Patents

Literature

161results about How to "Ensure travel safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Urban rail transit emergency passenger flow space-time distribution prediction method

ActiveCN110782070AReal-time calculation of inbound volumeReal-time calculation of outbound volumeForecastingState predictionSimulation

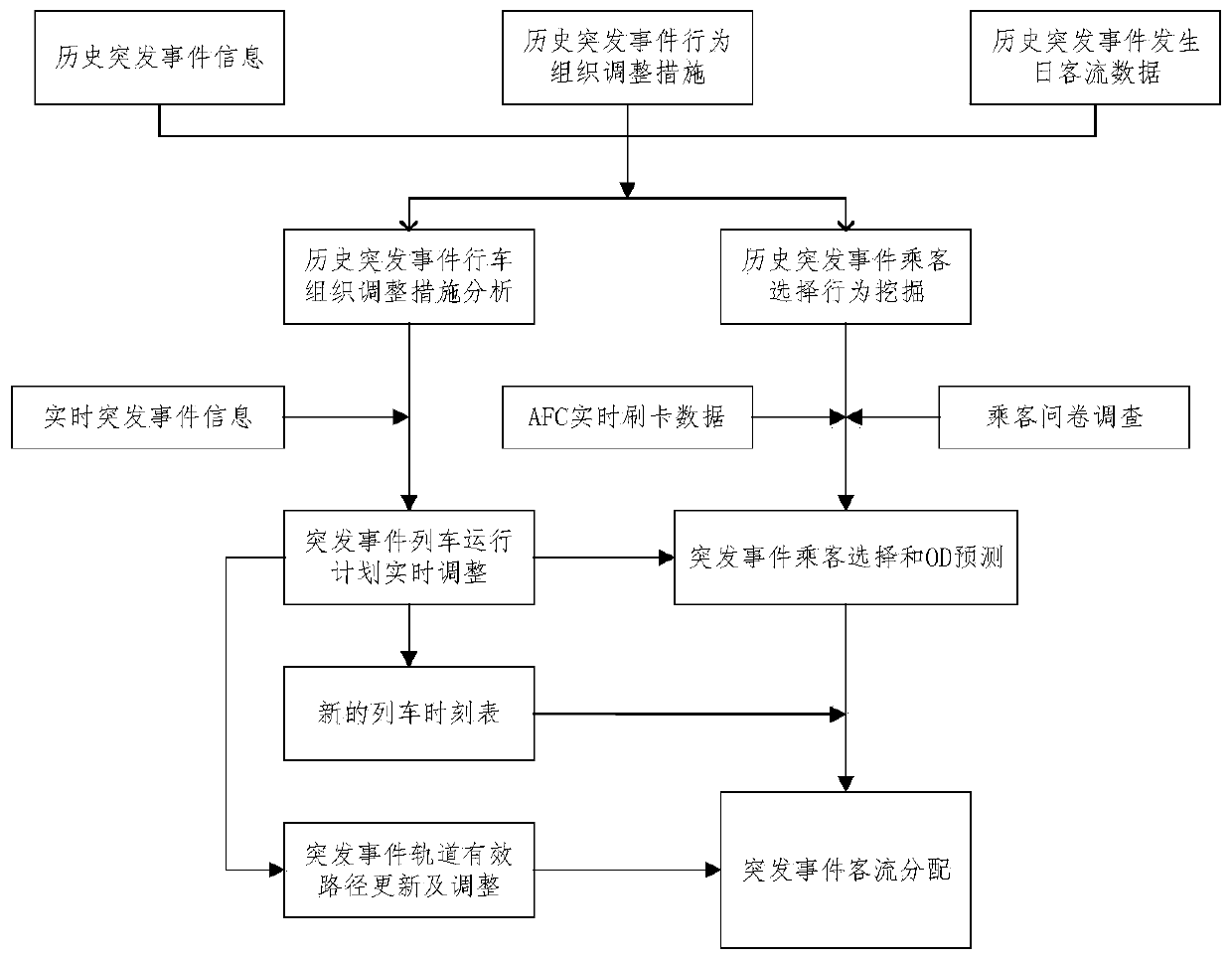

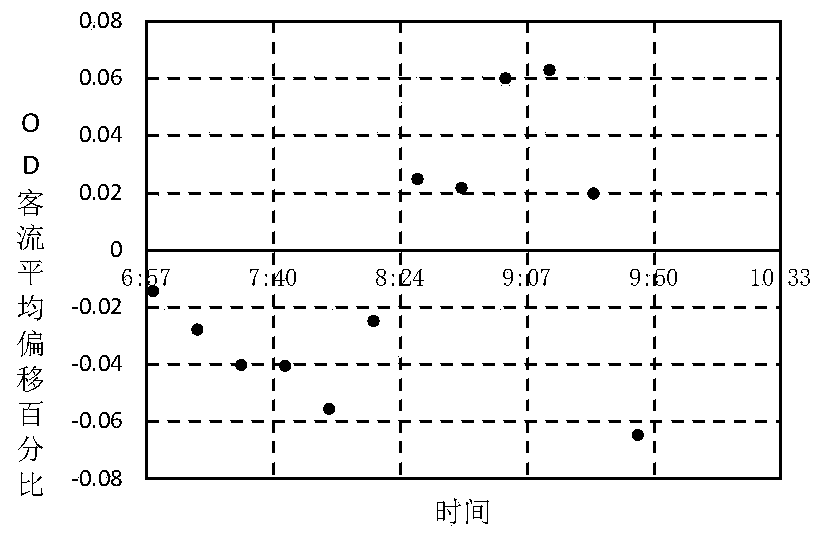

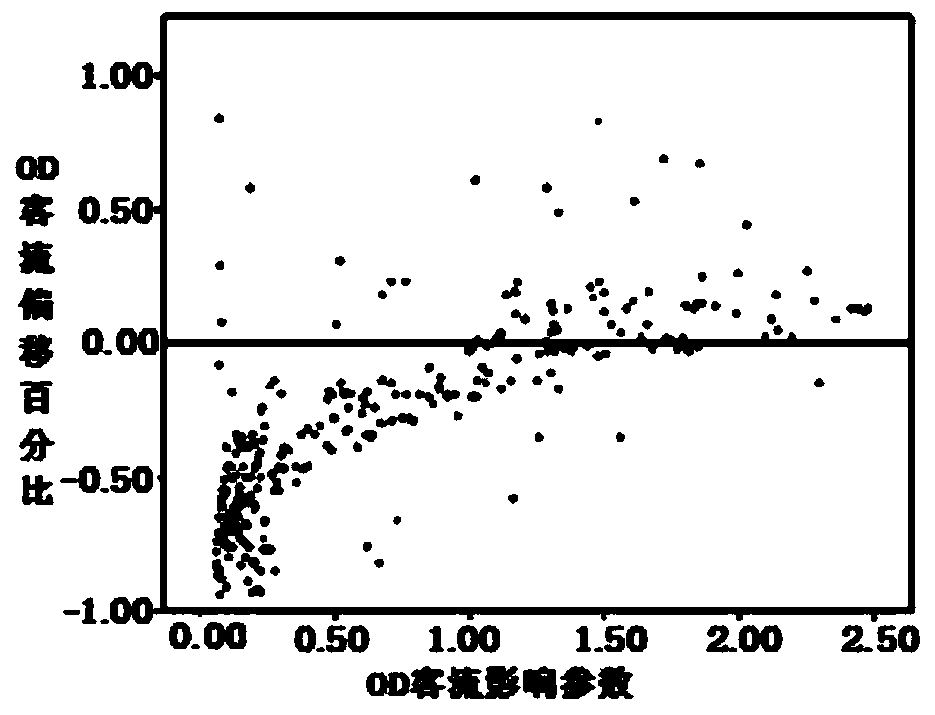

The invention provides an urban rail transit emergency passenger flow space-time distribution prediction method, which comprises the steps of analyzing historical emergency driving organization adjustment measures based on historical data, and mining passenger flow space-time distribution rules, influence ranges and passenger selection behaviors of historical emergencies; based on the AFC real-time card swiping data, predicting OD distribution under emergencies by using a space-time correlation prediction model in combination with a mining result of historical data; performing real-time adjustment and deduction on the train timetable under the emergency according to an analysis result of historical emergency driving organization adjustment measures, and updating an effective path of the track; and realizing rail transit passenger flow space-time distribution state prediction under different emergency scenes by combining the rail effective path updating result and the OD distribution prediction result under the emergency and based on a multipath probability distribution model. According to the method, the passenger flow distribution condition of the rail transit road network under the emergency situation can be accurately mastered in real time.

Owner:BEIJING TRANSPORTATION INFORMATION CENT +1

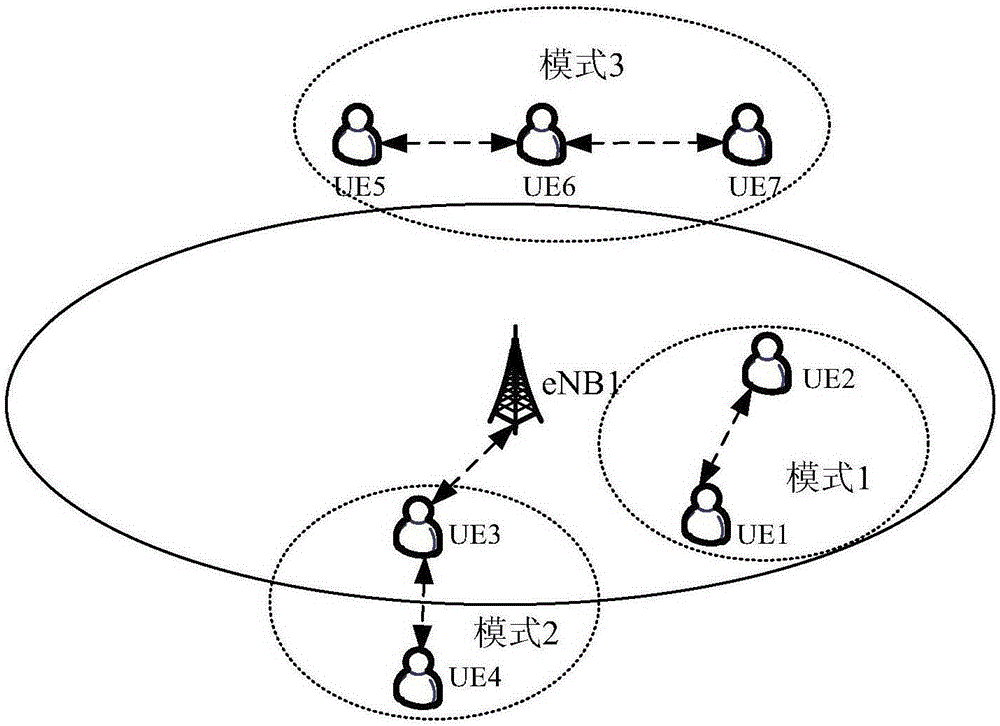

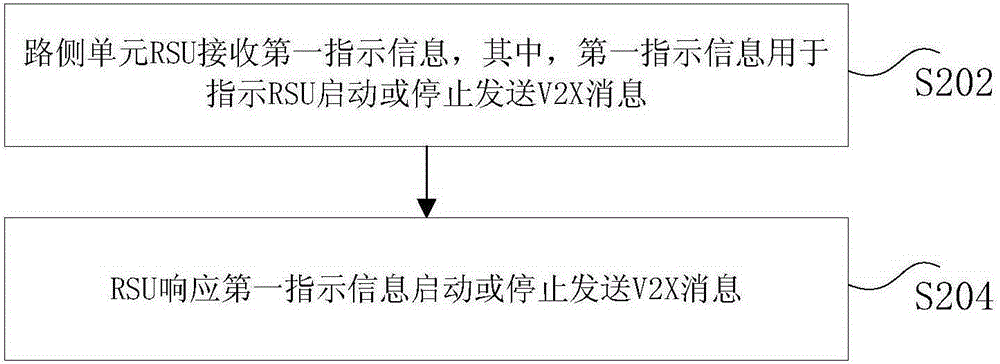

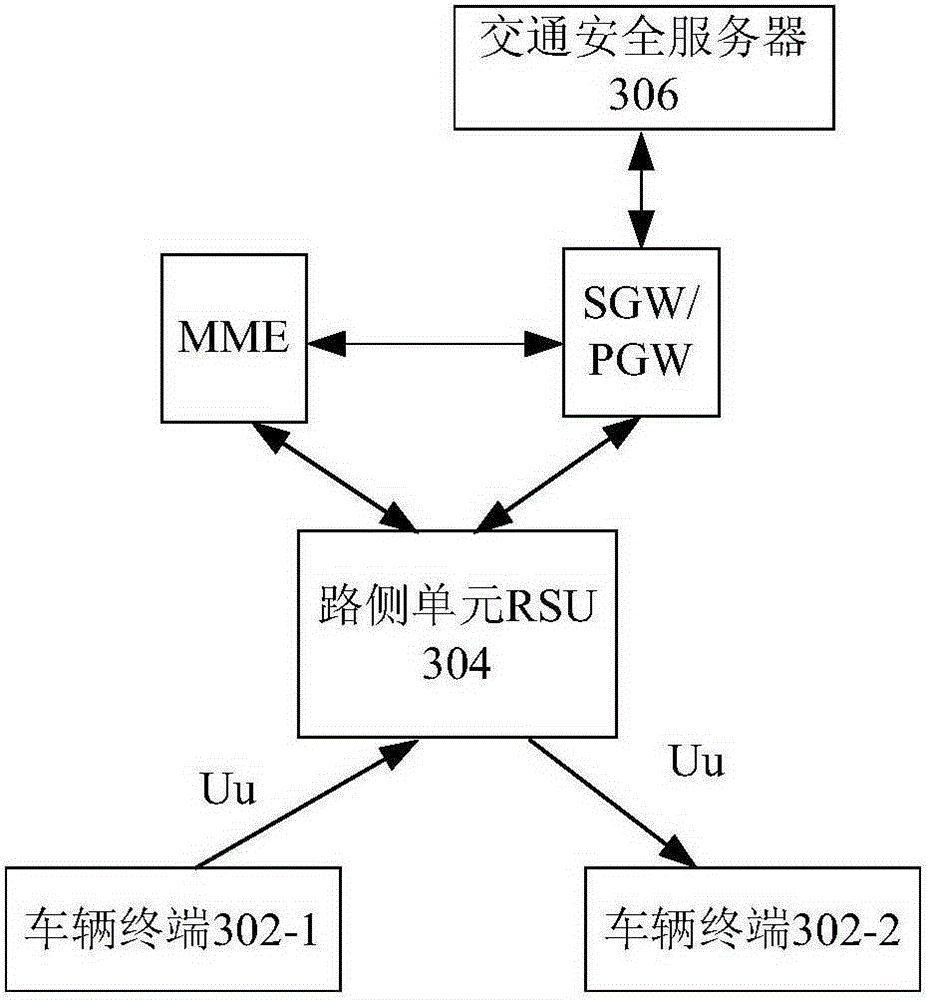

Internet of Vehicles communication control method and Internet of Vehicles communication control device

ActiveCN106507449ASolve wasteAvoid in timePower managementParticular environment based servicesThe InternetCommunication control

The invention provides an Internet of Vehicles communication control method and an Internet of Vehicles communication control device. The Internet of Vehicles communication control method comprises steps that a road side unit RSU is used to receive first instruction information, which is used to instruct the RSU to start or stop transmitting V2X messages; the RSU is used to respond to the first instruction information to start or stop the transmitting of the V2X messages. A problem of large communication power consumption caused by inability of reasonably controlling the communication process of the Internet of Vehicles is solved.

Owner:ZTE CORP

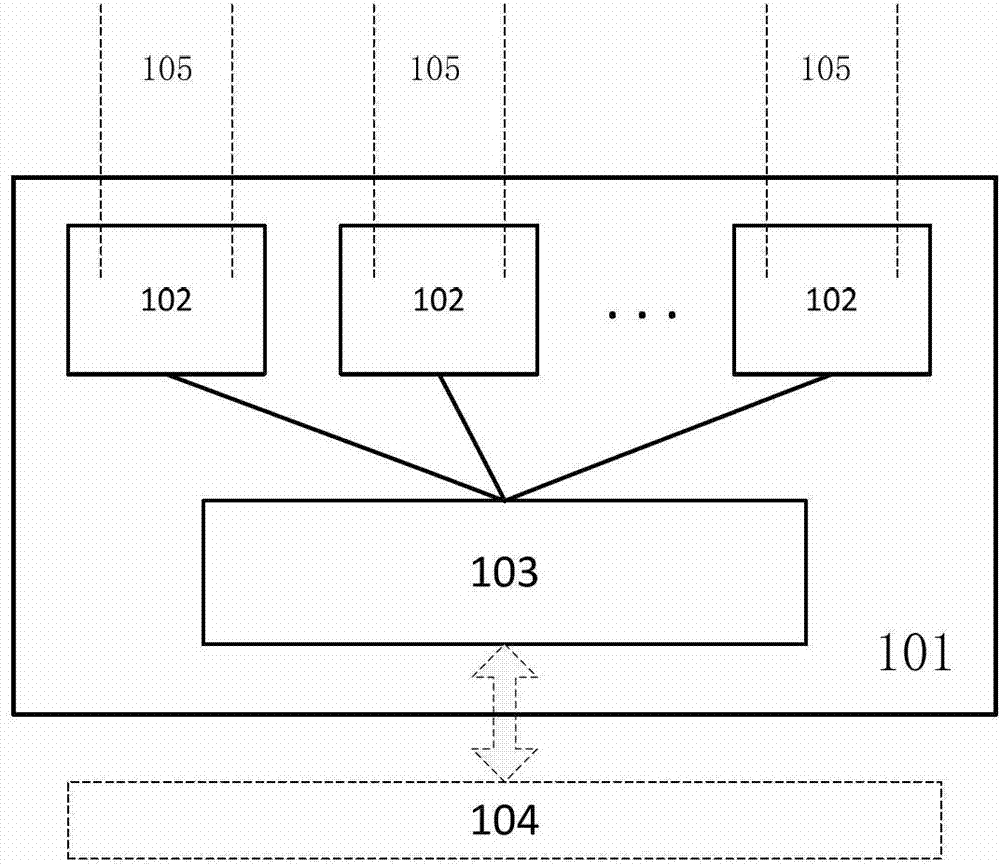

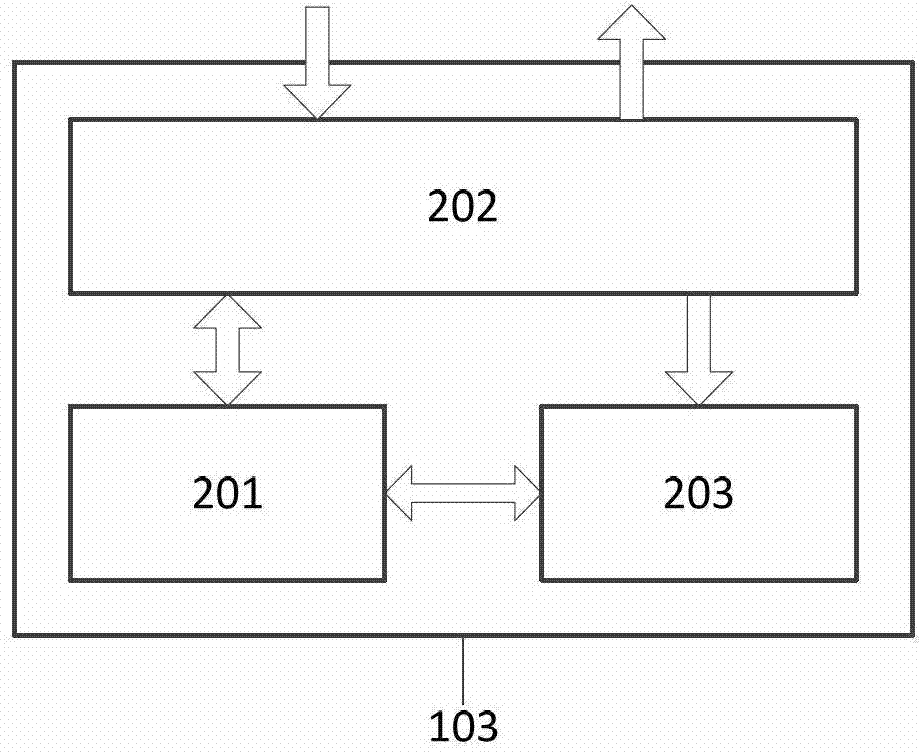

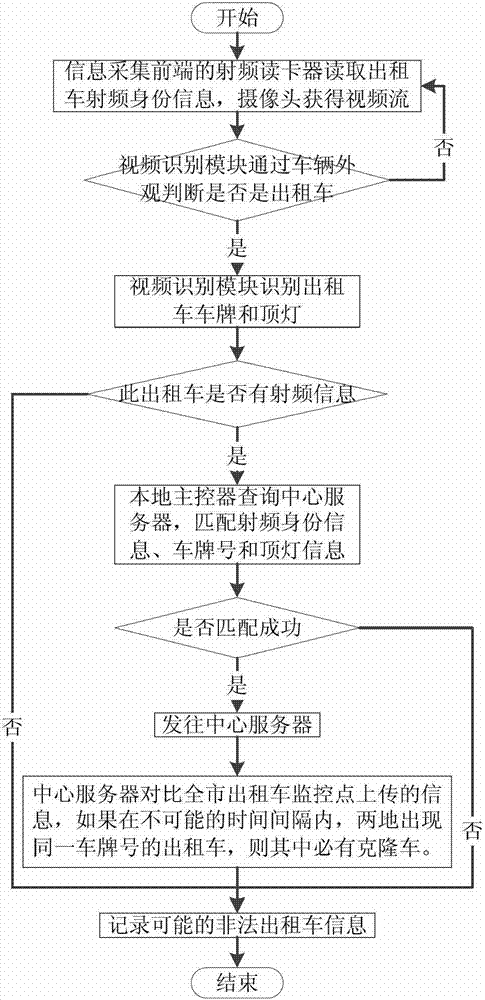

Device and method for detecting legality of taxi by integrating video recognition and radio frequency recognition

InactiveCN102890865AImprove accuracyPoorly madeRoad vehicles traffic controlPattern recognitionCard reader

The invention relates to a device and a method for detecting legality of a taxi by integrating video recognition and radio frequency recognition, which belongs to the technical field of the intelligent recognition and monitoring of the taxi. The device comprises an information collection front end and a local main controller and is matched with the inquiry of a database of a remote central server to realize the detection of legality of the taxi. The information collection front end comprises a camera and a radio frequency card reader. The local main controller comprises a control module, a communication module and a radio frequency recognition module, wherein the control module is used for coordinating each input and guaranteeing the inter-module coordination, the communication module is used for exchanging information with the information collection front end and the remote central server, and the video recognition module is used for recognizing the information such as a license plate and roof lights of the taxi. One local main controller and a plurality of information collection front ends are installed on one monitoring point and used for monitoring different lanes. By integrating the video recognition and the radio frequency recognition to verify the identity of the taxi, the legality of the taxi can be efficiently detected, the illegal taxi can be cracked down, the urban traffic order can be maintained, and the travel safety of citizens can be guaranteed.

