Patents

Literature

57results about "Leather articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

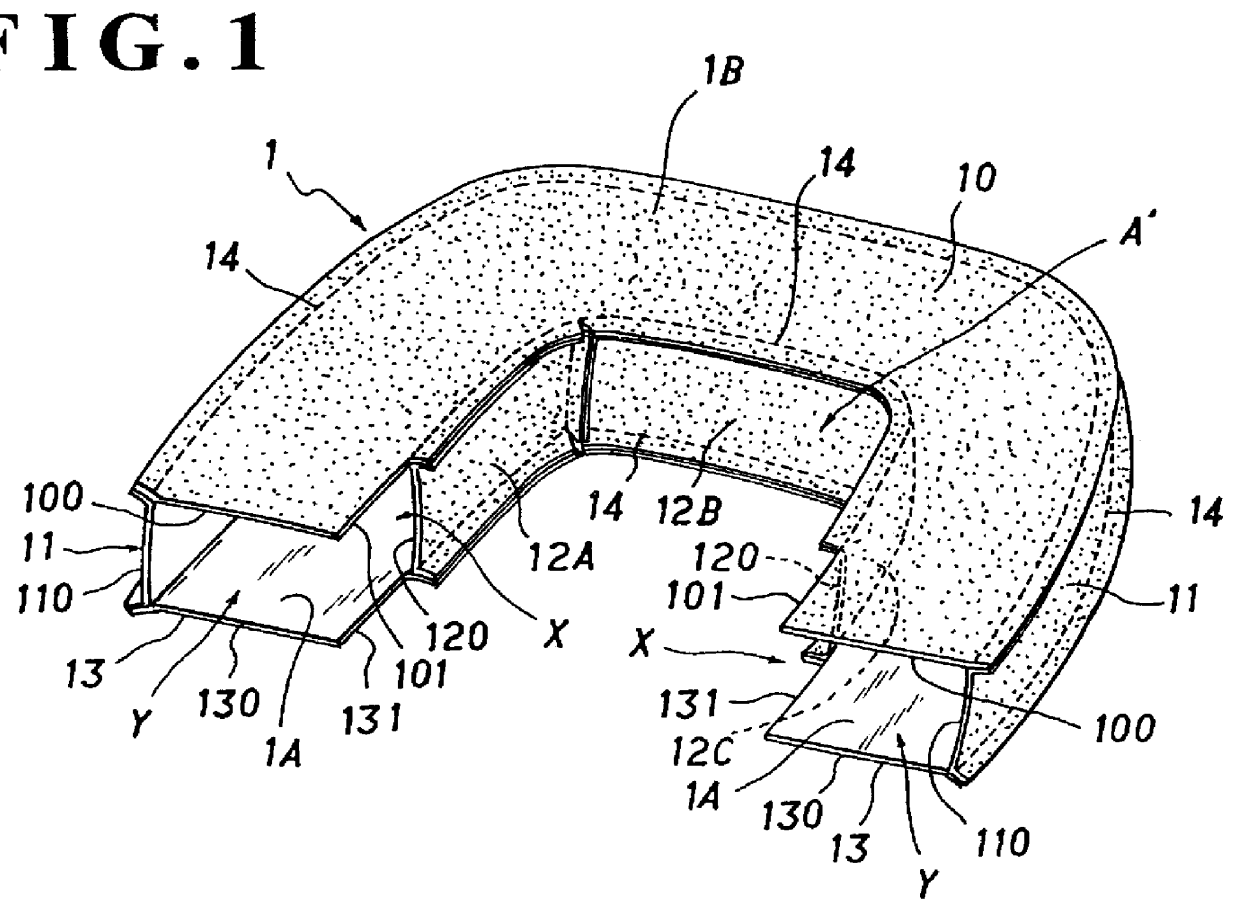

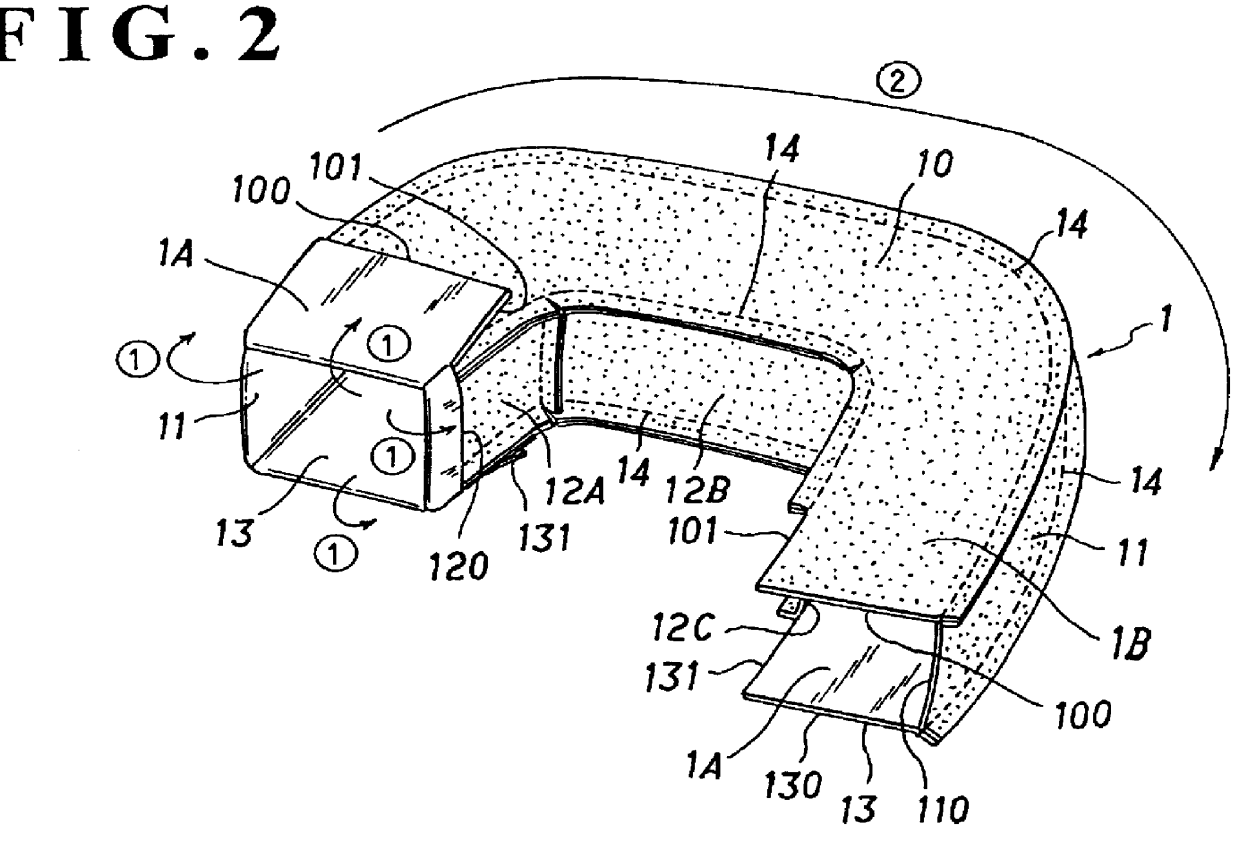

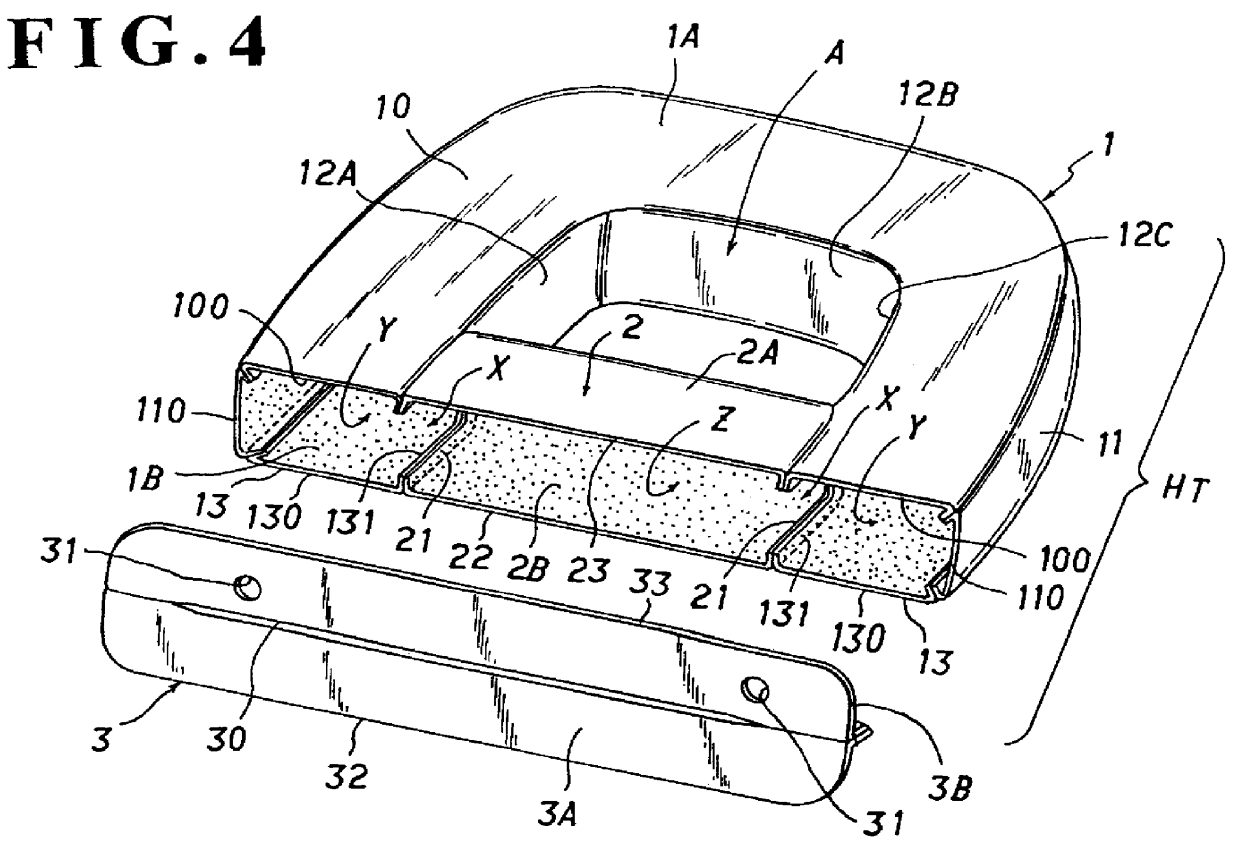

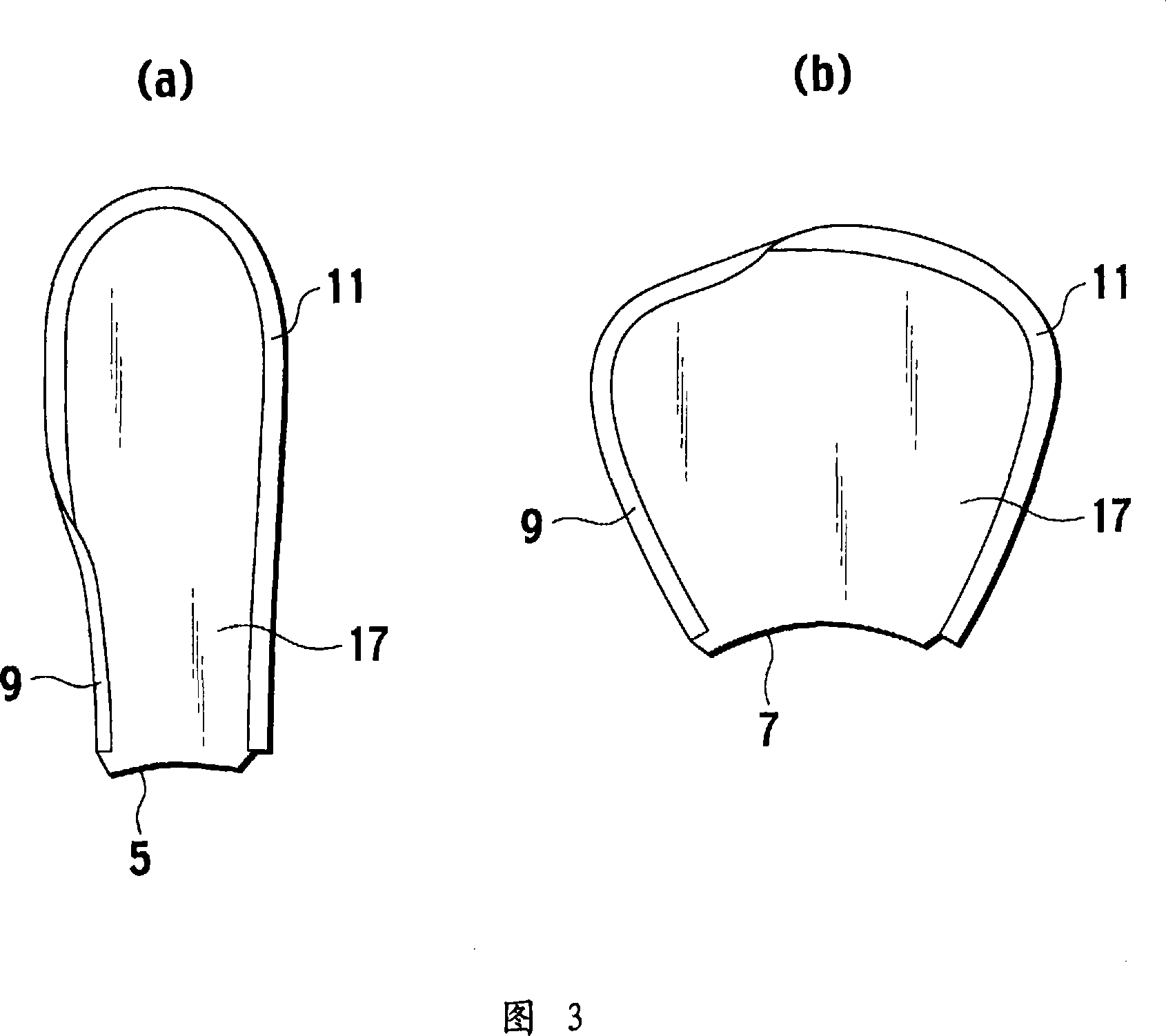

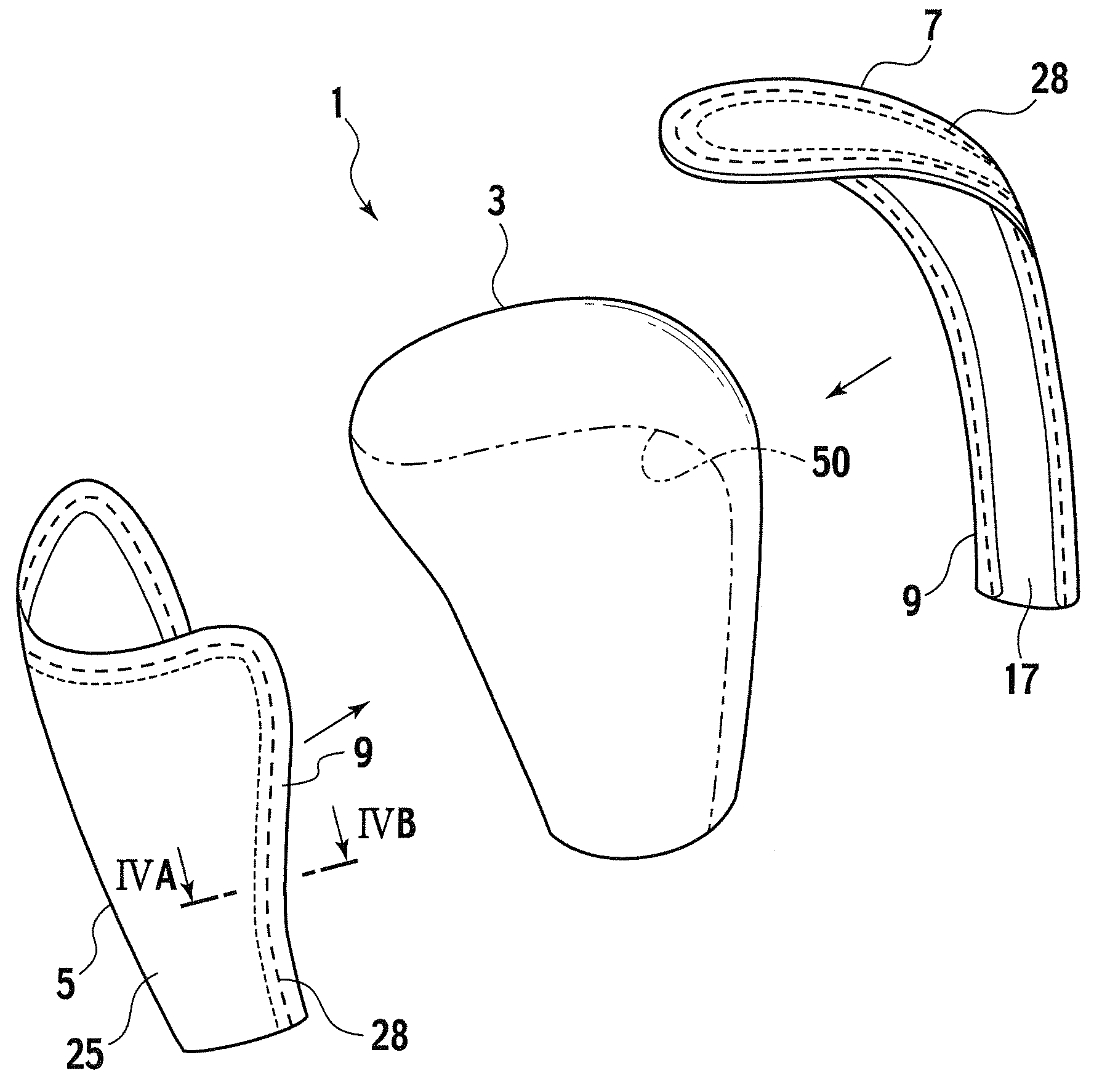

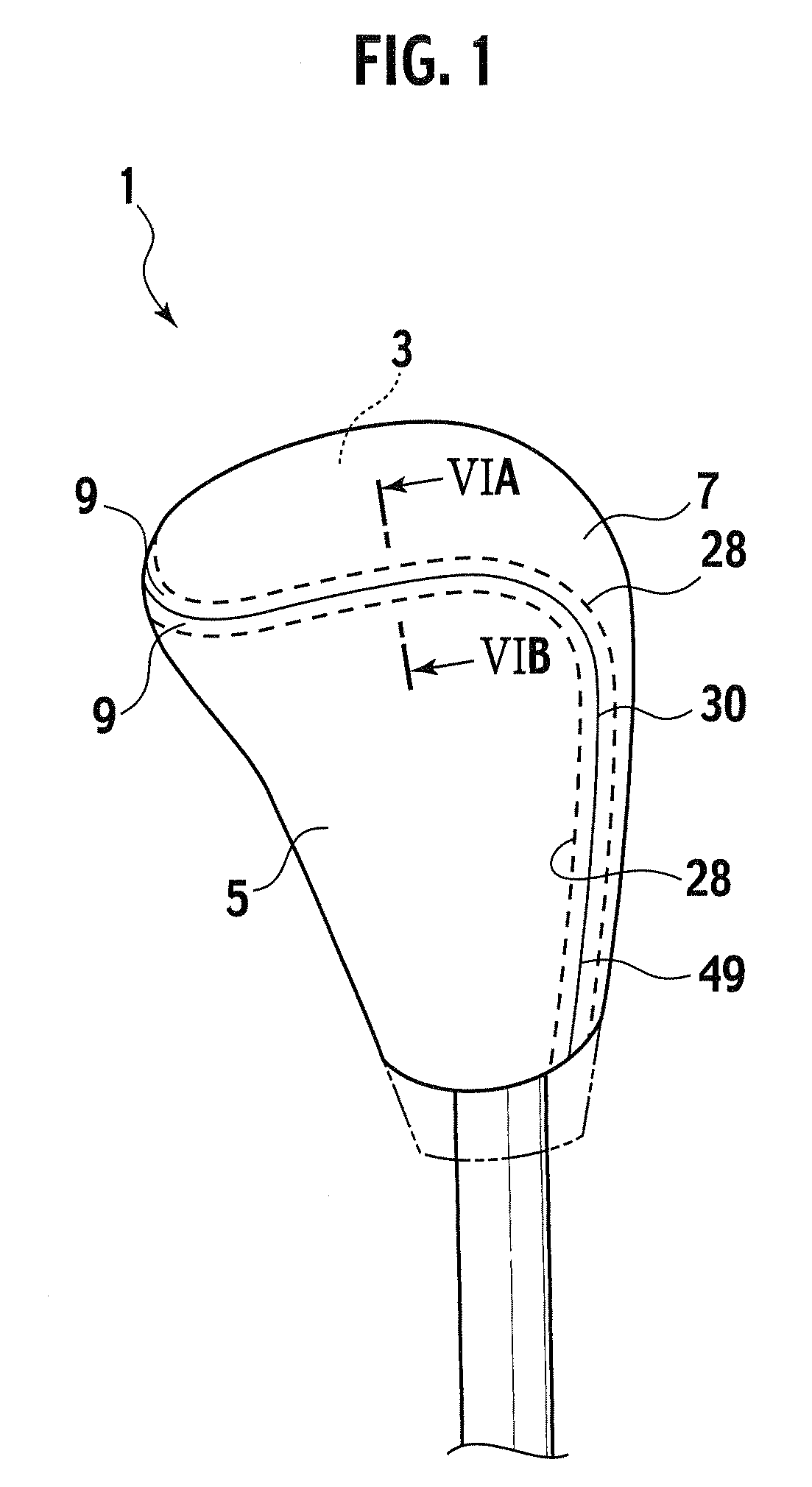

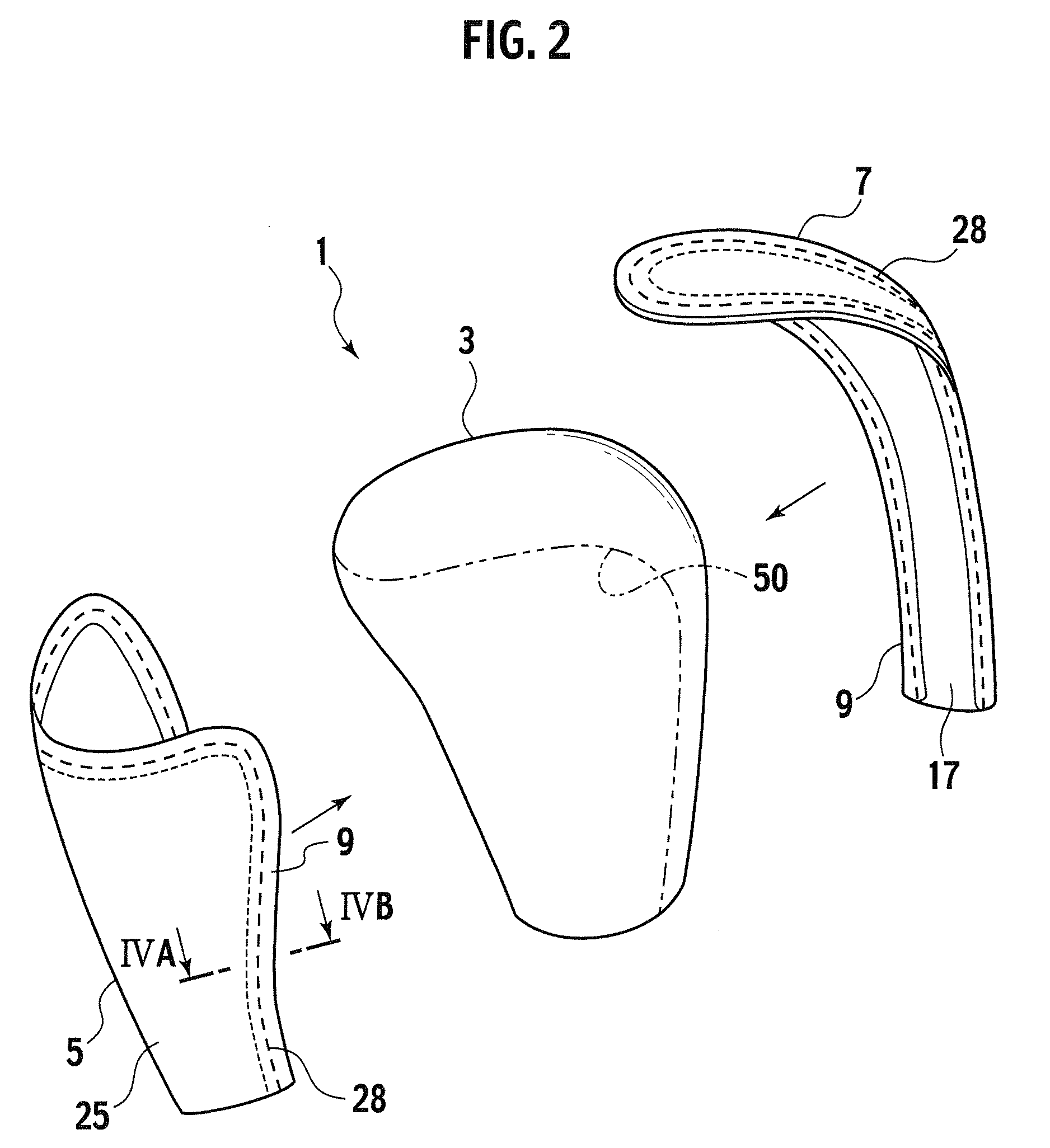

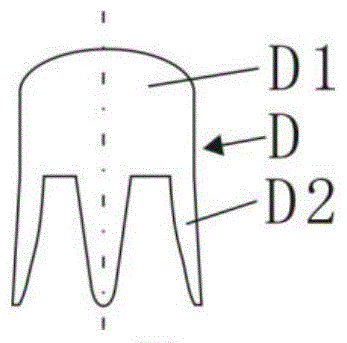

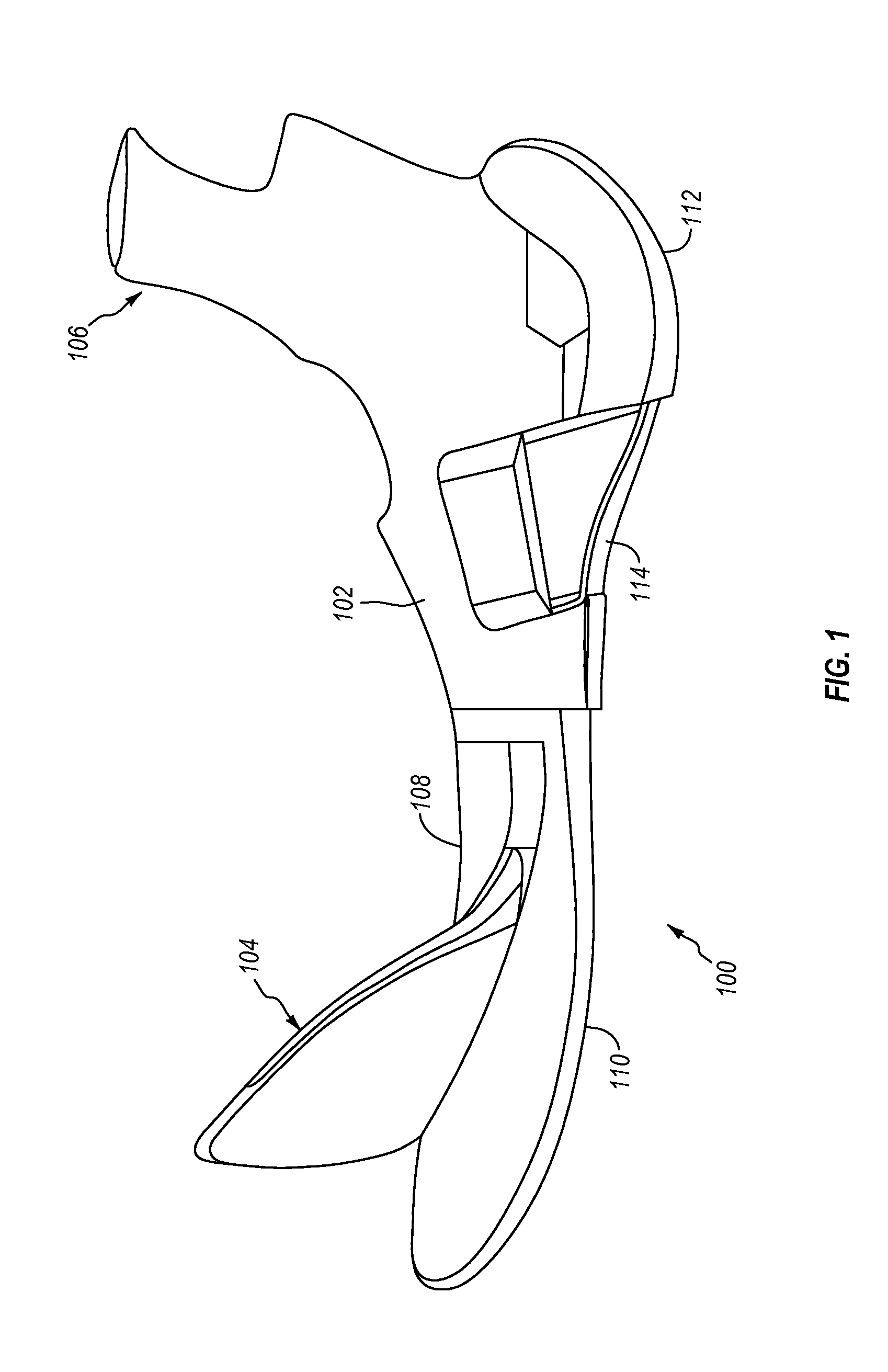

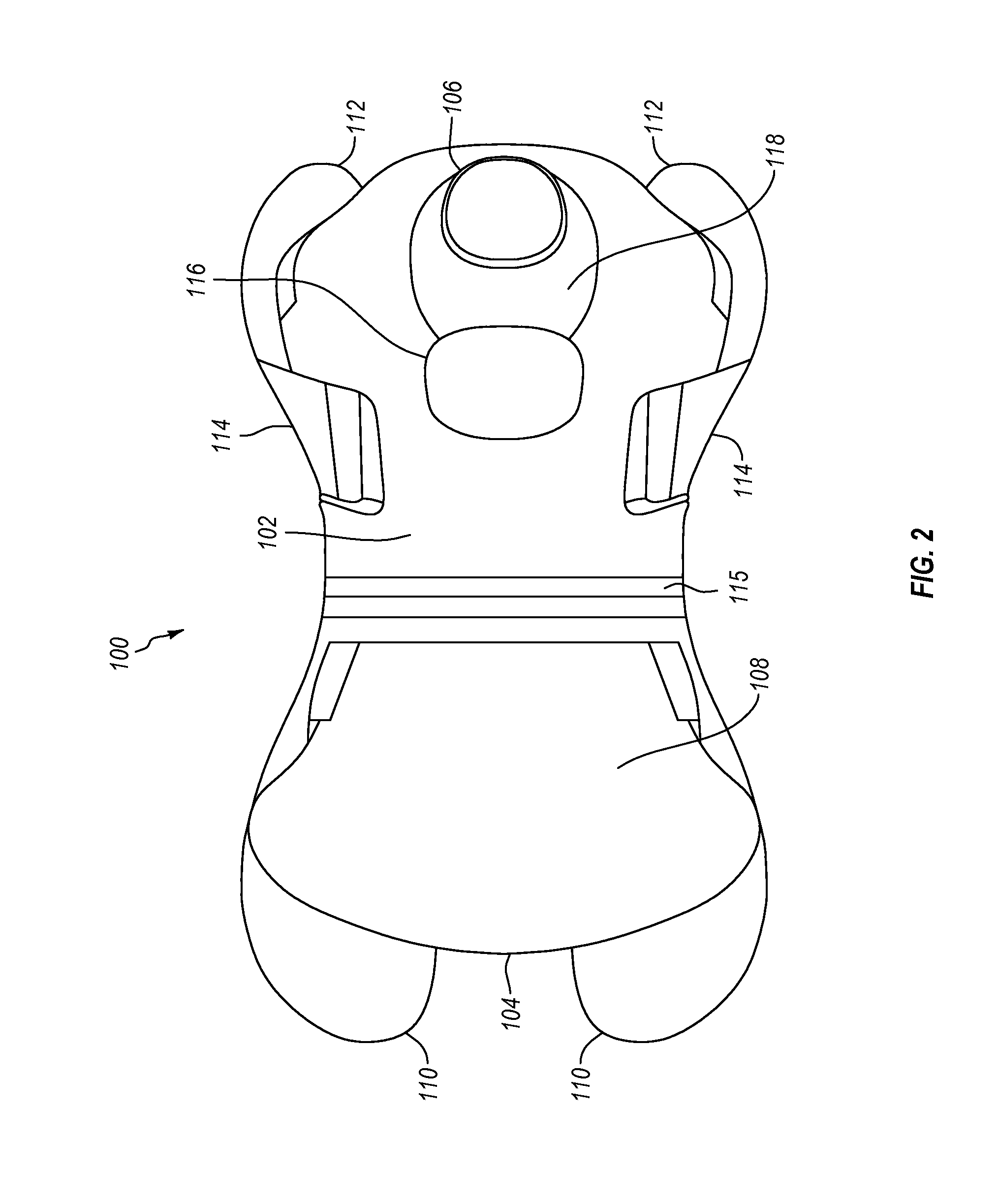

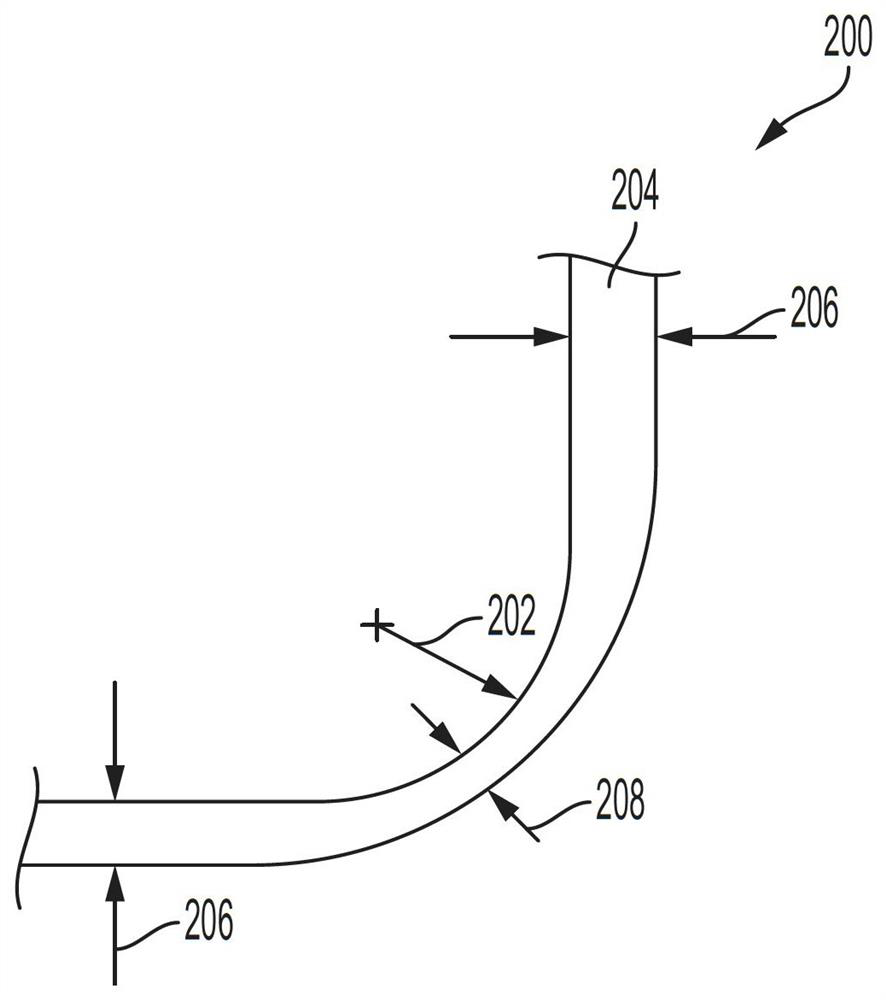

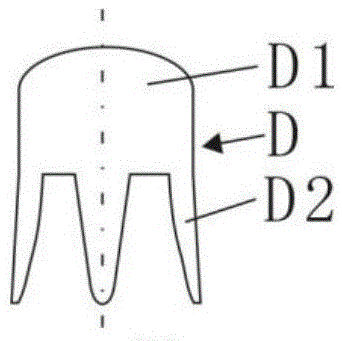

Method for forming a trim cover assembly of a donut-like or annular headrest for a vehicle seat

A method for forming a trim cover assembly of a donut-like headrest for use on a vehicle seat. A reversed first cover unit is provided, which has been formed in a reversed state, with its reverse side exposed outwardly, and which is of a generally inverted-U-shaped configuration having a pair of outward openings defined at one side thereof and a pair of inward openings defined inwardly thereof. This reversed first cover unit is turned over into a normal state, with its outer side exposed outwardly. Then, a second cover unit is sewn with such pair of inward openings of said first cover unit, such as to provide an opened side, so that an annular opening is defined by, and along all the foregoing pair of outward openings of said first cover unit and that opened side of said second cover unit. Thereafter, a third cover unit is sewn, at its peripheral end, with and along the thus-defined annular opening of first and second cover units, whereby a donut-like trim cover assembly is produced. In this way, it is easy to accurately sew the cover units together to provide a good constant shape and quality of a resultant trim cover assembly of a donut-like headrest.

Owner:TACHI S CO LTD +1

Processing method of vacuum forming for leather products

InactiveCN103158416AEasy to manufactureReduce manufacturing costDecorative surface effectsLeather articlesMaterials scienceRaw material

A processing method of vacuum forming for leather products comprises: step 1, making mold; step 2, heating raw materials of the leather products to a specified temperature, putting on surface of the mold, staying in vacuum forming conditions, and forming patterns on surfaces of the raw materials of the leather products, the patterns being corresponding to those on the surface of the mold; and step 3, cooling the raw materials of the leather products, and molding into the leather products for later use, wherein the specified temperature is 150-200 DEG C, the vacuum forming conditions are a vacuum degree range between 350-700 mmHg. According to the invention, the method is simple in technology, molds are convenient to prepare, products can be molded for one time, simulation of finished products is strong, and production efficiency is high.

