Flexible transporting steel frames

A technology of steel frame and support frame, applied in the field of transport frame, can solve problems such as high cost, non-compliance with railway transport specifications, and difficulty in meeting development needs, and achieve the effects of improving economic efficiency, reasonable stress and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

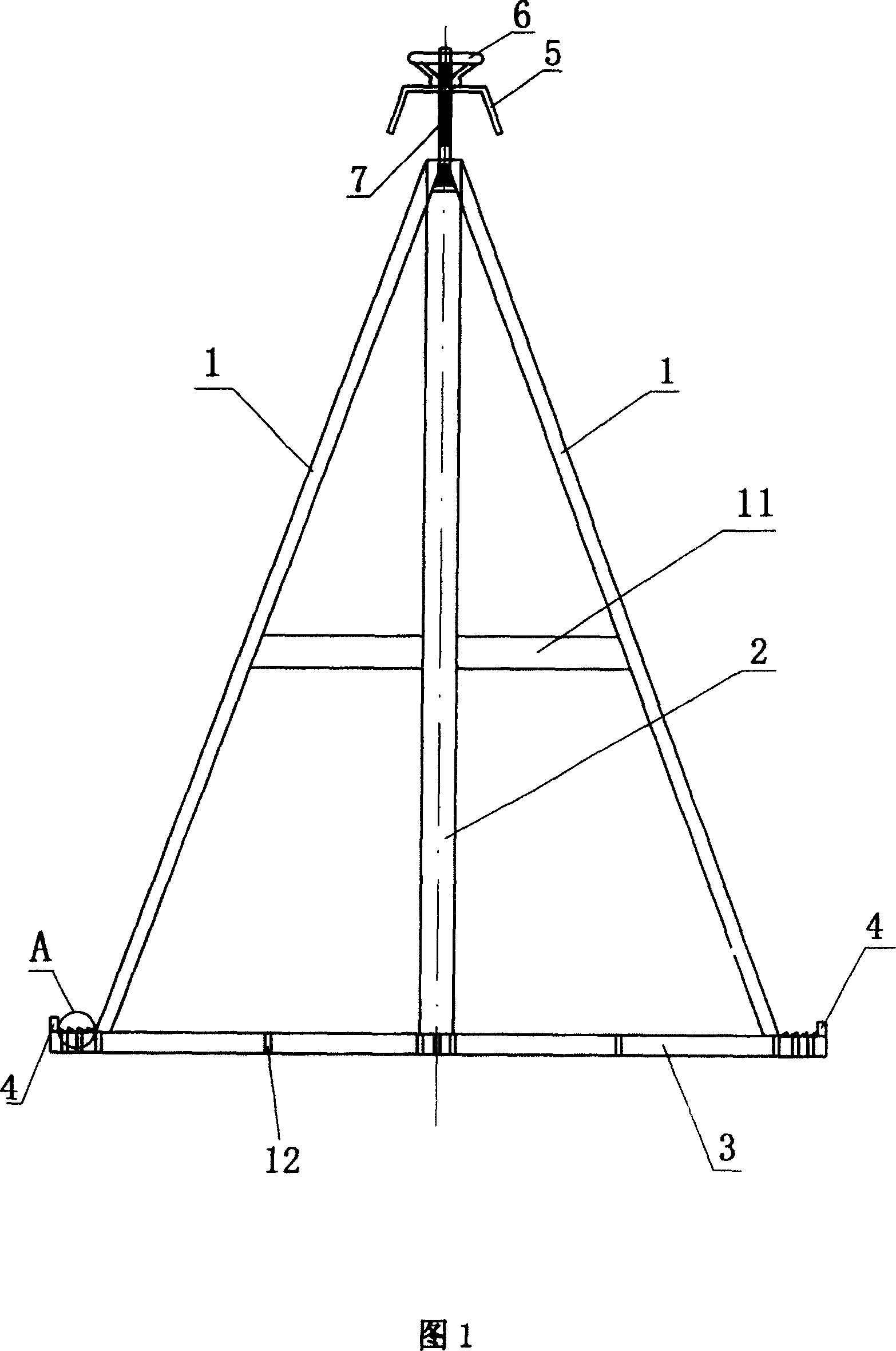

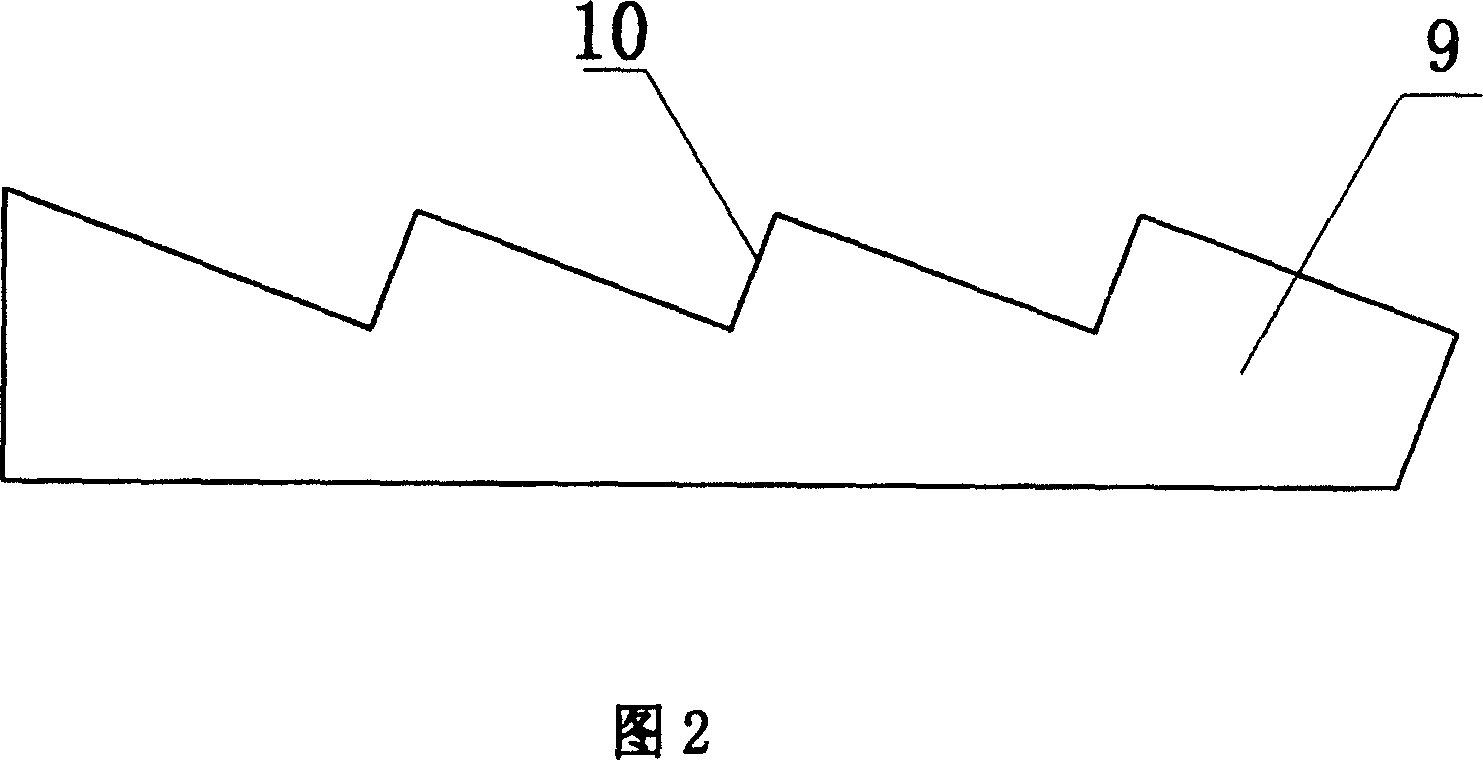

