Mobile Tower Crane

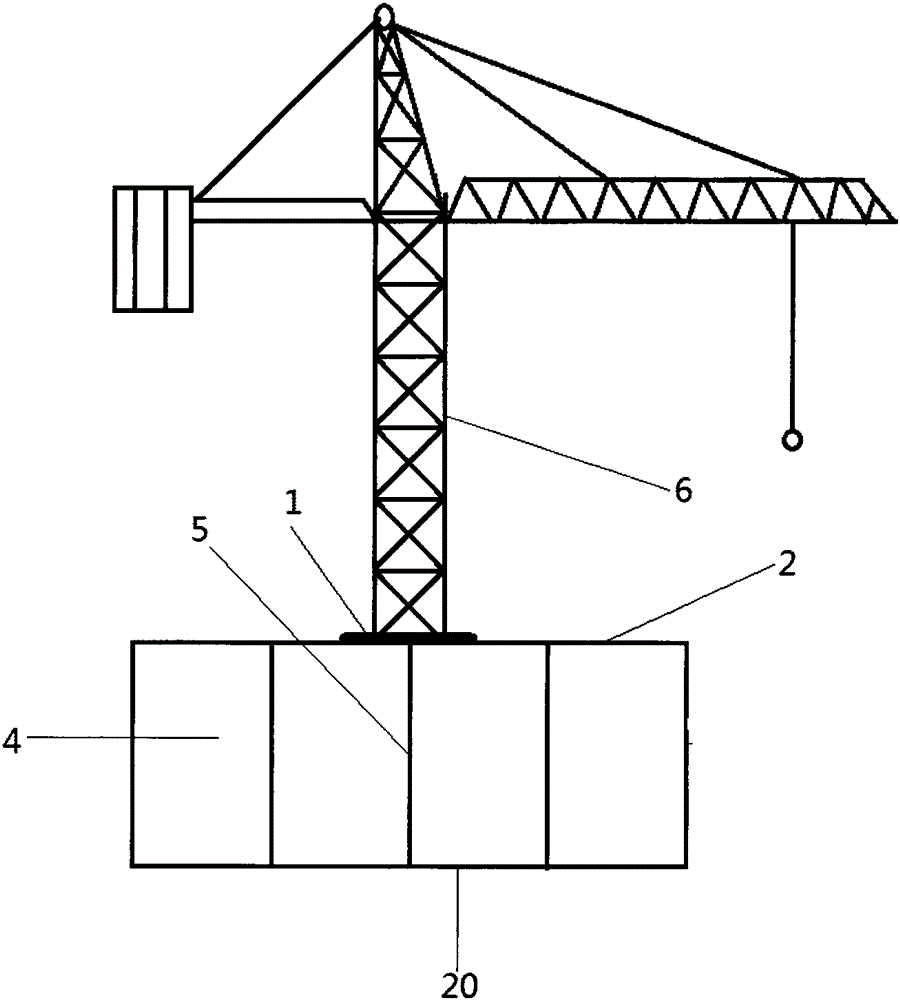

A tower crane base, mobile technology, applied in the direction of cranes, etc., can solve the problem of wasting RMB 400,000-500,000 and waste, and achieve the effects of convenient and fast loading and unloading, less waste, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

