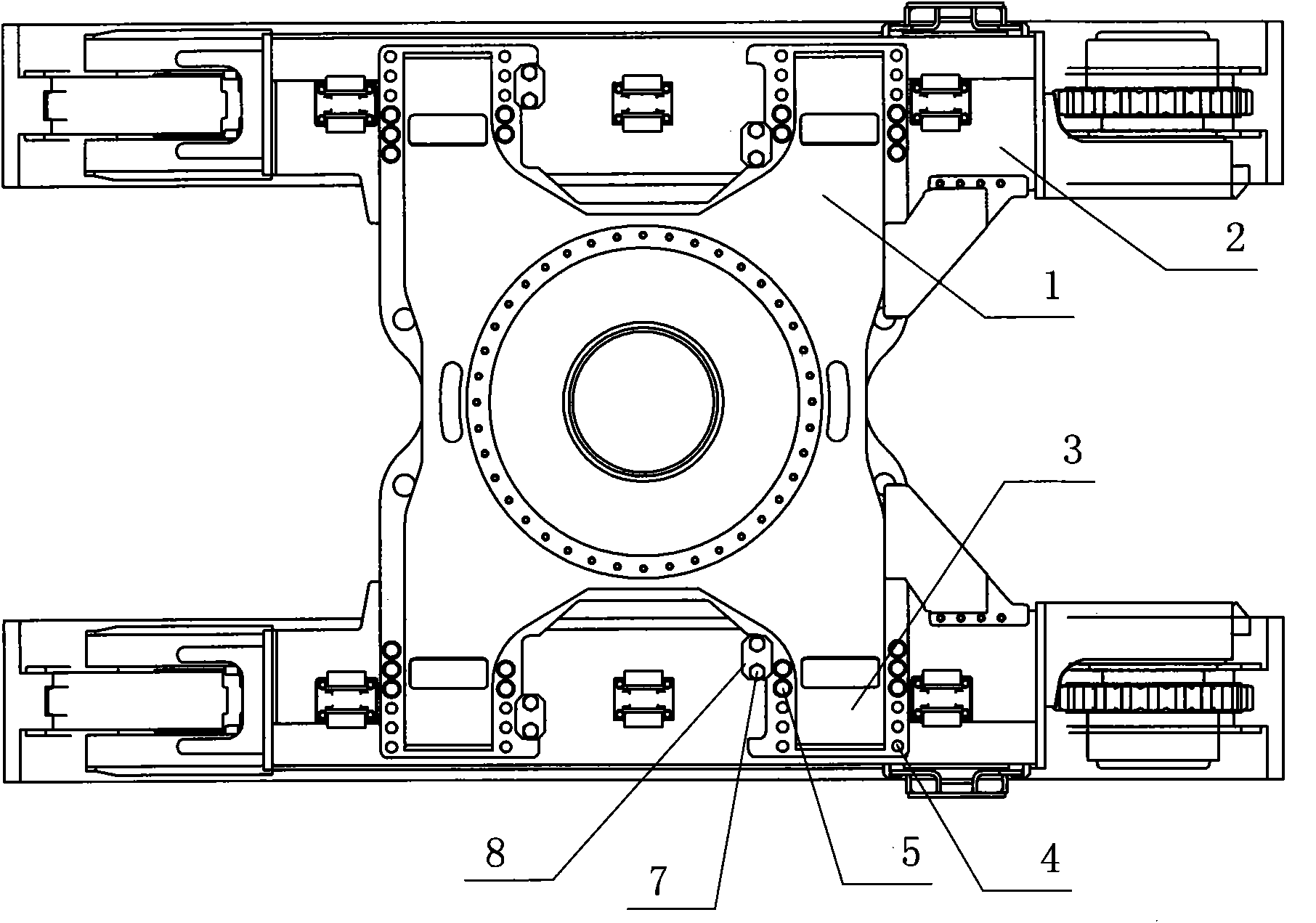

[0020] Embodiment one: see Figures 1 to 3 As shown, a telescopic chassis structure for an excavator includes a main frame 1, a left travel frame and a right travel frame 2, and two connecting ends 3 are symmetrically arranged on both sides of the main frame 1 , the two sides of the connecting end 3 are respectively provided with screw holes 4, corresponding to the screw holes 4 on the connecting end 3, a screw hole is provided on the walking frame 2, and a bolt 5 is also provided for matching with the screw hole, so The connecting end 3 and the walking frame 2 are connected through the bolt 5 and the screw hole 4 to form a threaded structure. The outer side of the bolt 5 is located on the upper part of the connecting end 3 and is also covered with a steel sleeve 6. The main frame 1 on the same side The inner sides of the two connection ends 3 are respectively provided with a limit structure in cooperation with the traveling frame 2, and the limit structure includes two limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com