Processing technology of automobile tire

A processing technology, a technology of automobile tires, applied in the field of auto parts processing, can solve the problems of hidden safety hazards for drivers, large tire wear, imperfect tire processing technology, etc., and achieve the effect of ensuring travel safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

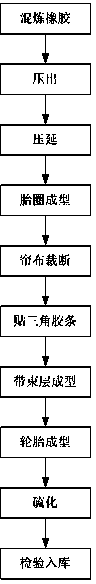

[0020] like figure 1 As shown, an automobile tire processing technology described in the embodiment of the present invention mainly includes the following steps:

[0021] 1) Kneading rubber: Mix the rubber liquid, operating oil, reinforcing agent, antioxidant, active agent and vulcanizing agent to make a rubber compound;

[0022] 2) Extrusion: put the rubber compound made after mixing into the extruder, and pass through the mold to obtain the tread and sidewall;

[0023] 3) Calendering: Pass the cord through the calender, and hang a layer of rubber on both sides of the cord to make the cord; the cord is nylon or polyester.

[0024] 4) Bead forming: a plurality of steel wires are hung with rubber compound and then wound to form a bead;

[0025] 5) Cord cutting: according to the tire specifications and tire structure, the cord is cut to the corresponding width, and the joints are connected;

[0026] 6) Paste the apex strip: extrude the apex strip through the extruder, and att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com