Marine rubber

A rubber and marine technology, applied in the field of marine rubber, can solve the problem of low compressive performance and achieve the effect of improving compressive performance and not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

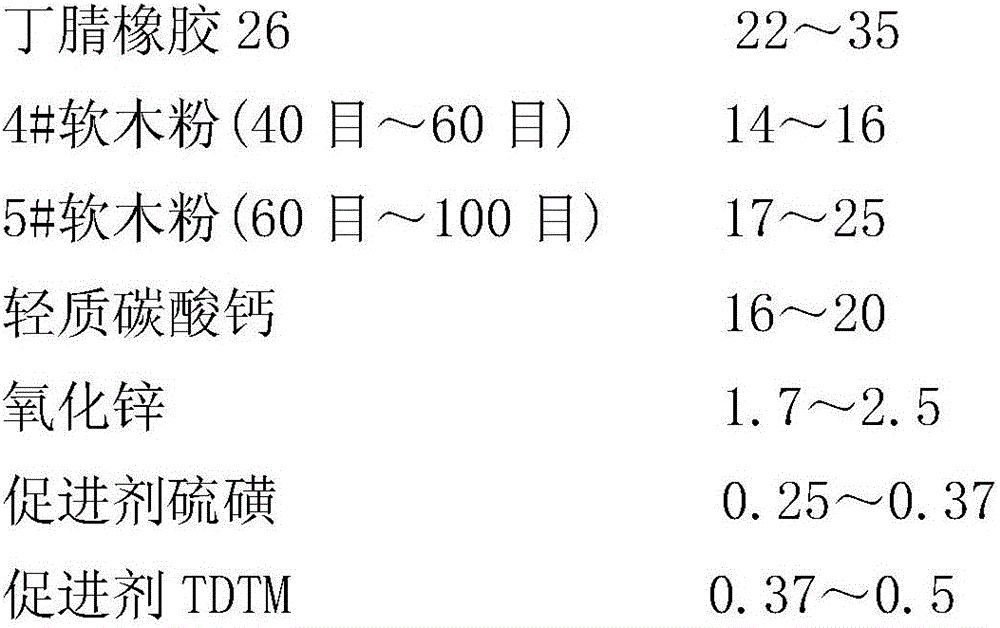

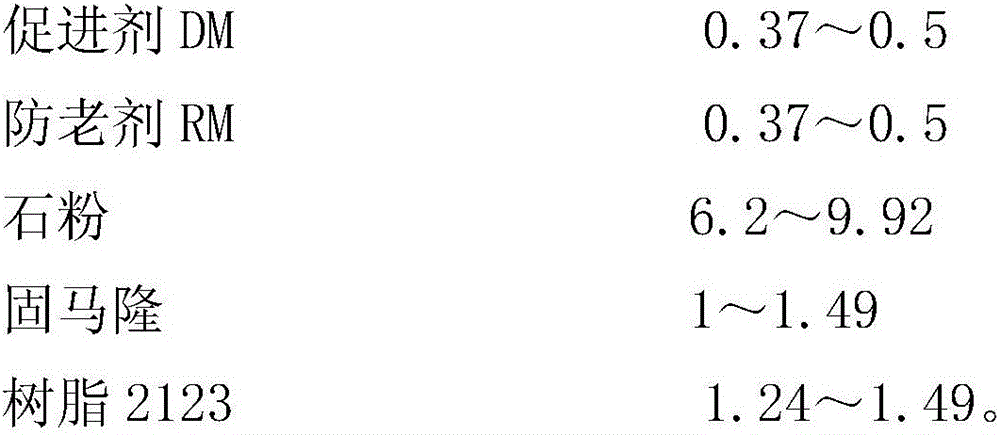

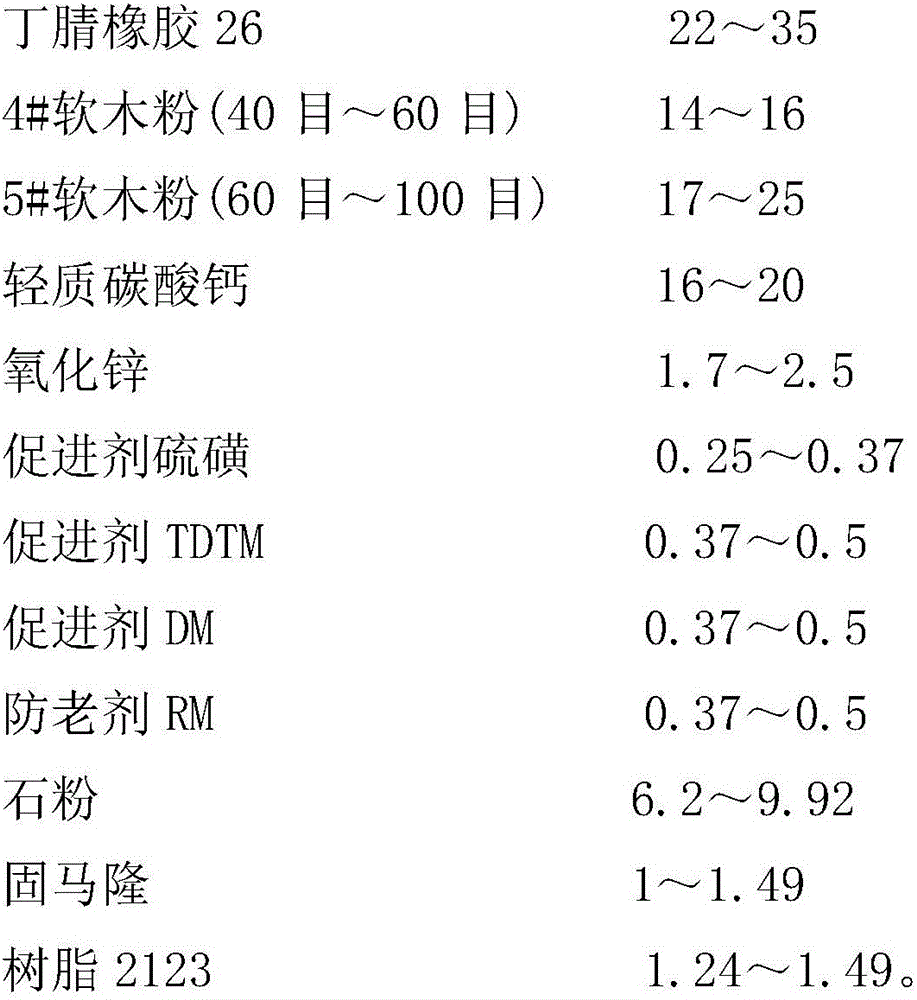

[0010] The invention discloses a marine rubber, which consists of the following components in mass percentage:

[0011] Nitrile rubber 26.58, 4# cork powder (40 mesh to 60 mesh): 16, 5# cork powder (60 mesh to 100 mesh): 25, light calcium carbonate: 20, zinc oxide: 2.5, accelerator sulfur: 0.37 , accelerator TDTM: 0.37, accelerator DM: 0.37, anti-aging agent RM: 0.37, stone powder: 6.2, solid Malone: 1, resin 2123: 1.24.

Embodiment 2

[0013] The invention discloses a marine rubber, which consists of the following components in mass percentage:

[0014] Nitrile rubber 34.65, 4# cork powder (40 mesh to 60 mesh): 16, 5# cork powder (60 mesh to 100 mesh): 17, light calcium carbonate: 16, zinc oxide: 1.7, accelerator sulfur: 0.25 , accelerator TDTM: 0.5, accelerator DM: 0.5, anti-aging agent RM: 0.5, stone powder: 9.92, solid Malone: 1.49, resin 2123: 1.49.

Embodiment 3

[0016] The invention discloses a marine rubber, which consists of the following components in mass percentage:

[0017] Nitrile rubber 30.85, 4# cork powder (40 mesh to 60 mesh): 15, 5# cork powder (60 mesh to 100 mesh): 22, light calcium carbonate: 18, zinc oxide: 2, accelerator sulfur: 0.3 , accelerator TDTM: 0.4, accelerator DM: 0.4, anti-aging agent RM: 0.4, stone powder: 8, solid Malone: 1.4, resin 2123: 1.25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com