Steel pipe connector

A technology for joints and steel pipes, which is applied in construction, building construction, etc., and can solve problems such as errors, complex production processes of joints, and cumbersome connection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

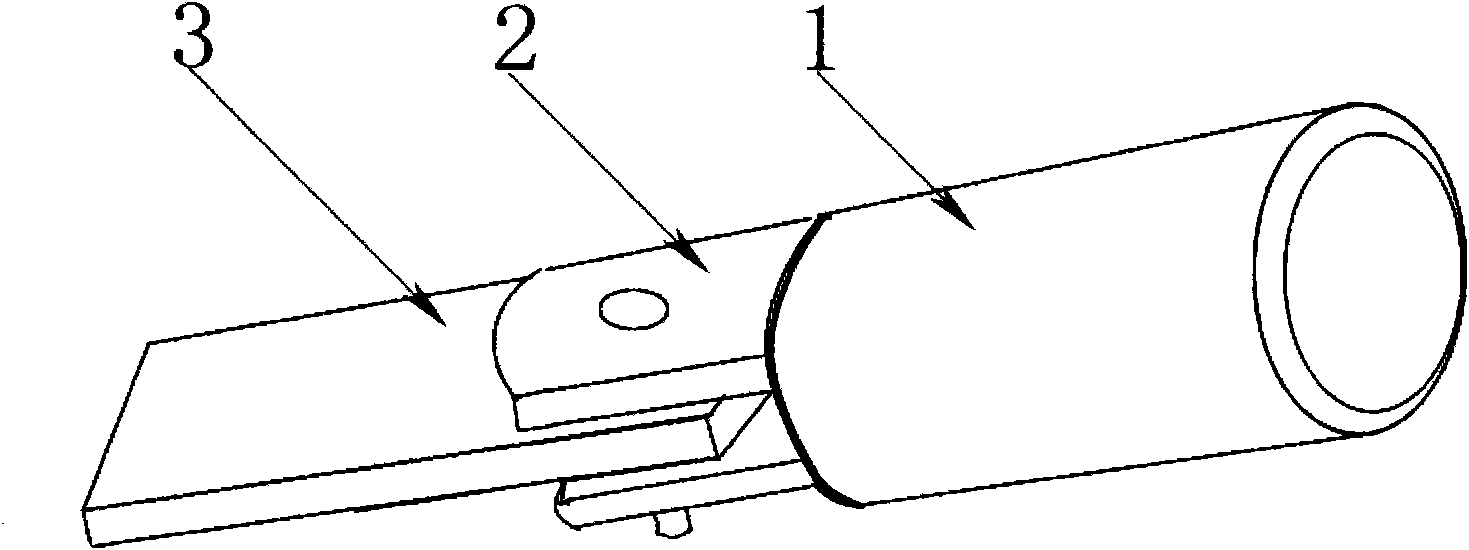

Examples

specific Embodiment 2

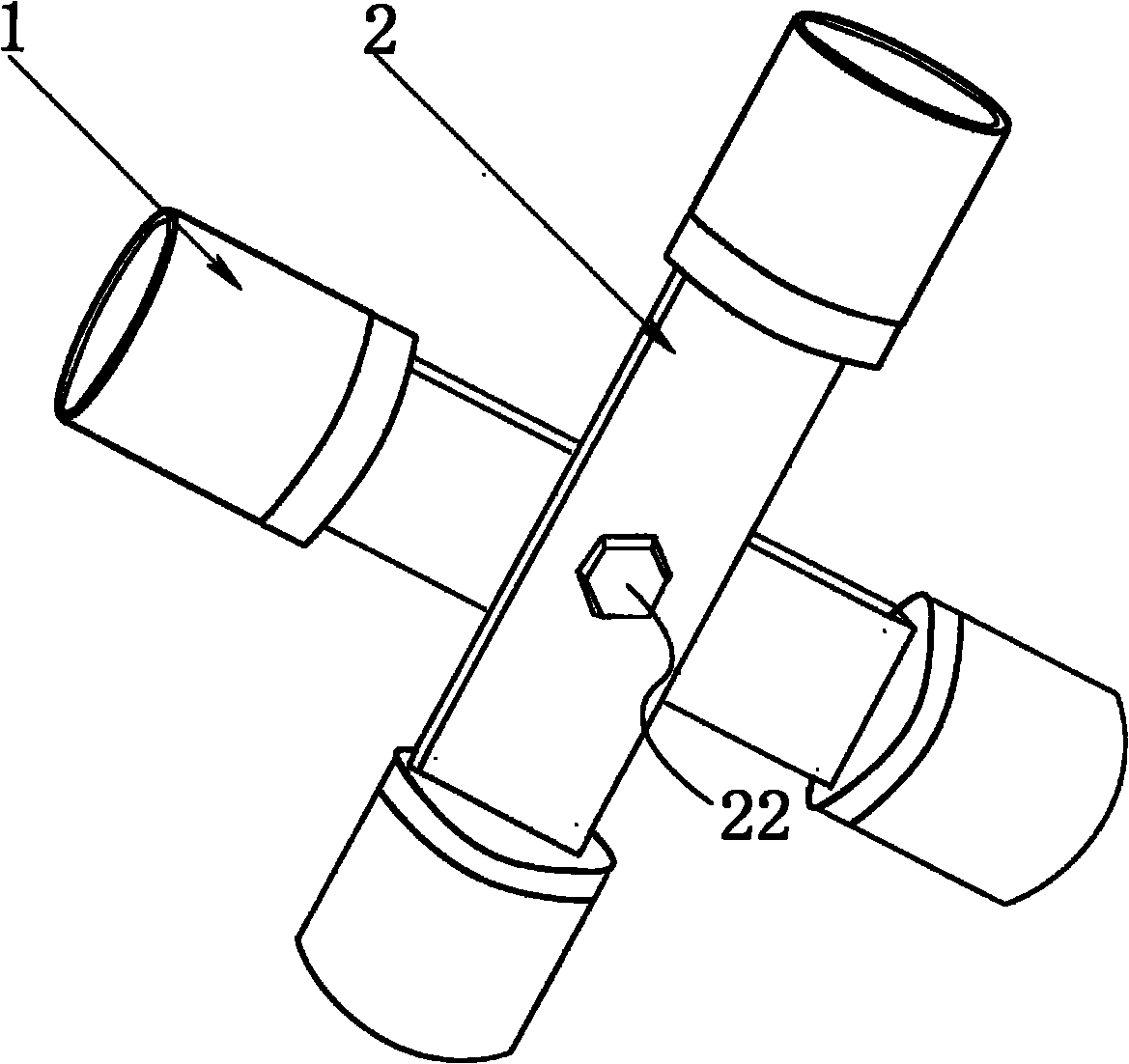

[0020] like Figure 4 As shown, the structure is basically similar to that described in the specific embodiment 1, but the difference is image 3 The connecting handle 2 of the steel pipe connector is two pieces, not one piece in the specific embodiment 1. When it is designed as two pieces, when it is connected with other connecting pieces 3, other connecting pieces 3 can be clamped. Bolt holes 21 are all provided on the two connecting handles, and the positions of the bolt holes 21 on the two connecting handles 2 are designed correspondingly.