Owner:SHANDONG UNIV

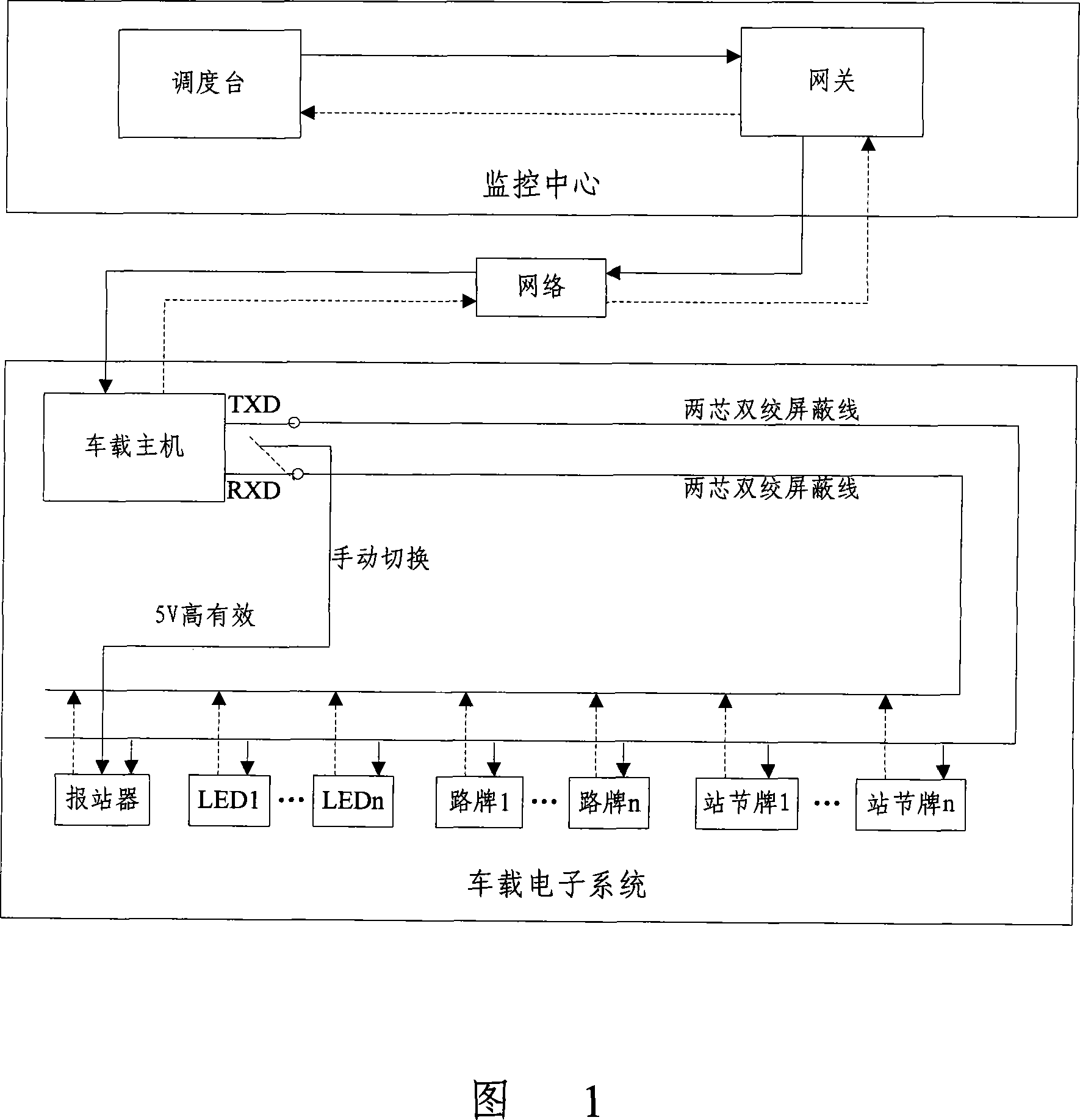

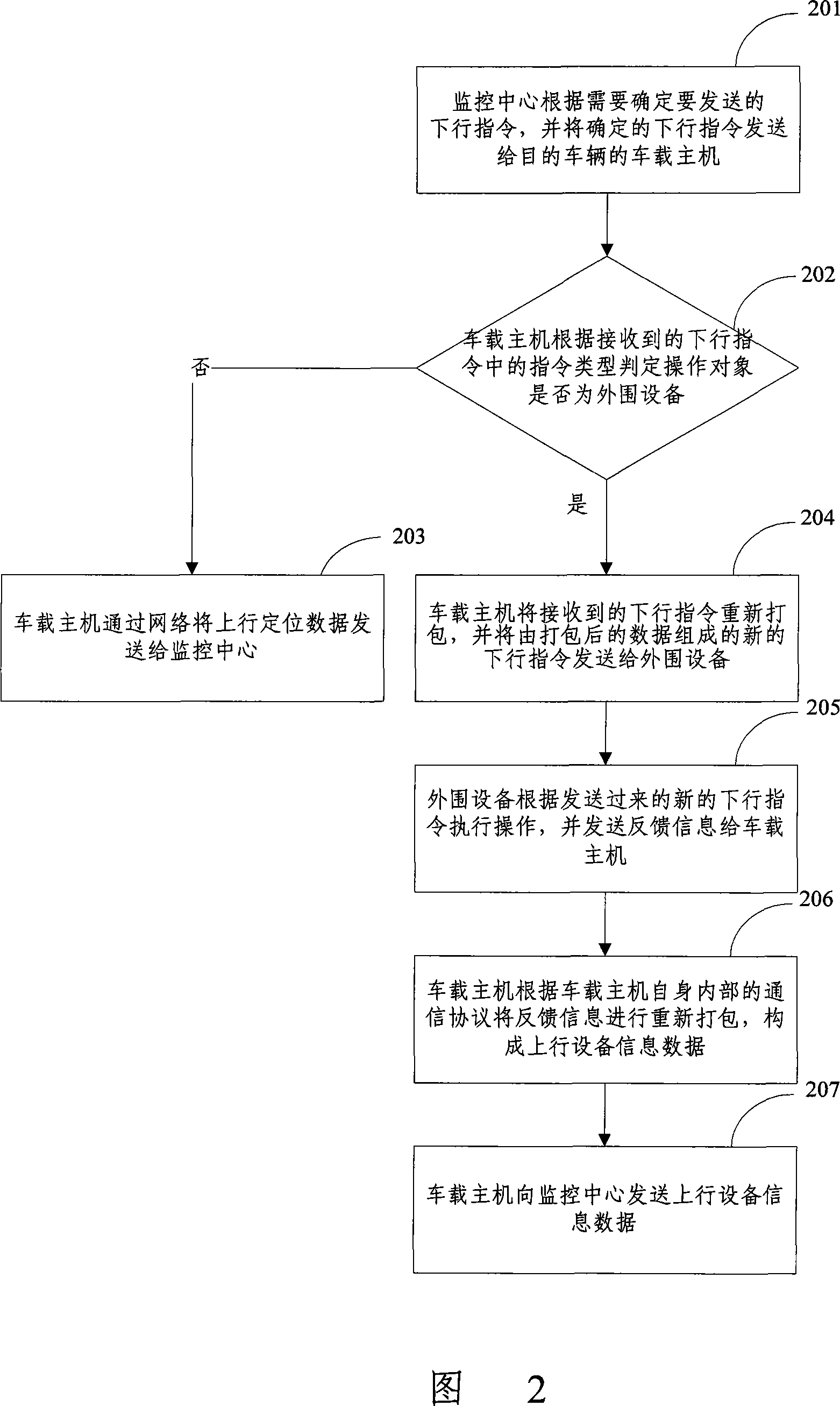

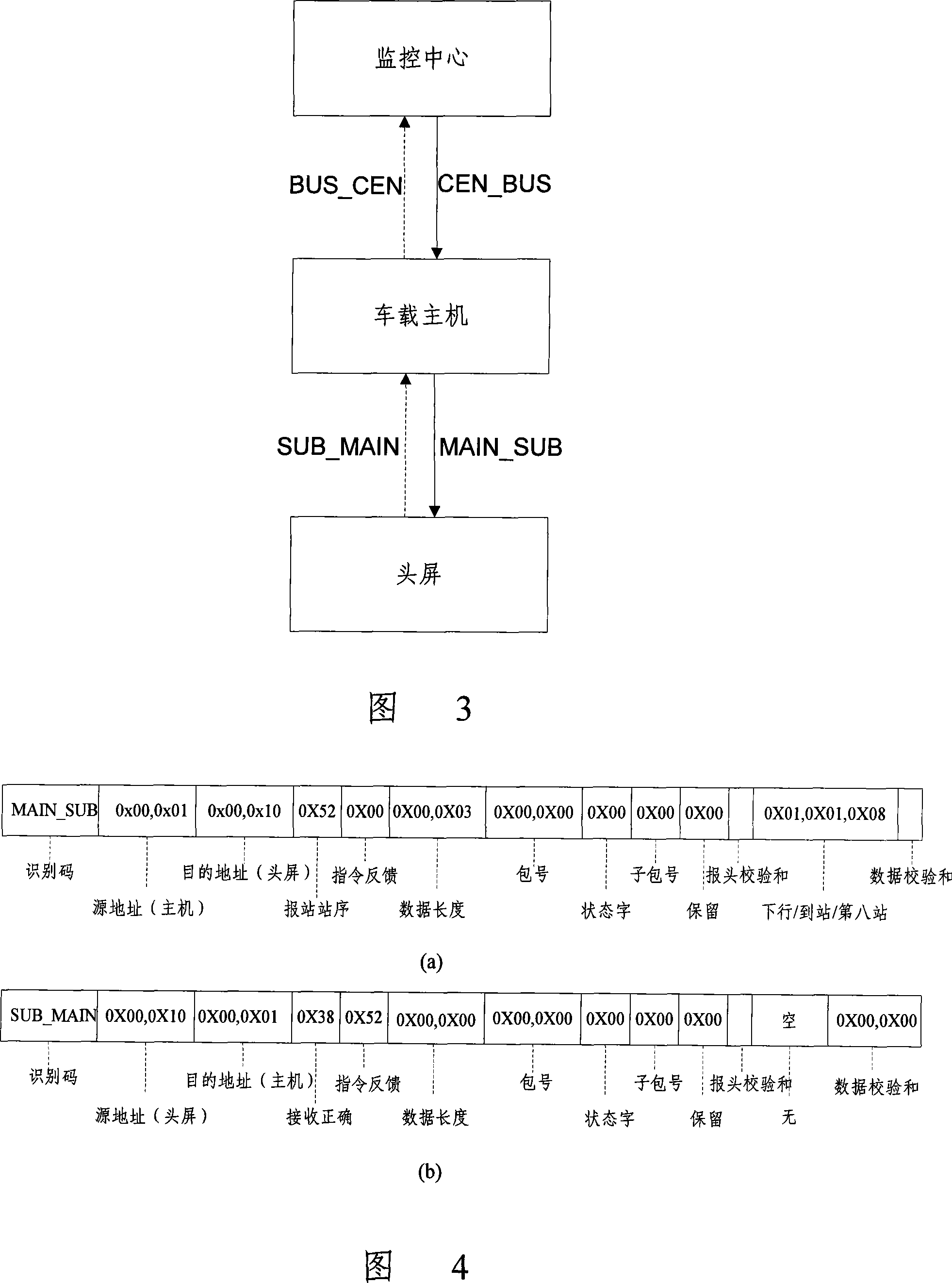

Intelligent public transportation system and implementing method thereof

InactiveCN101131795AAchieve integrationRealize information interactionRoad vehicles traffic controlFar distanceLED display

This invention disclose a intelligent bus system and its realize method, the monitor center of the system and the bus electric system change their information in network, the peripheral equipment of the bus electric system includes report station implement, LED display screen, the guidepost, station sign, all of these equipment are linked with the bus host computer; the monitor center can send the related dictate to the bus host computer in network, the bus host computer doing related operation to the related peripheral equipment according to the received dictate, the peripheral equipment uploads the feed back information to the monitor center, by the way, the bus host computer can locate in real time, and upload the orientation information according to the dictate of the monitor center. The monitor center can realize the far distance, real time monitor to the bus electric system, at the same, realize the entirety information alternate and share in the system.

Owner:BEIHANG UNIV +1

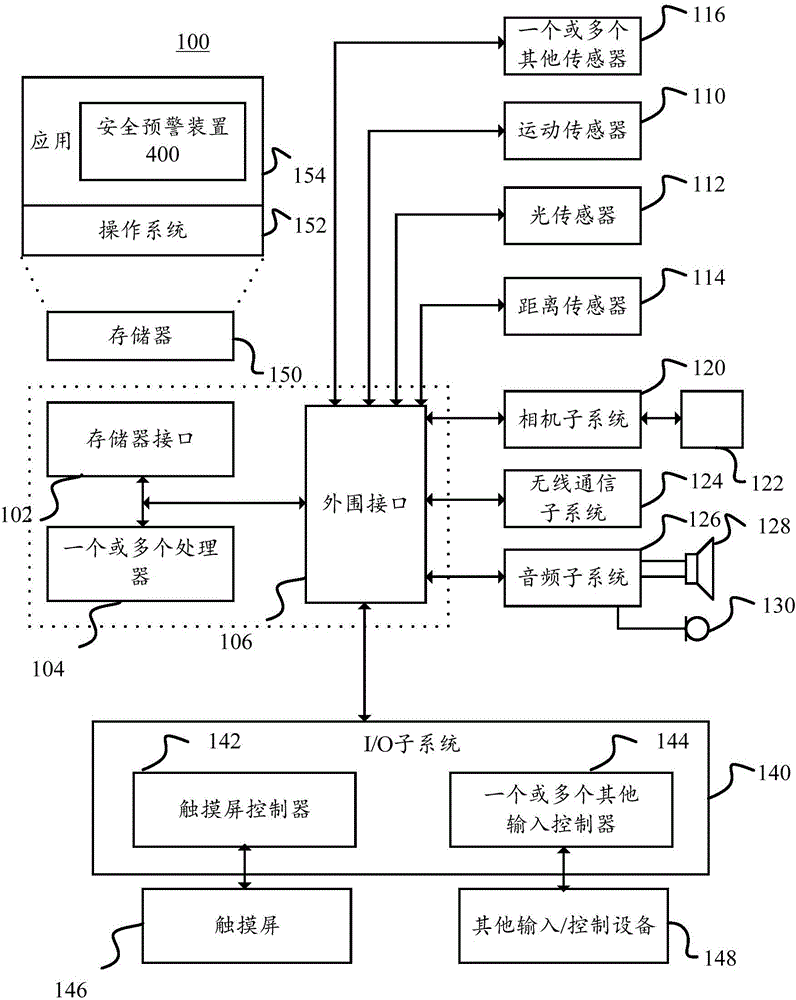

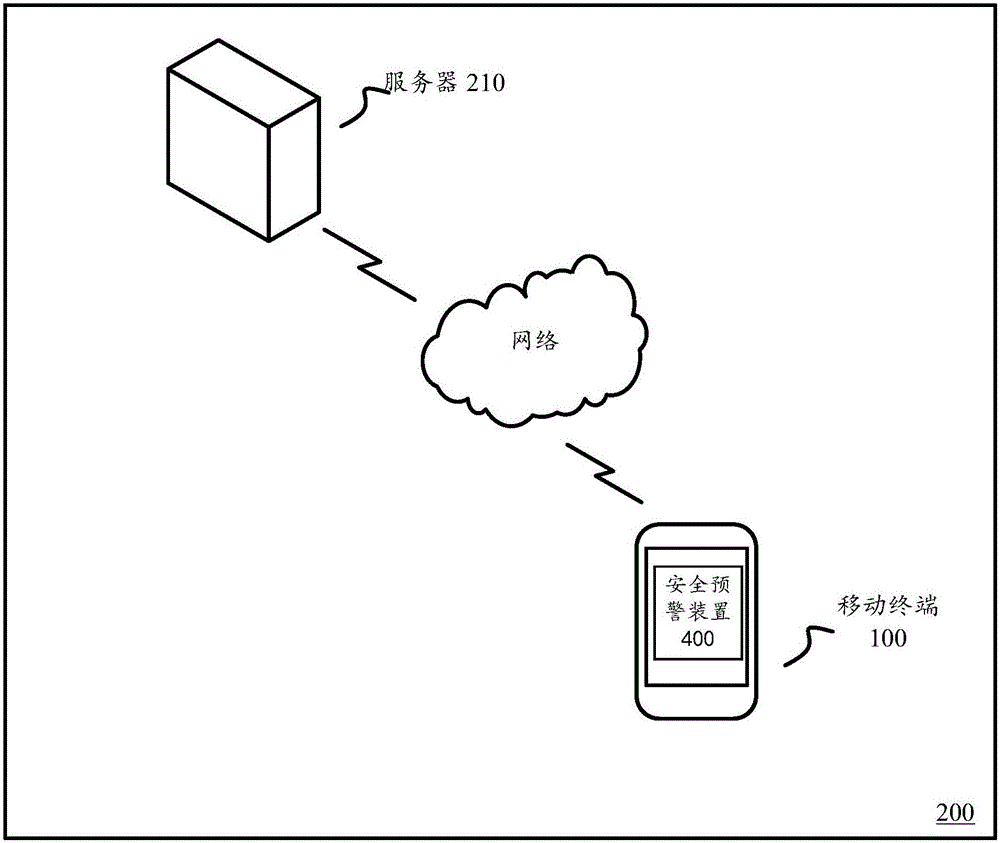

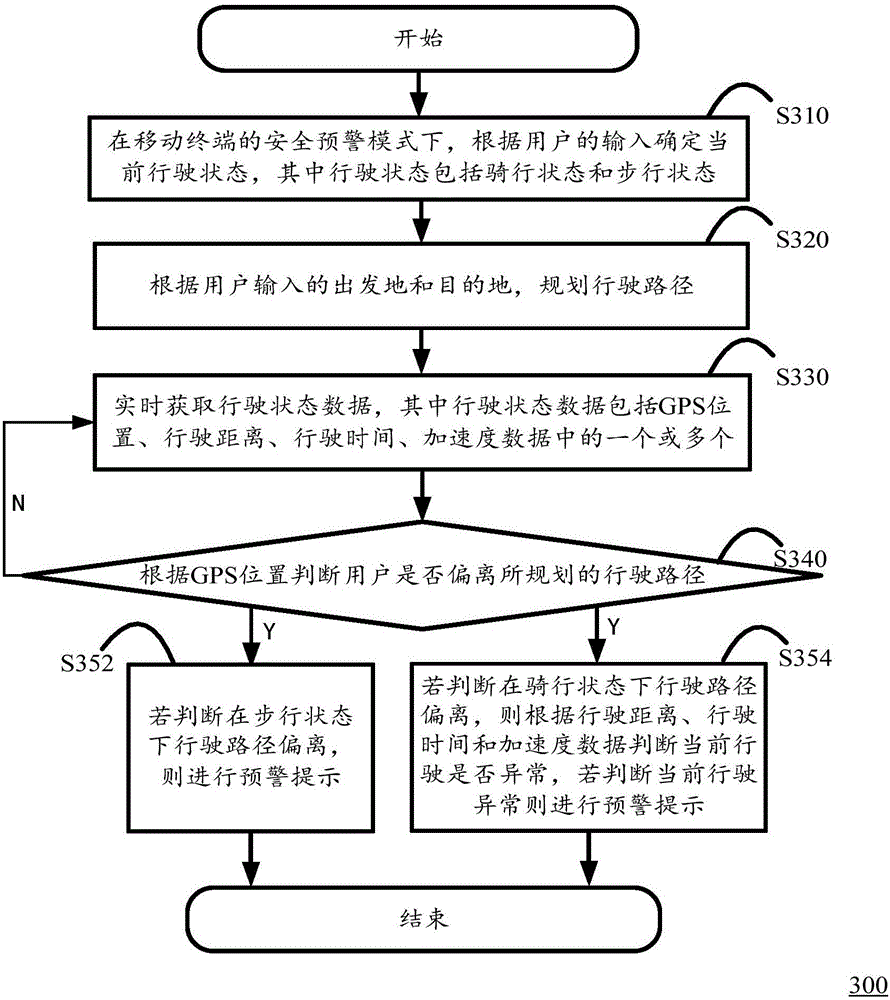

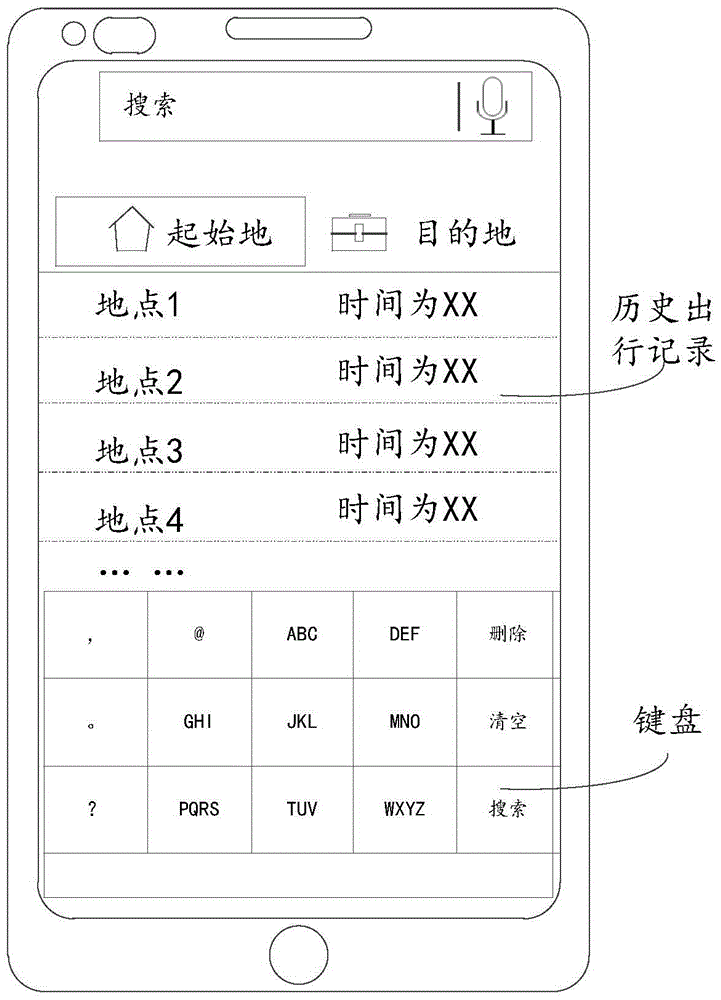

Safety early warning method, apparatus, and system based on mobile terminal

ActiveCN106056841AEnsure travel safetyJudging whether there is an abnormality in drivingAlarmsUser inputComputer terminal

The invention discloses a safety early warning method based on a mobile terminal. The method includes that under the safety early warning mode of the mobile terminal, a current running state is determined according to the input of a user, wherein the running state includes a riding state and a walking state; based on the departure place and the destination input by the user, the driving path is planned; the driving state data is obtained in real time and includes GPS position, driving distance, driving time, and acceleration data; whether the user deviates from the planned driving path or not is determined based on the GPS position; if the user deviates from the driving path under the walking state is determined, the early warning prompt is carried out; and if the user deviates from the driving path under the riding state is determined, whether the current driving is abnormal or not is determined based on the driving distance, driving time, and acceleration data, and the early warning prompt is carried out if the current driving is determined to be abnormal. The invention further discloses a safety early warning device and system based on a mobile terminal.

Owner:凌度(广东)智能科技发展有限公司

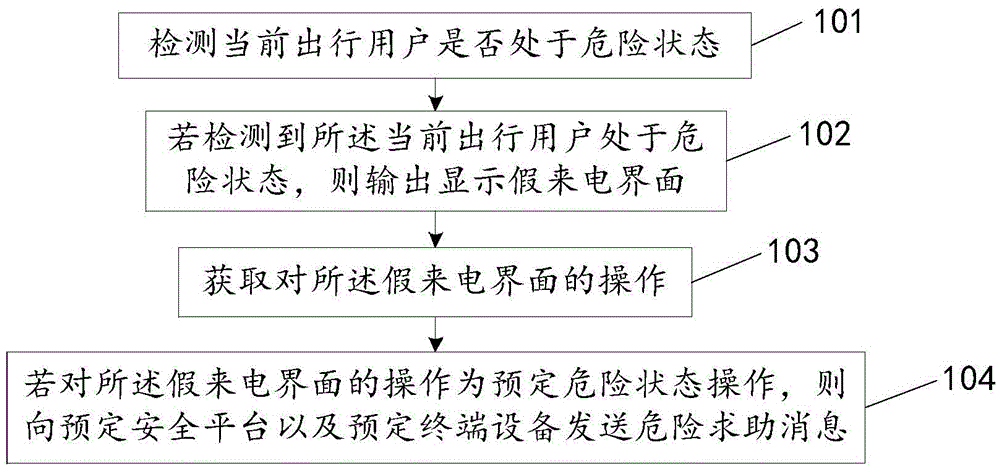

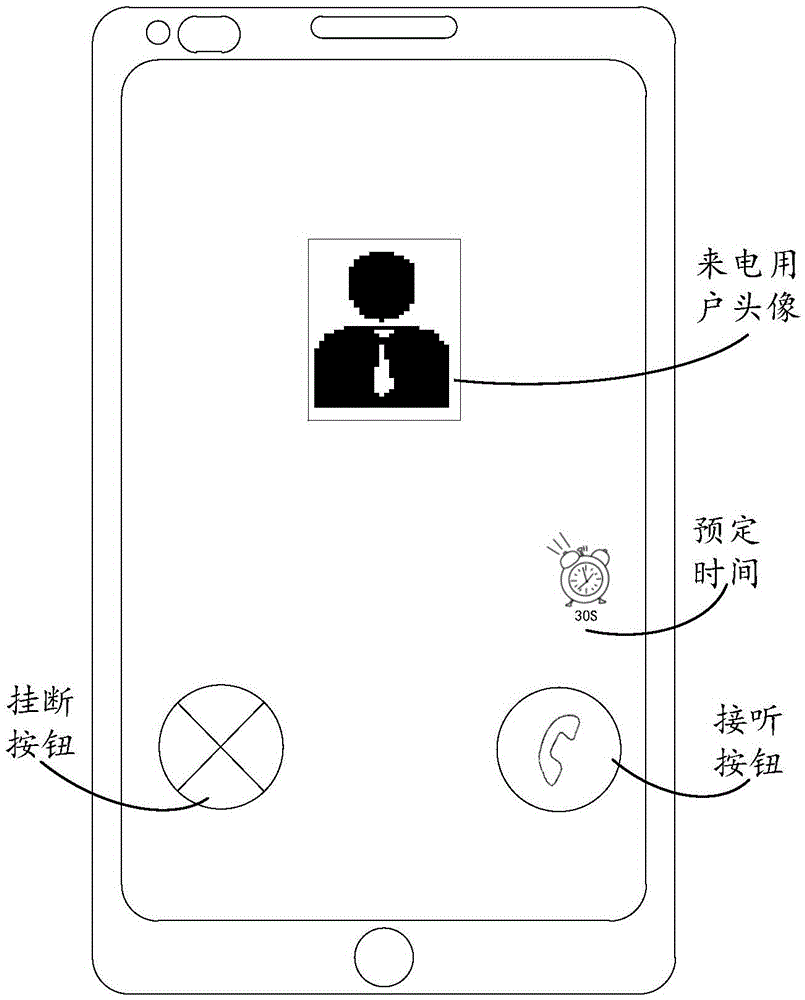

User's travel security alarming method and device

ActiveCN105554289AEnsure travel safetyTravel safety assuranceSubstation equipmentTerminal equipmentDistress signal

The invention discloses a user's travel security alarming method and device, relates to the technical field of Internet, and aims to timely send a distress signal when a user is in danger in a travel process, and precisely determine and send information of a location where he / she is in danger to ensure the user's travel security. According to the technical scheme, the method comprises the following steps of: detecting whether a user who is traveling is in a dangerous state or not; if the user who is traveling is detected in the dangerous state, outputting an interface for displaying a fake call; acquiring a fake call interface operation; and if the fake call interface operation is a predetermined dangerous state operation, sending a message for help in danger to a predetermined secure platform and a predetermined terminal equipment, wherein the message for help in danger comprises information for help in danger and information of a location where the message for help in danger is send out. The method and the device are mainly suitable for being used in a process that a mobile terminal detects the user's travel security.