Owner:吴聪裕 +1

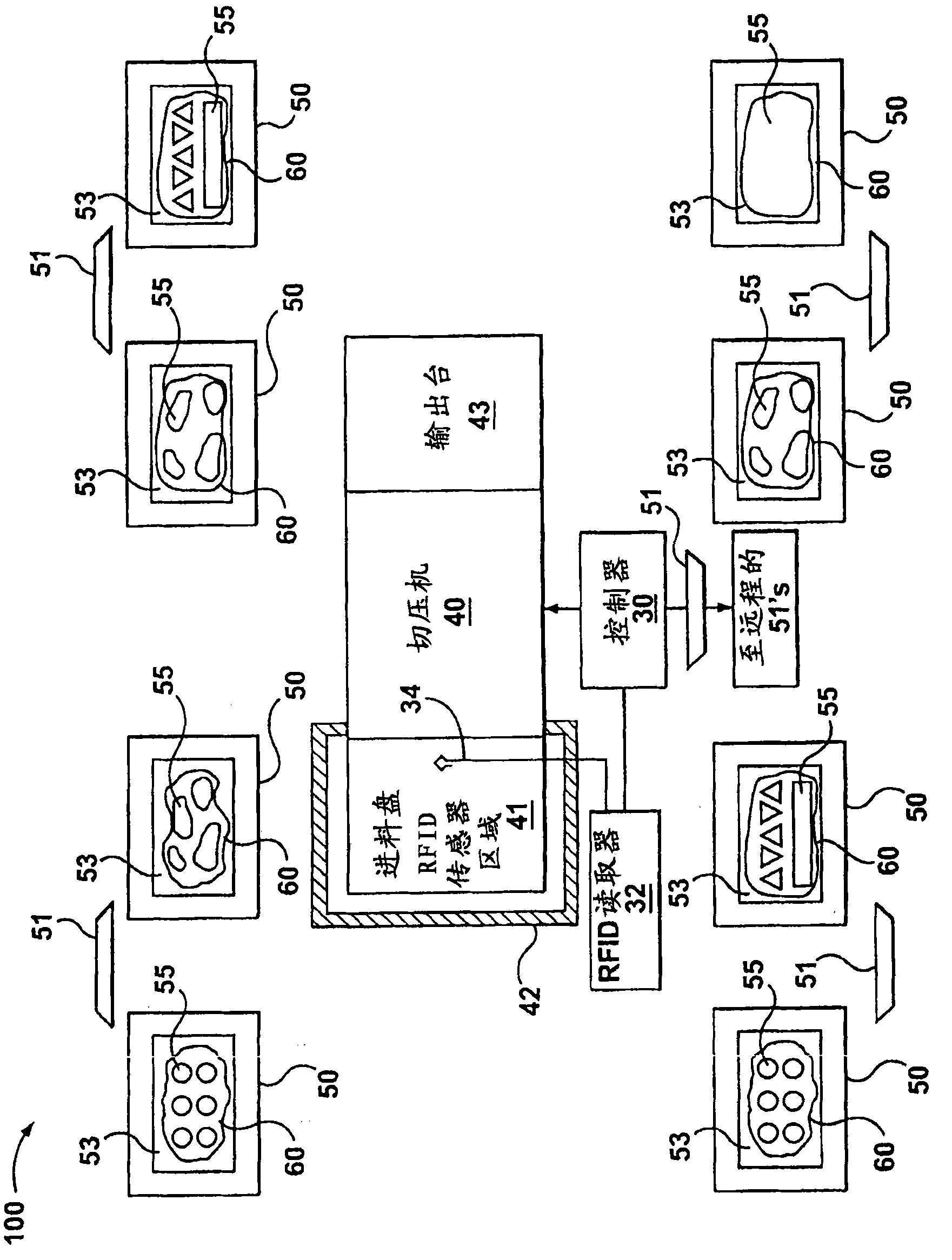

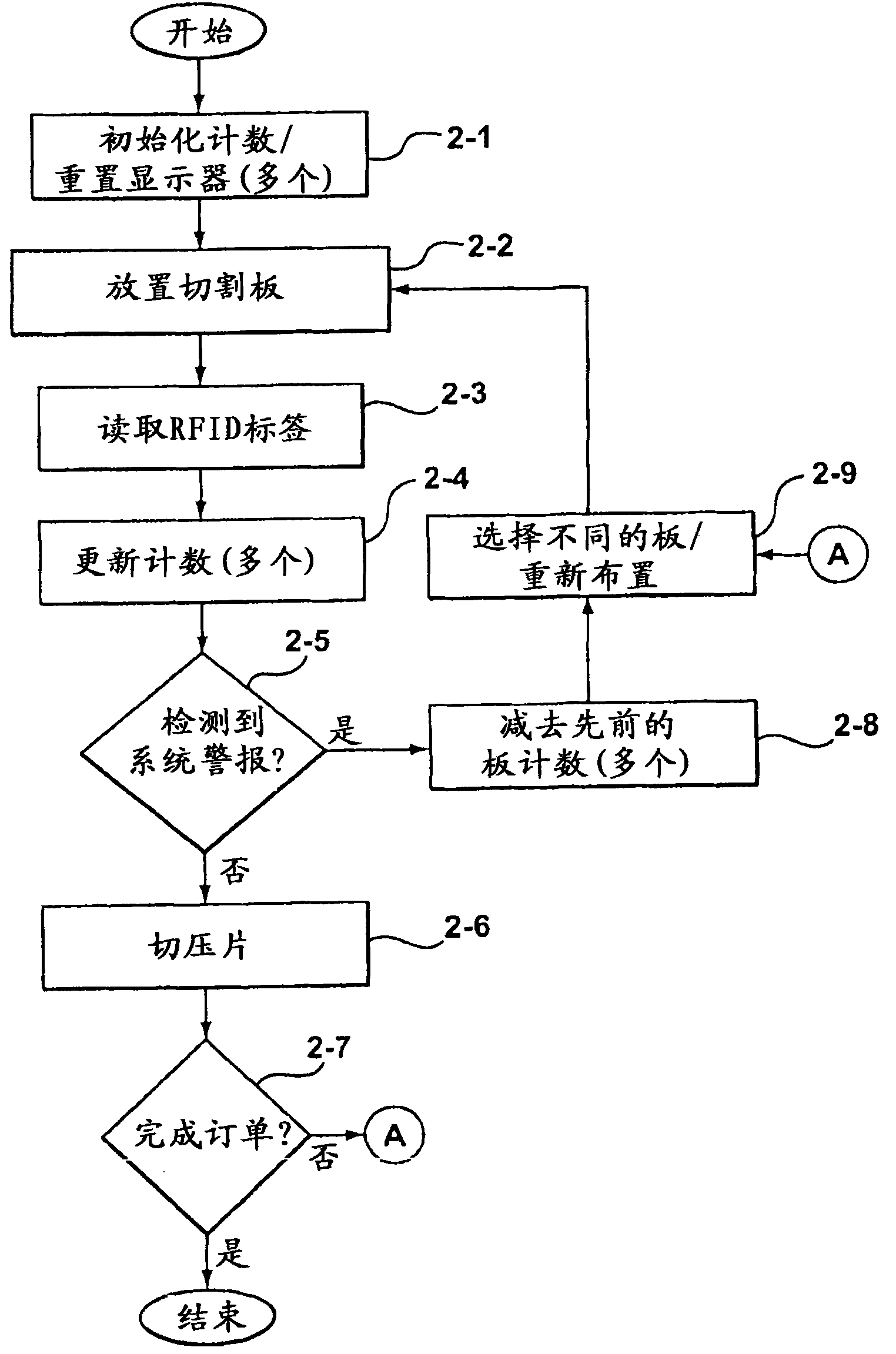

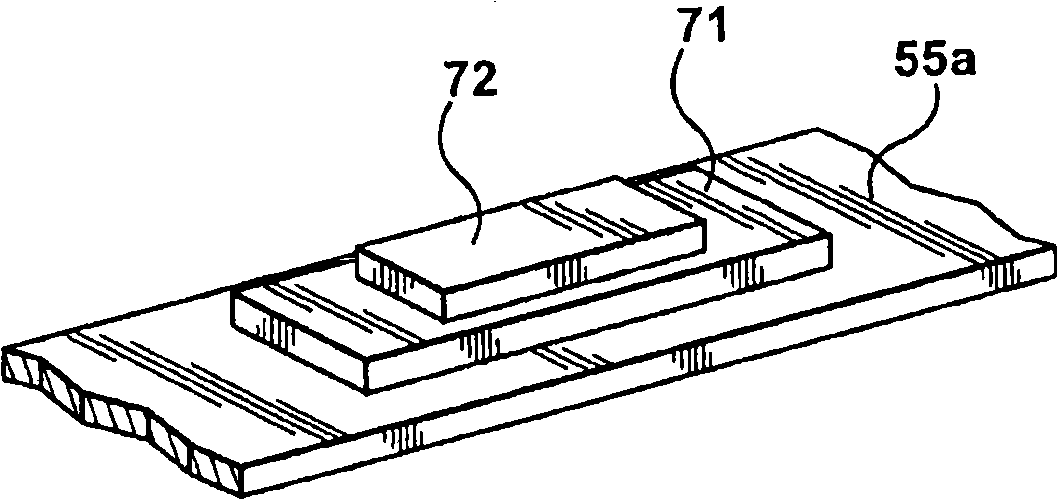

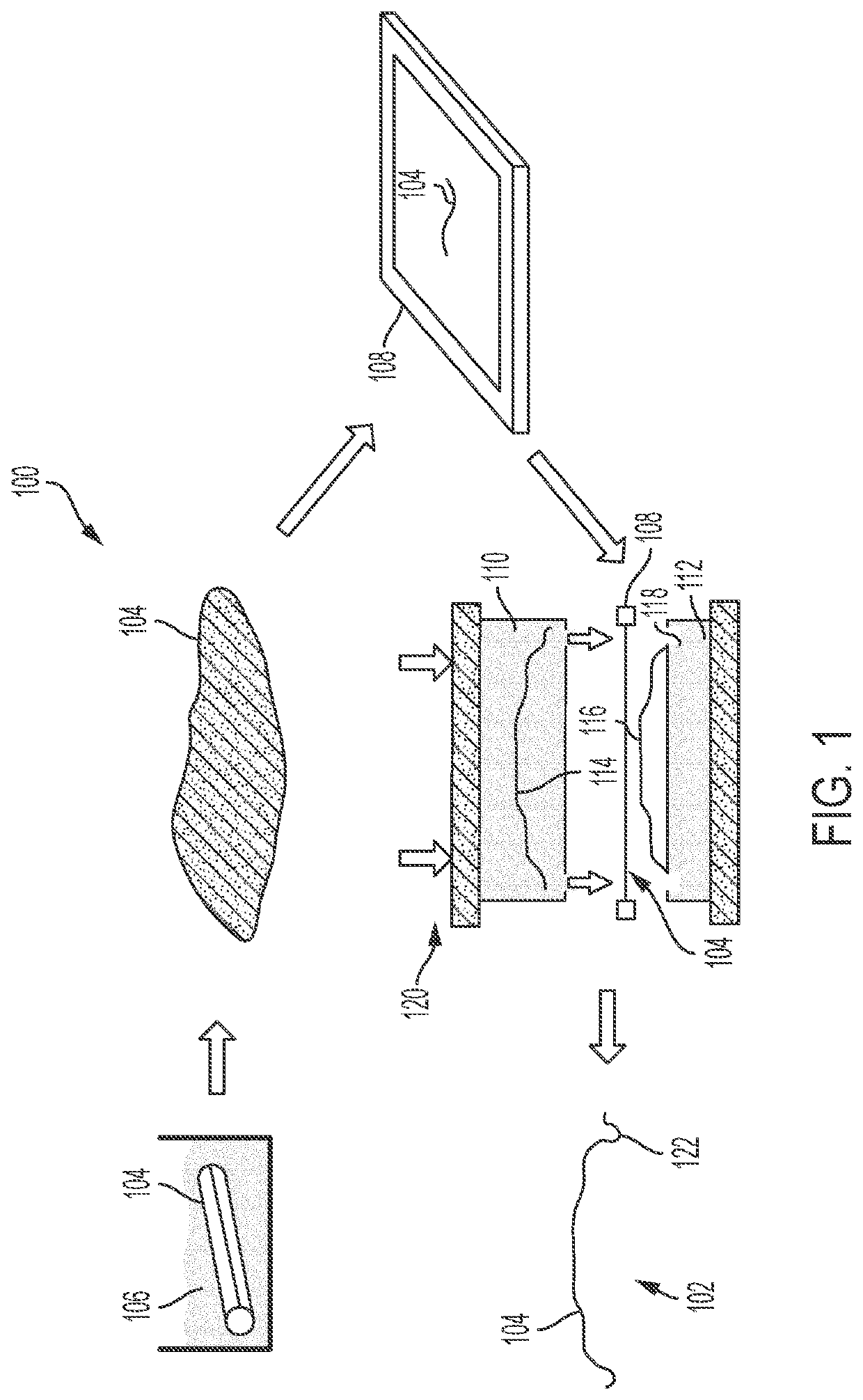

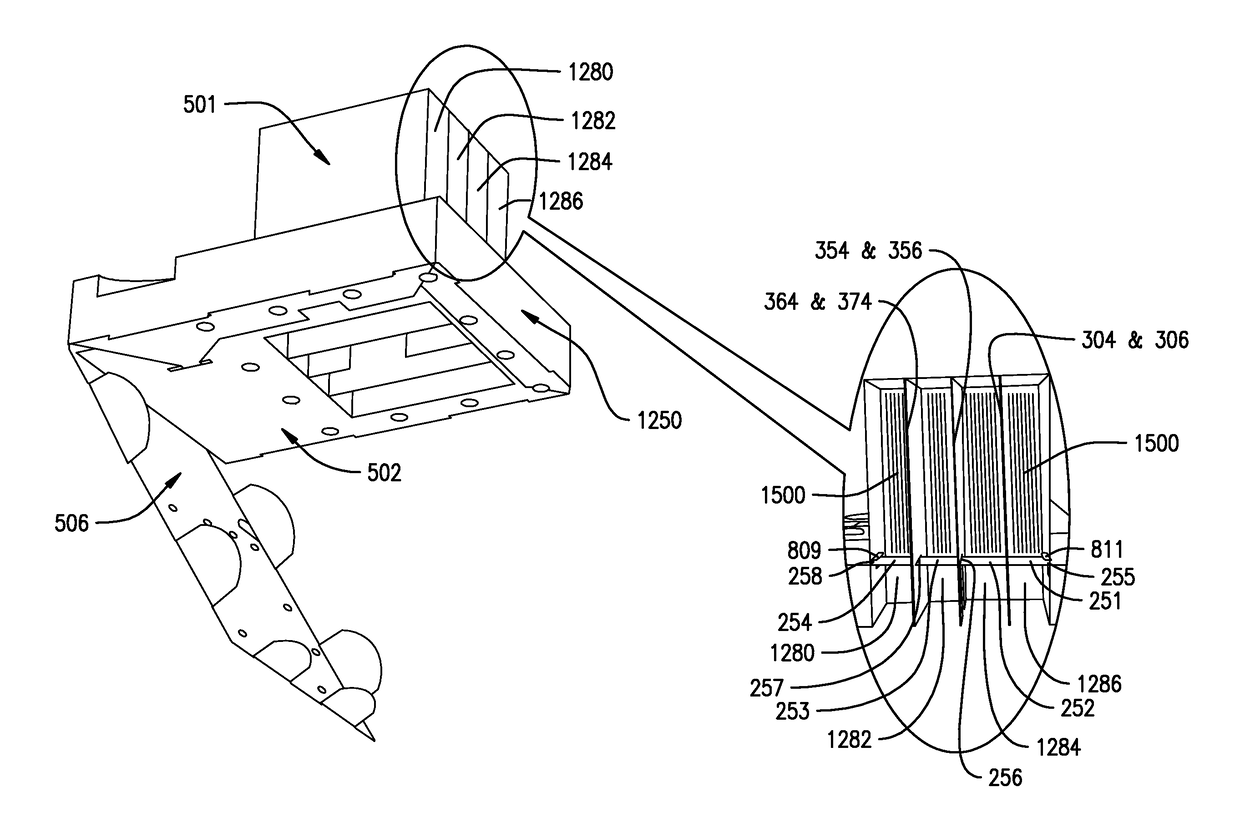

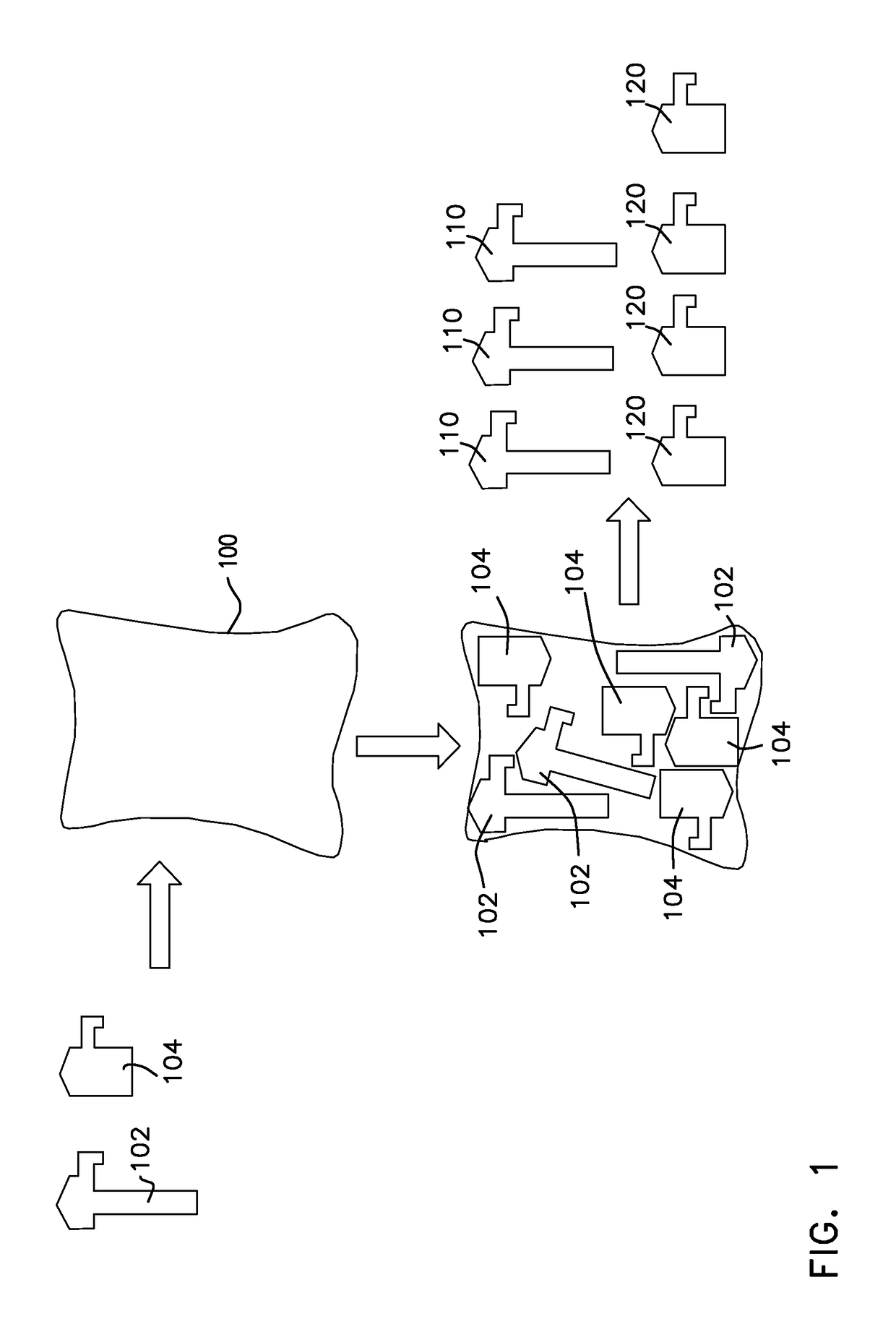

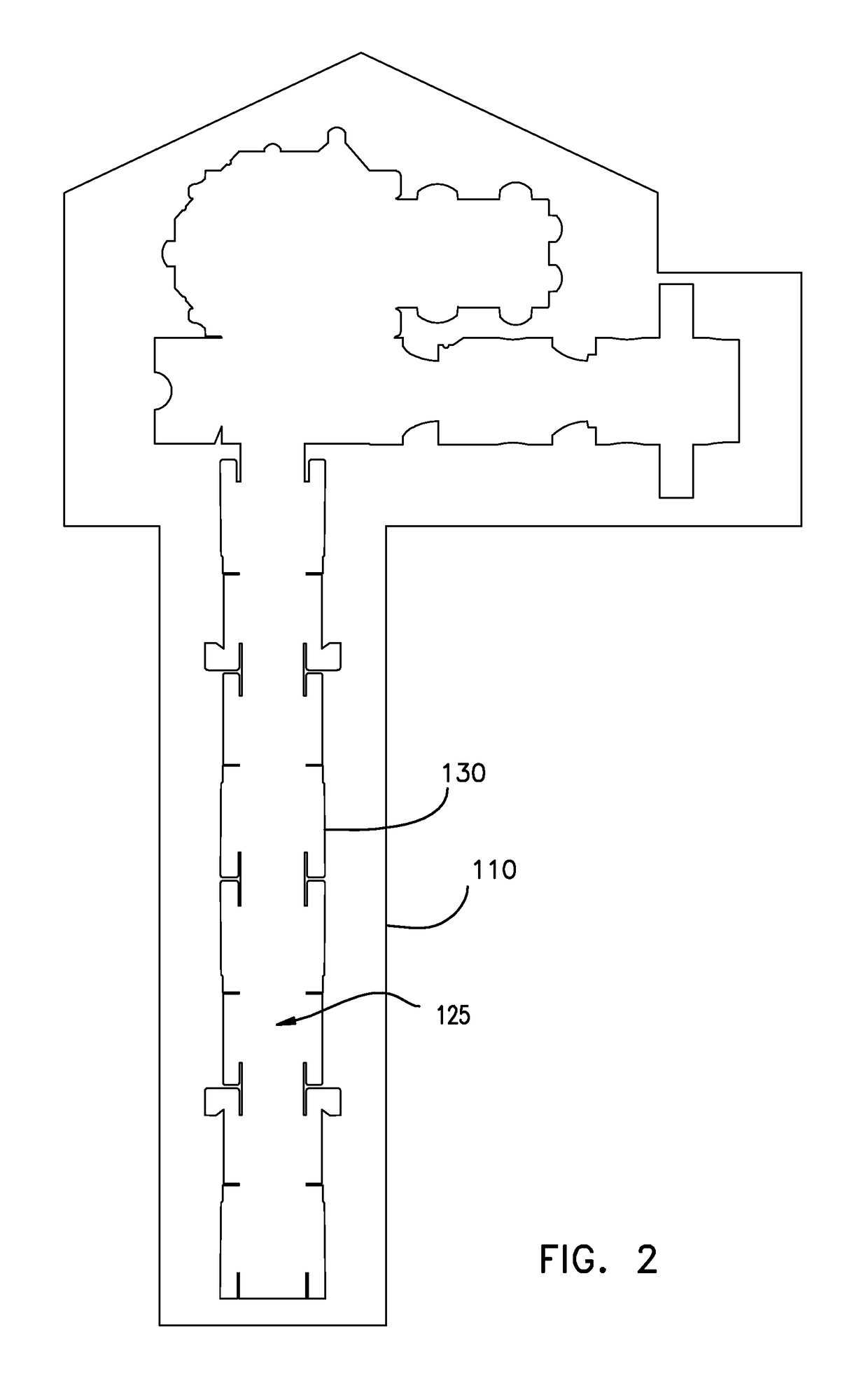

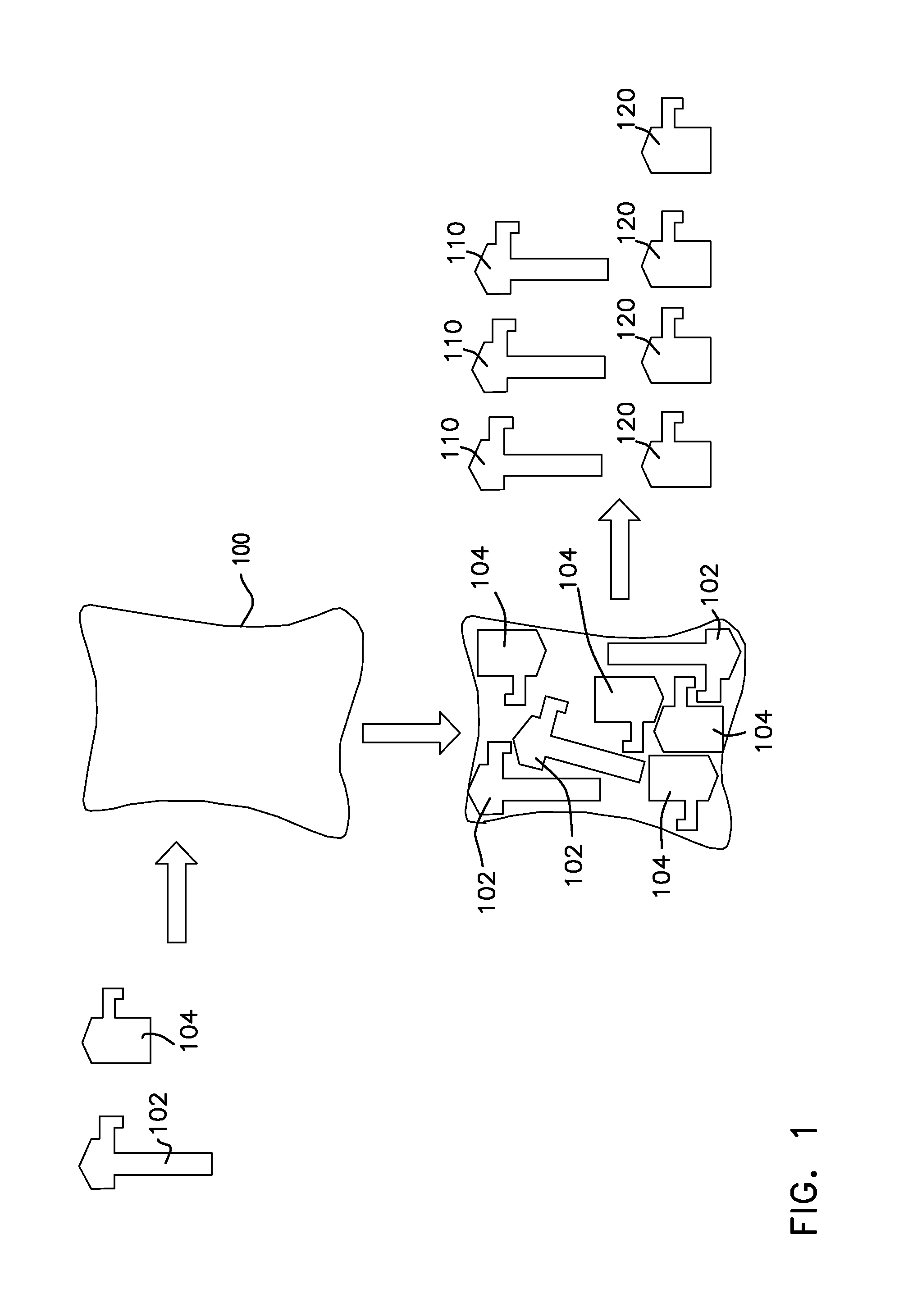

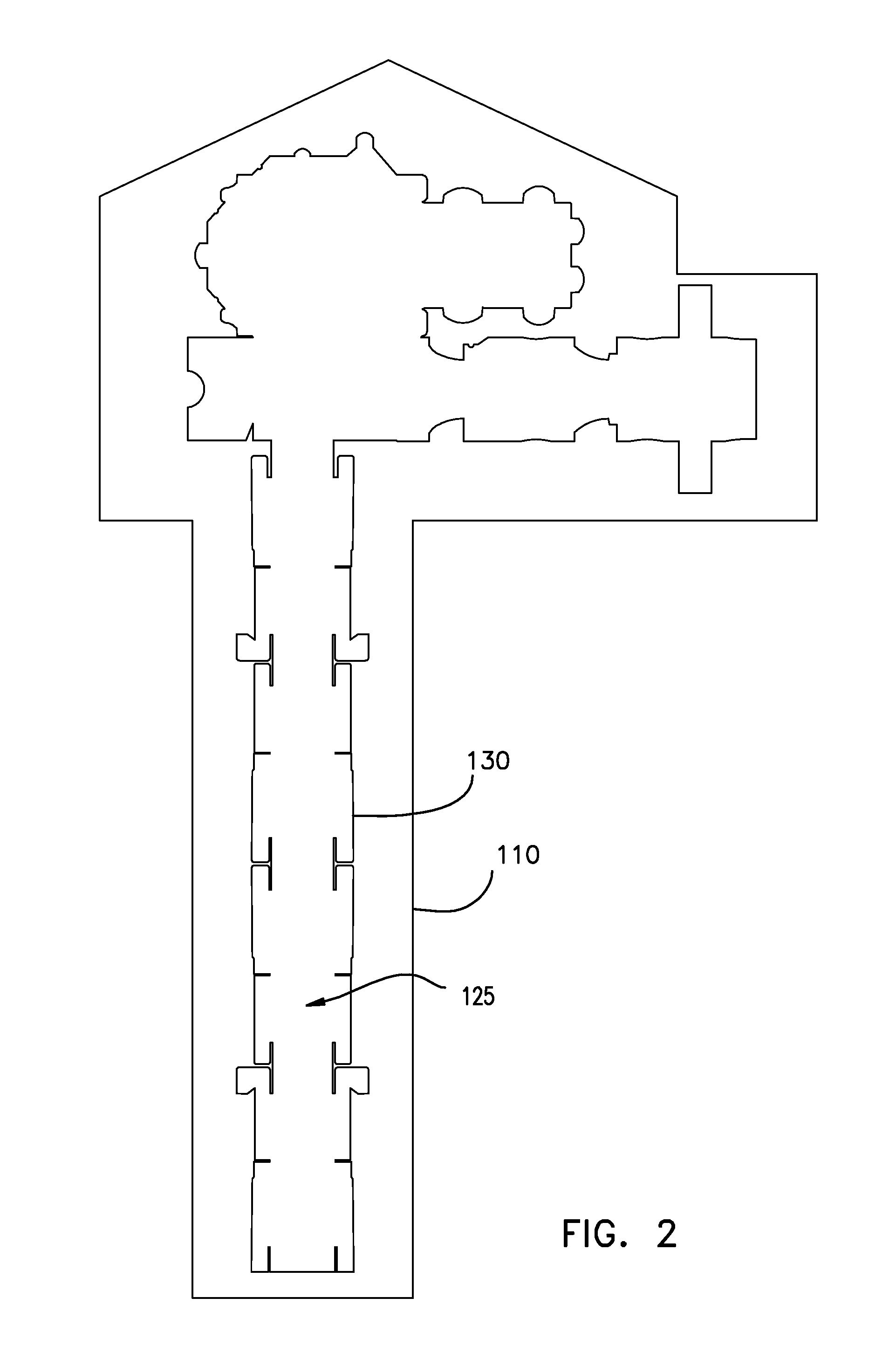

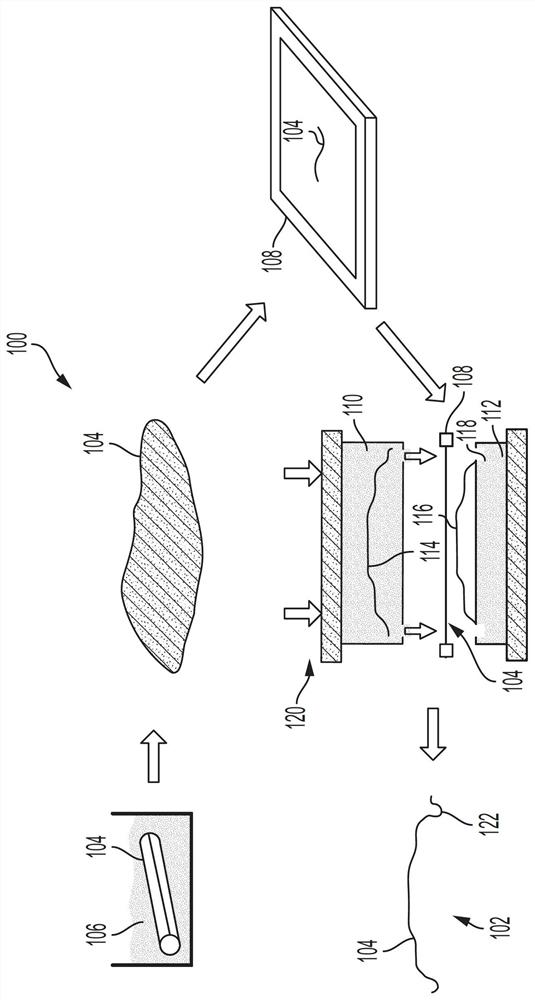

Systems and methods for real-time monitoring of die use or yield

InactiveCN101983117AProgramme controlLeather clicking/perforating/clickingRadio frequencyRadio-frequency identification

A method for monitoring die cutting comprising the steps of placing at least one cutting die on a hide, each cutting die having a particular pattern and an RFID (Radio Frequency Identification) tag coupled thereto, each RFID tag containing die-related information about that particular cutting