specific Embodiment 3

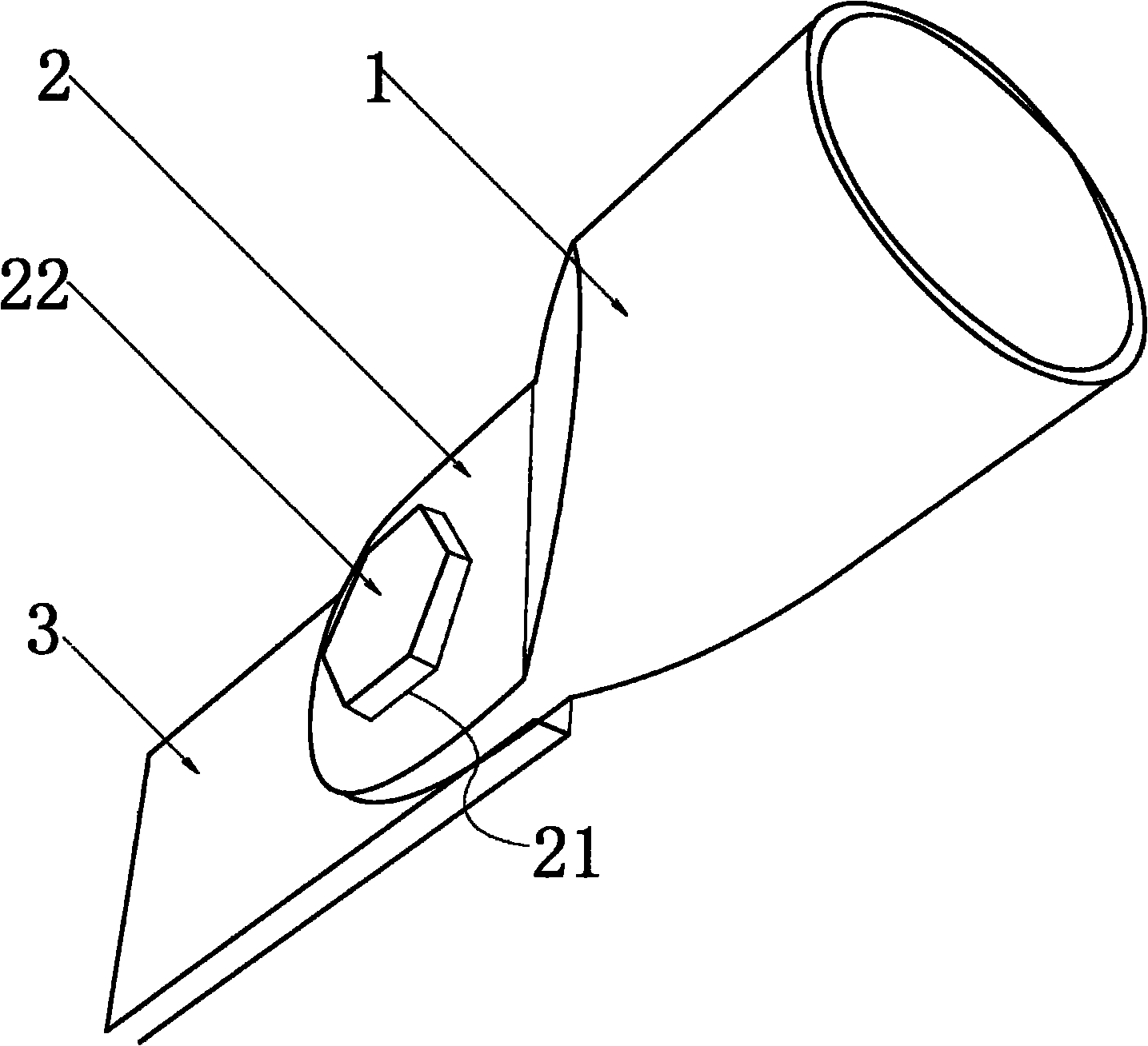

[0021] like Figure 5 As shown, the structure and design are basically similar to the steel pipe joint in embodiment 1, the difference is that instead of one bolt hole 21 being provided on the connecting handle 2, multiple bolt holes 21 are provided on the connecting handle 2 . According to the needs of other connectors 3 of different materials, it is possible that a bolt hole 21 cannot play a good fixing role at all.

specific Embodiment 4

[0022] like Image 6 As shown, the structure and design are similar to the steel pipe connector described in Embodiment 3, except that the connecting handle 2 is designed in two pieces for clamping other connectors. And the bolt holes 21 on the two connecting handles 2 are designed to be corresponding, so that the connecting handle 2 can be connected with other connecting parts 3 by bolts 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com