Owner:BEIJING QIHOO TECH CO LTD

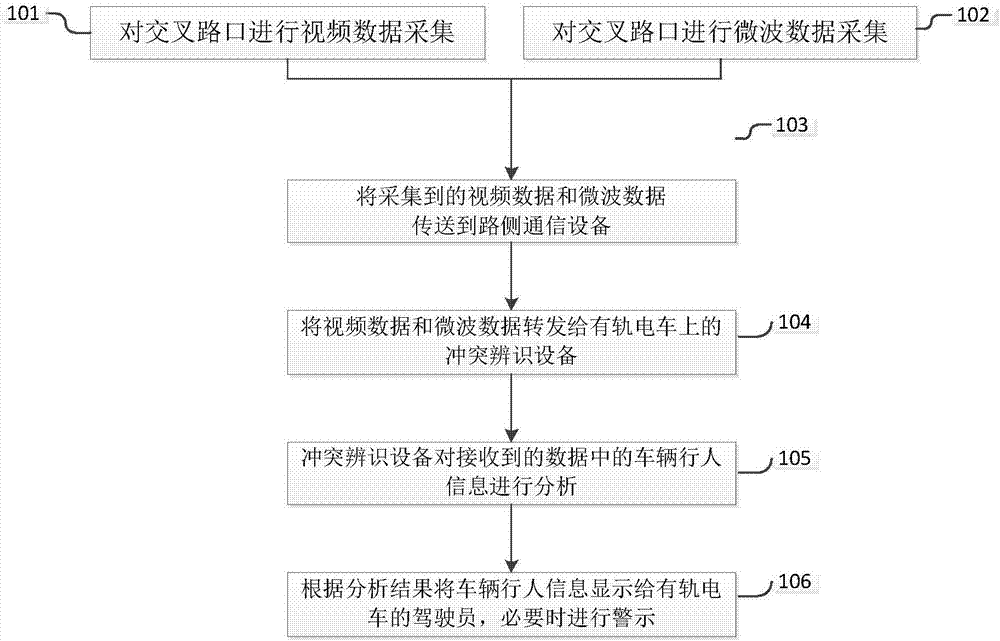

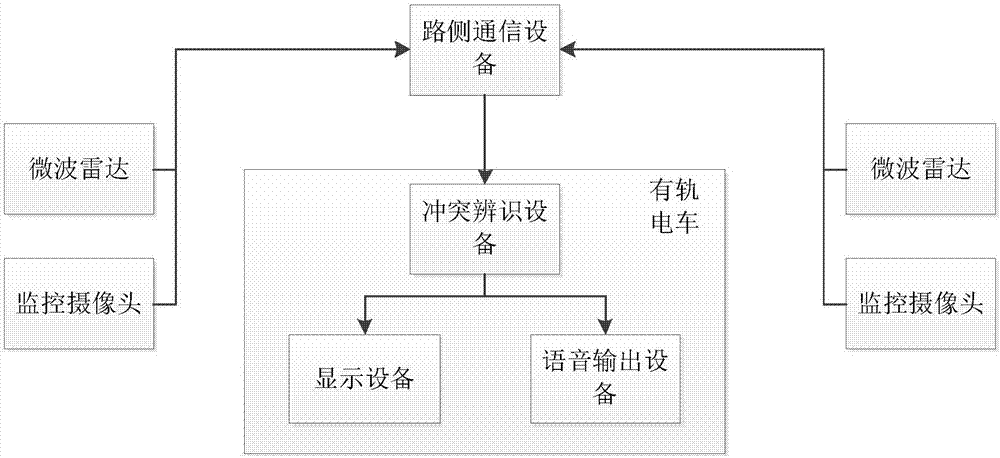

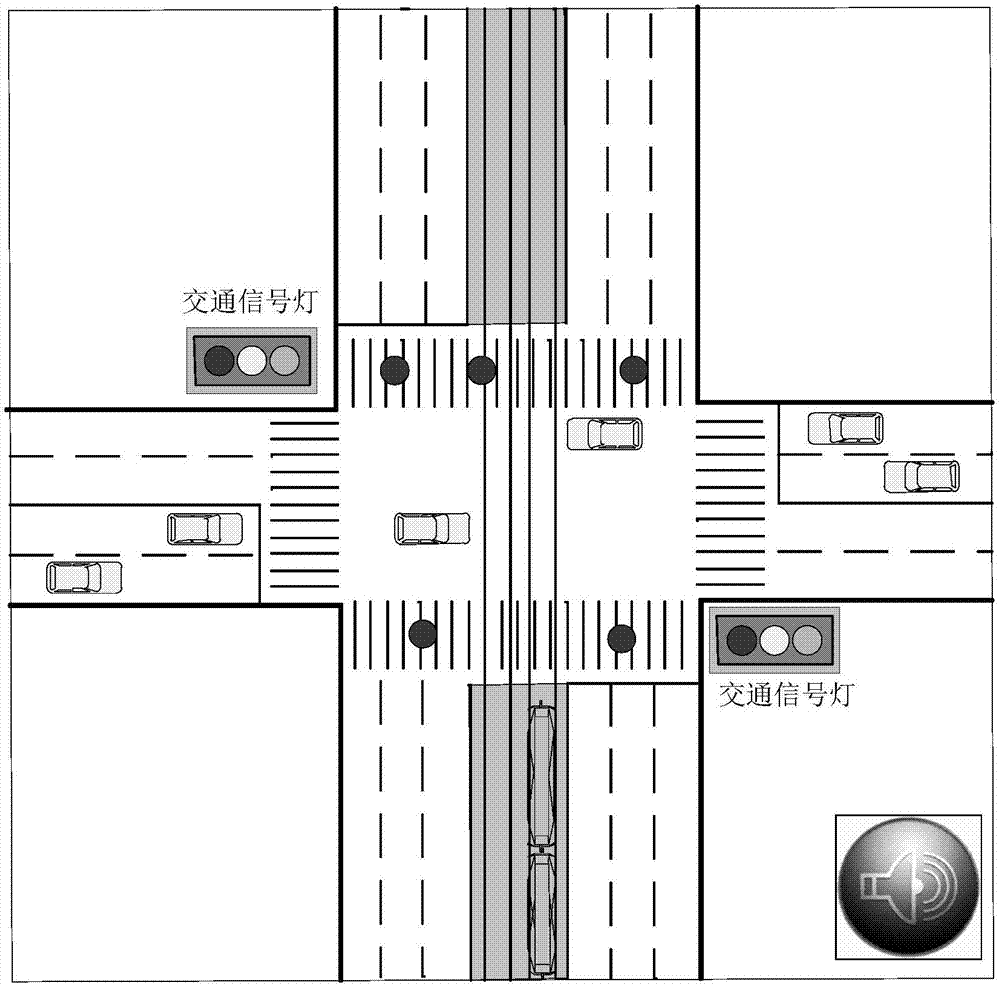

Method and system for preventing tramcars from collision at intersection

InactiveCN107067817ATimely collision avoidance measuresEnsure travel safetyAnti-collision systemsCollision preventionRegion of interest

The invention relates to a method and system for preventing tramcars from collision at an intersection. The method includes performing video data acquisition and / or microwave data acquisition on the interested area of the intersection to obtain the vehicles and pedestrian information in the interested area; analyzing the vehicles and pedestrian information to obtain the analyzed result of potential pedestrians and vehicles and / or vehicle collision; providing the vehicle and pedestrian information to the drivers of the tramcars according to the analysis result, wherein the vehicles and / or pedestrians with the potential pedestrians and vehicles and / or vehicle collision is warned. The video detection and microwave detection are fused, the real-time monitoring analysis is carried out to the intersection for the tramcars to pass, the vehicles and the pedestrians in a certain range of the intersection are monitored, the quantity and position are detected, the information is sent to the tramcars, so that the tramcars can take timely collision prevention measures, and the travelling safety of the pedestrians and the vehicles can be guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

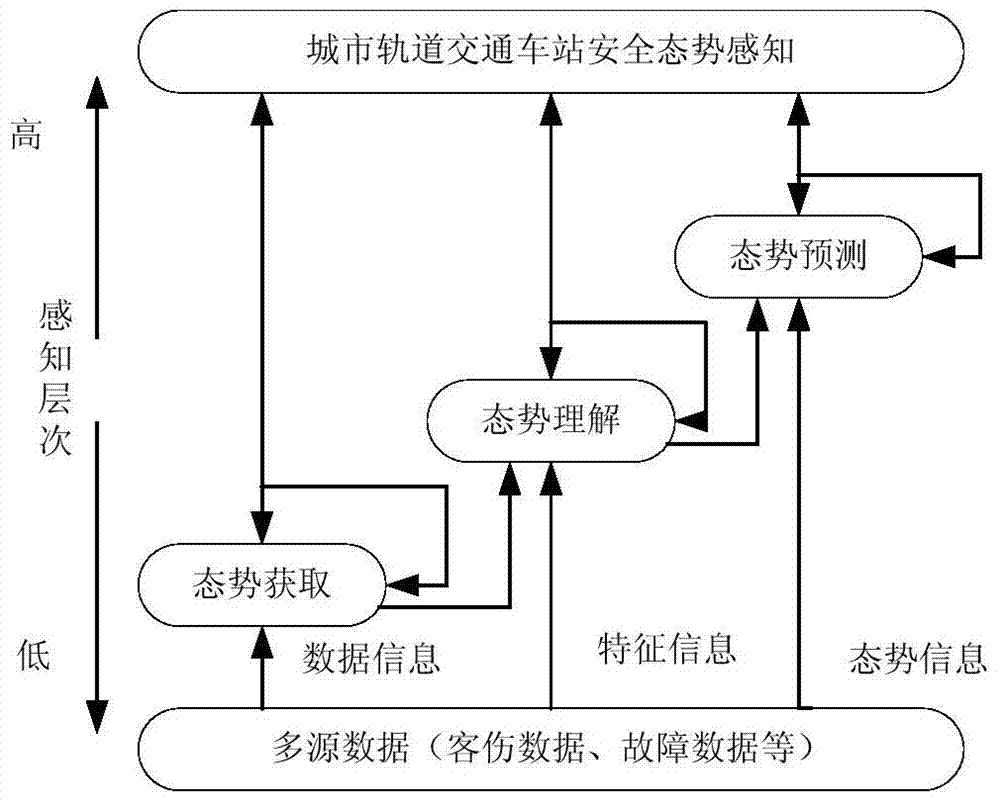

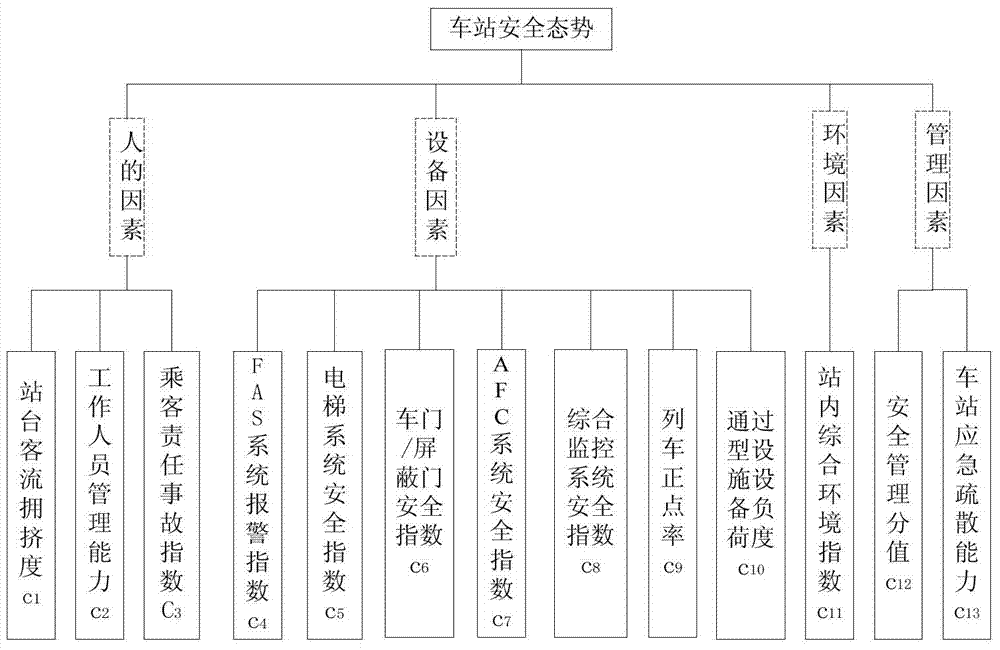

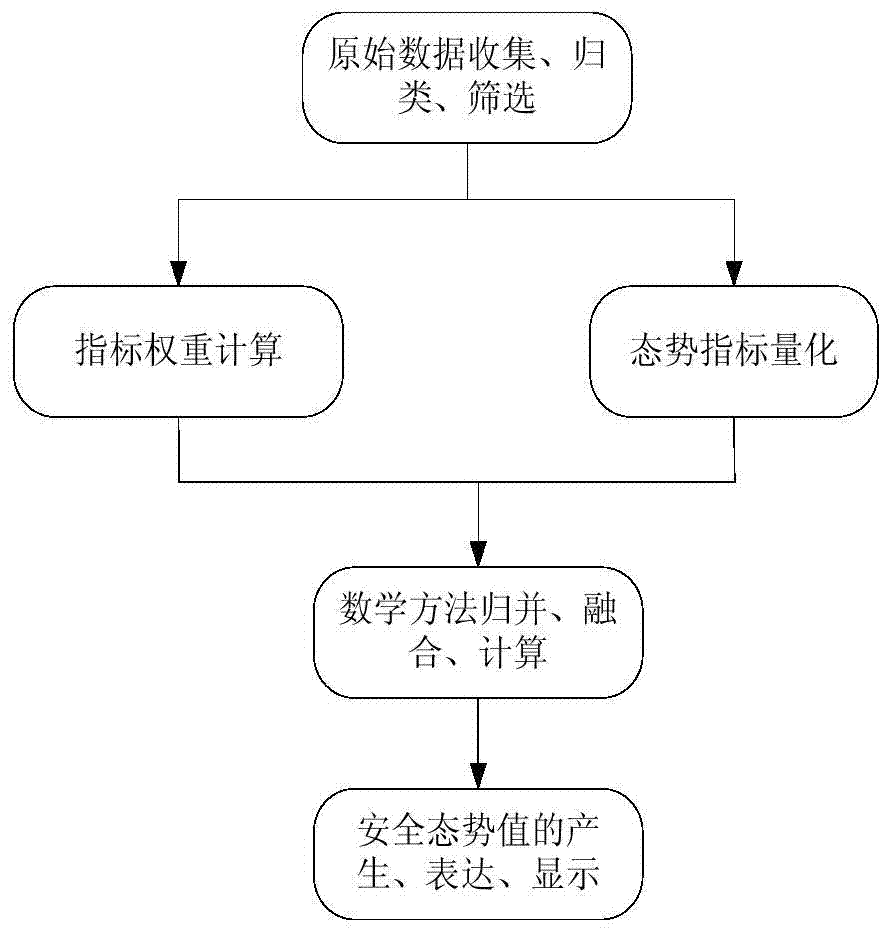

Method for sensing safety situation of urban rail transit station

InactiveCN104732286ASecurity Situation MasteryImprove the protective effectForecastingPredictive methodsEngineering

The invention provides a method for sensing the safety situation of an urban rail transit station. Through analyzing influences on traveling safety of passengers by the station, a complete safety situation sensing model for the urban rail transit station in detail is provided, methods, for obtaining, understanding and predicating the safety situation of the urban rail transit station are obtained, the safety situation of the urban rail transit station can be accurately mastered in real time, and the support is provided for reasonable and effective decision making; self-reasoning is performed on experience obtained from already existing knowledge, and the safety protection capacity of the passengers is improved; related safety variables of the urban rail transit station are obtained and understood, the safety situation in the future is predicated, and the station is instructed to adopt effective procedures for guaranteeing traveling safety of the passengers.

Owner:GUANGZHOU METRO GRP CO LTD

Forecasting technical scheme for traffic congestion spreading caused by waterlogging under bridge

ActiveCN103488893AConvenient travelEnsure travel safetyRoad vehicles traffic controlSpecial data processing applicationsTraffic congestionBusiness forecasting

The invention discloses a forecasting technical scheme for traffic congestion spreading caused by waterlogging under bridge. The forecasting technical scheme for the traffic congestion spreading caused by the waterlogging under bridge is characterized by comprising two models. According to the first model, a point section under the bridge is served as a central point of congestion caused by waterlogging, the central point is served as a starting point, and a range of congestion influence at the end of every forecasting period is obtained by multiplying the forecasted congestion spreading speed and the forecasting time when the range of congestion influence is forecasted in every forecasting period. According to the second model, at an initial first forecasting period, the point section under the bridge is served as the central point to obtain the boundary of a range of congestion influence at the end of the first forecasting period and at a second forecasting period, a boundary of the end of the first forecasting period is served as a starting point, a boundary of the end of the second forecasting period is obtained by utilizing products of the congestion spreading speed and the time, and the congestion spreading speed at the moment is a vector. The forecasting technical scheme for the traffic congestion spreading caused by the waterlogging under bridge has the advantages of providing warning information and traffic guidance to keep away from areas which are seriously influenced by the waterlogging, being convenient for people going out and guaranteeing travel safety of people.

Owner:北京交通发展研究院

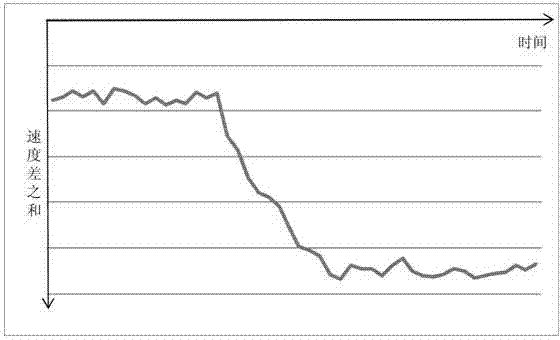

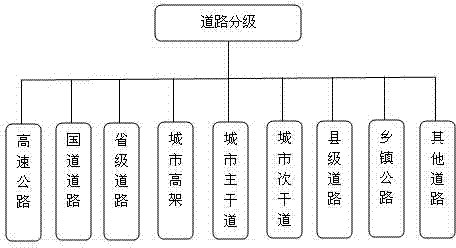

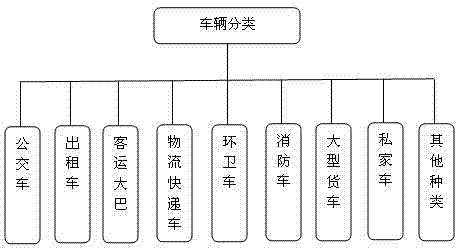

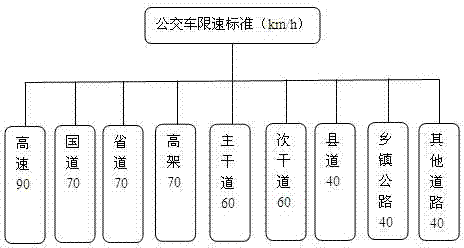

Vehicle grading speed-limiting monitoring method and device based on Internet of vehicles technology

ActiveCN103050013AFine vehicle monitoring meansThe monitoring results are reasonableRoad vehicles traffic controlEngineeringSpeed limit

The invention discloses a vehicle grading speed-limiting monitoring method and device based on an Internet of vehicles technology. The device comprise a positioning module and a speed-limiting module, wherein the positioning module comprises a GPS (Global positioning system) module, a base station positioning module and a sensor module, wherein the speed-limiting module comprises a road grading module and a vehicle classifying module. Due to the adoption of the vehicle grading speed-limiting monitoring method and device disclosed by the invention, all-weather non-blind area monitoring of vehicles can be realized.

Owner:JIANGSU HONGXIN SYST INTEGRATION

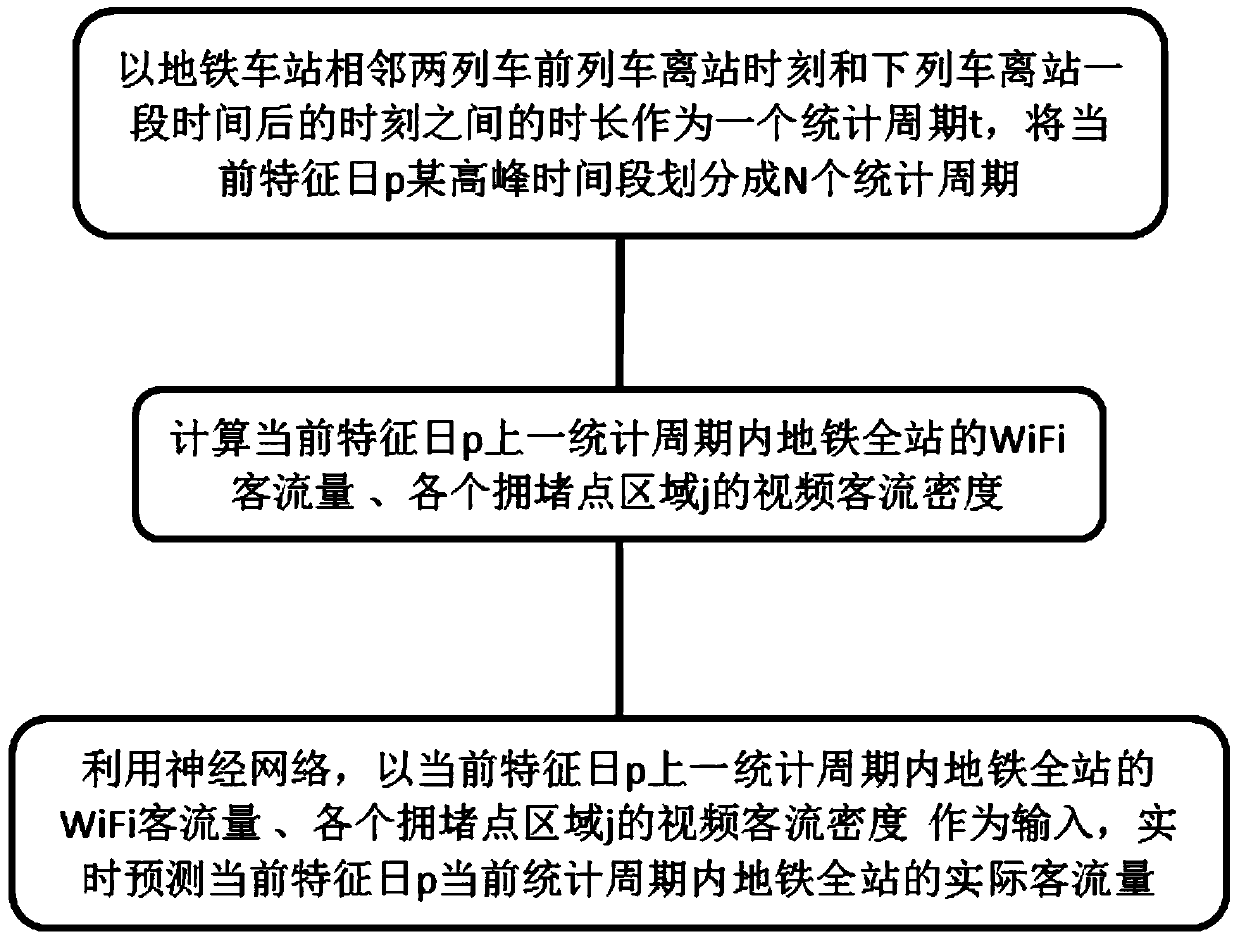

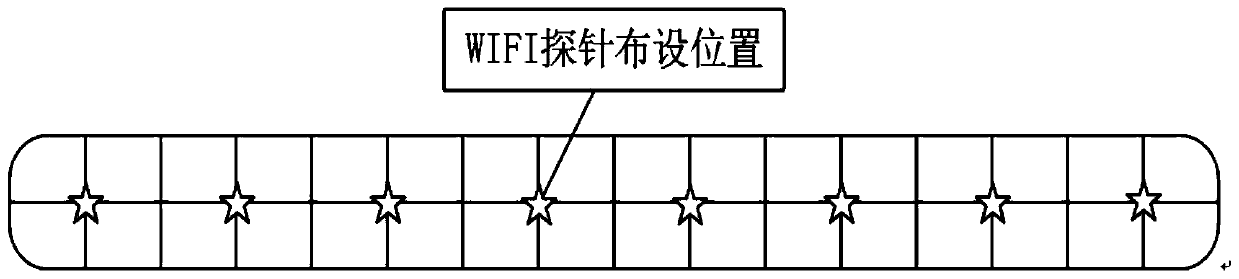

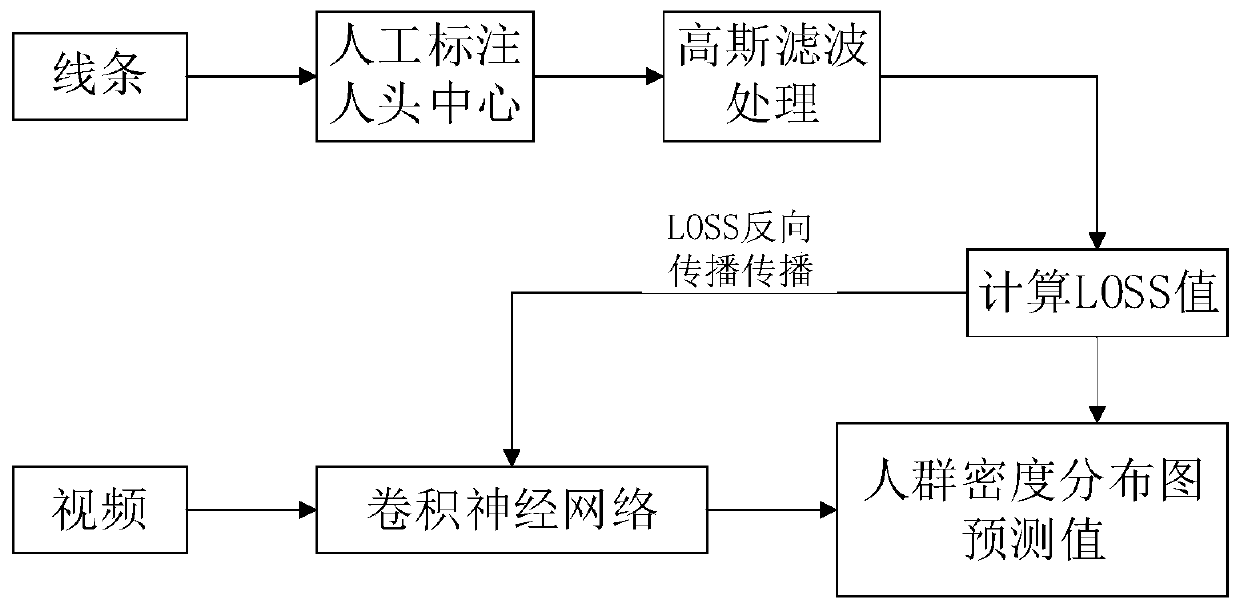

Real-time prediction method for passenger flow volume of rail transit subway station

ActiveCN110493816AImprove detection accuracyReduce limitationsNeural architecturesWireless communicationIntelligent managementEngineering

The invention belongs to the technical field of urban rail transit intelligent management. The real-time prediction method for the passenger flow volume of the rail transit subway station comprises the steps that the duration between the train departure moment before two adjacent trains of the subway station and the moment after the next train leaves the station for a period of time serves as a statistical period, and a certain peak time period of a current characteristic day is divided into N statistical periods; calculating the WiFi passenger flow Xt-1 of the whole subway station and the video passenger flow density of each congestion point area j in the last statistical period of the current characteristic day; wiFi passenger flow Xt-1 of a subway whole station and video passenger flowdensity of each congestion point area j in a previous statistical period of the current characteristic day are used as input; predicting the actual passenger flow Yt of the whole subway station in thecurrent statistical period of the current characteristic day in real time, thereby completing the real-time prediction of the passenger flow of the whole subway station in the current statistical period of the current characteristic day; and repeating the above steps to complete real-time prediction of the subway total station passenger flow volume in N statistical periods in a peak period.