die, repeatedly reading at least one RFID tag to obtain the die-related information for each RFID tag in real-time, based on the die-related information, determining whether the hide is ready for cutting, generating an output based on with whether the hide is ready for cutting, and when the hide is ready for cutting, cutting the hide.

Owner:ONTARIO DIE INT

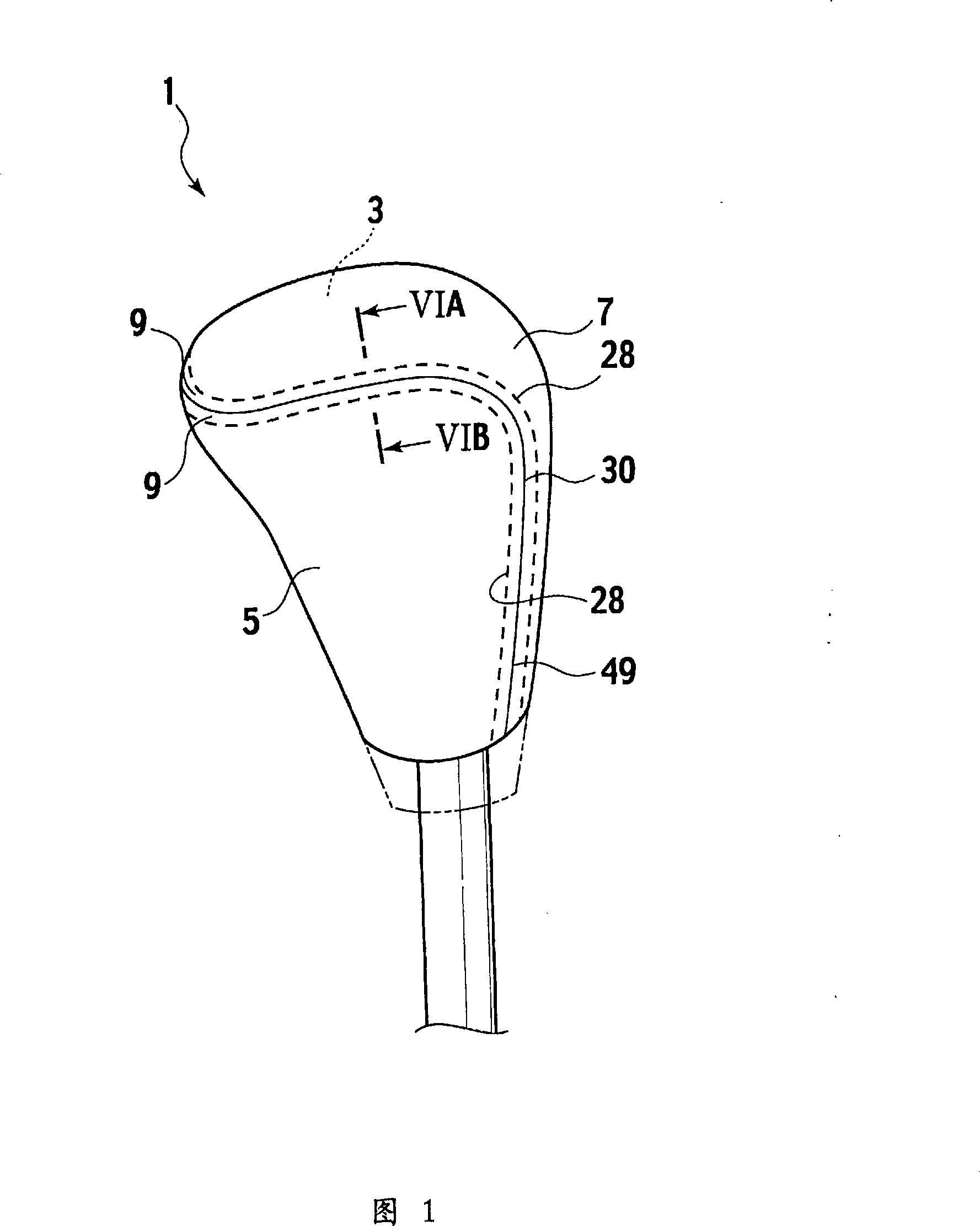

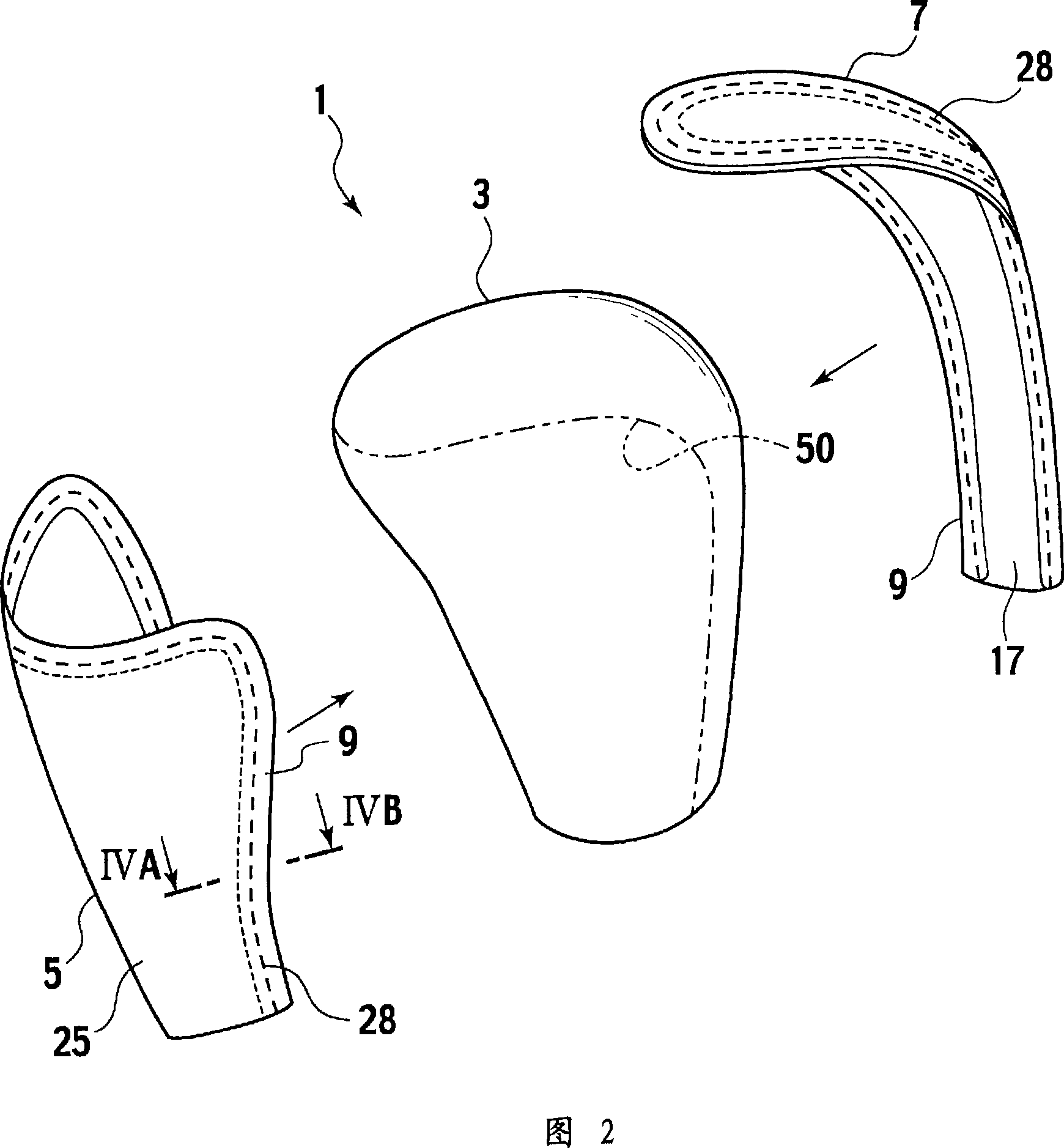

Leather and leather manufacturing method

ActiveCN101184661AAccurate shapeExact manufacturing methodMechanical apparatusHand wheelsEngineeringRaw material

In the leather (5) used to cover the shift handle (1), at the small rigid part with small bending rigidity formed along the end edge (21) of the leather material (20), the back side of the leather material (20) The leather material (20) is folded back in contact with each other to form an overlapping portion (9).