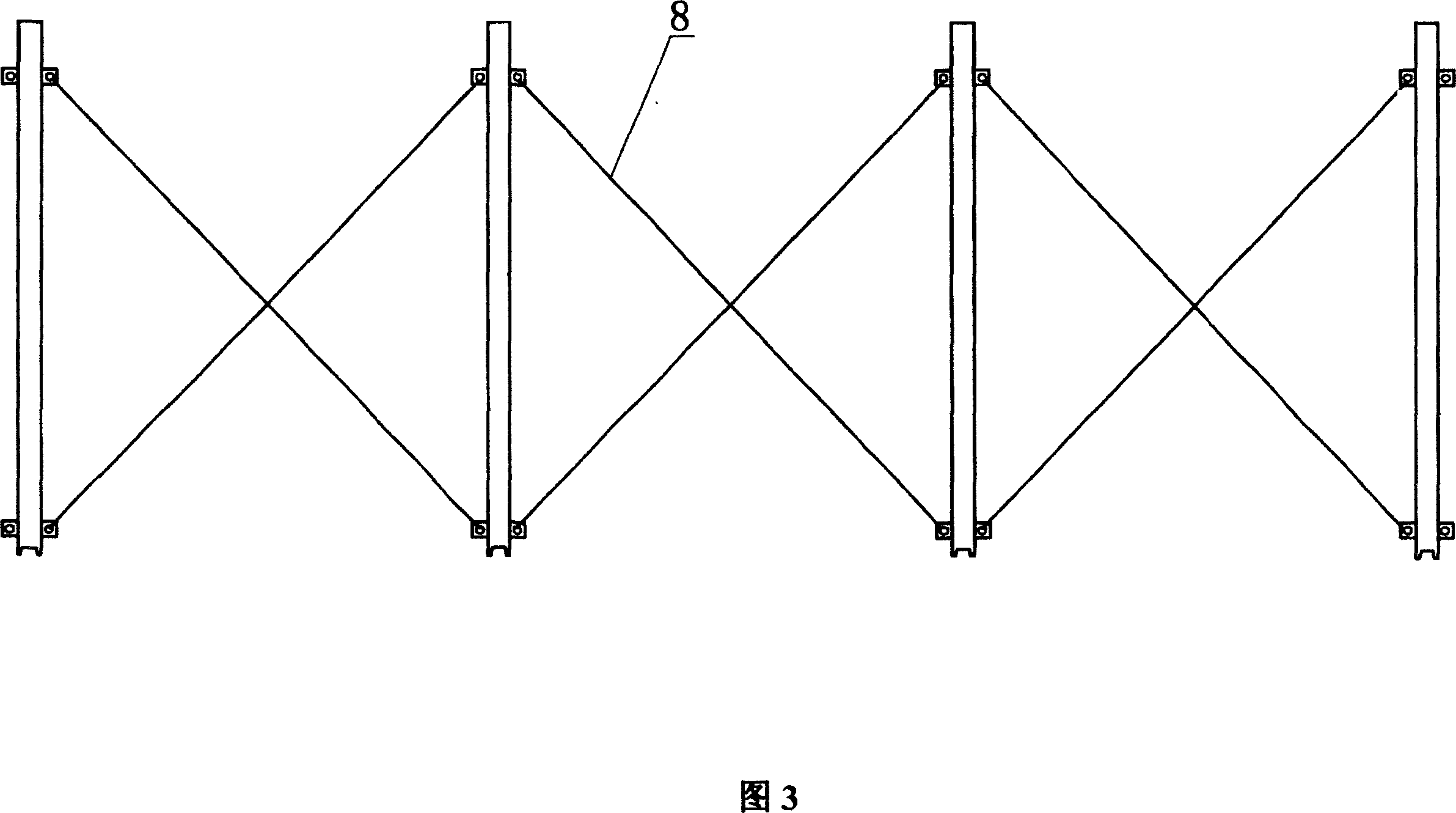

[0027] A kind of movable transportation steel frame that the present invention provides, as shown in Figure 1 and Figure 2, comprises several brackets that are fixedly connected together by scissors braces and arranged vertically and equidistantly; The A-shaped frame formed by the reinforcement rod 11 between the two oblique rods 1 and the support frame composed of the horizontal rod 3 and the vertical rod 2 vertically fixed in the center of the horizontal rod, and the reinforcement rod 11 and the vertical rod 2 are welded and fixed together, to strengthen the support. The apex and two supporting points of the A-frame are respectively welded and fixed on the vertical bar 2 and the horizontal bar 3 of the support frame, and the two ends of the horizontal bar 3 are symmetrically provided with stoppers 4, and the two supports of the stopper 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com