Owner:SHANGHAI UNIV OF ENG SCI

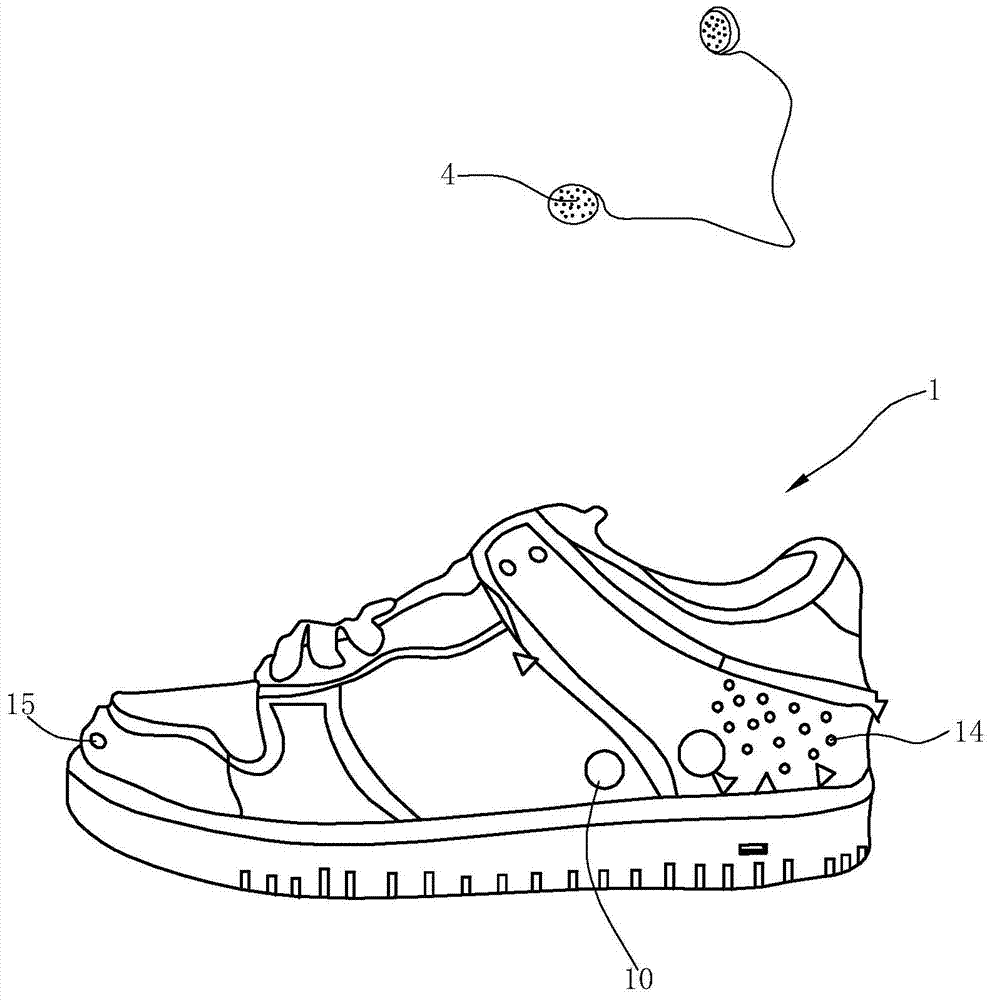

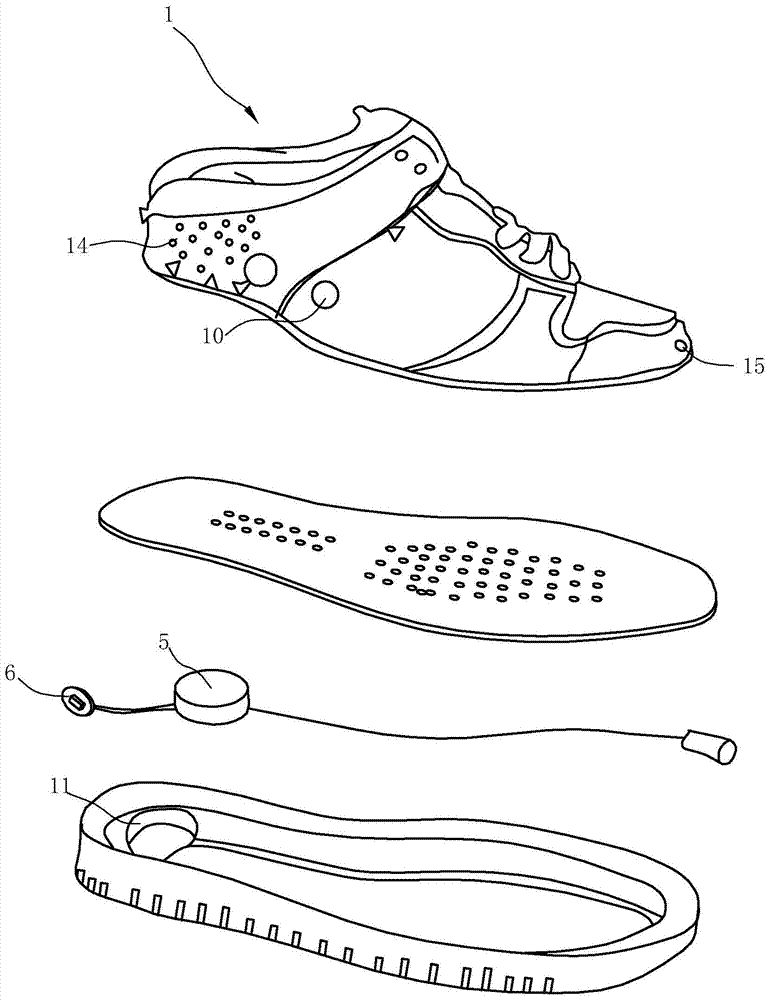

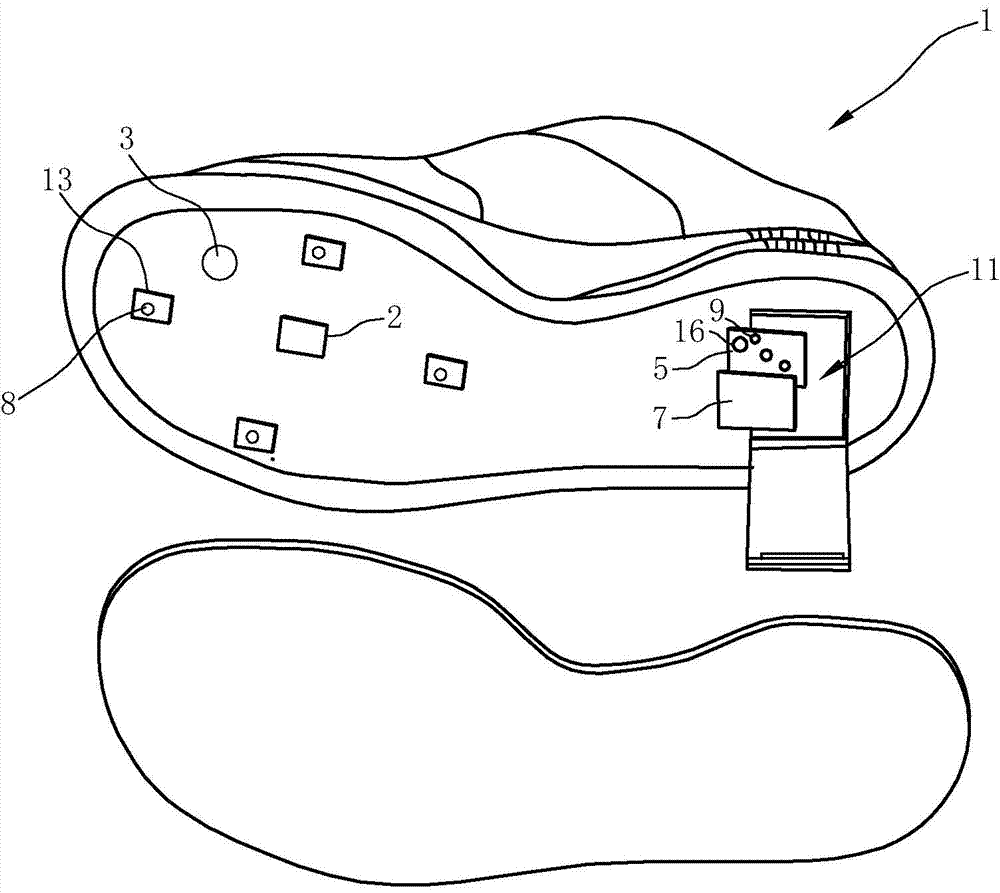

Navigation shoe special for blind person

ActiveCN103919664AIt has the function of positioning and navigationSafe walkingWalking aidsFootwearRoad surfaceEngineering

The invention relates to a navigation shoe special for a blind person. The navigation shoe comprises a shoe body, a wireless Bluetooth headset and a voice player, a navigation chip is arranged in the shoe body and connected with an infrared sensing probe arranged at the front end of the shoe body, an LED light emitting unit connected with a control device is arranged on the outer surface of the shoe body, and an isolating device is arranged on a pin of the LED light emitting unit. Compared with the prior art, the navigation shoe has the advantages that the blind person can sense road conditions through the navigation chip, and the infrared sensing probe on the shoe can give out different sensing signals and generate jittering of different degrees according to size and position of obstacles in front of and beside the blind person so as to help the blind person to effectively avoid the obstacles; the LED light emitting unit is arranged on the outer surface of the shoe body, so that when walking on a road, the blind person is enabled to be capable of receiving more attention and more help from the society and other people.

Owner:宁波市富罗迷鞋业有限公司

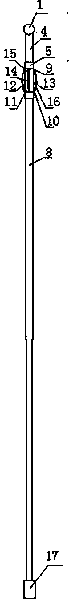

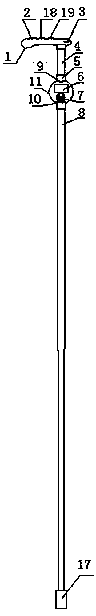

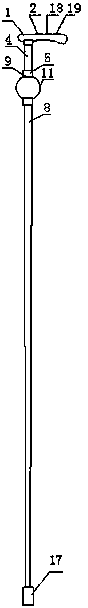

Intelligent monitoring walking stick for the aged and monitoring method thereof

ActiveCN104257050AEnsure travel safetyAvoid being overwhelmedWalking sticksSensorsEngineeringMechanical engineering

The invention provides an intelligent monitoring walking stick for the aged and a monitoring method thereof. The walking stick is structurally composed of a handle, a battery housing, a composite casing, a support rod and a health sign monitoring and alarming system, wherein a threaded connector is arranged on the lower portion of the handle and connected with the upper end of the battery housing through threads, the lower end of the battery housing is connected with a threaded connector at the upper end of the composite casing through threads, a threaded connector is arranged at the lower end of the composite casing and is connected with the upper end of the support rod through threads, a partition device is arranged in the middle of the composite casing and divides the composite casing into an electronic device chamber and a first aid medicine storeroom, flip type doors are arranged on the opening portions of the electronic device chamber and the first aid medicine storeroom, hinges are arranged on the edges of the bottoms of the electronic device chamber and the first aid medicine storeroom and are connected with the edges of the bottoms of a left flip type door and a right flip type door, press locks are arranged on the edges of the upper portions of the electronic device chamber and the first aid medicine storeroom and are connected with the edges of the upper portions of the left flip type door and the right flip type door, and a health sign monitoring and alarming system circuit board is fixed on the partition device.

Owner:山东中洁电讯科技有限公司

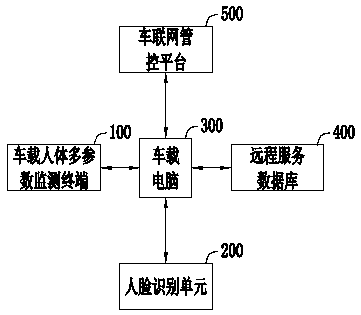

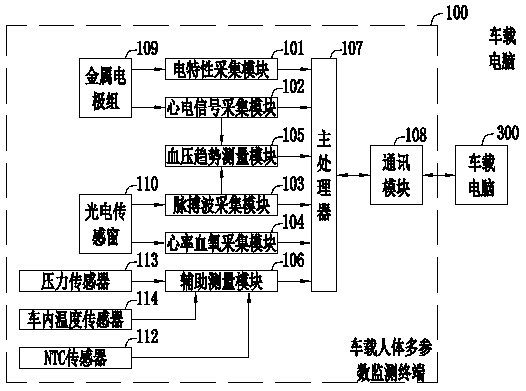

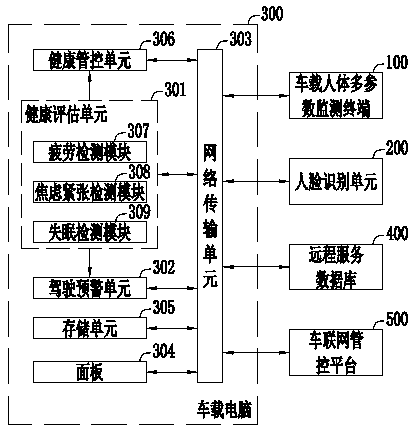

Driving control system and method based on car-mounted human multi-parameter monitoring terminal

PendingCN110491515AEnsure travel safetyMedical data miningDatabase management systemsControl systemNetwork control

The invention discloses a driving control system and method based on a car-mounted human multi-parameter monitoring terminal. The system comprises the car-mounted human multi-parameter monitoring terminal, a human face recognition unit, a vehicle-mounted computer, a remote service database and a car networking control platform. Health state monitoring is performed on a driver inside a car throughthe car-mounted human multi-parameter monitoring terminal, health evaluation information is obtained in real time before driving and during driving, then, whether or not early warning prompting or real-time intervention content is performed on the car and the driver is determined through the health evaluation information, multi-car linkage control is performed by means of the car networking control platform, and the user trip safety is ensured; in addition, long-term health control over the physical condition of the driver can be achieved, and the decision basis is supplied to enterprises forhealth control over driver workers by comparing and analyzing long-term health data of the driving process and driving intervals.

Owner:JIANGSU QINRUN TECH

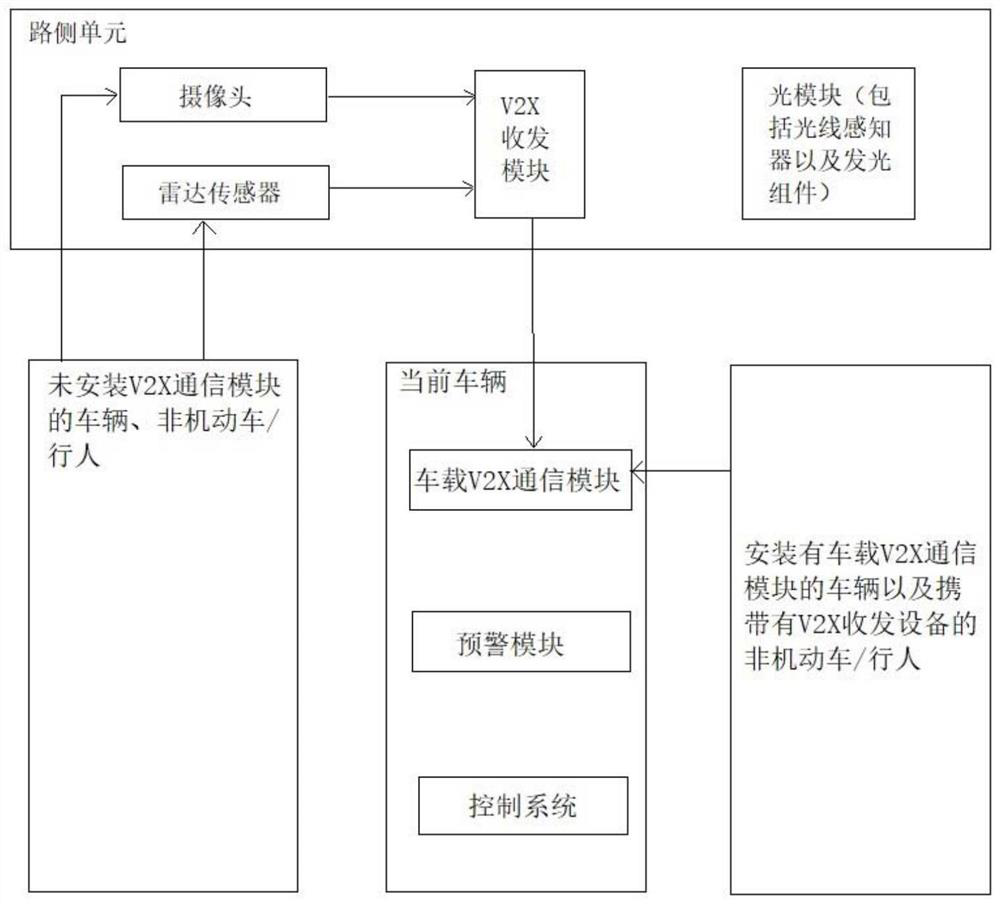

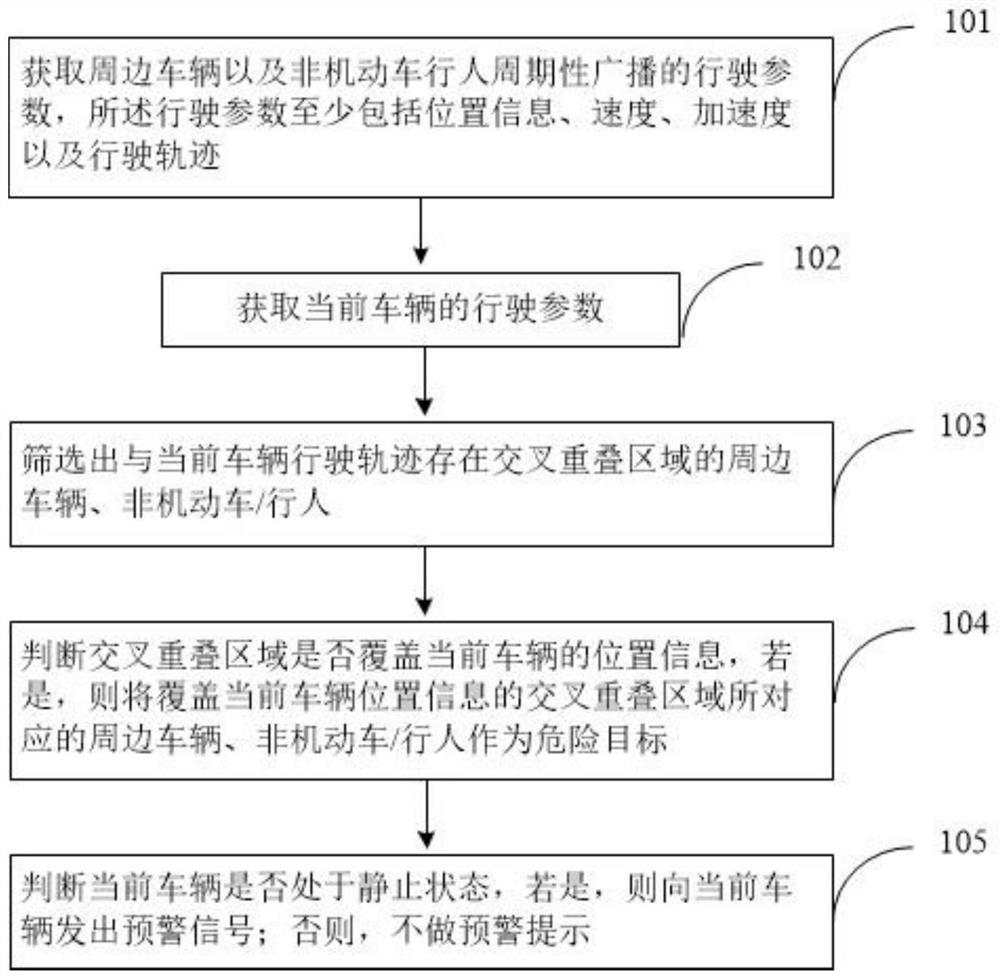

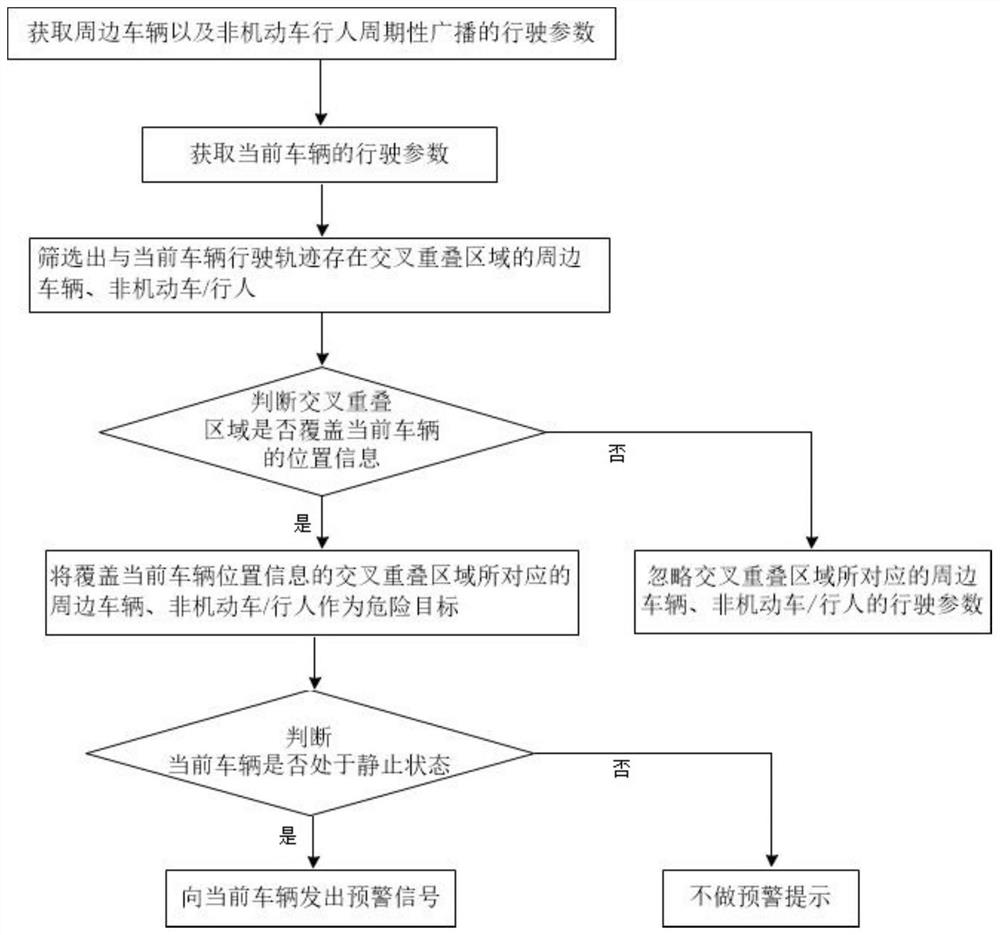

Vehicle door opening anti-collision early warning method based on V2X

InactiveCN113223311AEnsure travel safetyAnti-collision systemsAlarmsPotential accidentVehicle driving

The invention relates to a vehicle door opening anti-collision early warning method based on V2X. The method comprises the steps of obtaining driving parameters periodically broadcasted by surrounding vehicles and non-motor vehicles / pedestrians, and the driving parameters at least comprising position information, speed, acceleration and driving tracks; acquiring driving parameters of the current vehicle; screening out surrounding vehicles and non-motor vehicles / pedestrians which have a crossing and overlapping area with the current vehicle driving track; judging whether the crossing and overlapping area covers the position information of the current vehicle or not, and if yes, taking surrounding vehicles and non-motor vehicles / pedestrians corresponding to the crossing and overlapping area covering the position information of the current vehicle as dangerous targets; judging whether the current vehicle is in a static state or not, and if yes, sending an early warning signal to the current vehicle; or else, not giving an early warning prompt. According to the method, non-motor vehicles / pedestrians and traffic participants without V2X equipment can be considered in scene calculation, the defects existing in an existing vehicle door collision prediction method are overcome, and potential accidents can be eliminated.