Owner:MIDORI ANZEN

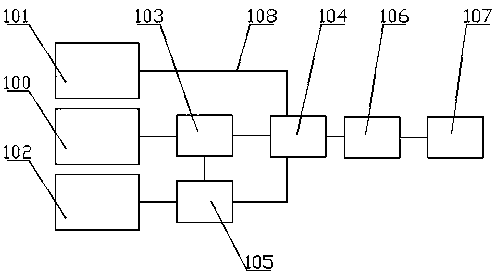

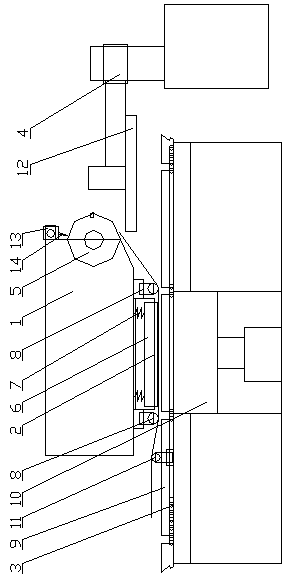

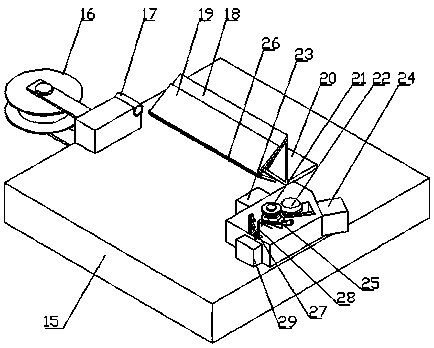

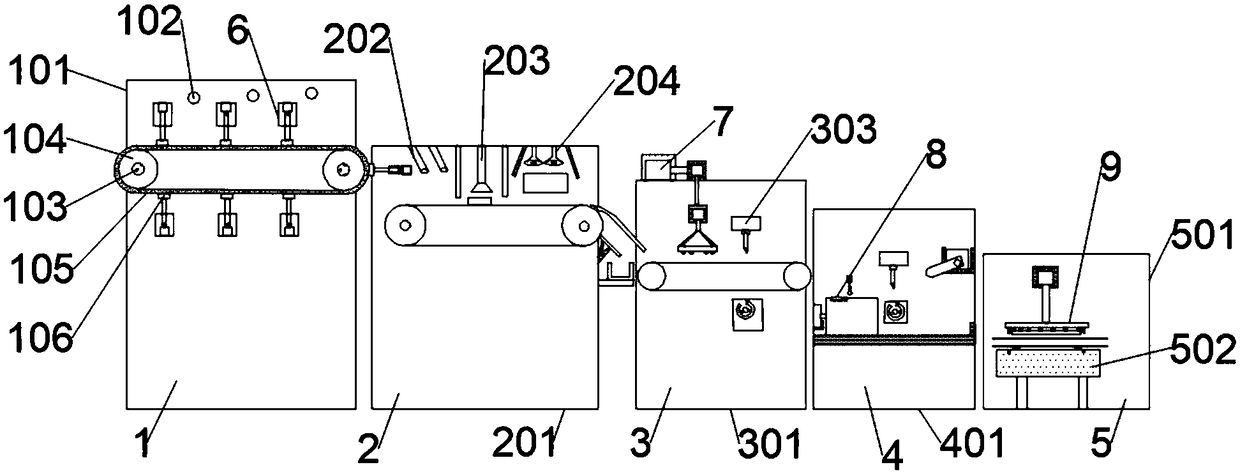

Bag production line

ActiveCN107802072AIncrease productivityImprove product qualityWork-feeding meansSevering textilesMaterials preparationLine tubing

The invention discloses a bag production line which comprises a surface material die-cutting machine (100), a steel wire framework tube wrapping machine (101), a lining polishing machine (102), an overlock sewing machine (103), a covering machine (104), a lining sewing section (105), an assembling and sewing section (106) and a roller fixing riveting section (107), wherein the surface material die-cutting machine (100) comprises an upper hydraulic mold base (1), a pressing die (2), a chain conveying machine (3) and a discharge manipulator (4); the steel wire framework tube wrapping machine (101) comprises an upper die base (1), a press die (15), a tube line disc (16), a line guide drum (17), a line shifting device, a tube wrapping device and a tube cutting device; the lining polishing machine (102) comprises a polishing platform (30), a polishing device, a feeding spraying device, a cutting device and a waste material recycling device. The bag production line has the advantages that the sections are connected through a conveyer belt, stream line production is achieved, different material preparation and mounting sections are operated automatically, the production efficiency and theproduction quality are greatly improved, the labor is saved, and the cost is lowered.

Owner:荆门展翔文化用品有限公司

Preparing method of case leather

ActiveCN104445039ABeautiful styleImprove visual effectsLeather clicking/perforating/clickingLeather surface mechanical treatmentTouch SensesColloid

The invention discloses a preparing method of case leather. The method comprises the steps that a. cow leather is selected, and the cow leather comprises a corium layer and a subcutaneous tissue layer; b. a sheet-shaped subcutaneous tissue layer is evenly cut on the subcutaneous tissue layer of the cow leather, and the cut sheet-shaped subcutaneous tissue layer is kept on the inner side of the cow leather; c. a needed embossment pattern is engraved on the cut sheet-shaped subcutaneous tissue layer, and the subcutaneous tissue layer on the outer periphery of the embossment pattern is removed; d. the cow leather with the embossment pattern engraved is placed in a three-dimensional forming mould, the embossment pattern part is pressed to the corium layer of the cow leather, and accordingly a protruding pattern structure consistent with the embossment pattern is formed on the outer surface of the corium layer of the cow leather; e. antiseptic treatment is carried out; f. colloid injection is carried out; and g. metal decorating piece embedding is carried out. Through the process design, according to the preparing method of the case leather, the case leather which is attractive in style, good in visual effect and obvious in touch sense can be produced.

Owner:GUANGZHOU TIANYIFANG LEATHER CO LTD

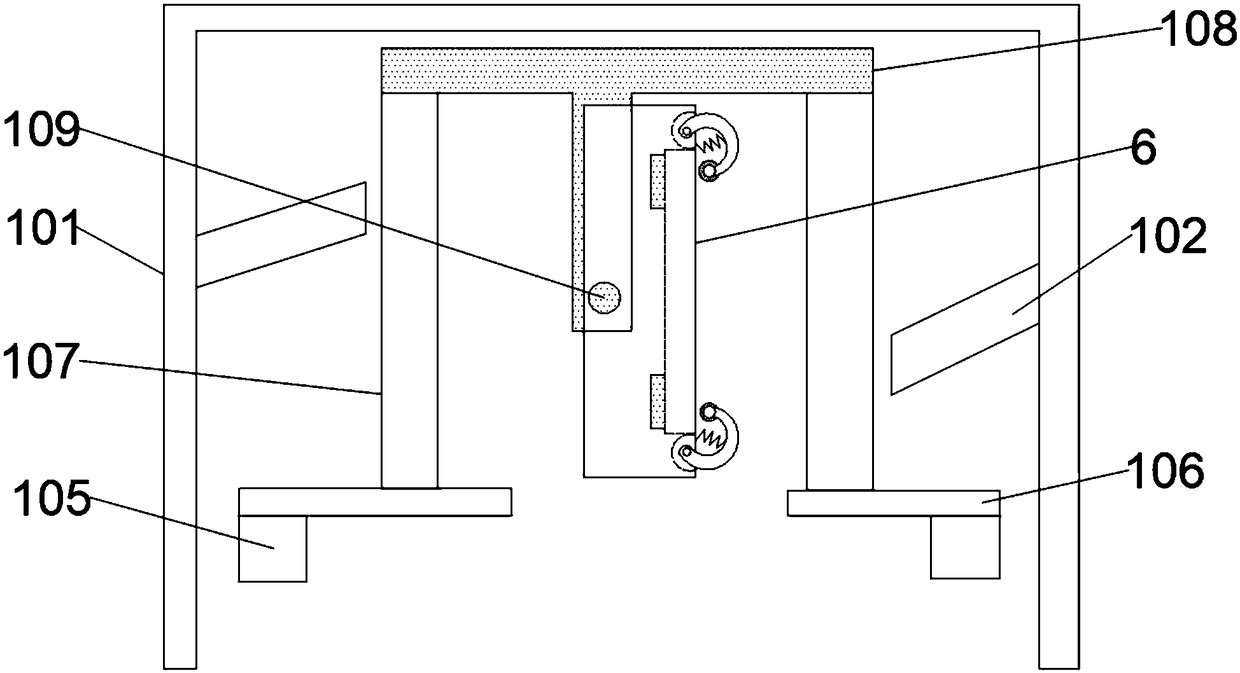

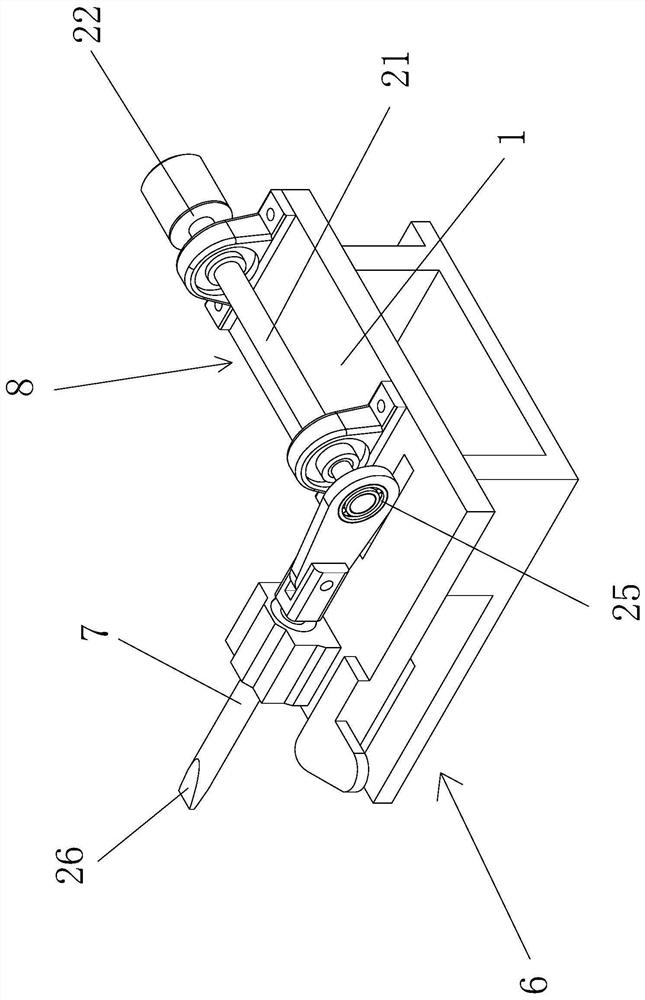

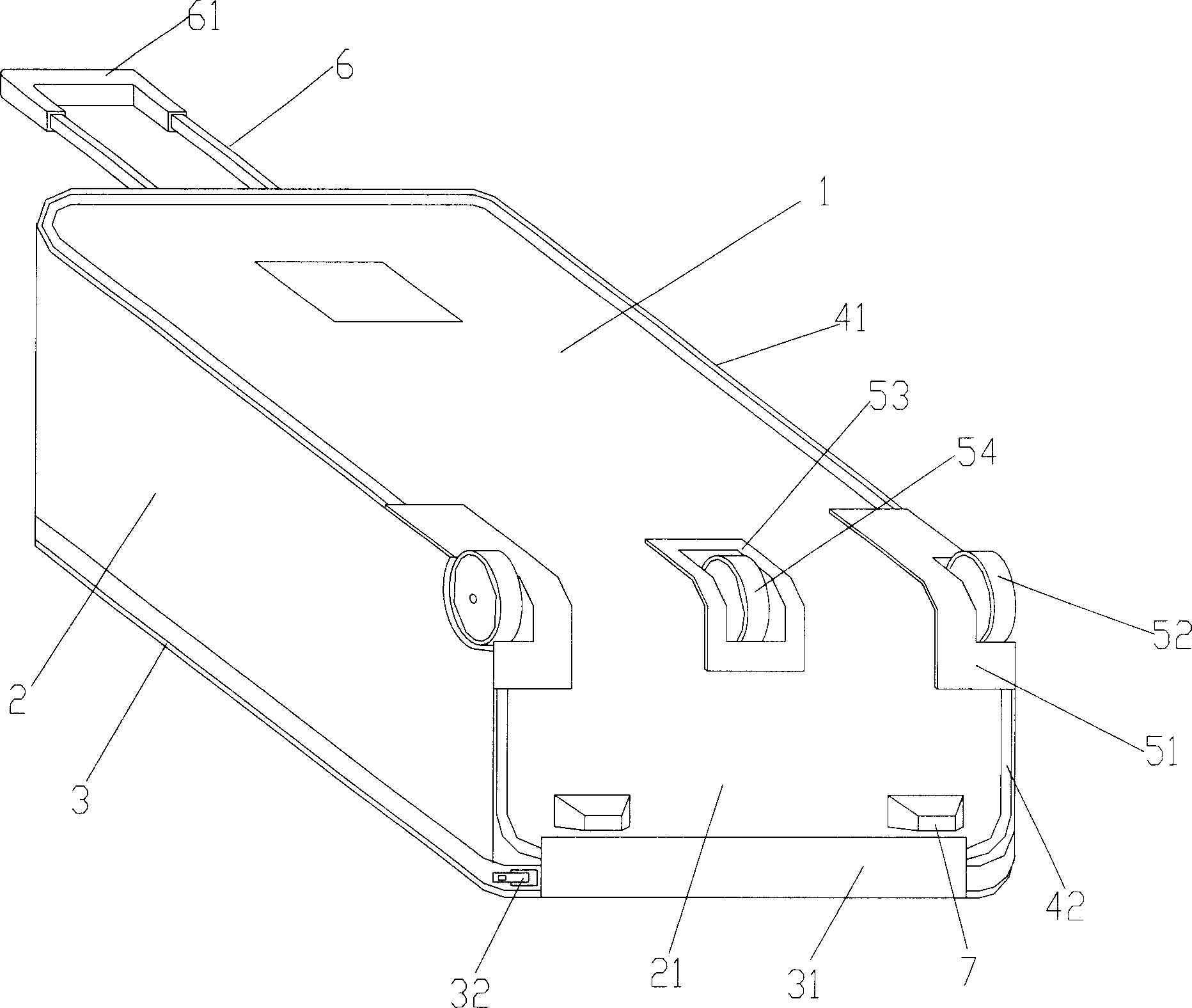

Rotary clamp for automatic production line of leather products

ActiveCN108483387AImprove drying efficiencyIncrease the areaWrappers shrinkageLeather articlesProduction lineEngineering

The invention discloses a rotary clamp for an automatic production line of leather products. The rotary clamp comprises a rotary clamp base, the rotary clamp base comprises a clamping base with a square normal section, and a cross bearing strip is arranged at the bottom of the clamping base; a leather groove is formed in the inner side of the top of the clamping base, and a plurality of balancingweights are further installed at the top of the clamping base; a plurality of leather clamping devices are arranged on the clamping base; each leather clamping device comprises a plurality of U-shapedclamping arms which are hinged to the top of the clamping base, and the bottoms of the U-shaped clamping arms are provided with iron pressing rods above the side of the leather groove; one side of each U-shaped clamping arm is connected with the clamping base through a spring, a rubber sleeve sleeves the outer side of each iron pressing rod, and electromagnets corresponding to the iron pressing rods in position are arranged at the bottom of the leather groove; by means of the cross bearing strip, when leather is placed in the leather groove, the situation that middle of the leather is concavedue to gravity is avoided; the top face of the cross bearing strip and the bottom face of the leather groove are located on the same plane so that the leather can be placed in the leather groove moresmoothly.

Owner:重庆瑞丰精密模具有限公司

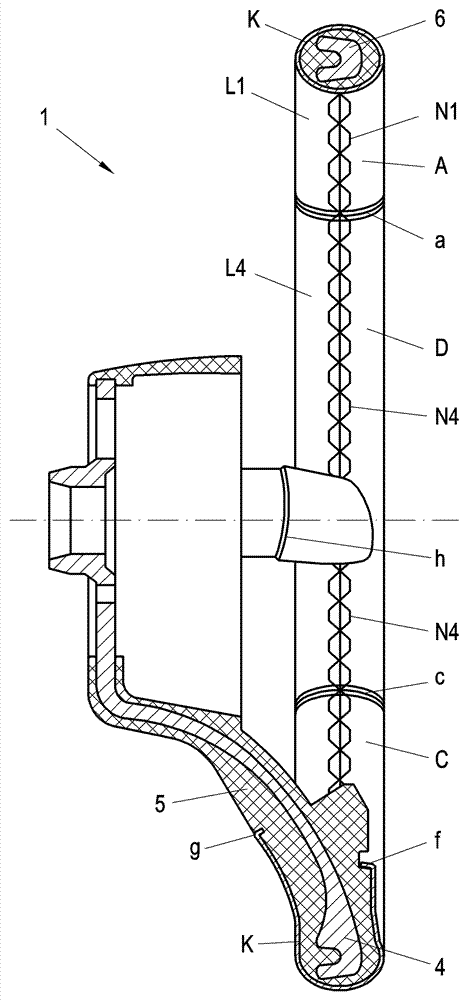

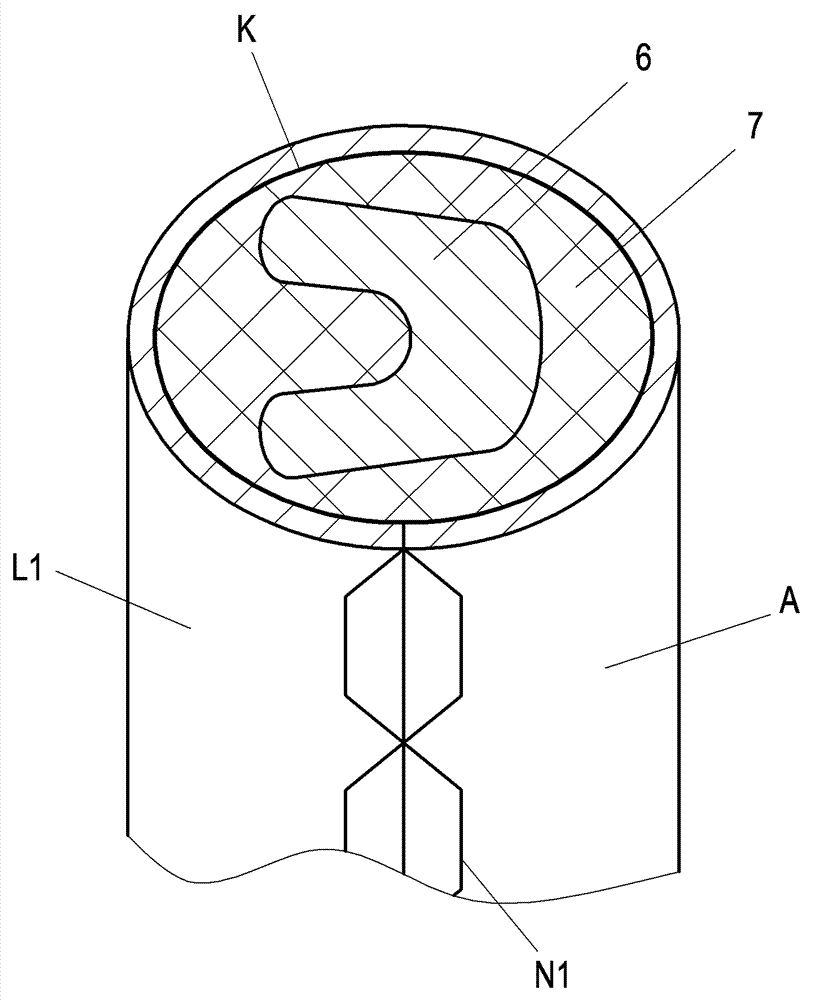

Leather And Manufacturing Method Of Leather

InactiveUS20090211394A1Accurate shapeControlling membersMechanical apparatusMechanical engineeringFlexural rigidity

In a leather 5 for covering a shift knob 1, it has a folded portion 9 formed by folding a leather material 20 such that back sides of the leather material 20 are set in contact with each other, at a small rigidity portion at which a flexural rigidity is small and which is formed along an edge 21 of the leather material 20.

