Industrial control system based on field bus and control network

An industrial control system and control network technology, which is applied in bus network, comprehensive factory control, comprehensive factory control, etc., can solve the problems of high performance requirements, high cost, and inability to take into account hardware cost overhead and stability of the main station processor, etc. Achieve the effect of shortening the development cycle, reducing performance requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

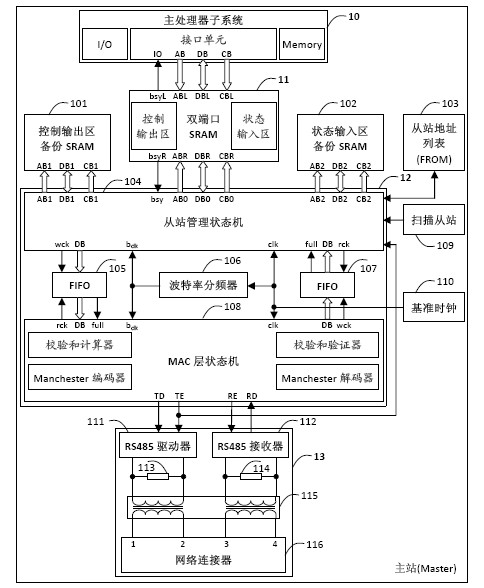

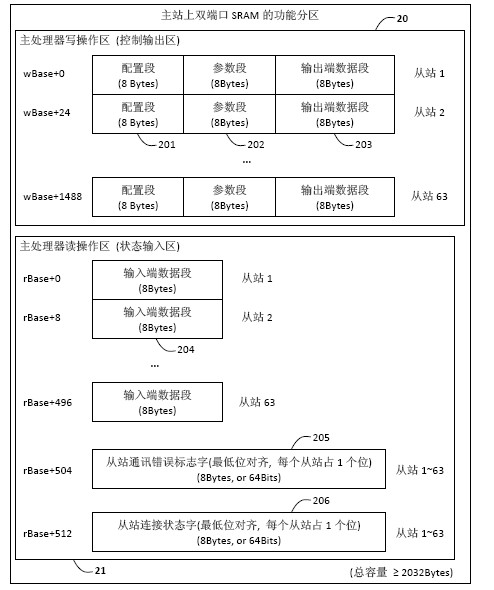

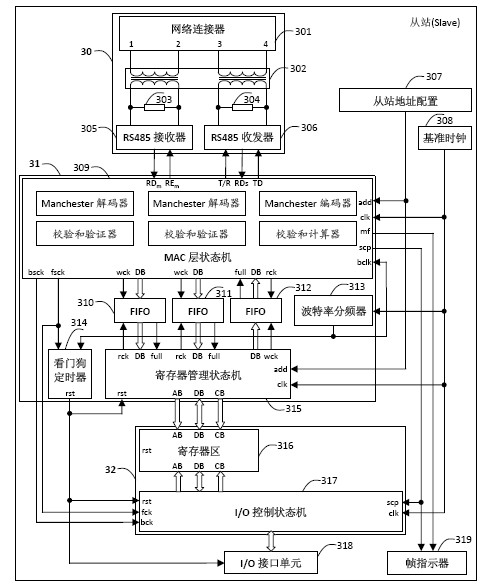

[0039] refer to Figure 1 to Figure 12 , an industrial control system based on a field bus and a control network, including a master station, a slave station and a network communication protocol, and a dual port is used between the main processor subsystem on the master station and the main communication protocol stack on the master station The SRAM exchanges data, and periodically and automatically completes communication between the described main communication protocol stack and the slave communication protocol stack on the slave station; the described slave station includes a slave communication protocol stack and an I / O controller, and the slave station includes a slave communication protocol stack and an I / O controller, and the slave station The communication protocol stack receives control instructions sent by the master station, and can also receive input termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com