Owner:NANJING DESAY SV AUTOMOTIVE CO LTD

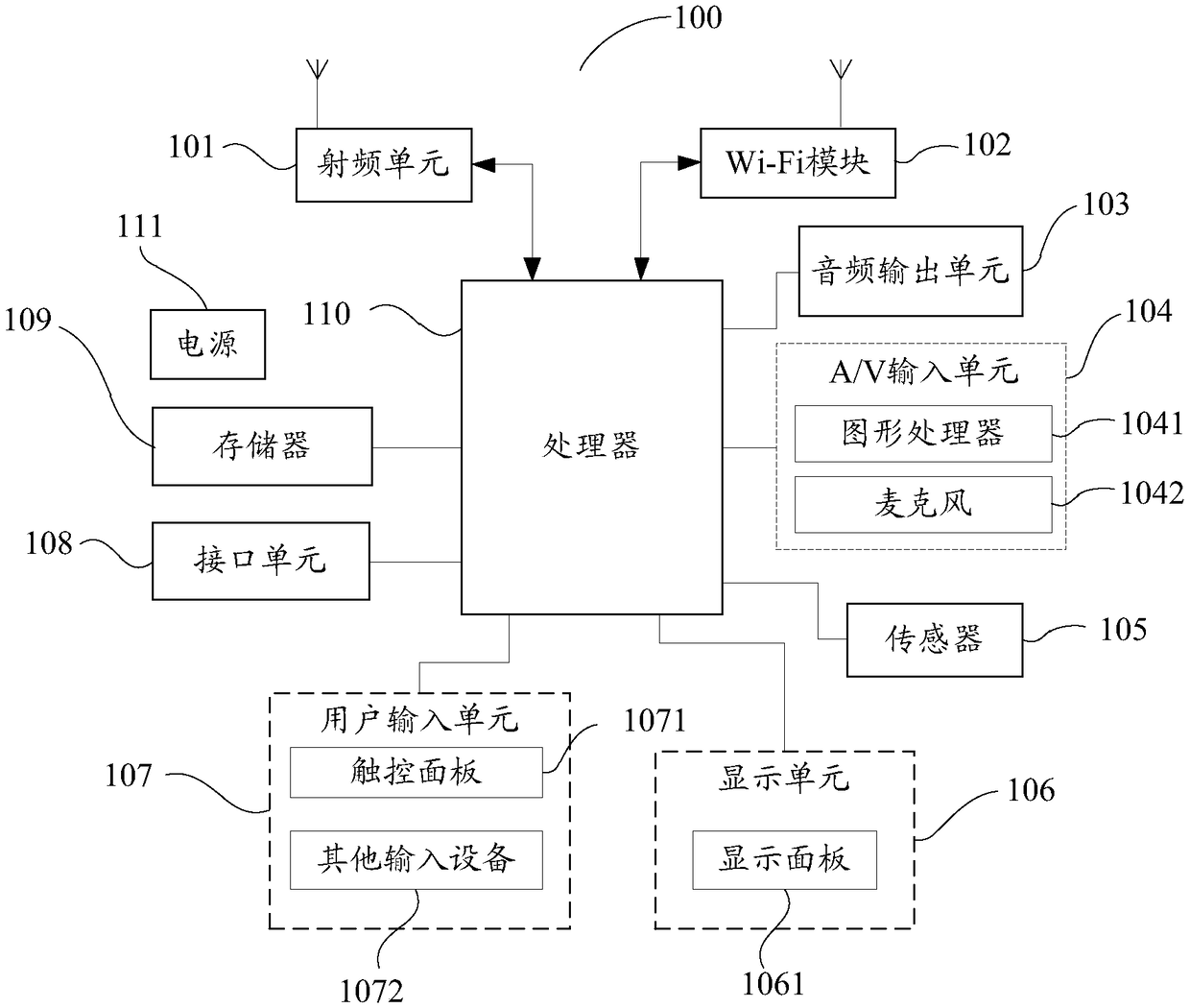

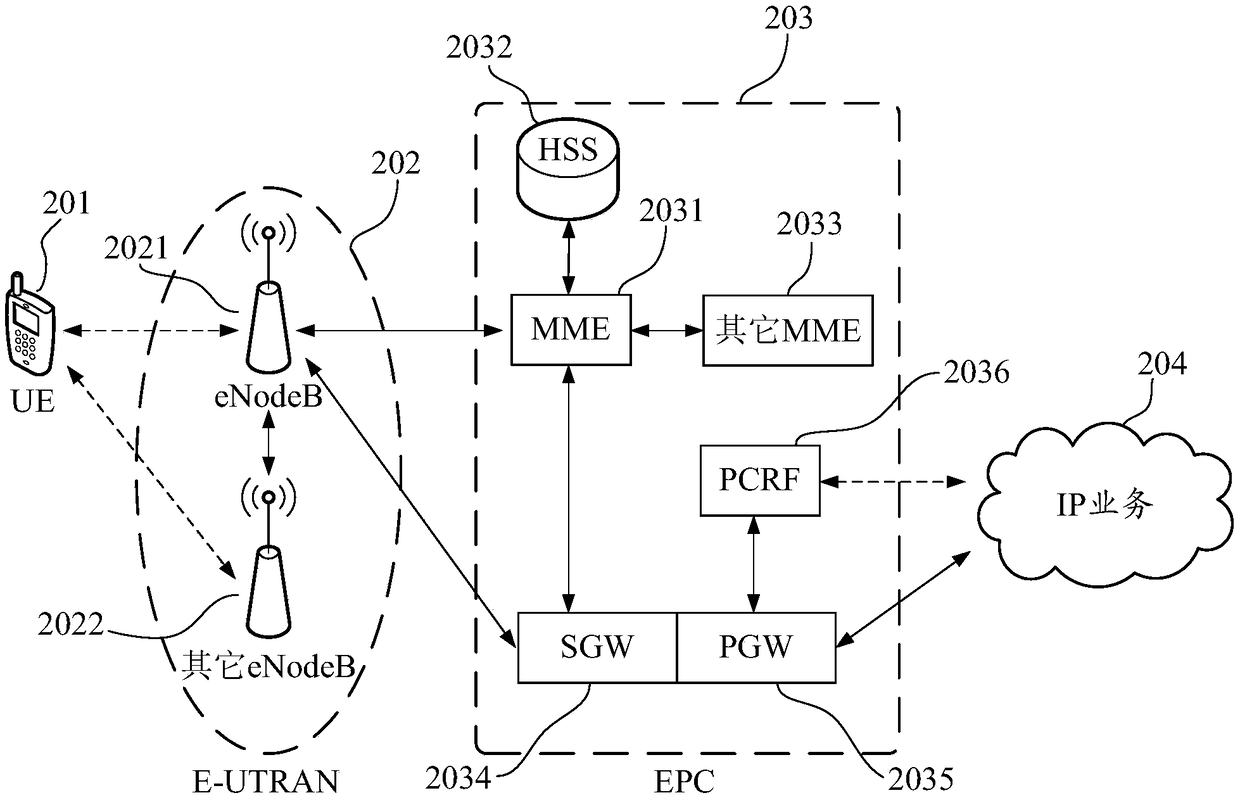

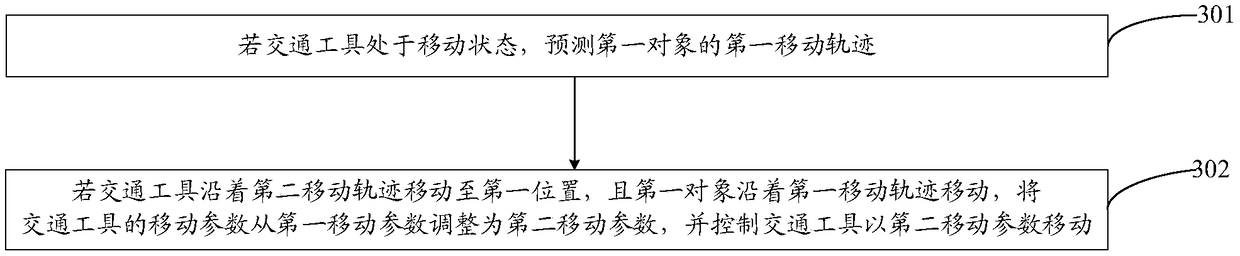

Information processing method, terminal and computer readable storage medium

InactiveCN109064746AImprove intelligenceAvoid collisionParticular environment based servicesDetection of traffic movementInformation processingComputer terminal

An embodiment of the invention discloses an information processing method. The information processing method comprises the steps that if a vehicle is in a moving state, a first moving track of a firstobject is predicted; and if the vehicle moves to a first position along a second moving track and the first object moves along the first moving track, moving parameters of the vehicle are adjusted tosecond moving parameters from first moving parameters, and the vehicle is controlled to move by the second moving parameters, wherein the second moving track represents a predicted moving track of the vehicle, the first position represents a position of the vehicle before the vehicle does not move to the second position, the second position represents an intersection position of the first movingtrack and the second moving track, and the second moving parameters are different from the first moving parameters. Embodiments of the invention furthermore disclose a terminal and a computer readablestorage medium. The problem of incapability of effectively avoiding pedestrians or non-motor vehicles not obeying traffic rules in related technologies is solved.

Owner:NUBIA TECHNOLOGY CO LTD

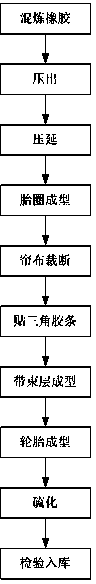

Processing technology of automobile tire

The invention discloses a processing technology of an automobile tire. The processing technology comprises the following steps: 1, carrying out rubber mixing, namely uniformly stirring rubber liquid, operating oil, a reinforcing agent, an anti-aging agent, an active agent and a vulcanizing agent to prepare a sizing material; 2, extruding, namely feeding the sizing material prepared after mixing to an extruding machine to obtain a tread and a side wall; 3, calendering, namely passing a cord thread through a calender, and coating each surface of the cord thread with one layer of sizing material to prepare a cord fabric; 4, forming a tire bead, namely after coating a plurality of steel wires with the sizing material, winding to prepare the tire bead; 5, cutting the cord fabric; 6, attaching a triangular rubber strip; 7, forming a belt ply; 8, forming the tire, namely assembling the parts obtained in steps 2 to 7 to prepare a green tire; 9, vulcanizing, namely vulcanizing the green tire by a vulcanizing machine to prepare a finished tire product; and 10, checking and warehousing. According to the invention, through rubber mixing, forming of the parts of the tire, preparation of the green tire, vulcanizing and checking, the quality of the produced tire can be ensured, and traveling safety of vehicles and people can be guaranteed.

Owner:WUXI BAISHUN MACHINERY PLANT

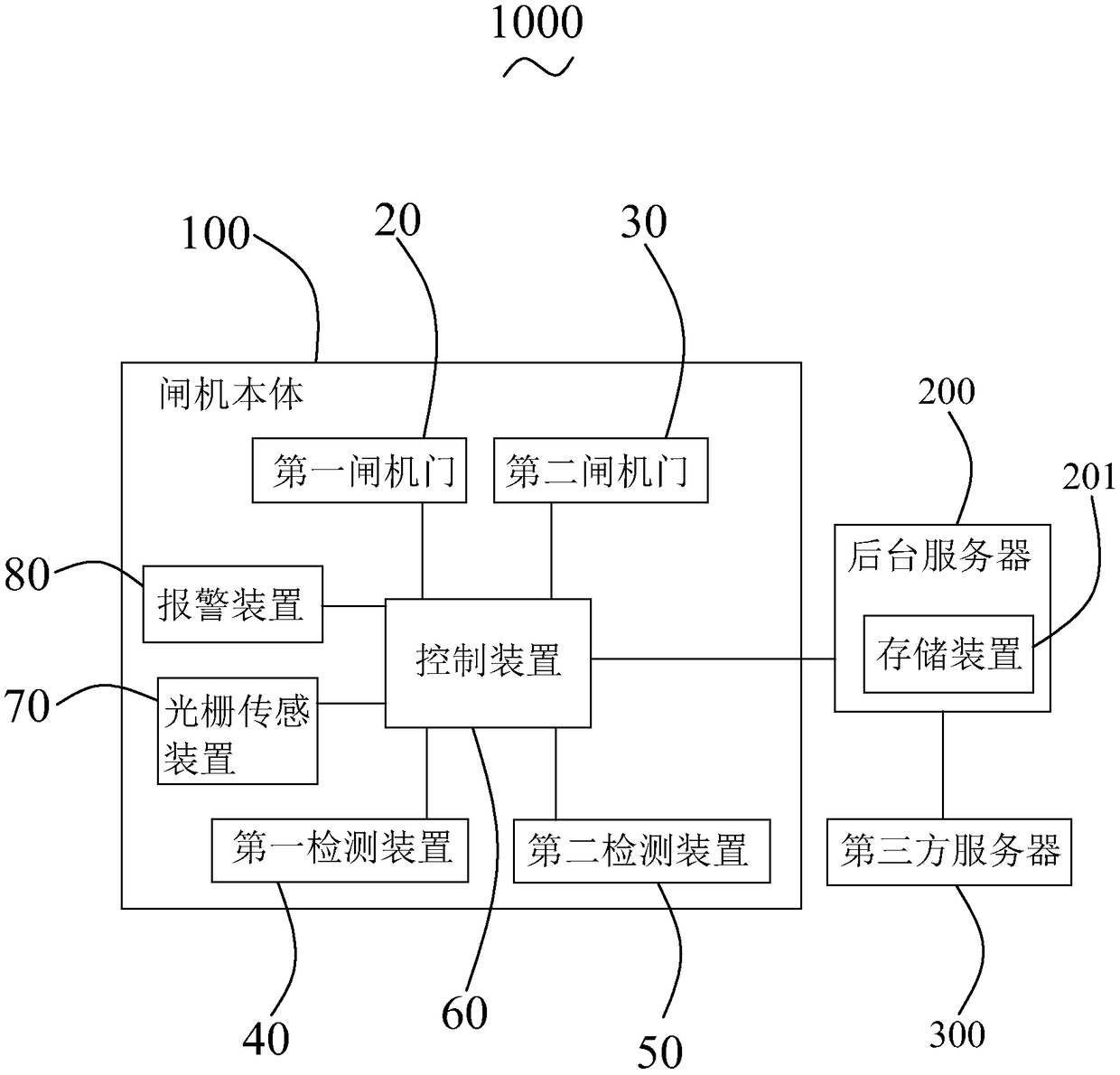

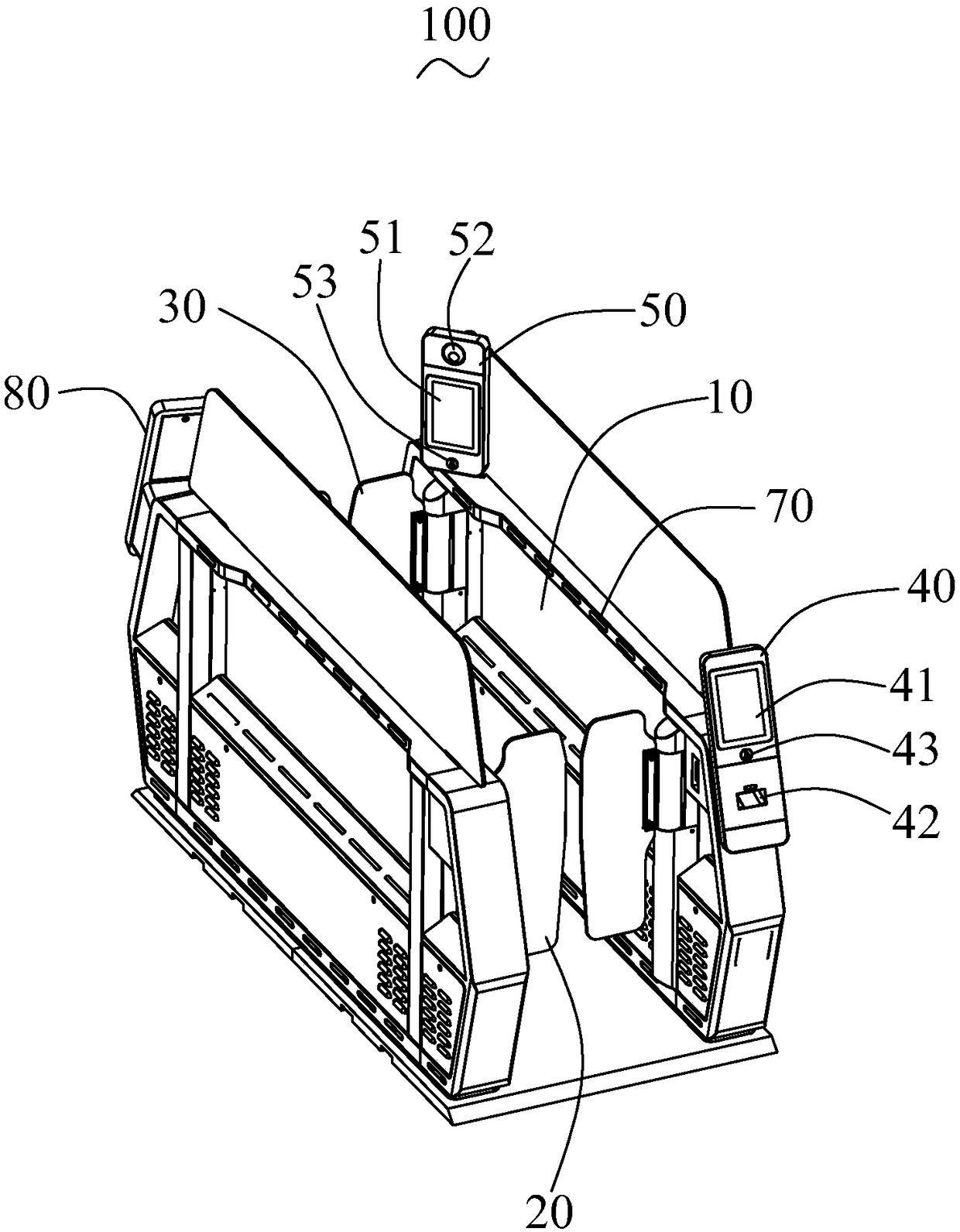

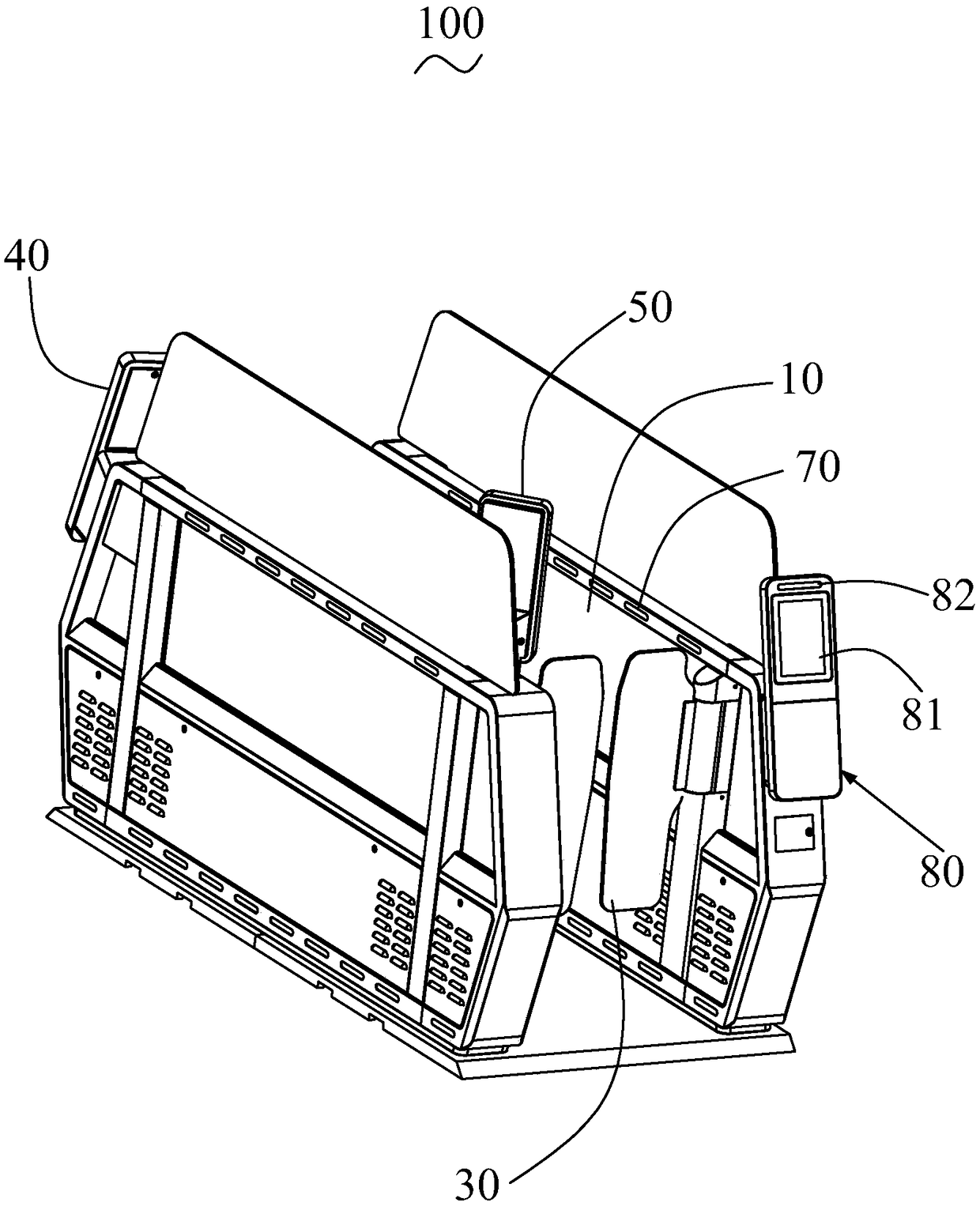

High-speed railway gate pass method and system

InactiveCN109410347AEnsure travel safetyTicket-issuing apparatusIndividual entry/exit registersFingerprintTelecommunications

The present invention provides a high-speed railway gate pass method. The method comprises the steps of: collecting passenger identity cards and ticket information by a first detection device, transmitting the passenger identity cards and the ticket information to a background server through a control device for verification, and performing analysis and determination by the background server to obtain a first verification result; inducting the quantity of passengers entering a channel by an optical grating sensing device in the channel, and sending the quantity to the control device for analysis and determination; collecting fingerprint information, face images or iris images of the passengers by a second detection device, transmitting the fingerprint information, the face images or the iris images to the background server through the control device for verification, and performing analysis and determination by the background serer to obtain a second verification result; and analyzingand determining whether the fingerprint information, the face images or the iris images collected by the second detection device are consistent with the identity card information collected by the first detection device and extracted by the background server or not. The present invention further provides a high-speed railway gate pass system. The high-speed railway gate pass method and system can effectively identify and control suspicious personnel when passengers have tickets checked and access the station so as to ensure the travel safety of the passengers.

Owner:深圳晟道科技有限公司

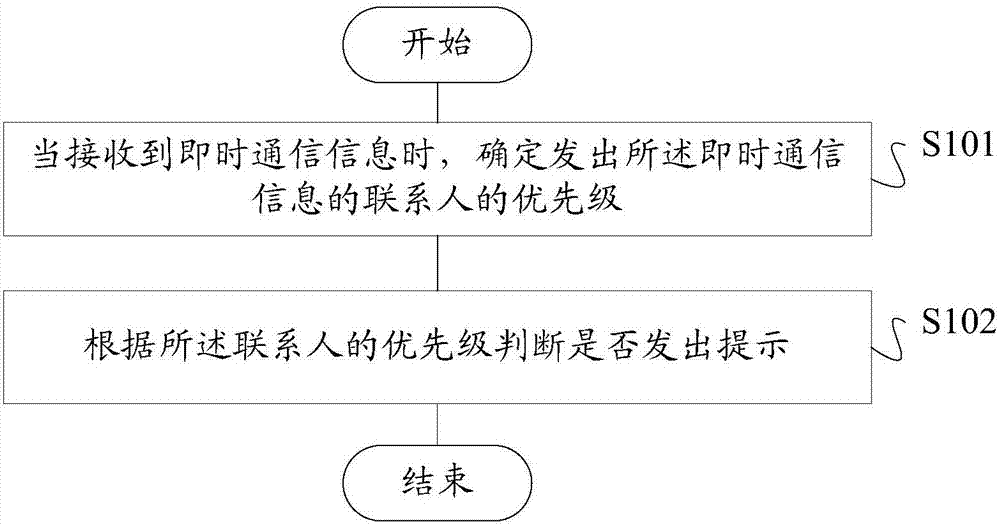

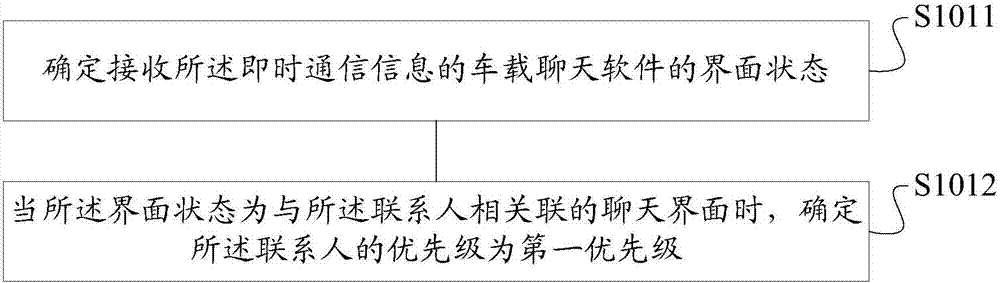

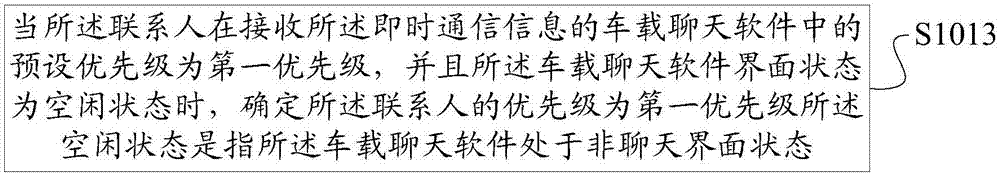

Instant messaging information management method for vehicle-mounted infotainment entertainment products, device, storage medium and terminal

ActiveCN107483324AReasonable managementImprove user experienceMessaging/mailboxes/announcementsData switching networksProduct baseComputer terminal

The invention relates to an instant messaging information management method for vehicle-mounted infotainment entertainment products, an instant messaging information management device for vehicle-mounted infotainment entertainment products, a storage medium and a terminal. The method includes the following steps that: when instant messaging information is received, the priority of a contact who sends the instant messaging information is determined; and whether a prompt is emitted is judged according to the priority of the contact. With the instant messaging information management method, the instant messaging information management device, the storage medium and the terminal provided by the technical schemes of the invention adopted, the instant messaging information for the vehicle-mounted infotainment entertainment products can be reasonably managed, and therefore, the use experience of vehicle-mounted infotainment entertainment product-based instant messaging of a user can be improved, and the driving safety of the user during a vehicle use period can be ensured.