Owner:MIDORI ANZEN

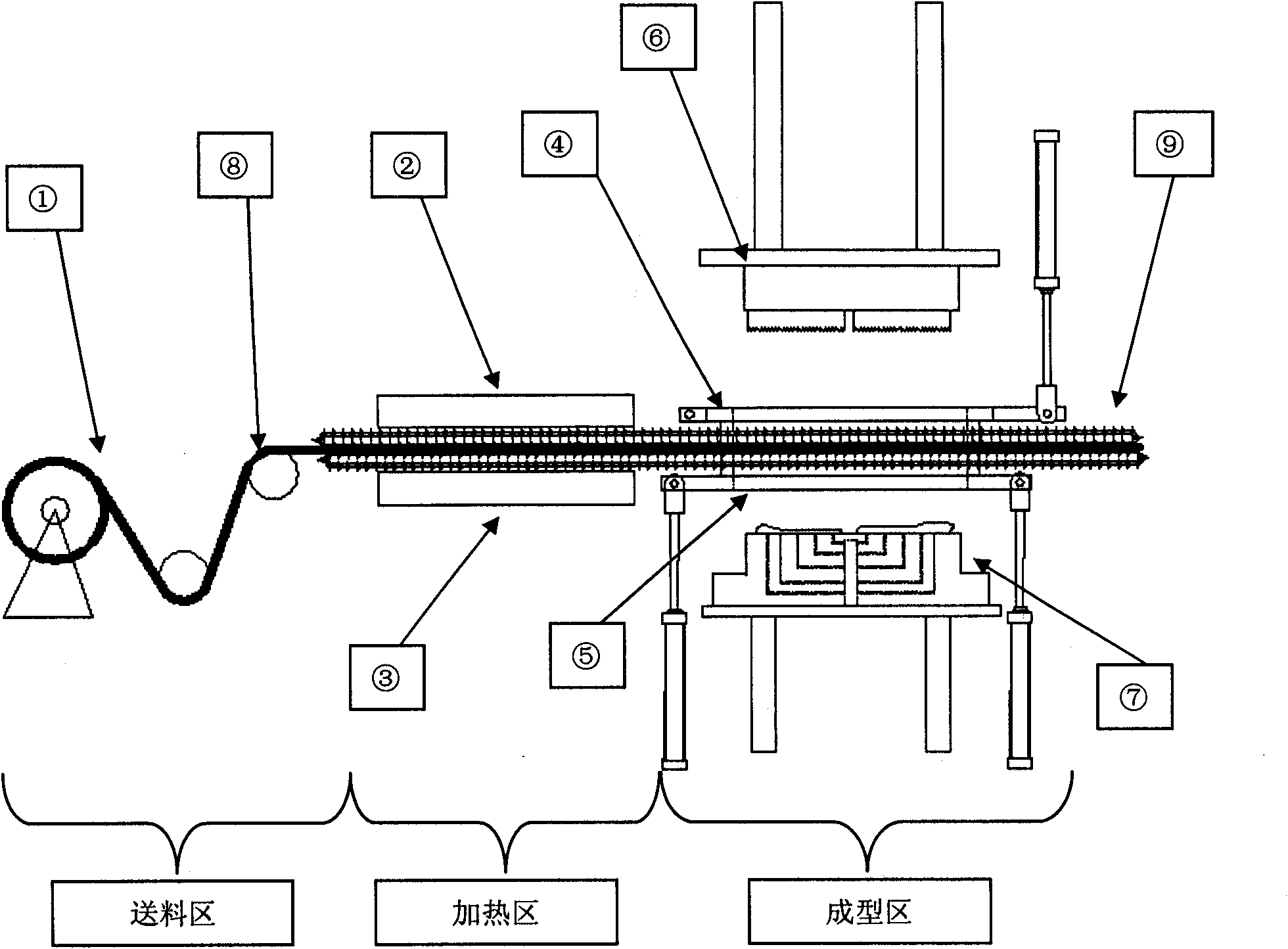

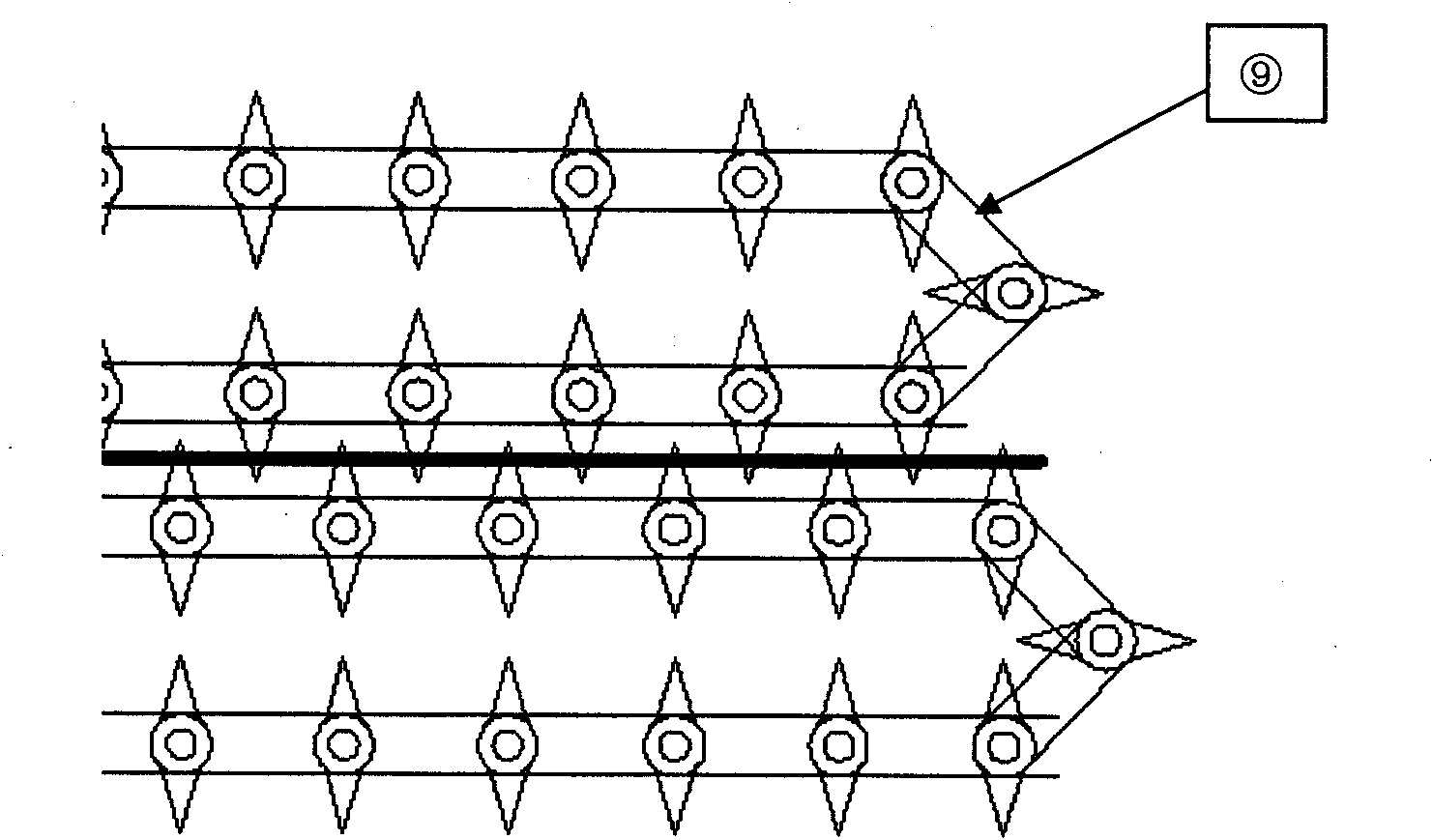

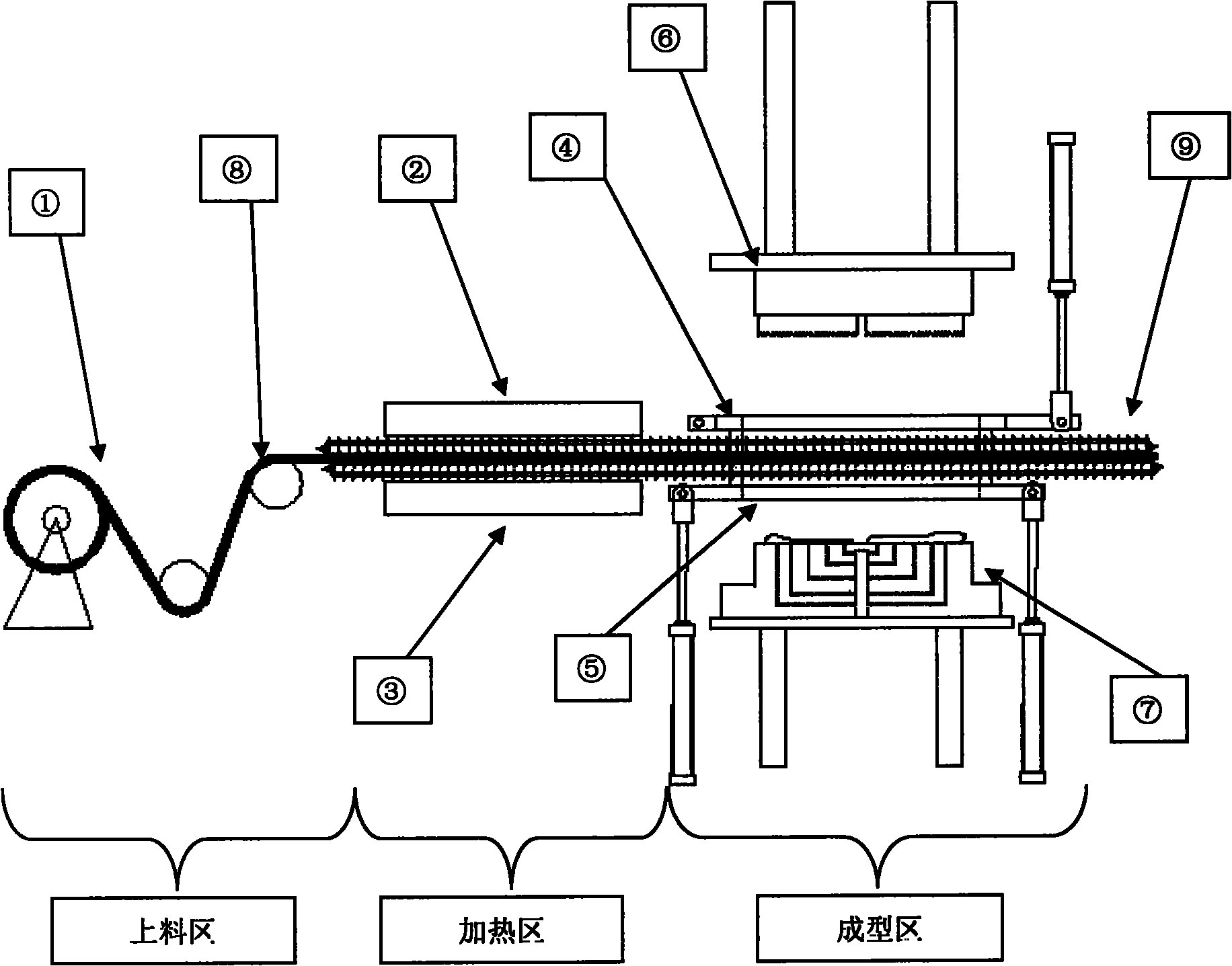

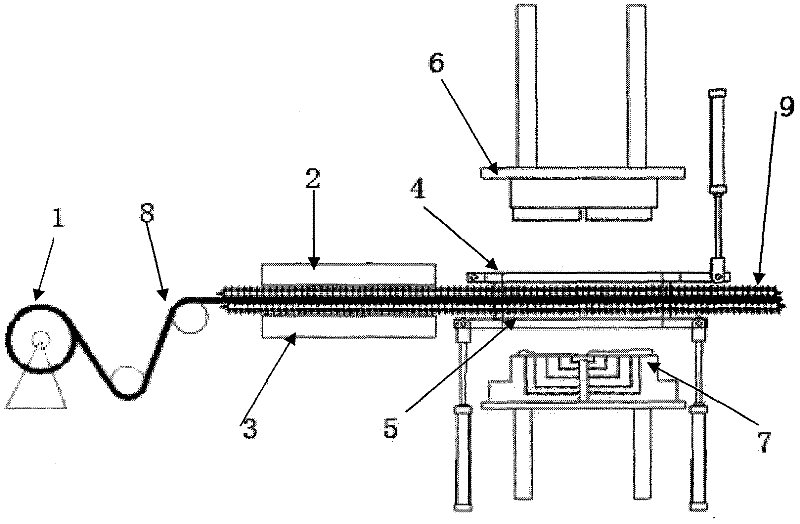

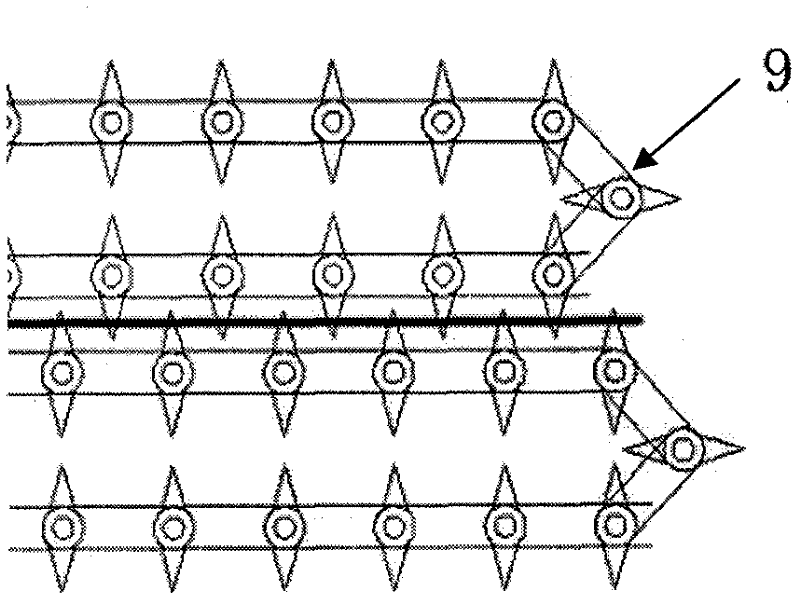

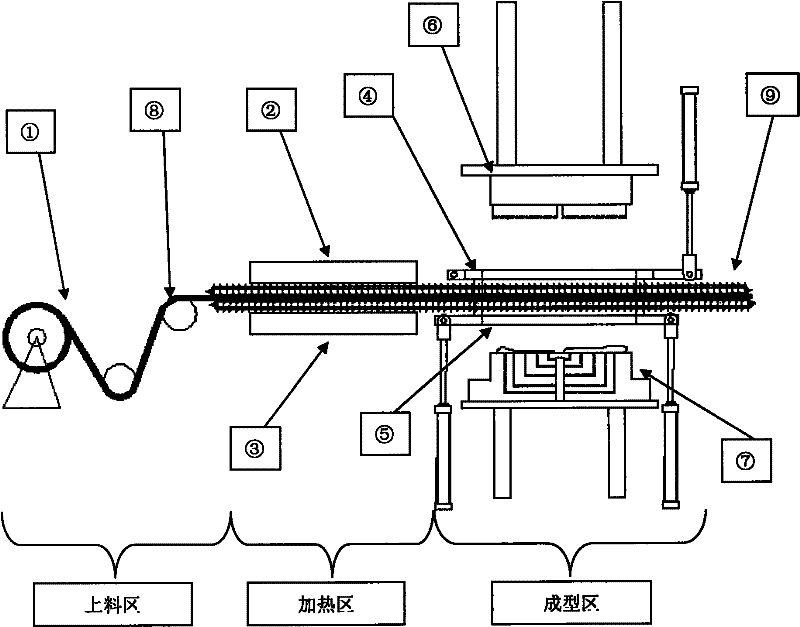

Vacuum adsorption molding method for realizing continuous production

ActiveCN101830424ARealize continuous productionIncrease productivityLeather articlesProcess engineeringSingle station

The invention discloses a vacuum adsorption molding method for realizing continuous production, which aims to improve vacuum adsorption molding production efficiency. In the method, a baking station and a molding station are separately arranged to form double stations; and rear-section leather can be heated at the same time when front-section leather is molded so as to realize the continuous production and avoid the problem that a single station of conventional vacuum adsorption methods makes sheet heating and vacuum molding required to be sequentially performed to cause a relatively longer period. The method has the advantages of greatly shortening a molding period and improving molding efficiency.