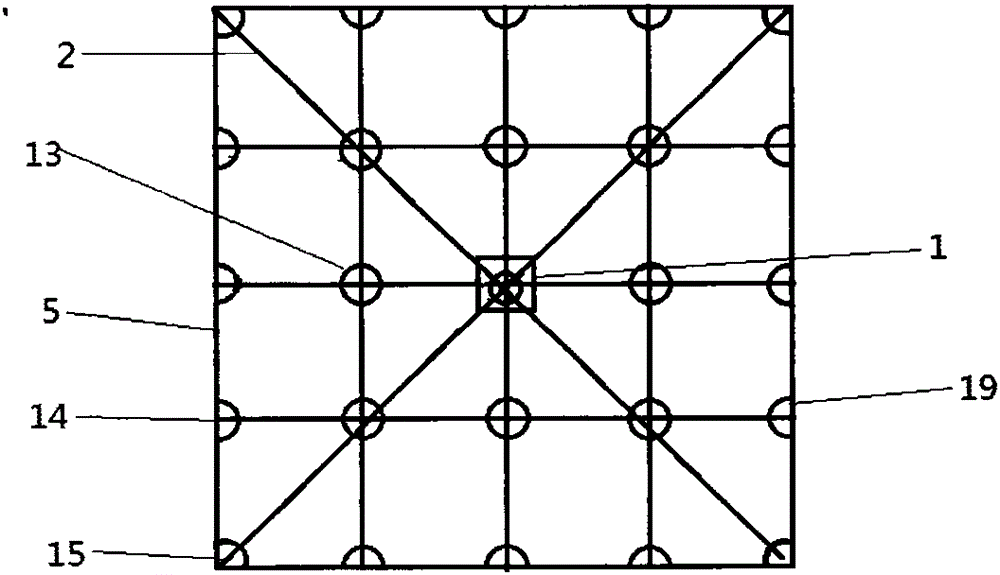

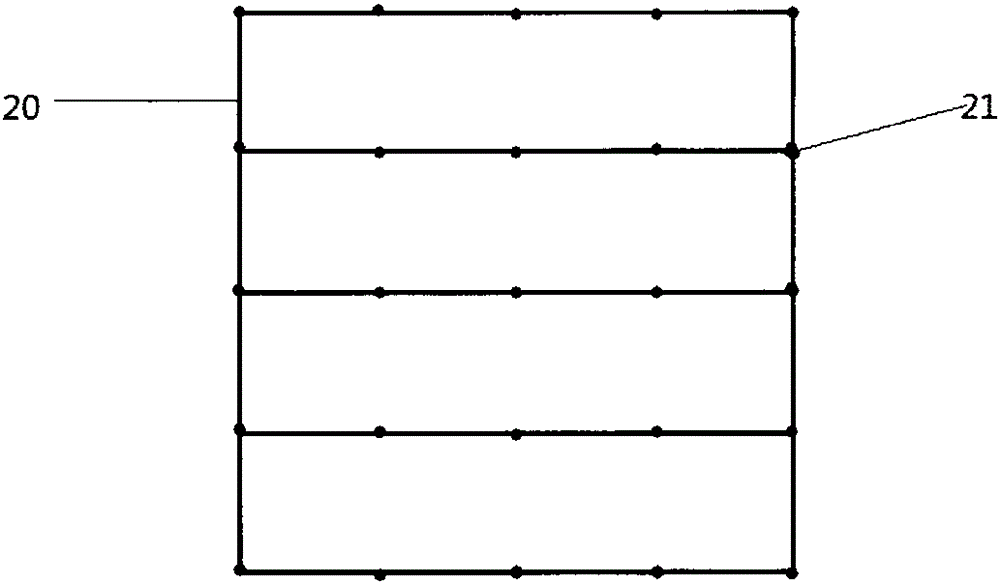

[0029] Embodiment 1, first at the desired position of the mobile tower, dig an earth pit according to the required size, put the bottom beam 20 into the earth pit after assembling (such as image 3 As shown) to lay the plank, first take two partitions 5, insert them into the grooves 16 on the corner assembly 15 respectively and place them vertically on one of the four corners of the bottom beam 20, and pass the bolt 3 through the corner assembly 15 Tighten the screw holes 18 and nuts 21 of the Ding assembly 14 and insert them with the partition plate 5, and then use the bolt 3 to pass through the screw holes 18 and nuts 21 in the Ding assembly 14 and tighten them firmly, so that the bottom beam 20 After the surroundings are installed, take the cross assembly 13 and the partition 5, insert one side of the partition 5 into the groove 16 of the installed small assembly 14, and insert the bolt 3 through the cross assembly 13 after firmly inserting the cross assembly 13 on one side....

Embodiment 2

[0030] Embodiment 2, with the center of the mobile tower hanger as the point, 8 tension beams 2 are set respectively, 4 of which are respectively connected to the screw rods 3 on the corner assemblies 15 at the four corners of the box body 4 and screwed firmly, and straddle them The screw 3 on the cross assembly 13 is screwed firmly, and the other four are vertically screwed to the screw 3 on the D assembly 14 in four directions, and the screw 3 on the cross assembly 13 that it crosses is screwed firmly. At this time, the beam 2 form a "meter" font on casing 4. The assembled cross assembly, the small assembly 14 and the corner assembly 15 are sealed with dustproof cloth 19 to prevent soil from entering (preventing from being bitten when dismantling). At this time, the soil taken out in the pit before is backfilled to each square three-dimensional box In the body 4, (also each casing can be sealed and filled with water with anti-seepage material), then after the stand 1 is fixe...

Embodiment 3

[0031] Embodiment three, when the tower crane needs to be moved to other construction sites after the completion of the project, the tower crane and the tower hanger frame 6 are first dismantled, and then after the stand 1 and the tension beams 2 in each direction are removed, all the bolts 3 are unscrewed with a hoist ( such as chain guides and cranes), firstly lift out the corner components 15 and small components 14 around the mobile tower crane seat, and then lift out the cross components 13 one by one. Each assembly), at last dividing plate 5 is proposed one by one, now only bottom beam 20 is left in the ground, as what inject in each three-dimensional casing 4 is that water is as mentioned above when dismantling, and last bottom beam also can take out.

[0032] The combined design of the present invention is conducive to installation and disassembly, and is conducive to transportation and storage. It occupies a small space. One tower crane only needs to be equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com