Systems and methods for real-time monitoring of die use or yield

A technology for productivity and monitoring systems, used in general control systems, control/regulation systems, home appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] This application includes by reference the entire contents of PCT / CA2007 / 001474 filed on August 28, 2007, entitled "SYSTEMS OR METHOD FOR TRACKING DIE USE OR YIELD".

[0069] The following description will provide examples of systems and methods for real-time monitoring of mold usage or throughput rates. However, in this document, one or more inventions that do not appear in the claims may be disclosed in the following description, and the claims in this document may not represent each device or method described below. Each part of any particular device or method. The content not required by the inventor and its assignee in this application does not mean abandoning any of the above inventions or contributing them to the public.

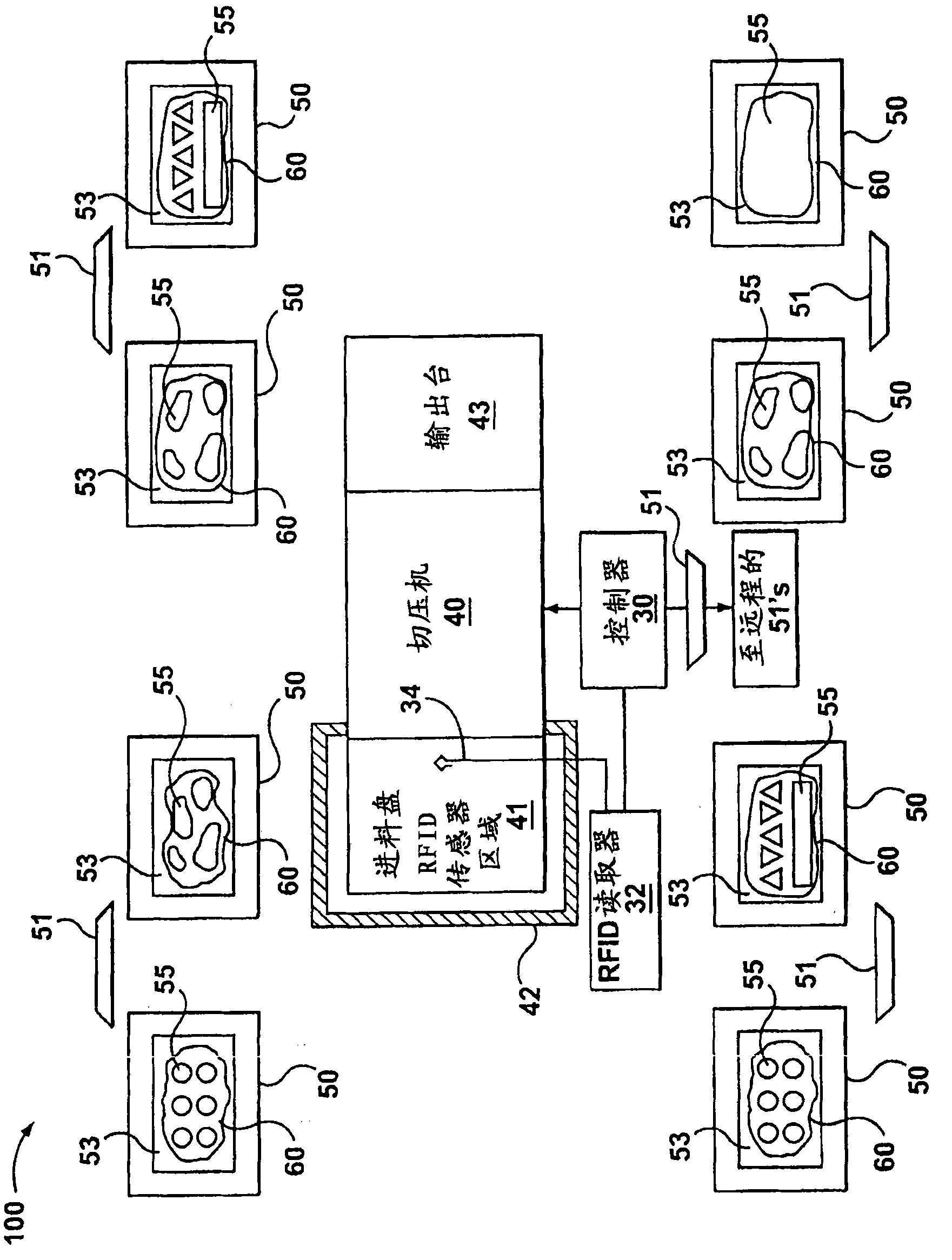

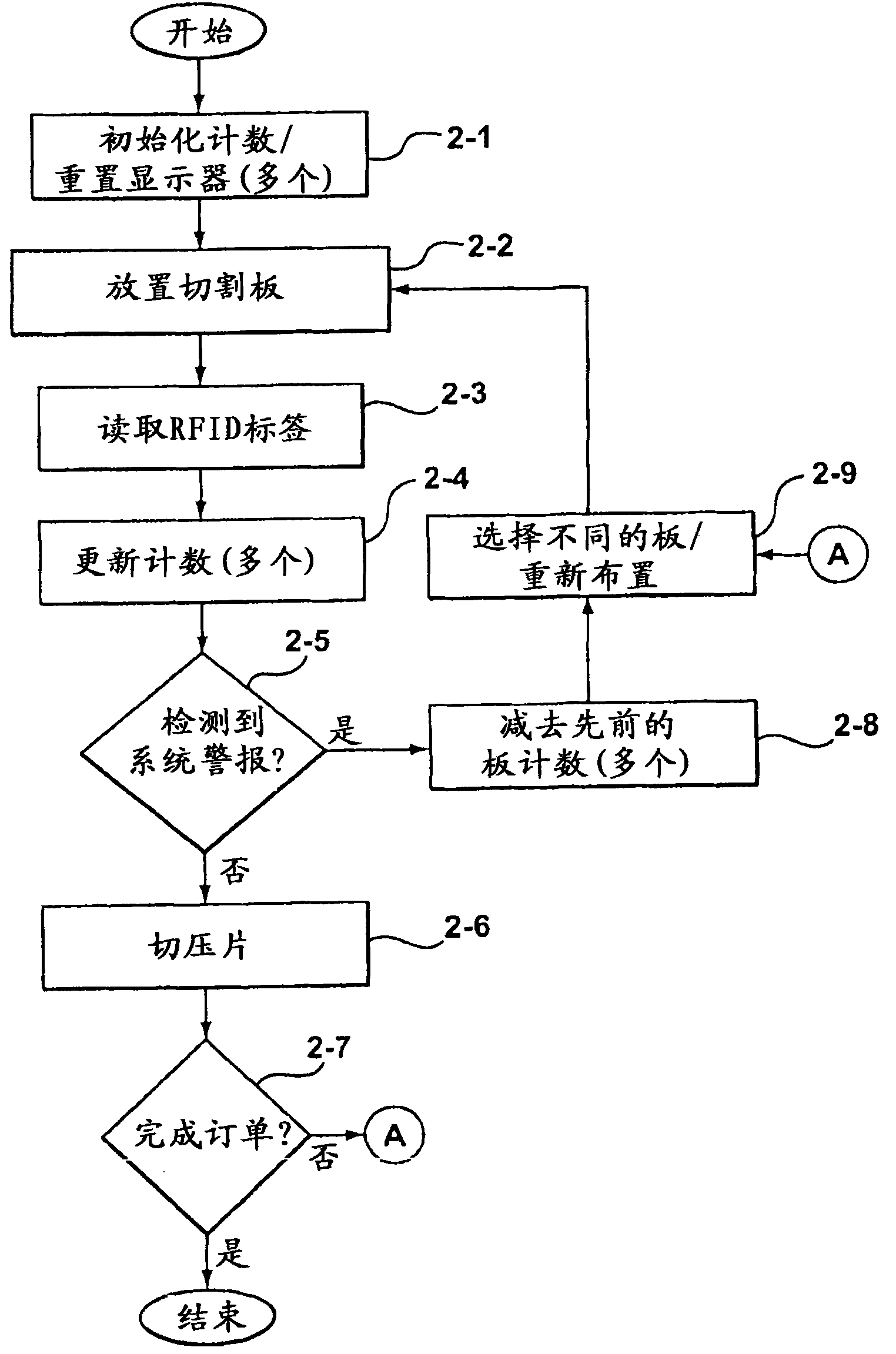

[0070] figure 1 A schematic diagram of a system 100 according to an example is shown. The system 100 generally includes a controller 30, a cutting press 40, a number of work stations 50 (optionally referred to as a nesting unit or an arrangement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com