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

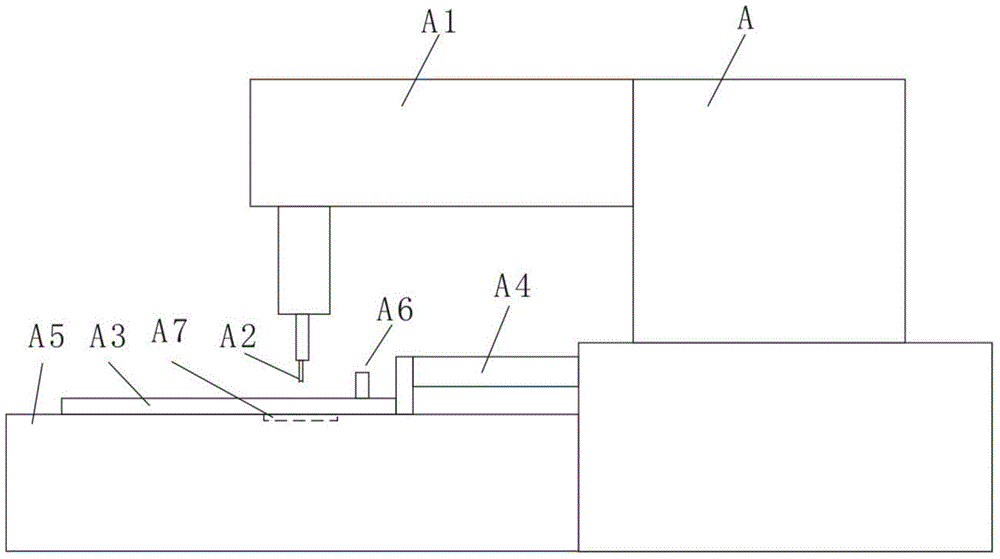

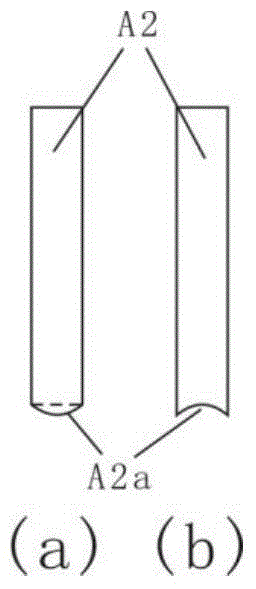

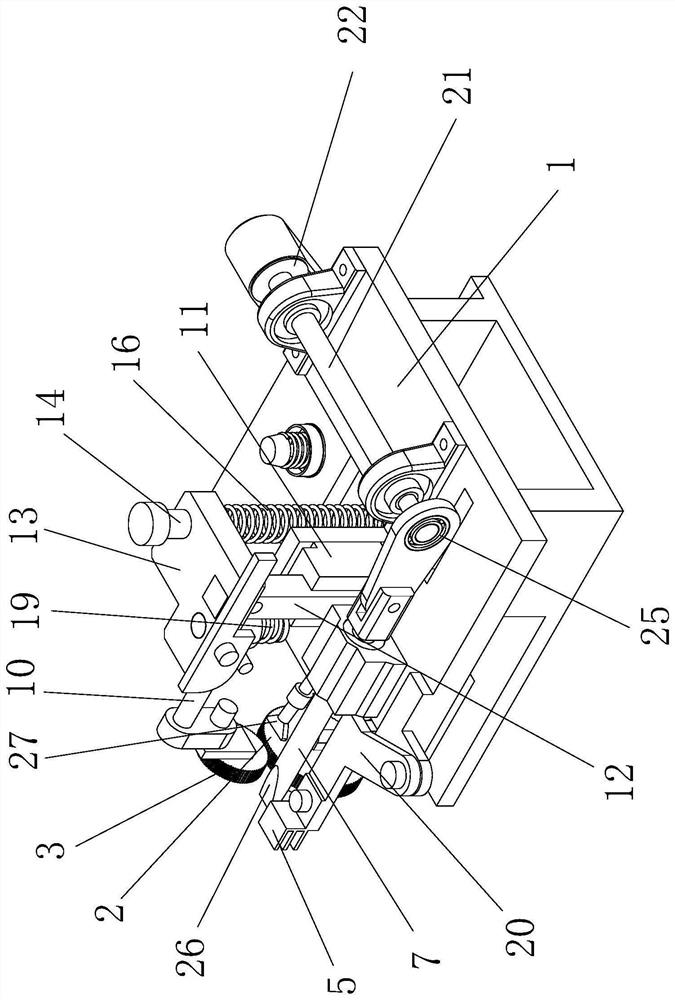

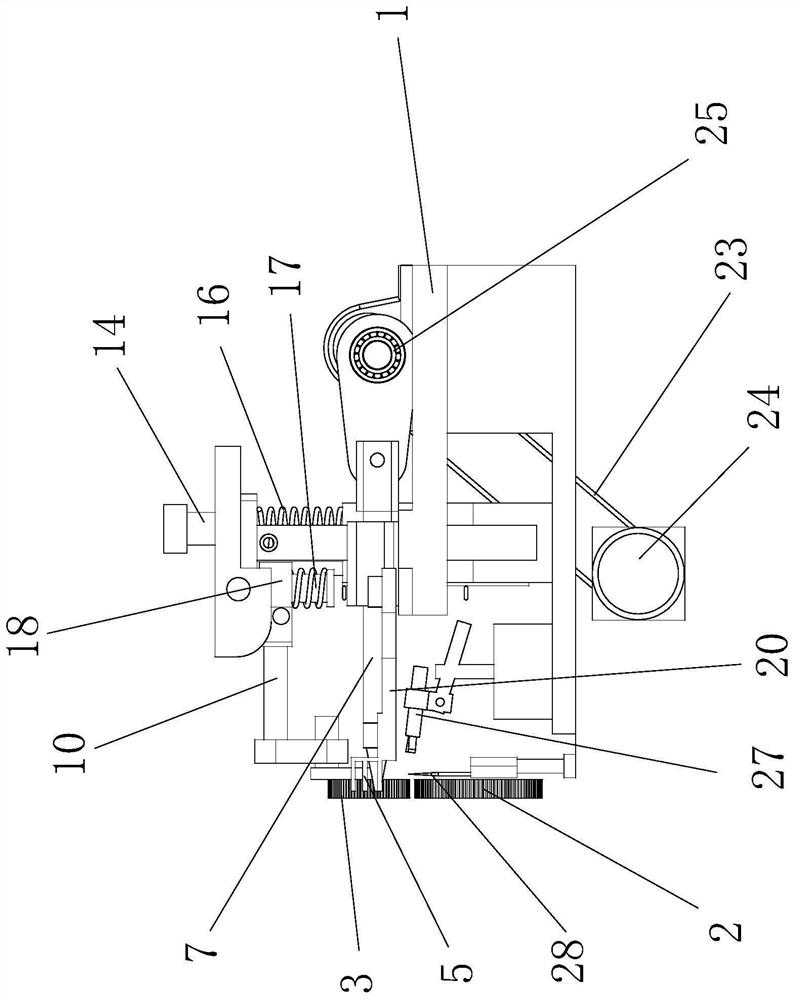

Single-formwork button making machine

The invention discloses a single-formwork button making machine which comprises a mainframe. The mainframe comprises a punch and a fixing frame, wherein the punch is installed on a machine head, and the fixing frame is installed on an X-axis moving frame and a Y-axis moving frame and located below the punch. A working table top is positioned below the fixing frame. A bottom module for being matched with the punch is arranged at the position of the working table top corresponding to the punch. The bottom module is provided with a foot curling bottom die for curling fastener paw parts is arranged on the bottom module, and the fixing frame is provided with a locating hole for locating and fixing a formwork module. Modified parts of the single-formwork button making machine are fewer, and compared with a newly developed button making machine, the single-formwork button making machine greatly reduces cost, saves time and is simple to operate. After the combination with a matched formwork, production efficiency is greatly improved, the fastener position error is 0.1 mm, fasteners are fixed firmly and are vertical and uniform in attitude, the paw parts of fasteners are just completely embedded in leather, the tail ends of paws are fully curled, and the pass rate is almost 100%. A die is provided with 1200-1400 fasteners, and the fasteners can be made in only 5 minutes.

Owner:四川非意欧国际皮革制品有限公司

Coated natural leather having low deformation

Coated natural leather, prepared from natural leather having polyurethane coated on its flesh side and having an improved (decreased) measure of deformation, is provided.

Owner:EI DU PONT DE NEMOURS & CO

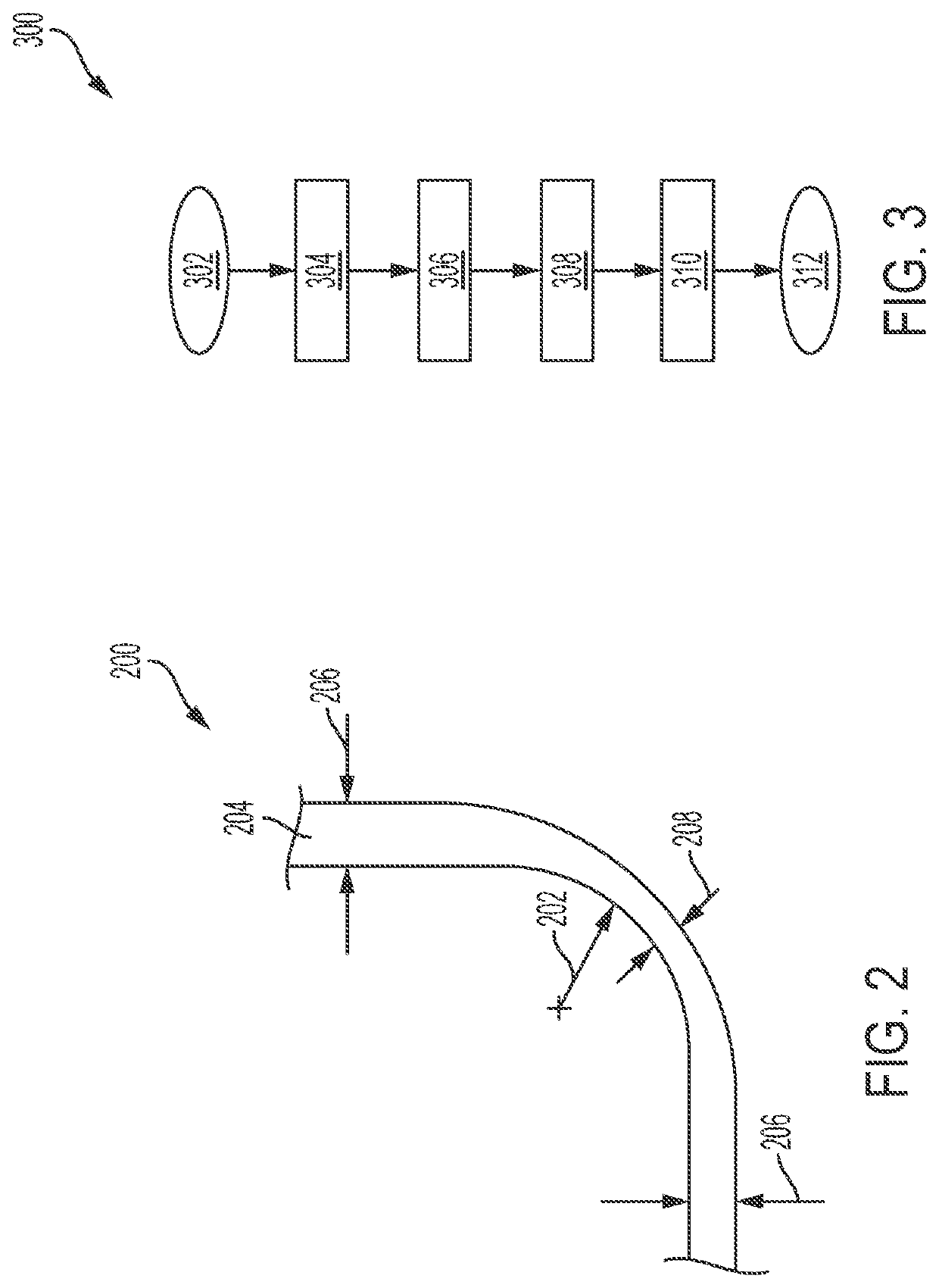

Interior trim panel for a vehicle and method of forming same

InactiveUS20210086411A1Liquid surface applicatorsSynthetic resin layered productsMechanical engineeringAutomotive engineering

An interior trim panel for a vehicle includes a leather layer defining a feature having a radius of less than five millimeters, and a backing layer adhered to the leather layer and providing a support structure for the leather layer. A method of forming the interior trim panel includes clamping the leather layer in a frame to securely fix the edges of the leather layer, positioning the leather layer between compression mold dies defining a complementary surface having a feature with a radius of less than five millimeters, and compressing the leather layer between the dies.

Owner:GM GLOBAL TECH OPERATIONS LLC

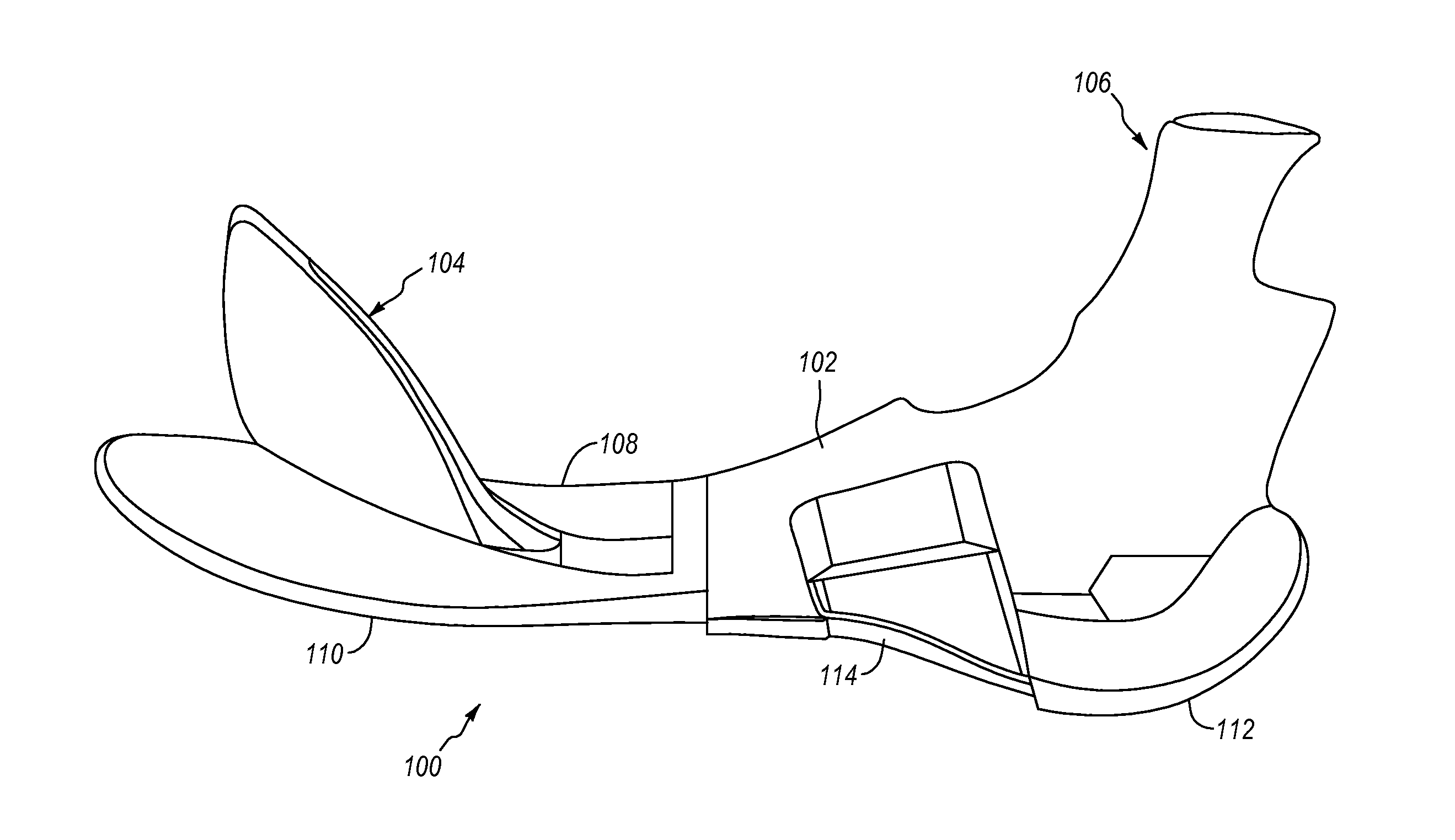

Injection molded saddle with cover

A saddle may be manufactured through the injection molding of a core. The core may then be reinforced by the application of a pliable reinforcement layer, such as pre-impregnated epoxy glass, which may then be hardened. A finishing layer may then be applied to the reinforcement layer to complete the saddle.

Owner:MCCLELLAN BRAD

Method for applying leather to vehicle interior parts

InactiveCN102712330AOptimize locationReduce method stepsAdhesive processesHand wheelsAdhesiveMechanical engineering

The invention relates to a method for producing leather (L) for applying to components (1), comprising the following process steps: providing finished leather (L) and applying an adhesive layer (K) to the rear face of the leather (L) or to a composite material face in case of a leather composite material, wherein a bonding adhesive is used for building up the adhesive layer (K), allowing repositioning of the leather (L) or the leather composite material essentially an arbitrary number of times.

Owner:WOLLSDORF LEDER SCHMIDT & GES

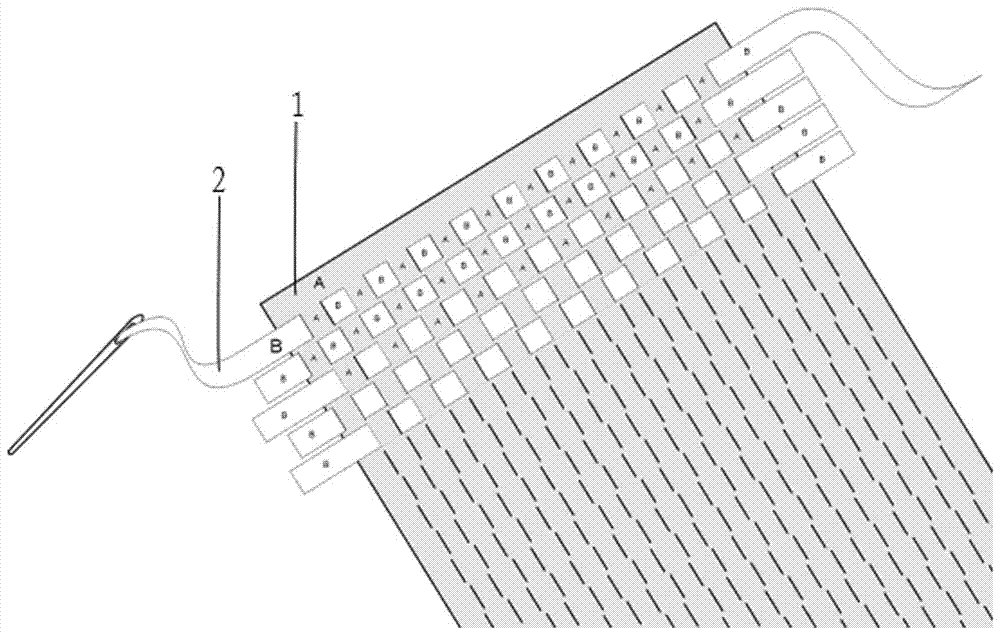

Hand-knitted bag production method

InactiveCN107048642AUniform weaving rulesWill not deformLamination ancillary operationsSevering textilesWear resistantEngineering

The invention discloses a production method of hand-woven bags. In the first step, the fabric B is cut into strips by using a precision stripping machine; in the second step, the fabric A is lasered out of a multi-row regular arrangement by laser punching. hole; the third step is to artificially insert the holes of each row on the fabric A through the strip fabric B; the fourth step is to cut the woven fabric A and fabric B into the required shape; the fifth step is to The cut fabrics in the four steps are superimposed with ironing cloth and reinforced by the ironing machine; in the sixth step, the reinforced fabrics are sewed and processed into bags in the workshop. In the present invention, the laser punches regularly arranged holes on the fabric A, inserts the strip-cut fabric B into the fabric A, the weaving rules are uniform, no deformation, and the effect is good; the woven fabric is cut, superimposed and ironed, Reinforced, and finally sewed and processed into bags in the workshop; products produced by this process are more wear-resistant, not easy to deform, and the defective rate is greatly reduced.

