Bracket-free laminated yoke rotor body structure of hydraulic generator

A technology for hydroelectric generators and laminated yokes, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., and can solve problems such as the inability to install rotor brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

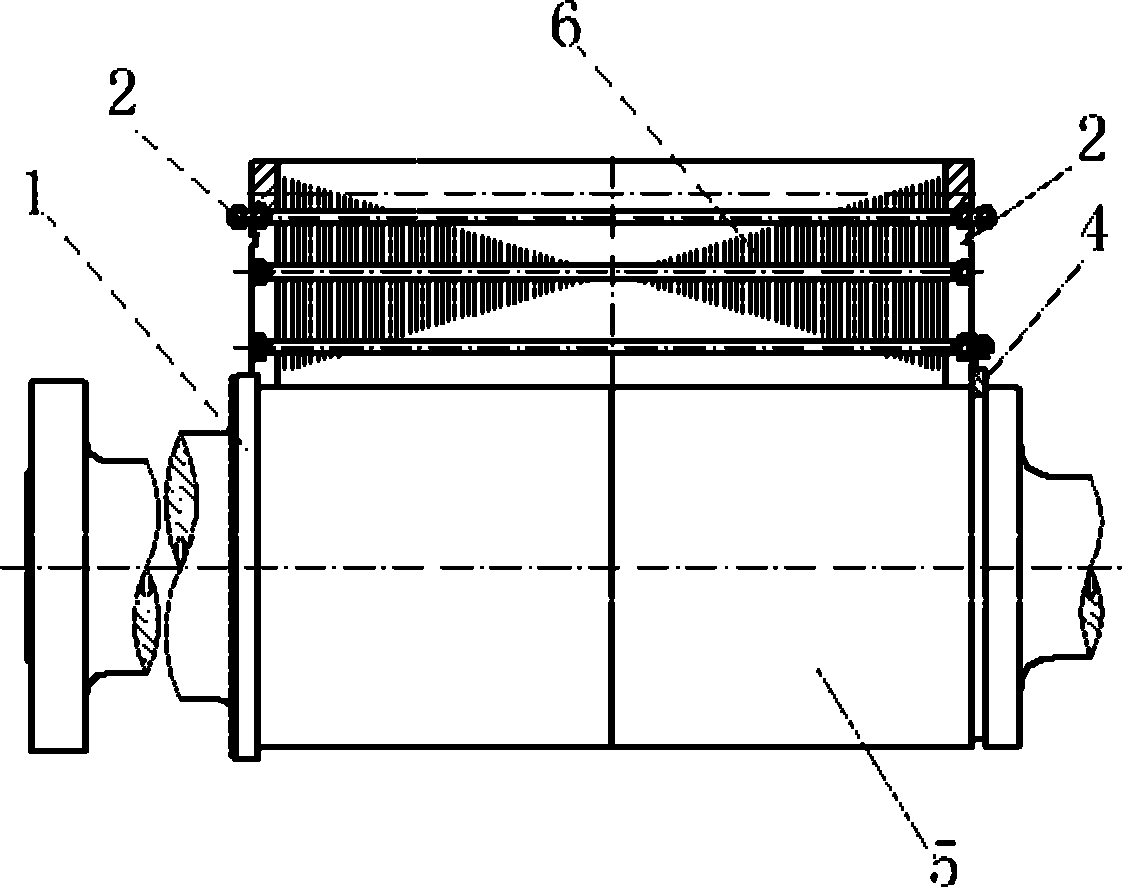

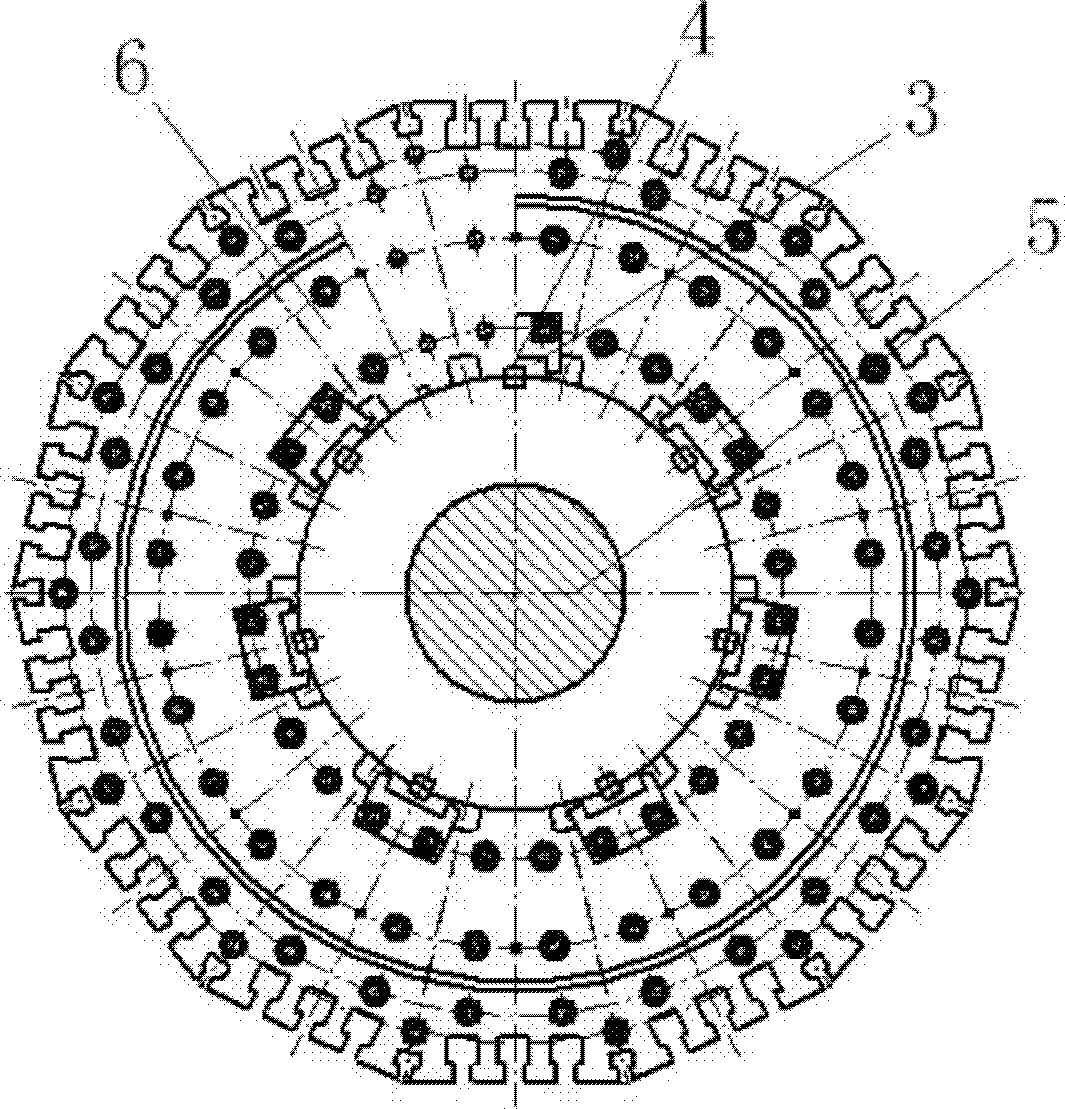

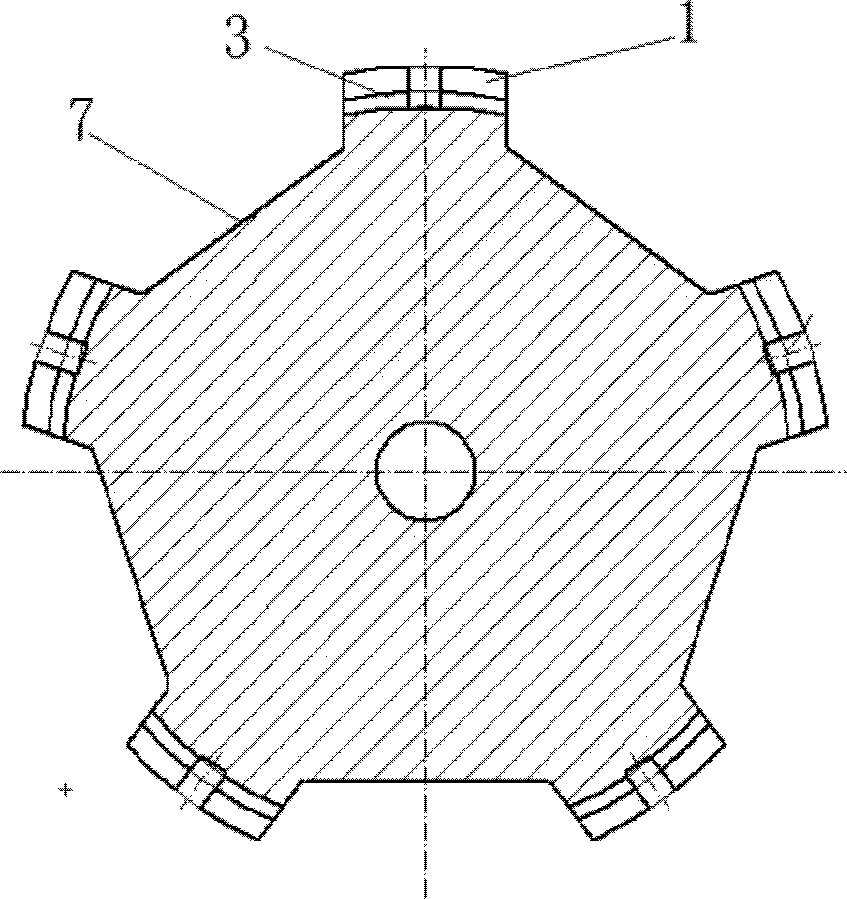

[0010] attached figure 1 It is a schematic diagram of the front view of the structure of the hydroelectric generator without support laminated yoke rotor body of the present invention, and the attached figure 2 It is an axial schematic diagram of the rotor body structure of the hydraulic generator without support laminated yoke in the present invention. In the figure, 1 is the main shaft positioning step, 2 is the lower pressure plate, 3 is the main shaft positioning rib keyway, 4 is the radial key, and 5 is the Main shaft, 6 is lamination yoke. It can be seen from the figure that the structure of the rotor body of the hydro-generator with no brackets and laminated yokes in the present invention increases the diameter of the main shaft yoke section according to the width of the yoke segments, and processes positioning steps 1 and positioning ribs on the outer circle of the main shaft yoke section. The keyway 3 and the yoke sector are directly stacked on the outer circle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com