Owner:SHANGHAI QINGGAN INTELLIGENT TECH CO LTD

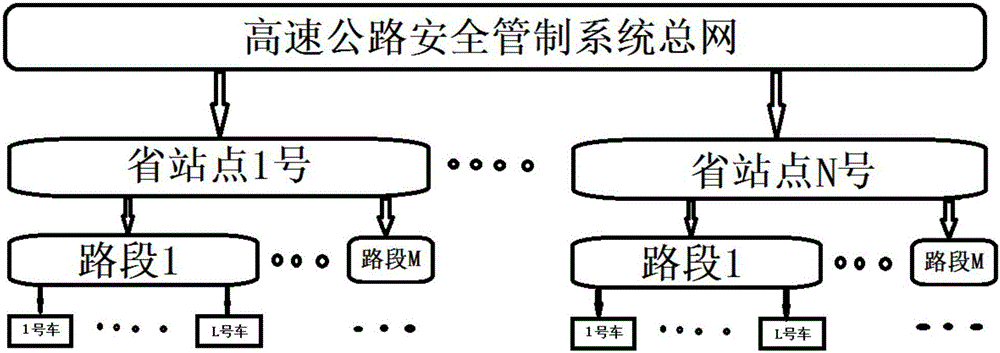

Traffic safety control method for highway

InactiveCN105730444AReduce incidenceEnsure travel safetyVehicle headlampsVehicle fittingsThe InternetSafety control

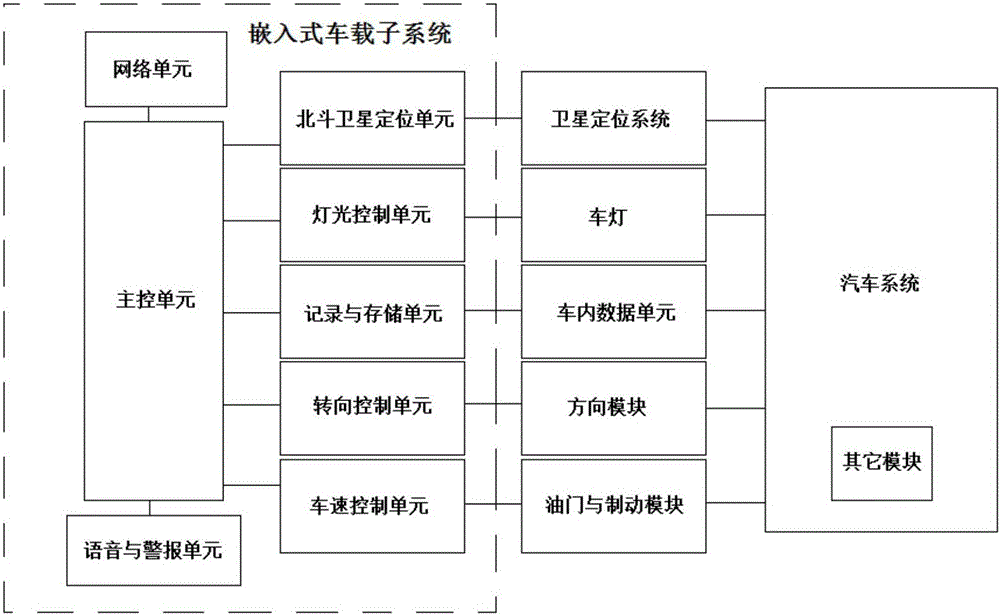

The invention provides a traffic safety control method for a highway. The traffic control method for the highway comprises a traffic management main system and vehicle-mounted subsystems. Each vehicle-mounted subsystem comprises a main control unit and an accelerator and brake integrated vehicle speed control unit, a Beidou satellite positioning unit, a steering control unit, a lamplight control unit, a voice prompt unit, a network unit and a storage unit, wherein the accelerator and brake integrated vehicle speed control unit, the Beidou satellite positioning unit, the steering control unit, the lamplight control unit, the voice prompt unit, the network unit and the storage unit are connected with the main control unit. Each vehicle starts the corresponding vehicle-mounted subsystem at an entrance of the highway, the vehicle-mounted subsystem transmits the road condition and the vehicle operating condition to the traffic management main system in real time, and the traffic management main system transmits commands to the subsystems in real time, so that traffic flow control is formed. According to the traffic safety control method for the highway, the operating tracks of the vehicles on the highway are monitored through the means of the Internet of Things, road crossing behaviors are prejudged and corrected automatically, the assistance is provided for standardizing and executing of traffic rules, and the traffic control method for the highway is high in efficiency.

Owner:WUHAN UNIV

Method, device and system for returning shared vehicles

InactiveCN107689151AAvoid cluttered parkingAvoid causing disorderly parkingRoad vehicles traffic controlIndividual entry/exit registersComputer scienceCurrent user

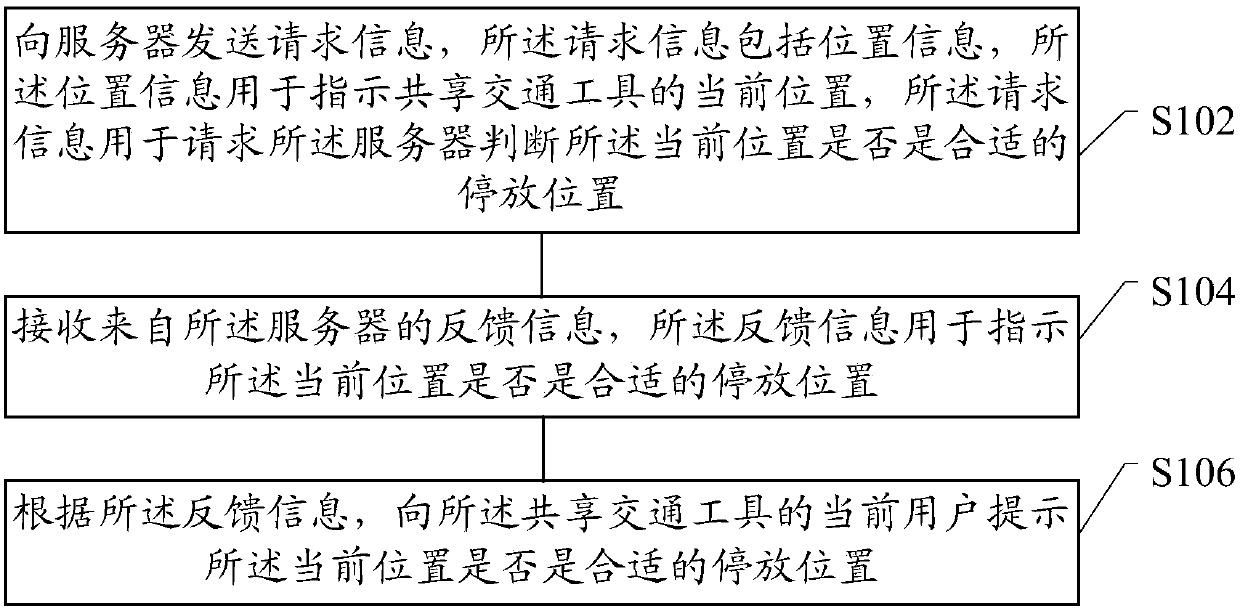

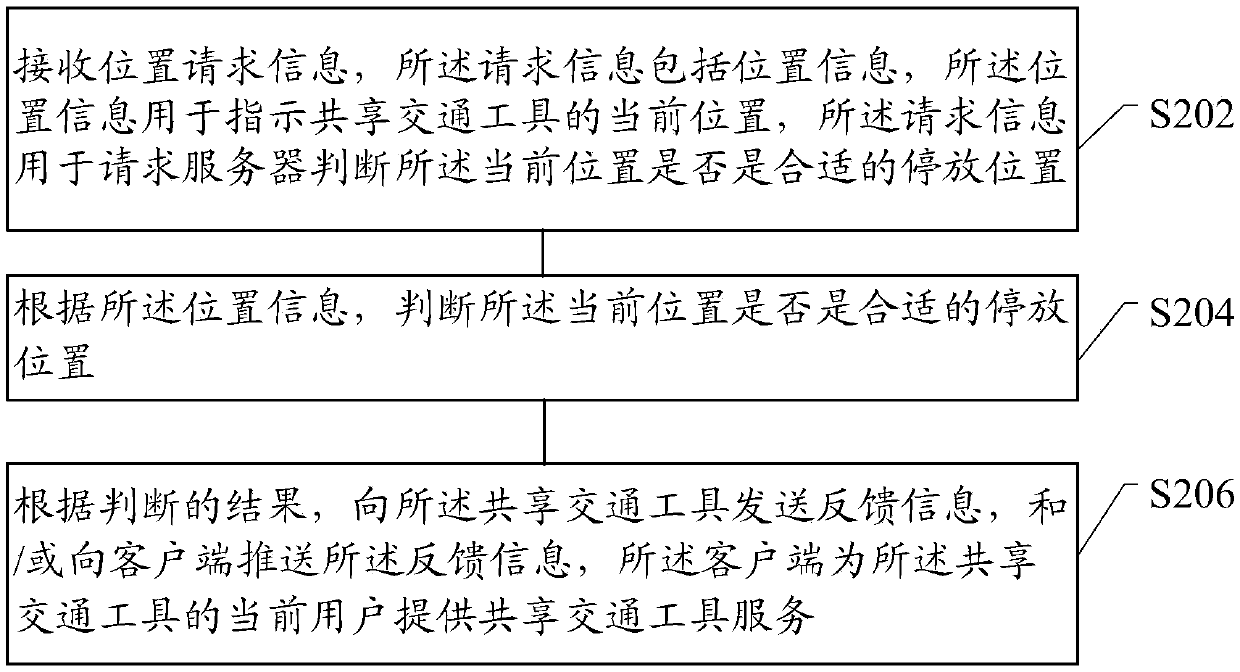

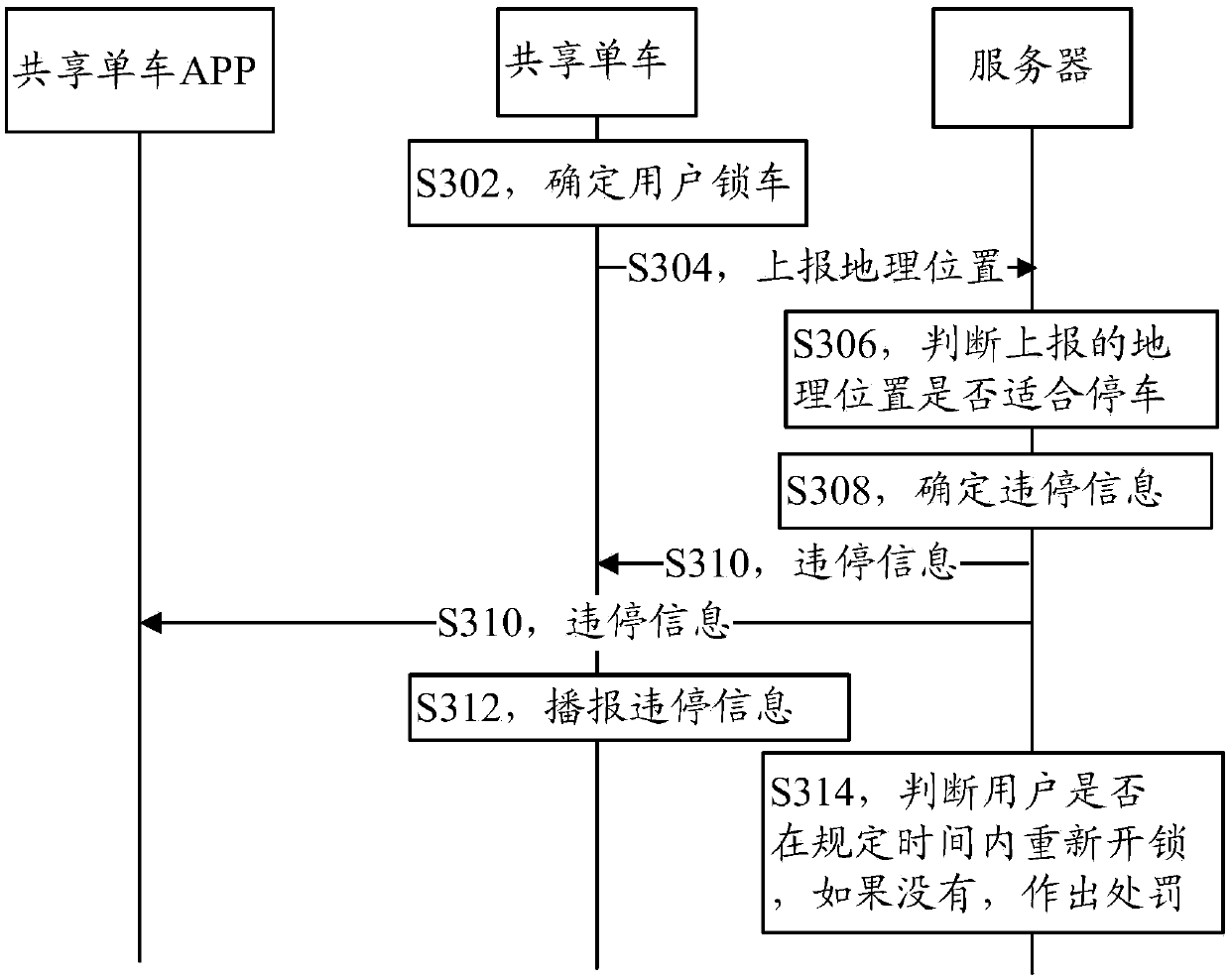

The embodiment of the invention discloses a method, device and system for returning shared vehicles. The method includes the steps that request information is sent to a server, and comprises positioninformation, wherein the position information is used for indicating current positions of the shared vehicles, and the request information is used for requesting the server to judge whether the current positions are suitable parking positions or not; feedback information from the server is received, wherein the feedback information is used for indicating whether the current positions are the suitable parking positions or not; according to the feedback information, whether the current positions are the suitable parking positions or not is reminded to the current users of the shared vehicles.

Owner:ADVANCED NEW TECH CO LTD

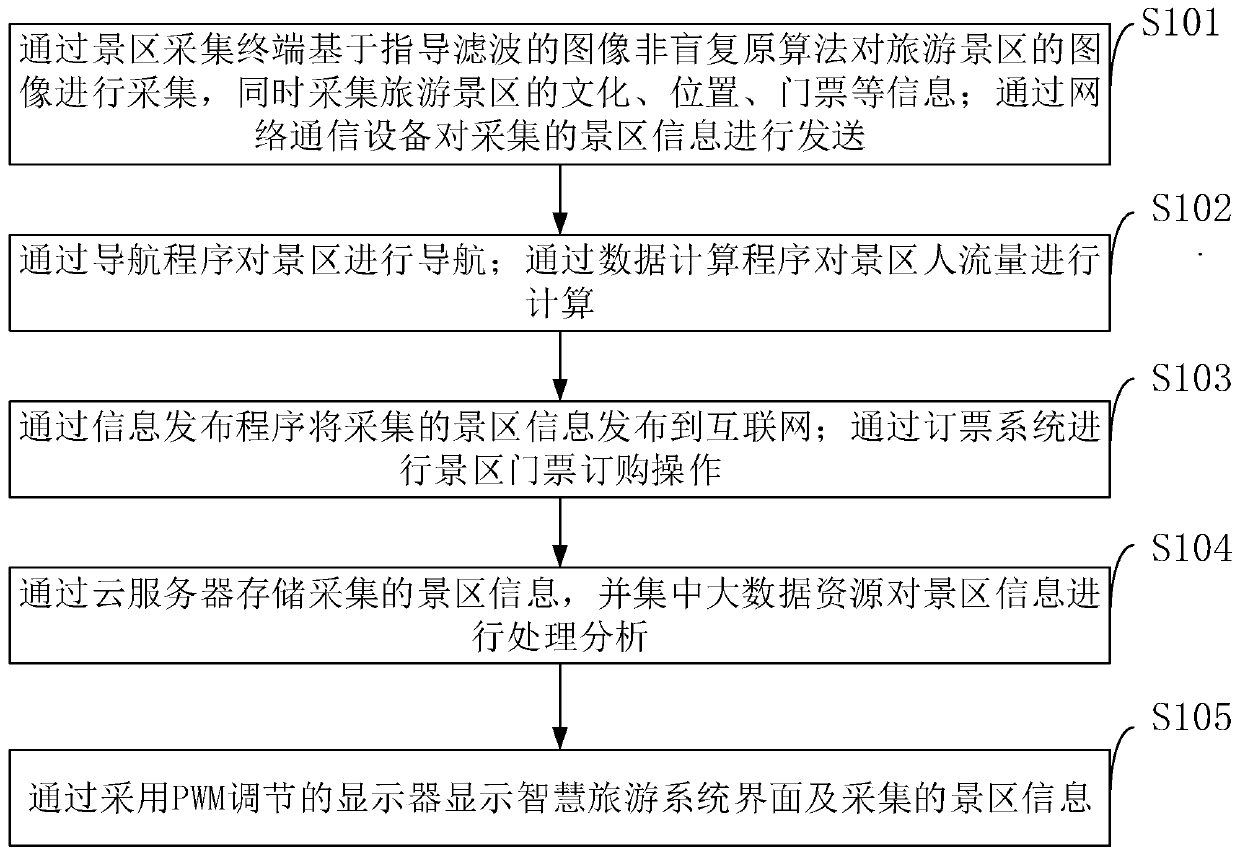

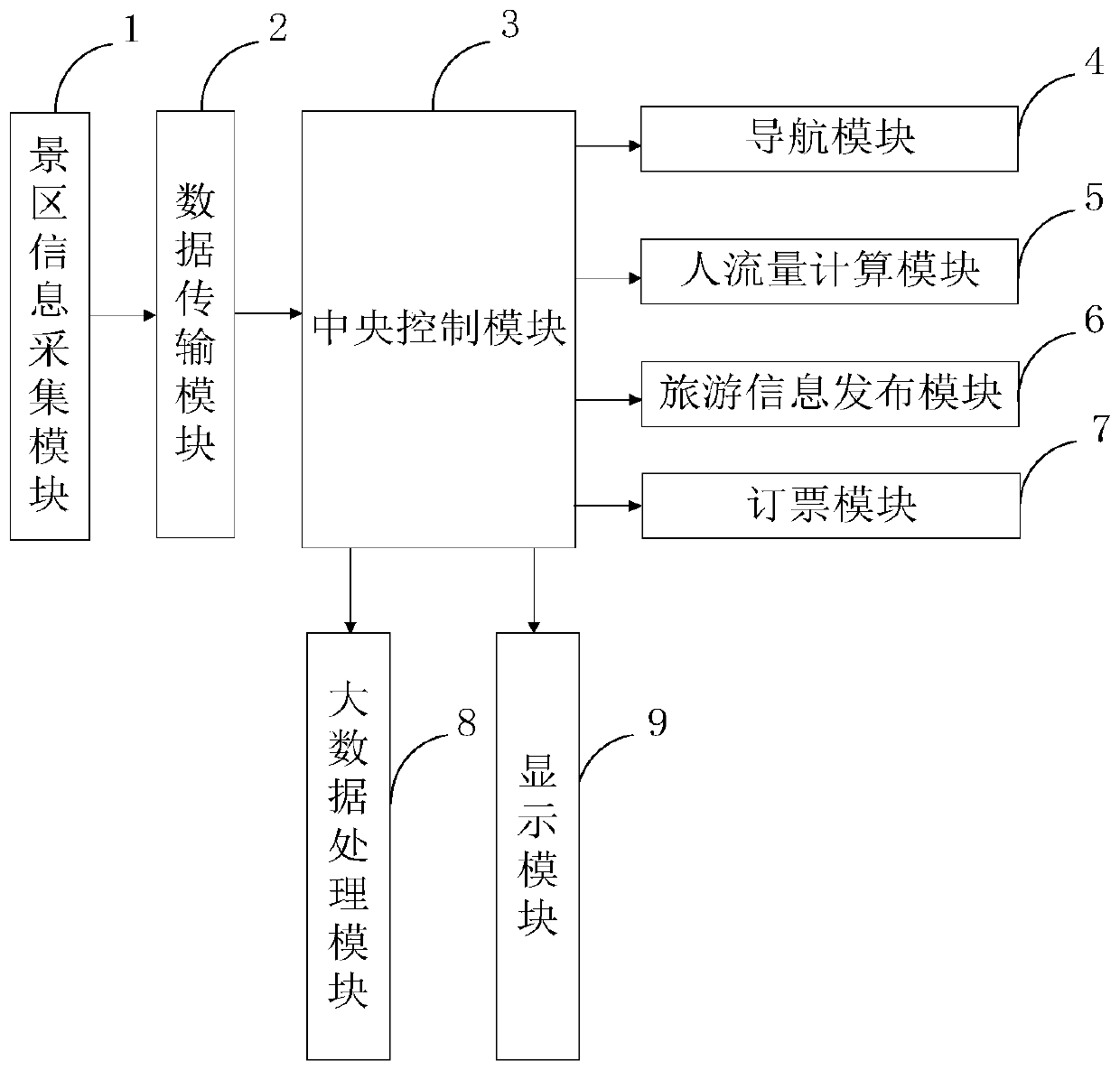

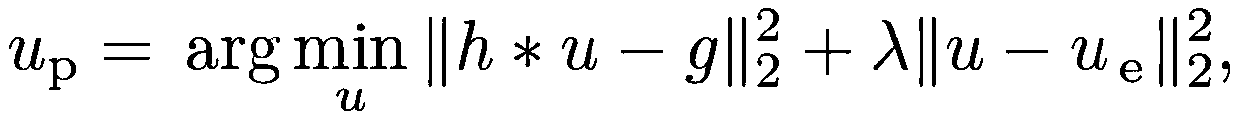

Intelligent tourism system and method based on big data co-construction and sharing

PendingCN110135609AImprove accuracyAccurately obtainedReservationsCharacter and pattern recognitionTravel modeThe Internet

The invention belongs to the technical field of smart tourism, and discloses an intelligent tourism system and method based on big data co-construction and sharing. The method includes: collecting images of tourism areas and collecting culture, positions and ticket information of the tourism areas at the same time; sending the acquired scenic spot information through the network communication equipment; navigating the scenic area through a navigation program; calculating the scenic spot visitor flow through a data calculation program; issuing the collected scenic spot information to the Internet through an information issuing program; carrying out scenic spot ticket ordering operation through a ticket ordering system; storing collected scenic spot information through the cloud server, andcentralizing big data resources to process and analyze the scenic spot information; displaying an intelligent tourism system interface and collected scenic spot information through a PWM-adjusted display. According to the invention, various behaviors such as scenic spot visitor flow, tourist travel modes, tourist consumption capability, tourist return rate and the like are calculated and analyzed,so that the accuracy of data analysis is improved.

