Overtemperature alarm device for solar energy component framing machine

A technology of solar modules and alarm devices, applied to measuring devices, thermometers, electrical components, etc., can solve problems such as not easy cooling, component damage, deformation, etc., and achieve the effect of avoiding framing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

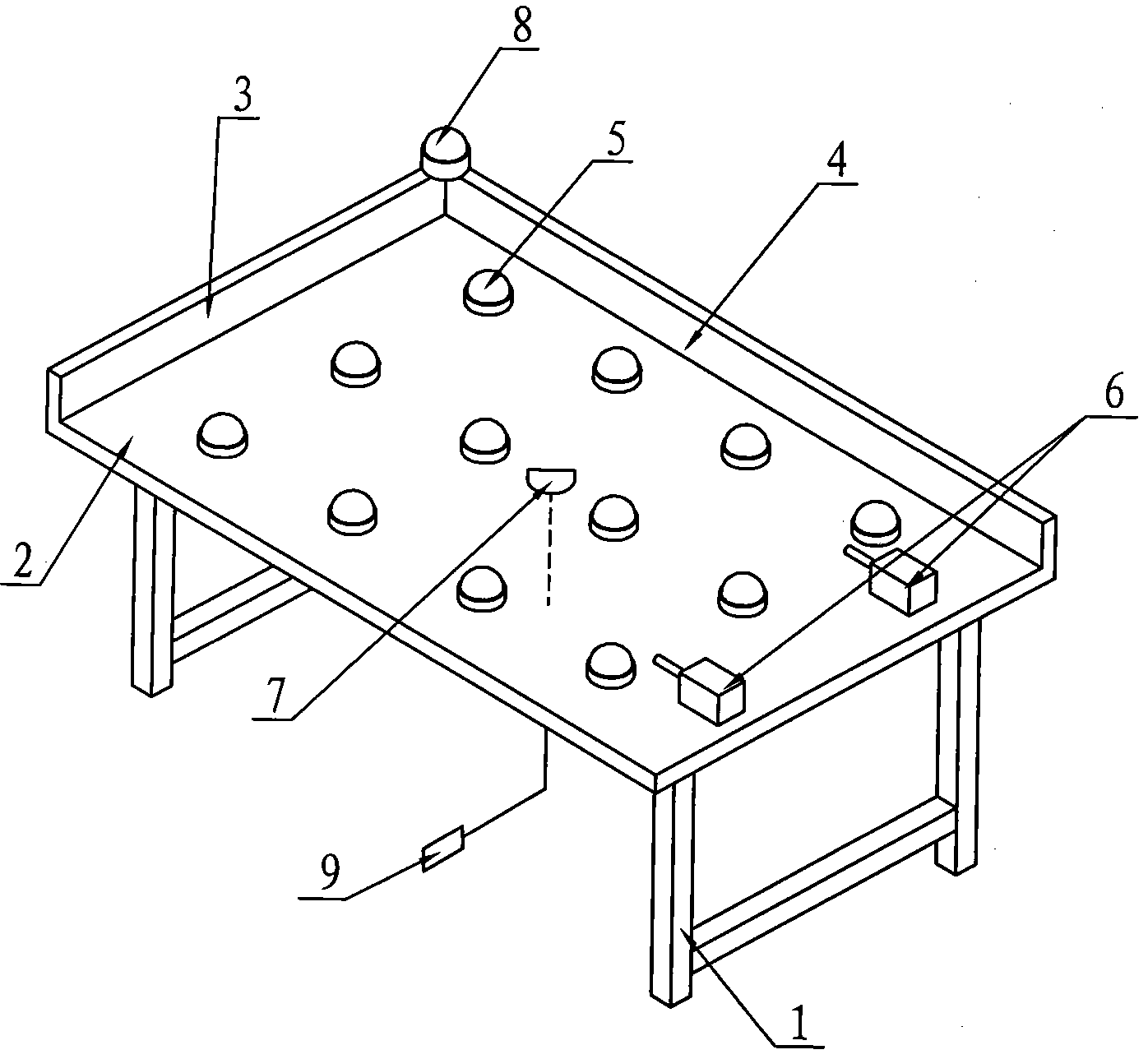

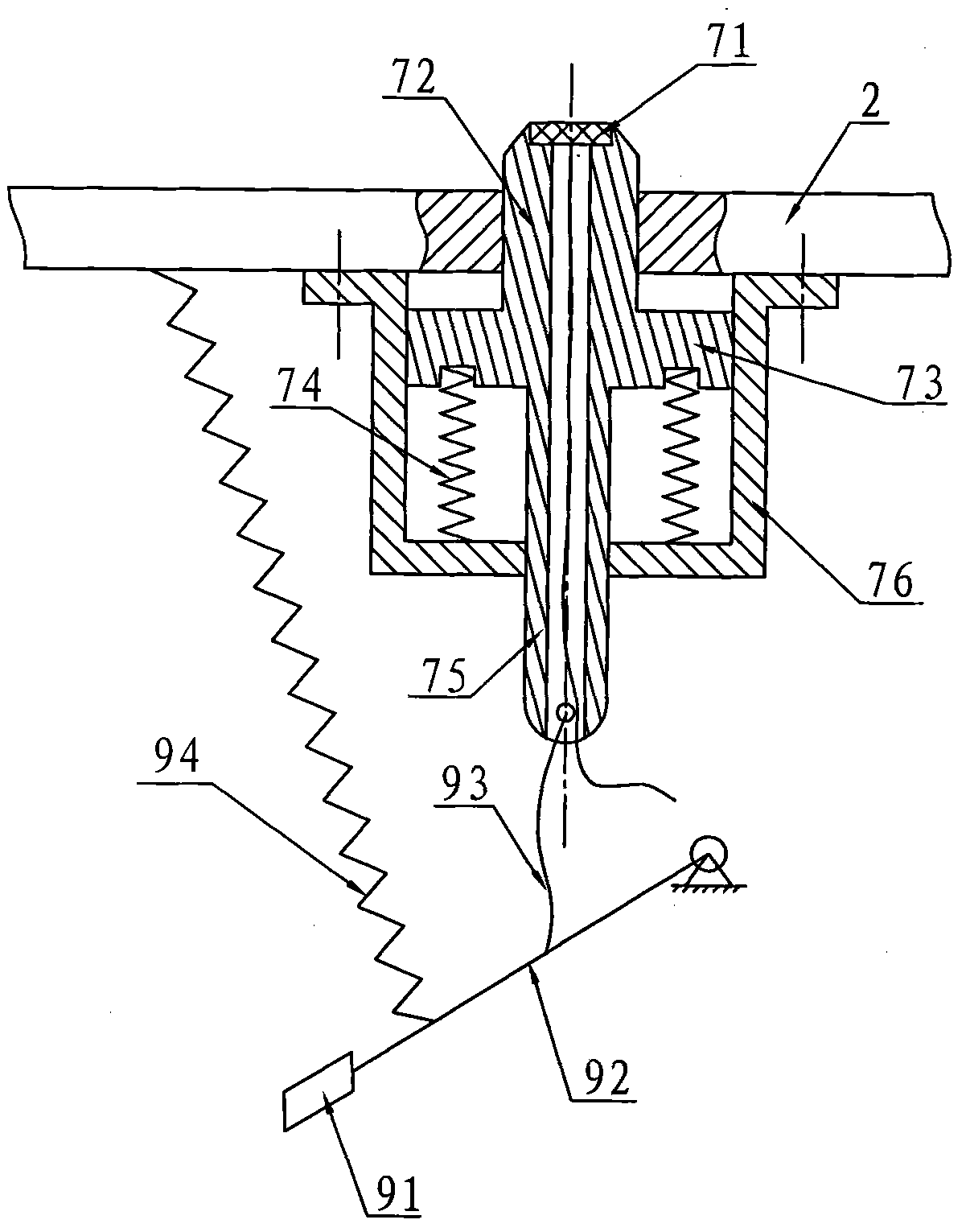

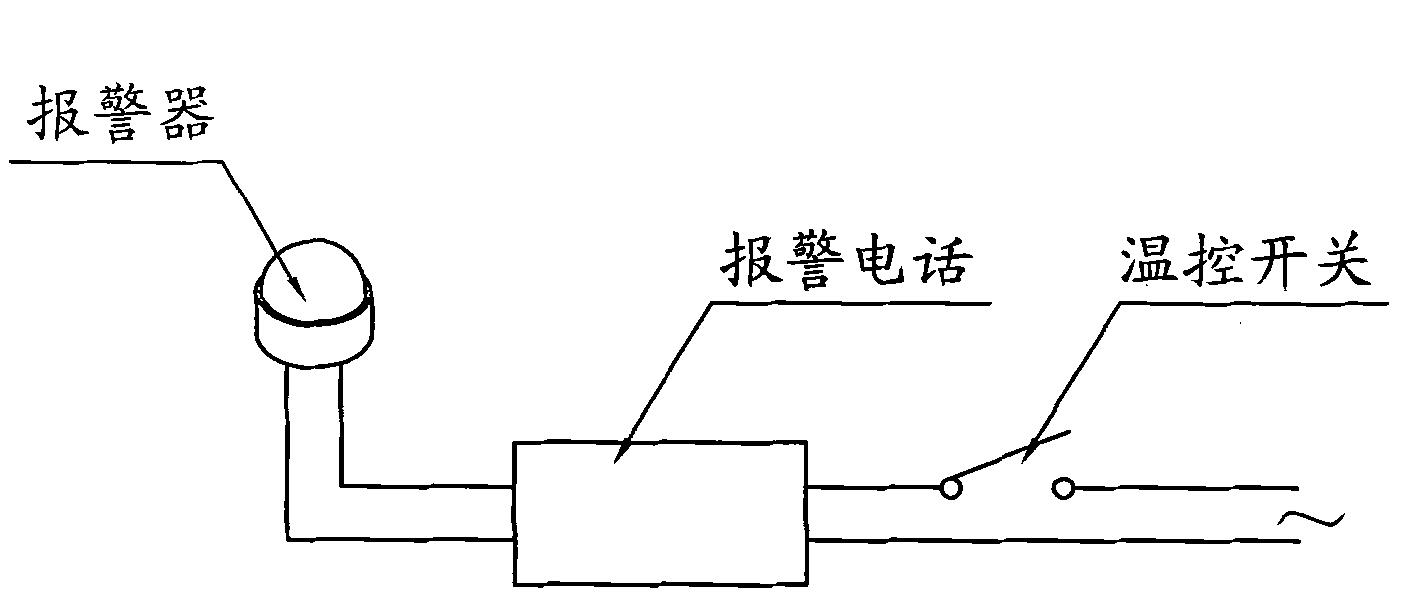

[0020] The over-temperature alarm device of the solar module framing machine, such as Figure 1-Figure 3 As shown, it includes a workbench 1, a packaging table 2, a short positioning side 3, a long positioning side 4, a rolling support body 5 and a packaging cylinder 6, the packaging table 2 is fixed on the workbench 1, the short positioning side 3 and the long positioning side The positioning side 4 is fixed on the packaging table 2, and the short positioning side 3 is perpendicular to the long positioning side 4, the rolling support body 5 is evenly arranged on the packaging table 2, and the packaging cylinder 6 is installed on the packaging table 2, and is located on the short positioning side 3 On the other side of the packaging table 2, a laminate temperature measuring probe 7 is provided at the center of the packaging table 2, an alarm device 8 is installed on the frame loading machine, and a foot of the laminate temperature measuring probe 7 is provided below the packagi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap