Oled display panel with PWM control

A technology for display panels and driving transistors, applied to static indicators, instruments, etc., can solve problems such as difficulty in reducing costs and complicated transistor manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

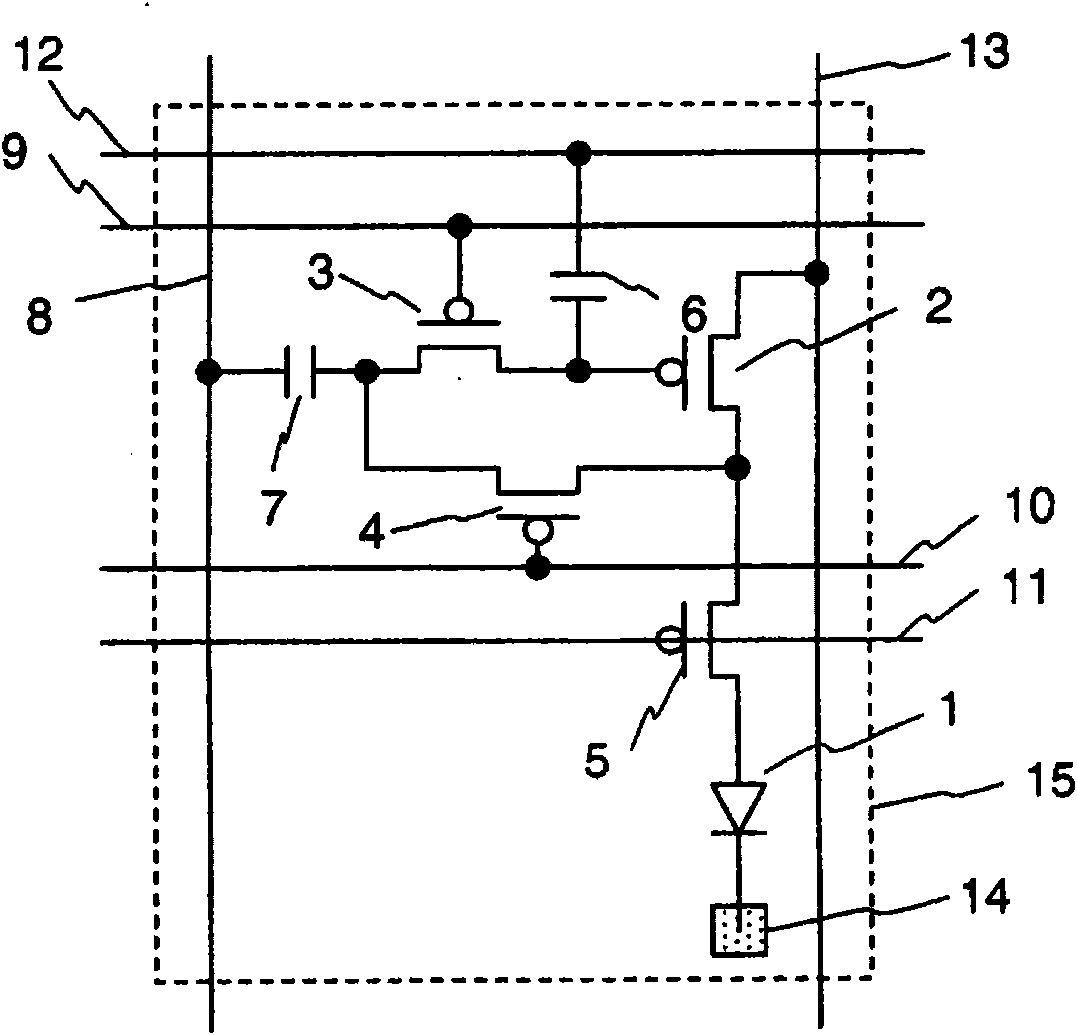

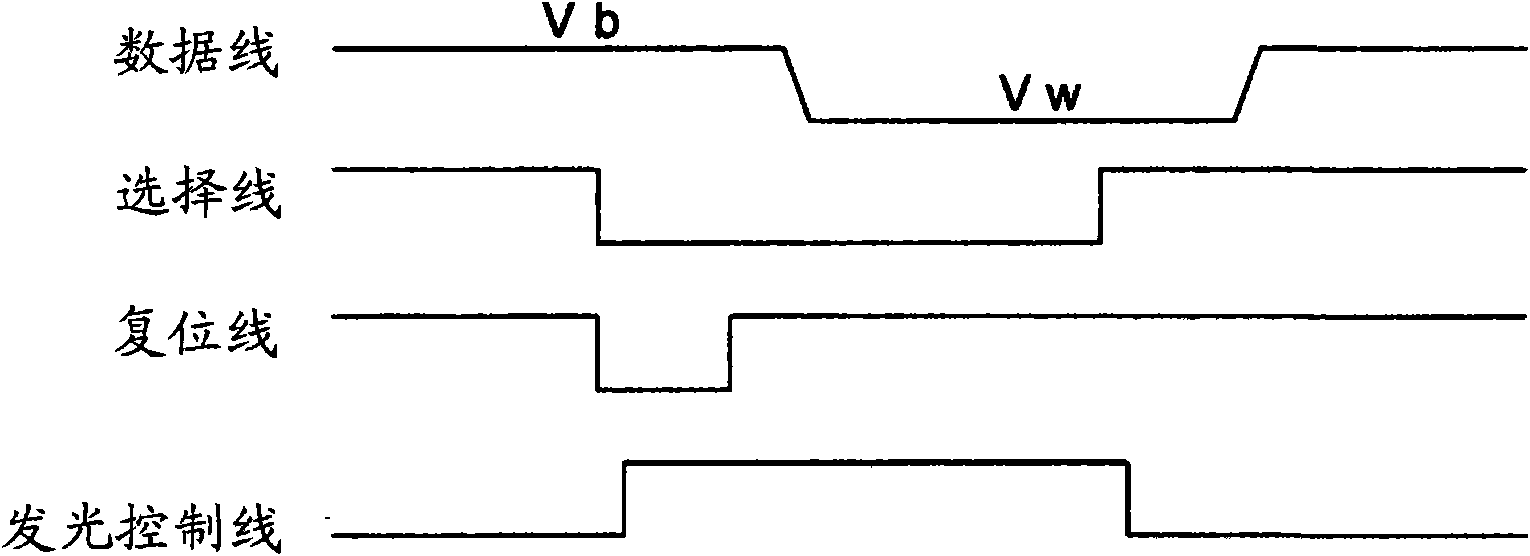

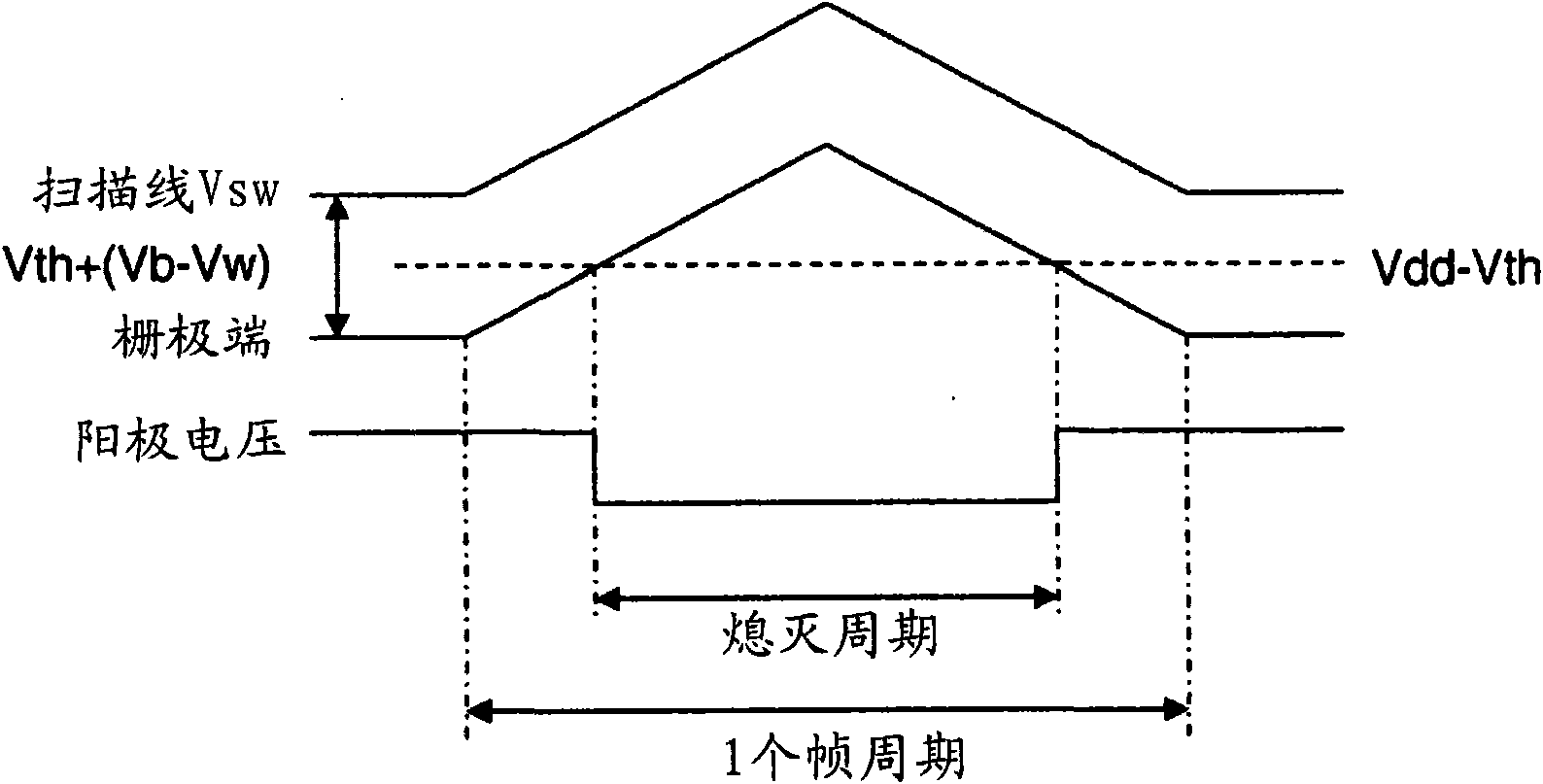

[0018] figure 1 An exemplary structure of a pixel 15 in a display according to an embodiment is shown in . The pixel 15 includes an organic EL element 1 , a drive transistor 2 , a selection transistor 3 , a reset transistor 4 , an emission control transistor 5 , a storage capacitor 6 , and a coupling capacitor 7 . It should be noted that each transistor uses a P-type thin film transistor.

[0019] The drive transistor 2 is constructed such that its source terminal is connected to the power supply line 13 shared by all pixels, its drain terminal is connected to the source terminal of the light emission control transistor 5 and the source terminal of the reset transistor 4, and its gate terminal is connected to the storage capacitor 6 One terminal of the storage capacitor 6 is connected to the source terminal of the selection transistor 3 , and the other te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com