Owner:CENT SOUTH UNIV

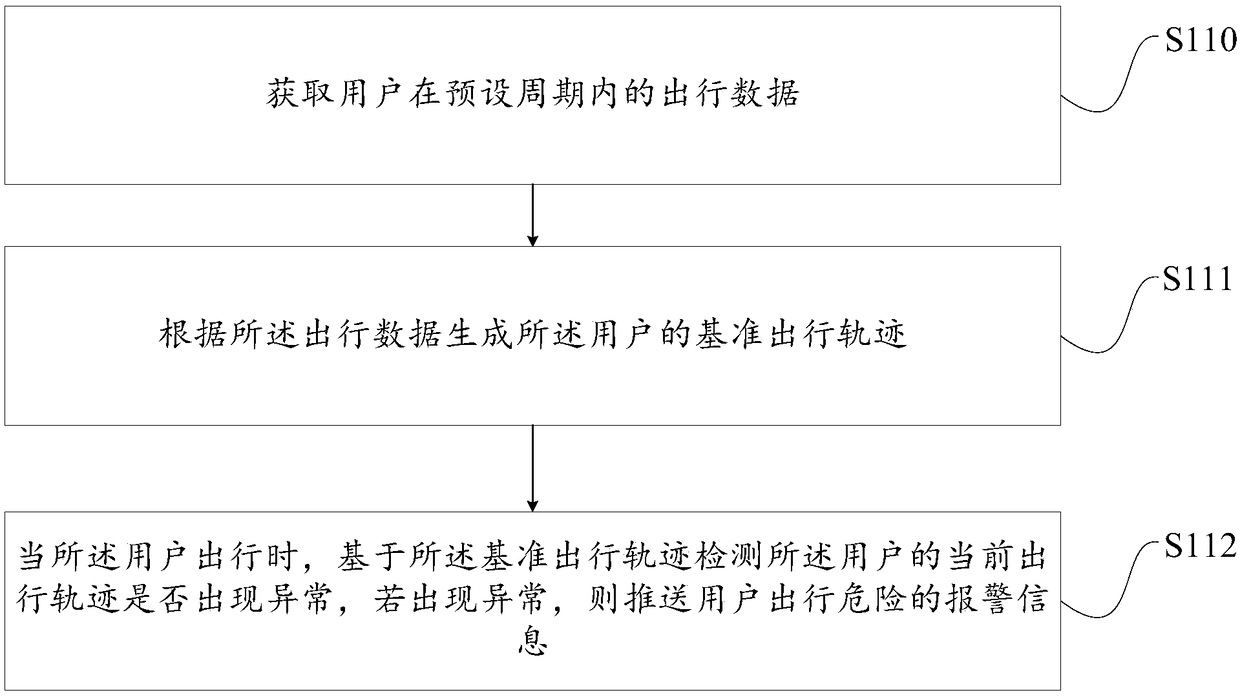

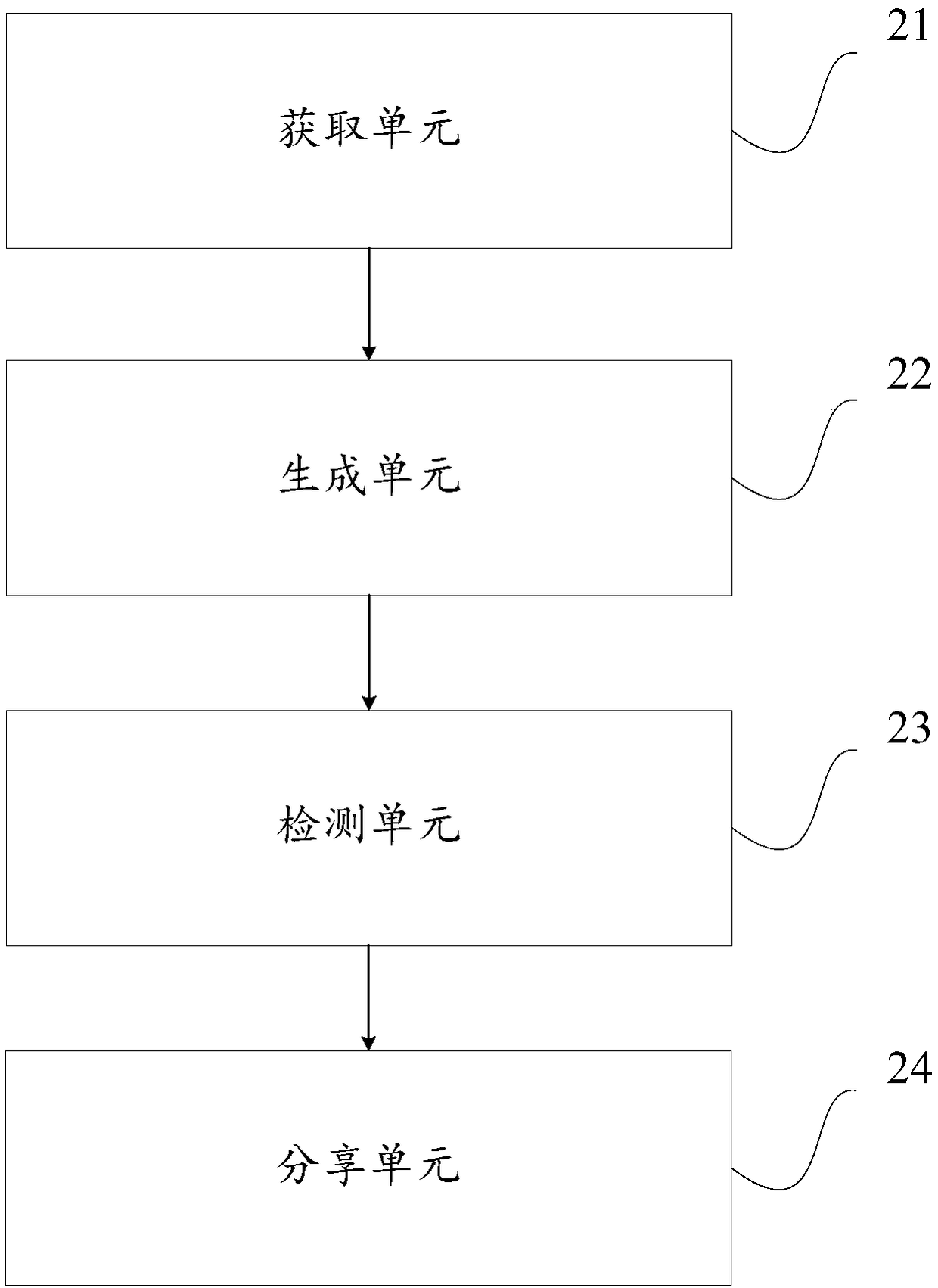

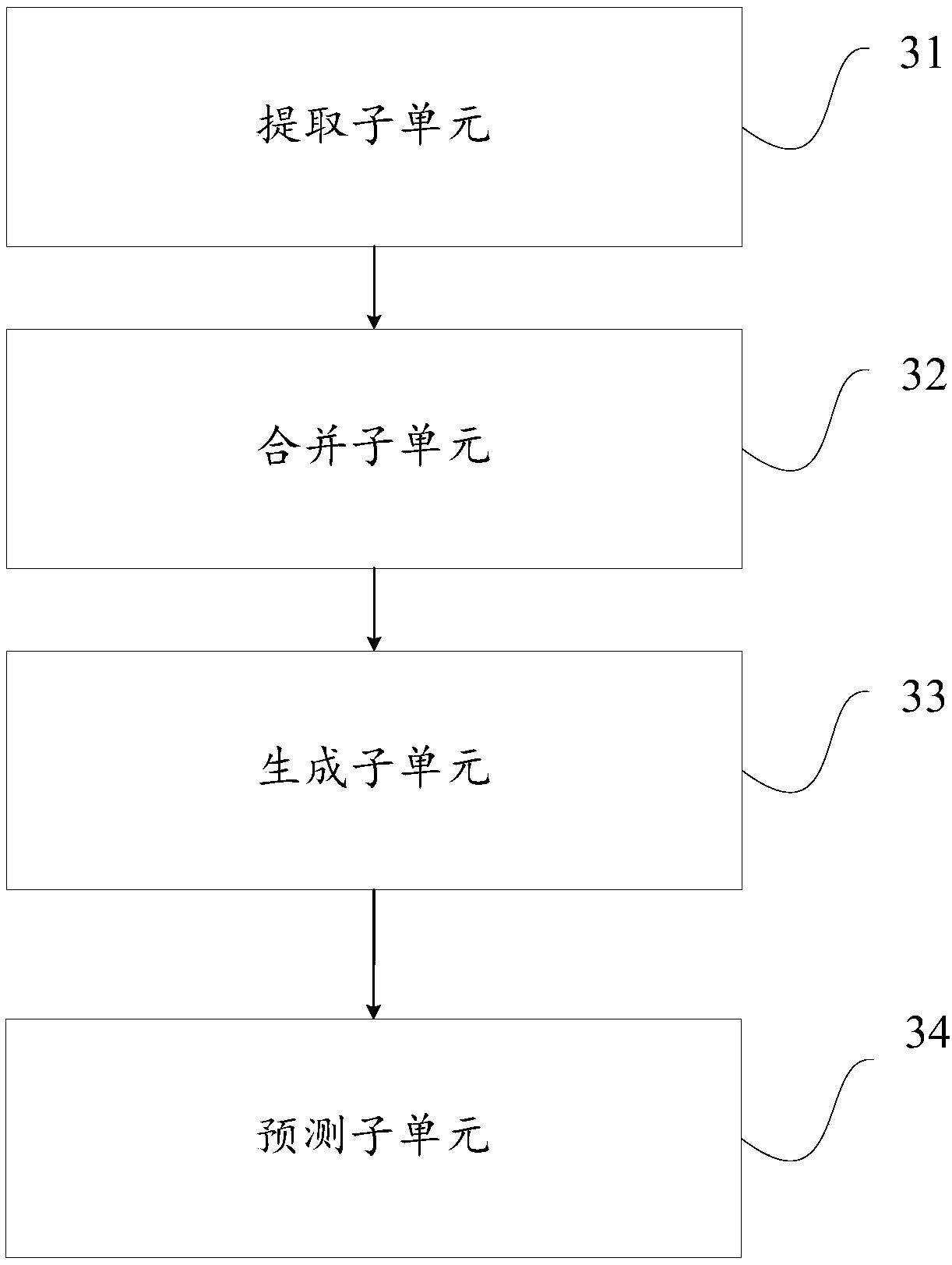

Method and device for identification of user travel track and computer device

ActiveCN109195113AEnsure travel safetyAlarmsLocation information based serviceSimulationComputer device

The embodiment of the invention provides a method and a device for identification of user travel track and a computer device. The method comprises the steps of: obtaining travel data of a user in a preset period; according to the travel data, generating a standard travel track of the user; and when the user goes out, detecting whether the current travel track is abnormal or not based on the standard travel track, and if yes, pushing alarm information of user travel risk. Therefore, a standard travel track of the user in advance is generated according to the user travel habit, and when the usergoes out, detection of the current travel track of the user is performed according to the standard travel track, if anomaly is detected, the alarm information of the user travel risk is automaticallypushed to ensure the travel safety of the user.

Owner:BEIJING QIHOO TECH CO LTD

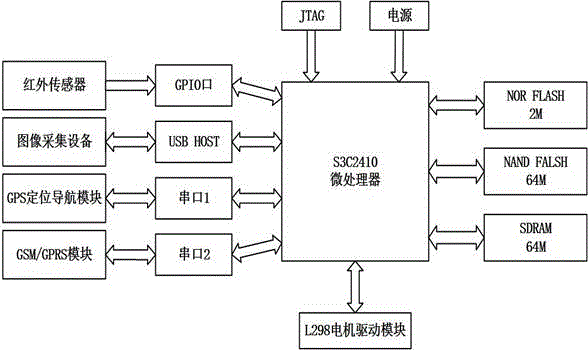

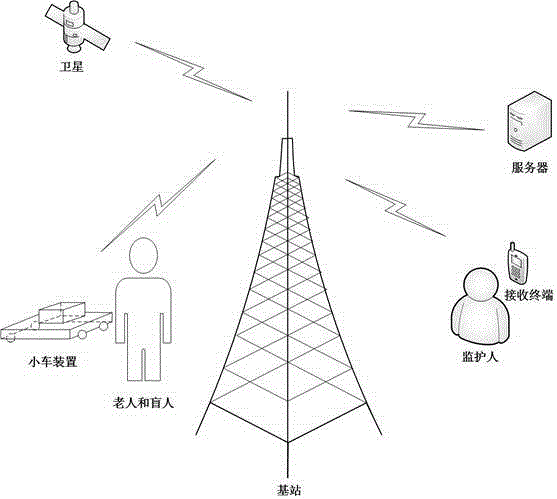

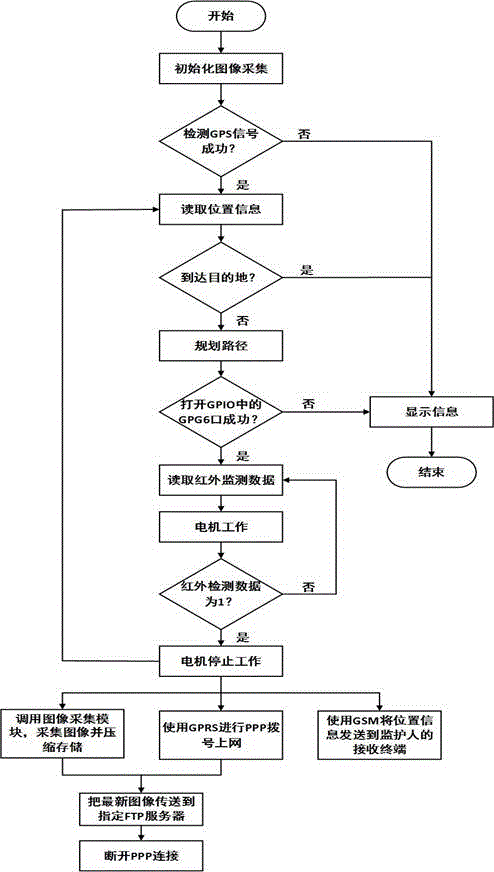

Intelligent trolley health surveillance device capable of achieving real-time tracking

InactiveCN105902369AReduce volumeConvenient and safe travelInstruments for road network navigationWalking aidsEngineeringGps positioning

The invention provides an intelligent trolley health surveillance device capable of achieving real-time tracking. The intelligent trolley health surveillance device takes an intelligent trolley as a carrying platform and comprises a main controller module, an infrared monitoring module, a CMOS image acquisition module, a GPS positioning and navigating module, a GSM-GPRS information transmission module, a motor driving module and a terminal power supply module, wherein the main controller module is connected with the other modules; the infrared monitoring module is used for monitoring obstacles and transmitting information to the main controller module for processing, the CMOS image acquisition module is used for image acquisition, the GPS positioning and navigating module is used for positioning and navigating the old and the blind, the GSM-GPRS information transmission module is used for achieving image transmitting and short message sending, the motor driving module is used for controlling movement of the trolley, and the terminal power supply module is used for supplying a power supply needed by the device. When the device is used, the old and the blind can use the device for navigation and obstacle avoidance in the walking process, and guardians can acquire position information and real-time pictures of the old and the blind in time when something happens to the old and the blind.

Owner:NANCHANG UNIV

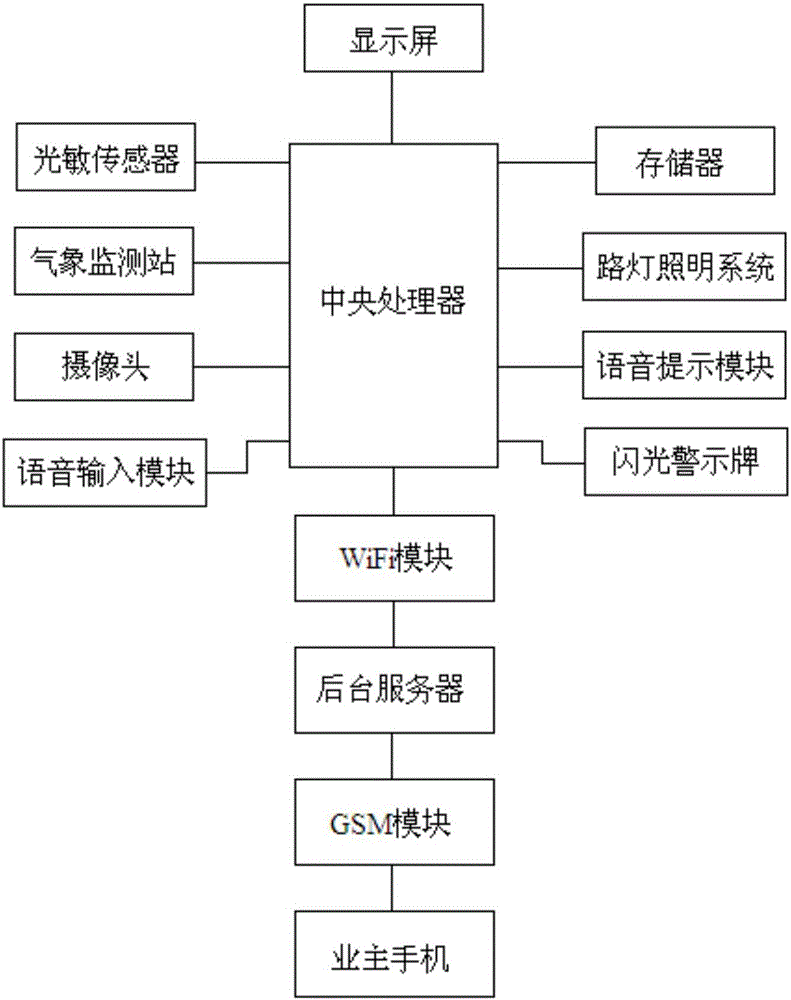

Community environment monitoring and warning system based on Internet of Things

InactiveCN106603981AConvenient travelHigh activityElectric light circuit arrangementEnergy saving control techniquesThe InternetEngineering

The invention discloses a community environment monitoring and warning system based on the Internet of Things. The system includes a photosensitive sensor and a meteorological monitoring station, a central processing unit, a background server and a proprietor mobile phone, the output ends of the photosensitive sensor and the meteorological monitoring station are connected with the input end of the central processing unit, and the output end of the central processing unit is connected with a street lamp illuminating system; the system also includes a camera, a voice input module, a flash warning board, a display screen and a voice prompt module, the output ends of the camera and the voice input module are connected with the input end of the central processing unit, and the output end of the central processing unit is connected with the flash warning board, the display screen and the voice prompt module; and the central processing unit performs wireless communication with the background server through a WiFi module, and the background server performs wireless communication with the proprietor mobile phone through a GSM module. The community environment monitoring and warning system based on the Internet of Things facilitates traveling of the proprietor, ensures traveling safety of the proprietor, and enabling the proprietor to learn related situations without going out.

Owner:合肥铭志环境技术有限责任公司

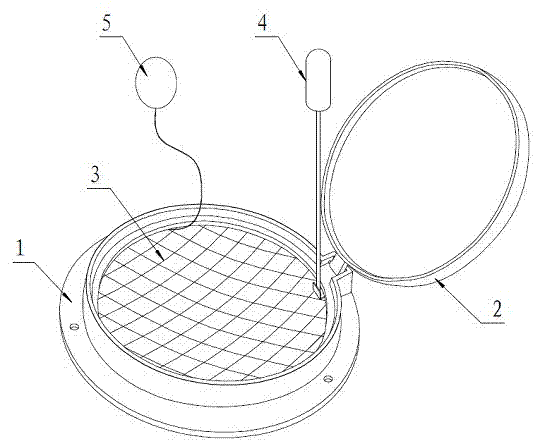

Well cover with open protecting and warning function

InactiveCN103758152APrevent falling wellEliminate potential safety hazardsArtificial islandsAlarmsEngineeringWellhead

The invention discloses a well cover with open protecting and warning function belonging to the technical field of water conservancy project, according to the technical solution, the well cover comprises a well ring fixed on a wellhead, a well cover and a safe net, the ring surface of the inner side of the well ring is provided with an annular element rest being coaxial with the well ring, the lower part of the inner side of the well ring is provided with a plurality of safe net hanging rings evenly distributed along the circumference; the outer edge of the well cover presses on the element rest at the inner side of the well ring and one side of the well cover is hinged to the well ring; the safe net is circular and is provided with a plurality of hooks along the circumference and the hooks match with the safe net hanging rings on the well ring. According to the well cover, the safe net and a plurality of well cover open protecting and warning devices are formed based on the traditional well cover, the invention can effectively prevent that the passer or article falls into the well no matter the opening reason for the well cover and send the warning information for the passers and vehicles by a variety of ways.

Owner:STATE GRID CORP OF CHINA +2

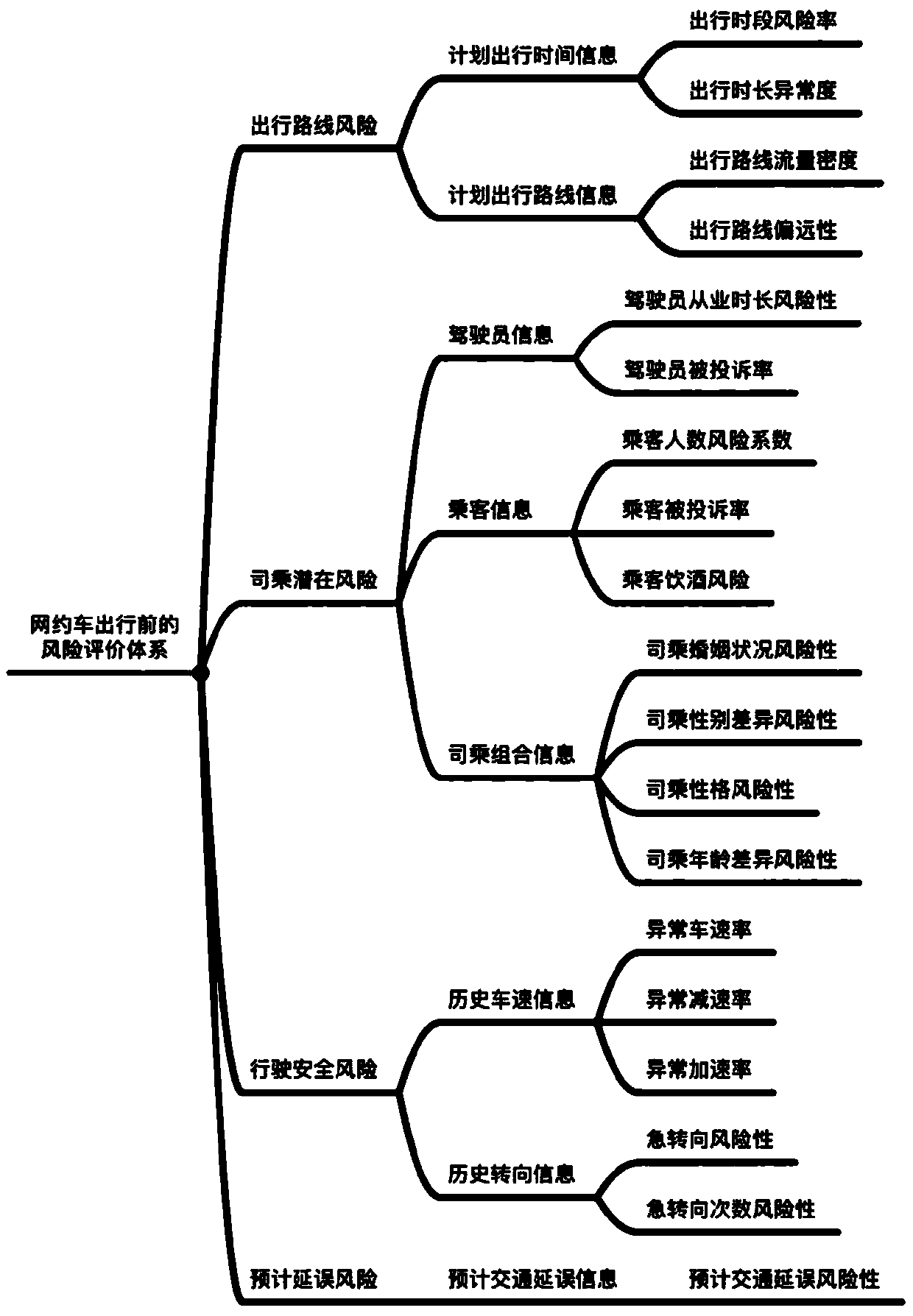

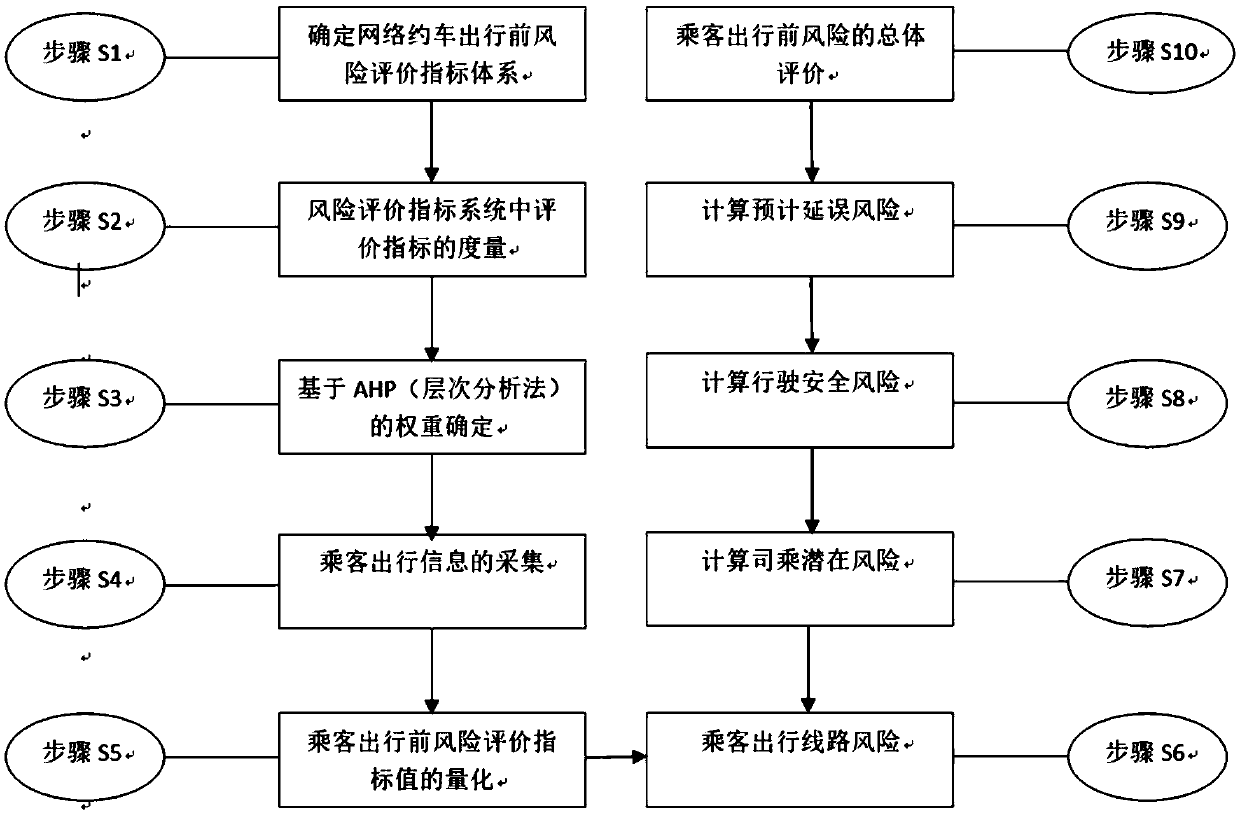

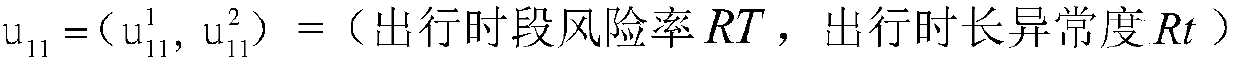

A risk evaluation method before online car-hailing travel

PendingCN109636257AEnsure travel safetyThe evaluation content is comprehensiveResourcesDriver/operatorComputer science

The invention provides a risk evaluation method before online car-hailing travel. According to the method, various kinds of information involved in the traveling process, including traveling order information, vehicle information, driver information, driver driving behavior information and passenger information, are collected, a fuzzy set evaluation method is applied for analysis, and a corresponding conclusion is obtained to provide reference for passenger traveling. Compared with existing online car-hailing driver travel evaluation (such as driving fatigue, drinking driving and the like), the method has the advantages; According to the online car-hailing travel risk evaluation method, the evaluation content is more comprehensive, the travel risk evaluation requirement can be better met,unexpected situations can be prevented, potential safety hazards can be killed in a cradle state, police force and manpower resources needed when an accident really occurs can be saved, and the travelsafety of passengers is guaranteed.

Owner:CHANGAN UNIV

Wind-resistant billboard

Owner:陈晶雅

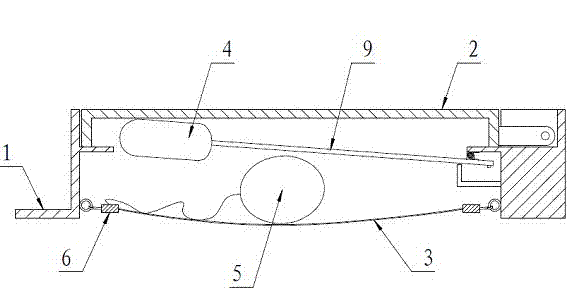

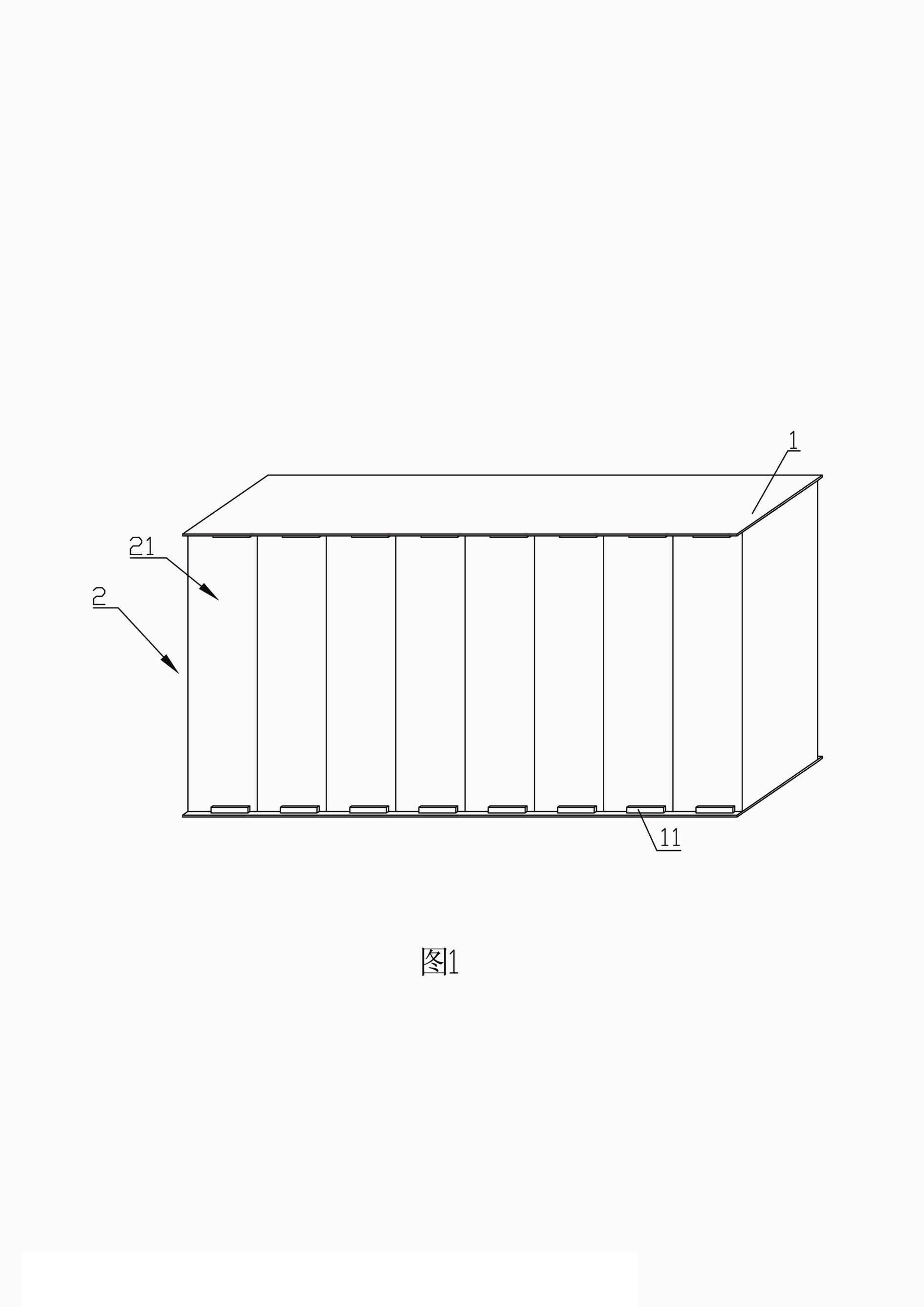

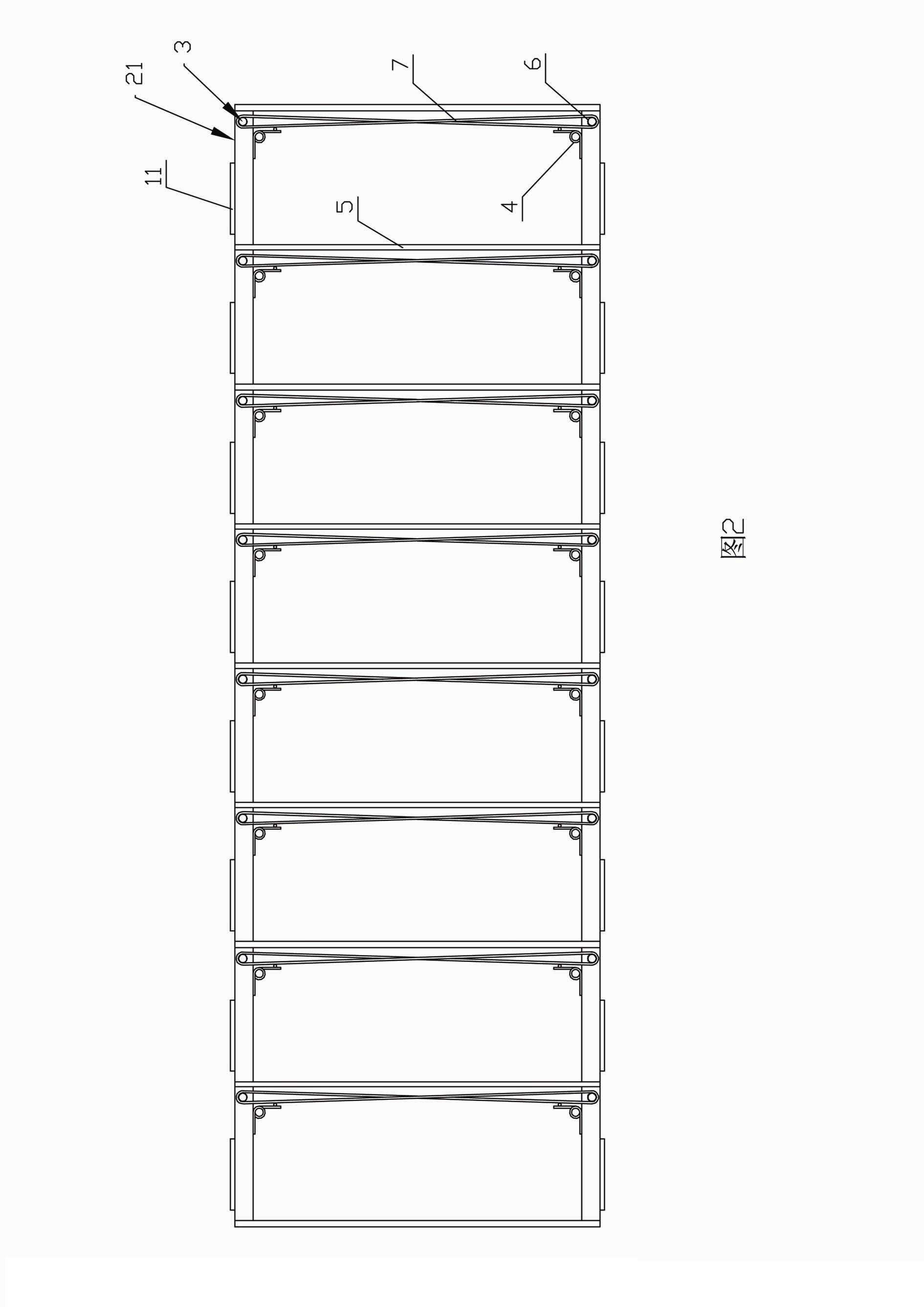

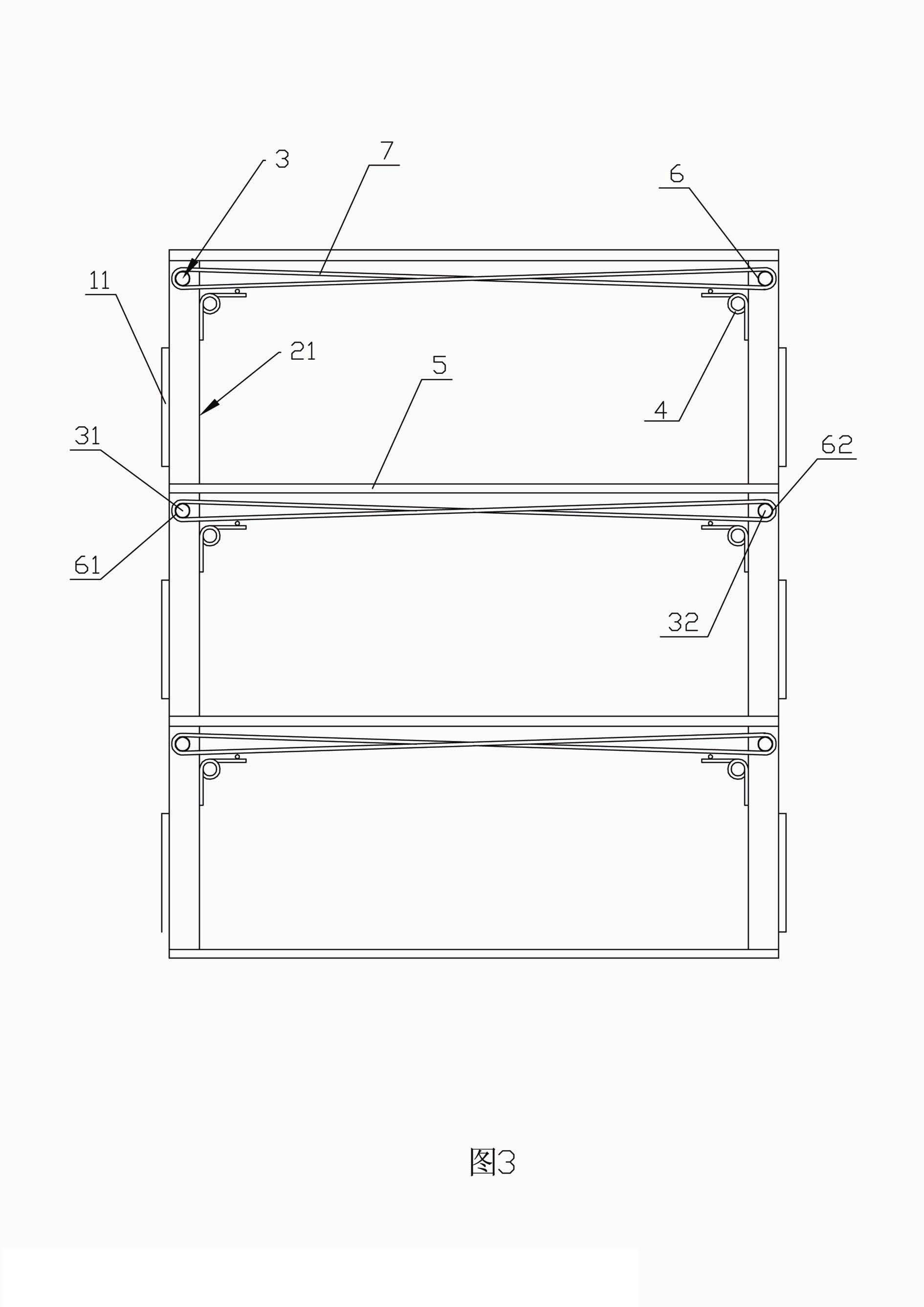

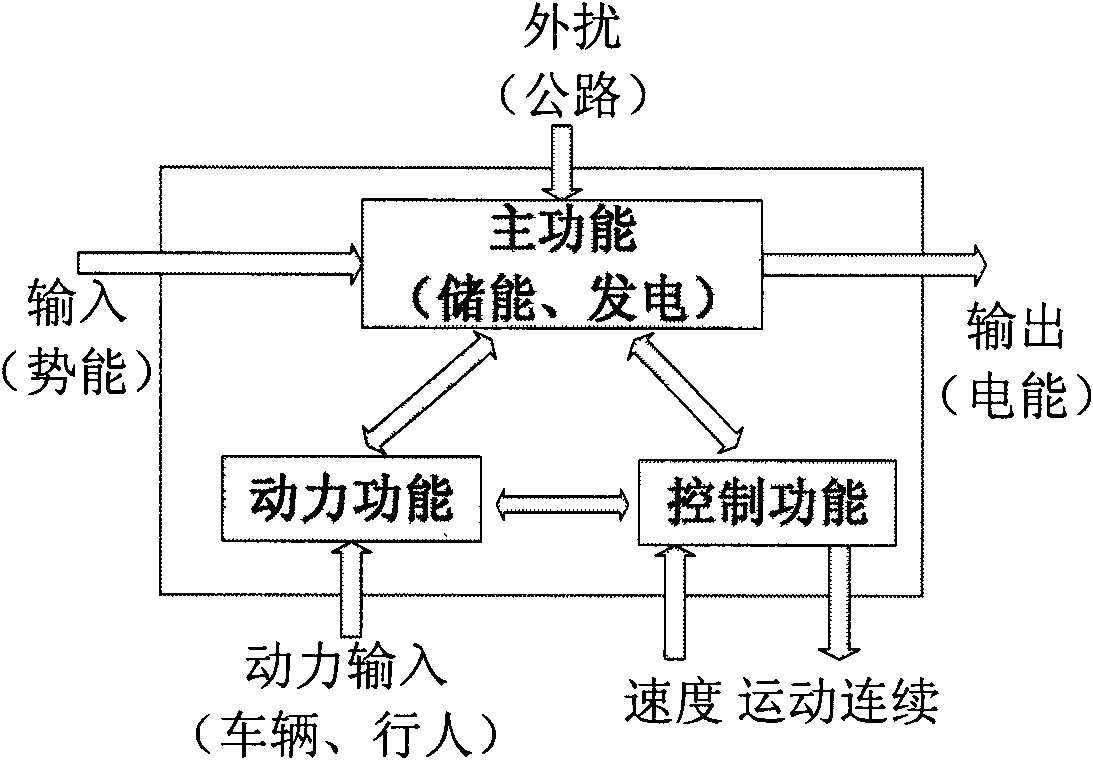

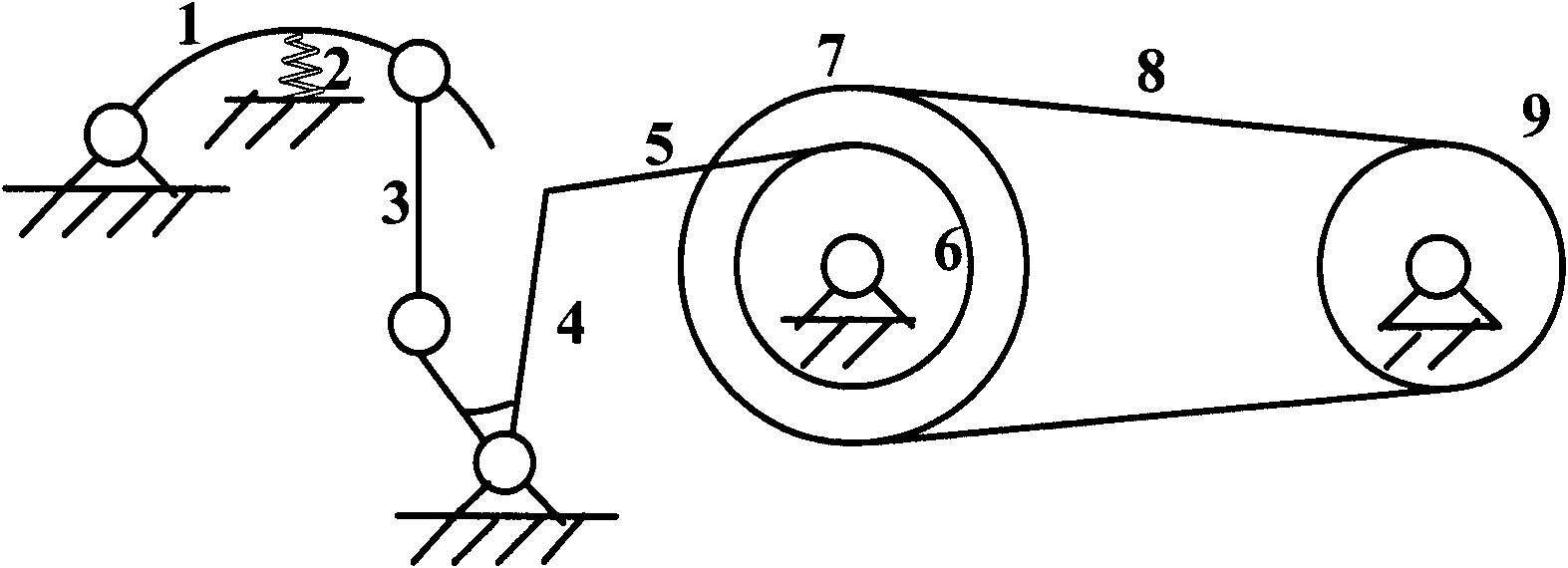

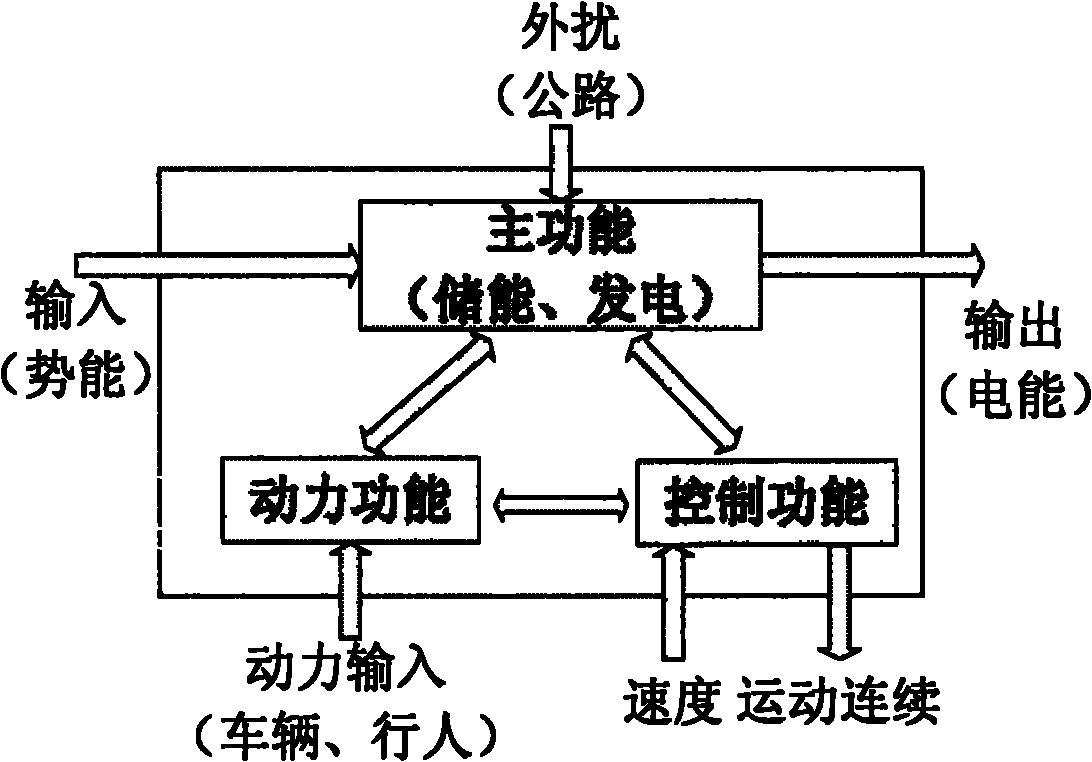

Road surface power generation device by using micro difference

InactiveCN101975148AAvoid traffic accidentsEnsure travel safetyMachines/enginesMechanical power devicesDynamoVoltage

The invention discloses a road surface power generation device by using micro difference, which consists of a frame, a stamping plate, a pressing rod, a rope, a flywheel, belt wheel and a generator, and is characterized in that: the stamping plate is connected with the pressing rod to form a four-rod mechanism; an offsetting spring is arranged below the stamping plate; the pressing rod is connected with the flywheel through the rope; the flywheel is fixedly connected with a large belt wheel; the belt wheel is connected with the generator through a mechanical transmission device; and the generator is connected with a load through a voltage stabilizer and a storage battery. The road surface power generation device is used for converting potential energy into kinetic energy and finishing energy signal amplification. The arranged offsetting spring and the flywheel guarantee the continuous generation of energy; and an energy storage and power generation module is used for converting the kinetic energy into electric energy and realizing energy collection and storage so as to fulfill the aim of accumulation. Meanwhile, a deceleration strip can provide guarantee for reducing the incidence of traffic accidents.

Owner:SHENYANG JIANZHU UNIVERSITY

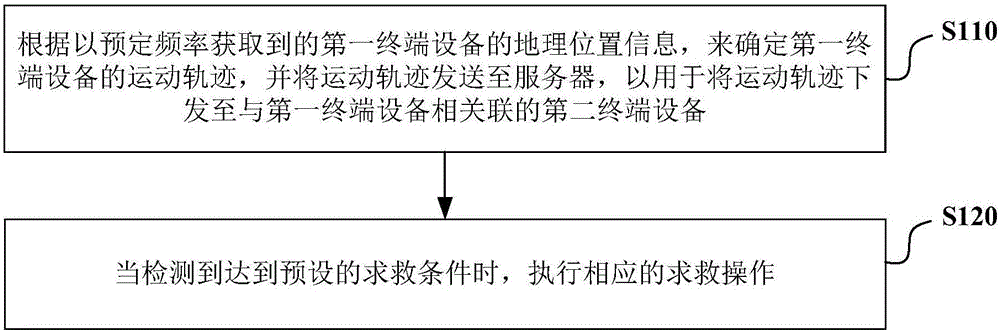

Line safety monitoring method and apparatus

InactiveCN106454742AEnsure travel safetyEffective rescueWireless commuication servicesTransmissionEmergency rescueGeolocation

The invention provides a line safety monitoring method and apparatus. The line safety monitoring method includes the steps: according to the geographical location information of first terminal equipment by means of the preset frequency, determining the motion trail of the first terminal equipment and sending the motion trail to a server so as to issue the motion trail to second terminal equipment related with the first terminal equipment; and when a preset call-for-help condition is satisfied according to detection, executing the corresponding call-for-help operation. By means of the line safety monitoring method and apparatus, the motion trail of the first terminal equipment is determined so that the user of the second terminal equipment can grasp the motion trail; when the user is in various emergency circumstances, the corresponding call-for-help operation can be automatically emitted through the first terminal equipment, and various call-for-help operation triggered by the user actively can be emitted, so that the user can obtain all-round emergency rescue. Furthermore, the line safety monitoring method and apparatus can improve the probability of providing timely effective rescue when the user is in danger during the trip, so that the trip safety of the user can be greatly guaranteed.

Owner:BEIJING ANYUNSHIJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com