Owner:刘亚飞

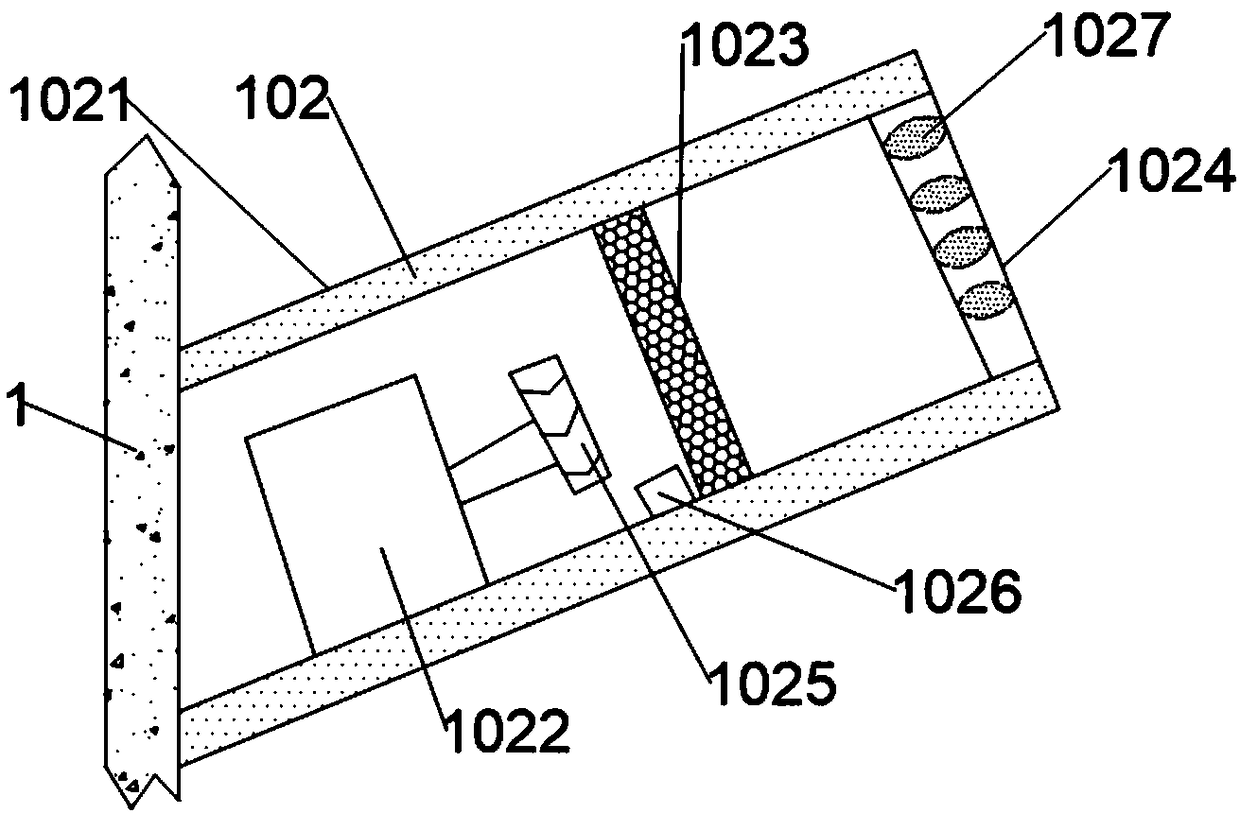

Method of manufacturing a phylactery and a phylactery manufactured thereby

ActiveUS10085581B2Enhanced rigidity maintenanceImprove rigidityLeather clicking/perforating/clickingReligious equipmentAnimal skinManufacturing engineering

A method of manufacturing a phylactery, the method including providing an initial stage phylactery workpiece formed of animal skin, cutting the initial stage phylactery workpiece to define a second stage phylactery workpiece, the cutting including forming at least outline cut lines, interior cut lines and incised lines, and folding the second stage phylactery workpiece along at least some of the incised lines to define the phylactery.

Owner:GREENBERG NOAH JEREMIAH

Method of manufacturing a phylactery and a phylactery manufactured thereby

ActiveUS20150359373A1Improve rigidityImprove registrationLeather clicking/perforating/clickingReligious equipmentEngineeringAnimal skin

A method of manufacturing a phylactery, the method including providing an initial stage phylactery workpiece formed of animal skin, cutting the initial stage phylactery workpiece to define a second stage phylactery workpiece, the cutting including forming at least outline cut lines, interior cut lines and incised lines, and folding the second stage phylactery workpiece along at least some of the incised lines to define the phylactery.

Owner:GREENBERG NOAH JEREMIAH

Leather product and preparation method thereof, and watch

ActiveCN110817786AImprove waterproof performanceGood weather resistanceBiochemical fibre treatmentLight resistant fibresPolymer scienceWeather resistance

The invention relates to a preparation method of a leather watchband. The preparation method comprises the steps that a leather product body is provided; the leather product body is sequentially soaked in a first treating agent and a second treating agent for ultrasonic treatment; and the leather product body subjected to the soaking treatment is subjected to drying treatment to obtain a leather product, wherein the first treating agent is a fluoroacrylate compound with the relative molecular weight of 200-400; and the second treating agent is fluoroalkyl trialkoxysilane with the relative molecular weight of 500-800. A leather watchband and a watch are disclosed. According to the preparation method, a protective layer with a complete structure is formed on the surface of the leather product body, so that the water resistance of the leather product is relatively high, and meanwhile, the leather product has excellent antifouling, weather resistance, friction resistance, deodorization andself-cleaning performance.

Owner:ZHUHAI ROSSINI WATCH IND

Splicing method of waste materials generated by fur processing

The invention discloses a splicing method of waste materials generated by fur processing. According to the method, fragmental materials generated during fur processing are spliced through sewing to form a spliced raw material with a certain specification, the spliced raw material is subjected to the steps including fur ironing, fur carding, water adding for reduction, hanging-airing, adhering, edge cutting and finishing, and thus a finished product is processed; or the spliced raw material is subjected to fur ironing, fur carding, miscellaneous color removal, washing, airing, dyeing and aftertreatment, and thus the finished product is processed. According to the method, the waste materials generated during the production process are processed to form the product with certain specification,the spliced finished products divided according to the color are processed to form the finished products with different fur path lengths, or are processed to form novel finished products achieving the color standard. With the method provided by the invention, the fragmental materials are enabled to become valuable materials, the processed finished product has the product diversification, the additional valve of the product is increased, especially, the fashion trend is formed in Europe and America, meanwhile, due to the recycling of the waste materials, the production cost is greatly reduced,the product effectiveness is improved, and certain profound significance is obtained for the environmental protection problem during fur processing.

Owner:青铜峡市祥云皮草有限责任公司

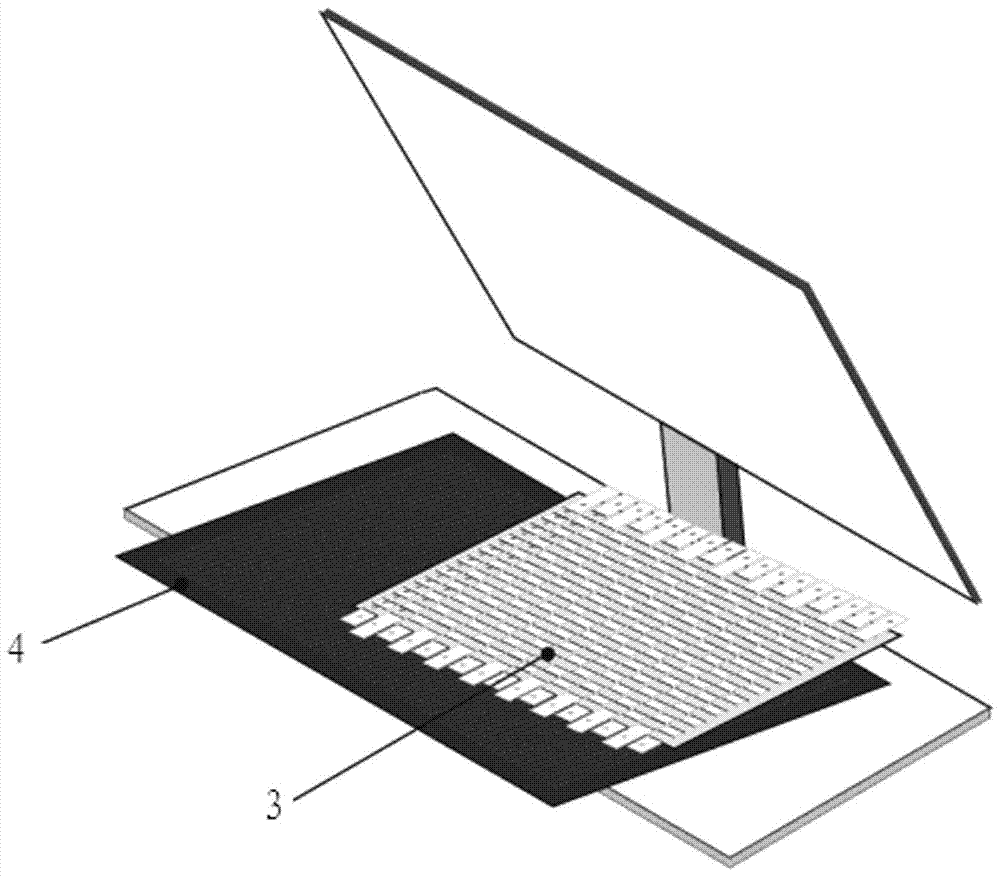

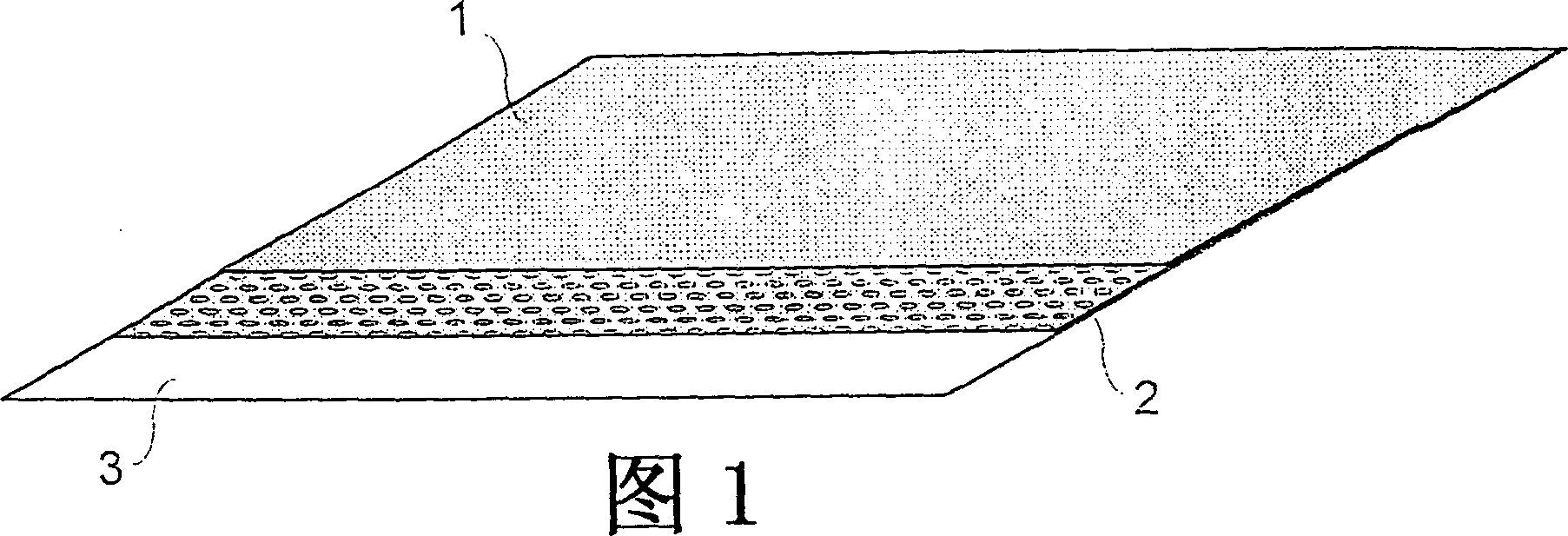

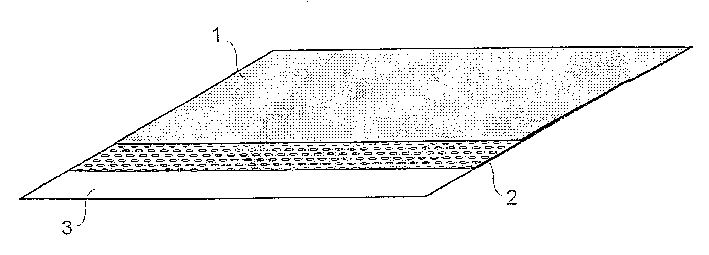

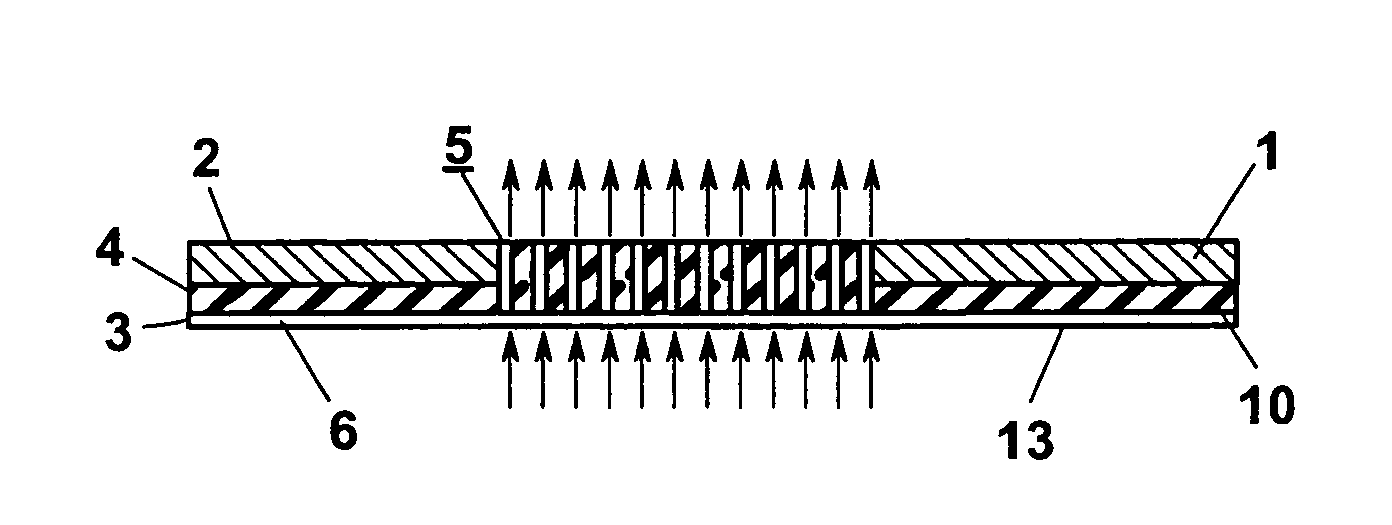

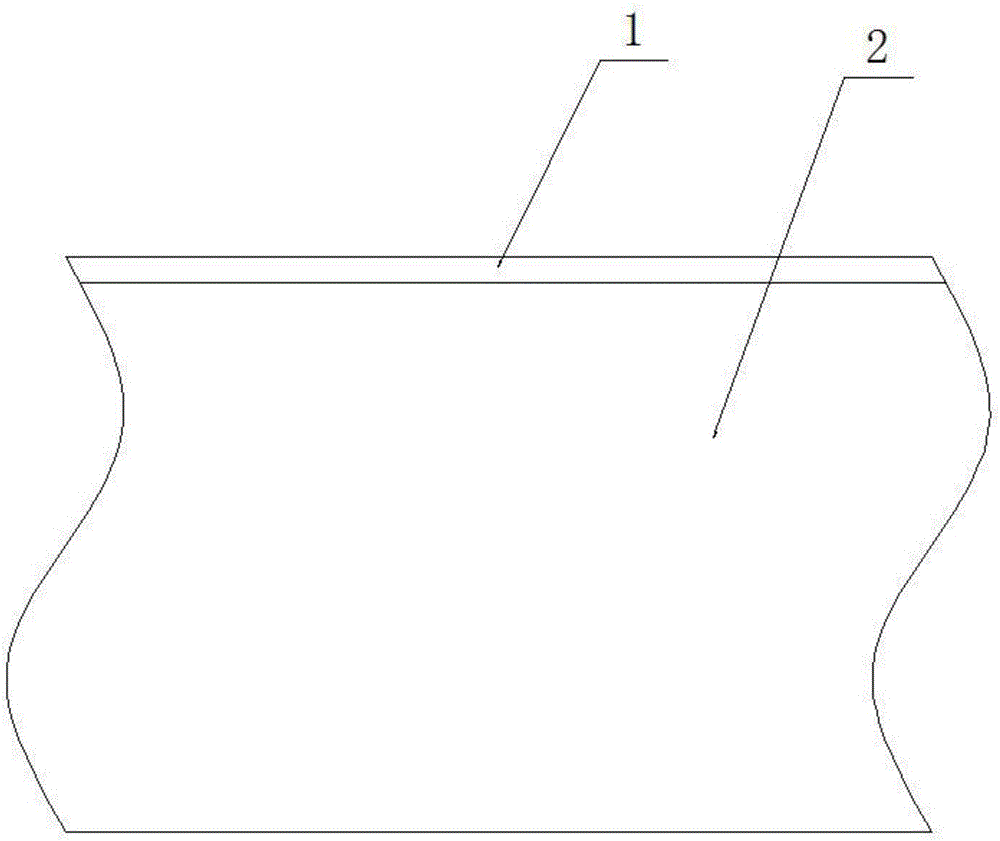

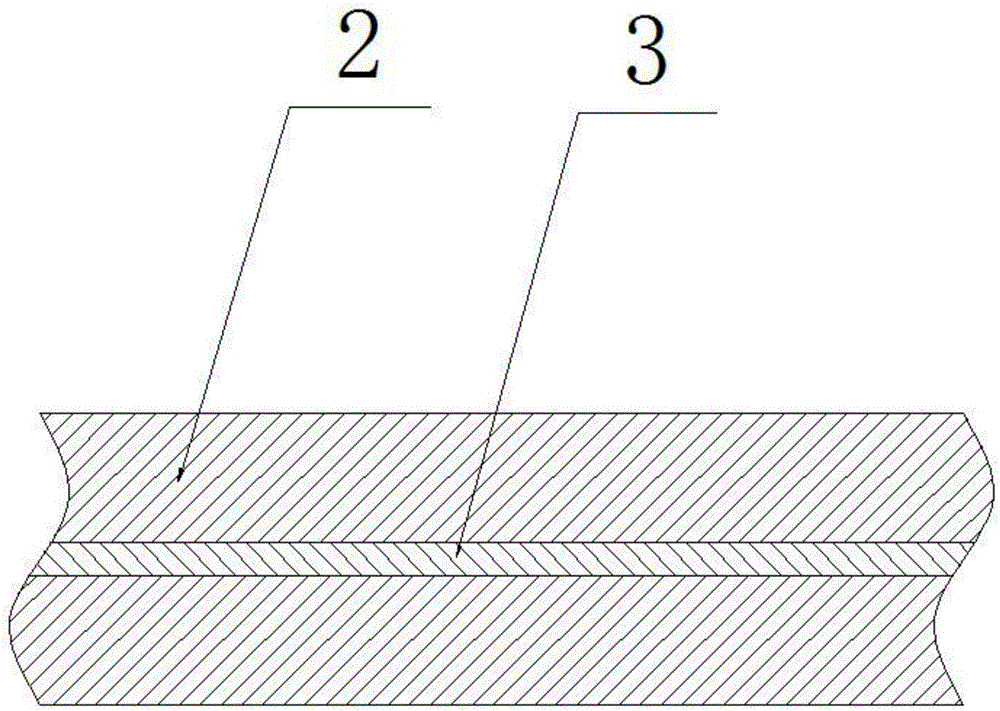

Process for waterproofing leather and leather obtd. by means of said process and shoes containing said leather

InactiveCN1158392CPrevent penetrationGuaranteed comfortGarment special featuresSolesPolymer scienceEngineering

A process for waterproofing leather (1) includes pressing on the internal surface of the leather (1) at least one semi-permeable membrane (2) whose surface contacting the leather (1) is provided with a glue pattern. The glue pattern of the semi-permeable membrane (2) is preferably thermoadhesive, and therefore the pressing of the membrane on the leather (1) is preferably a hot pressing. Further, the semi-permeable membrane (2) is preferably elastic, non-porous and combined with a support sheet (3). The leather obtained by the process is also provided.

Owner:OUTDRY TECH

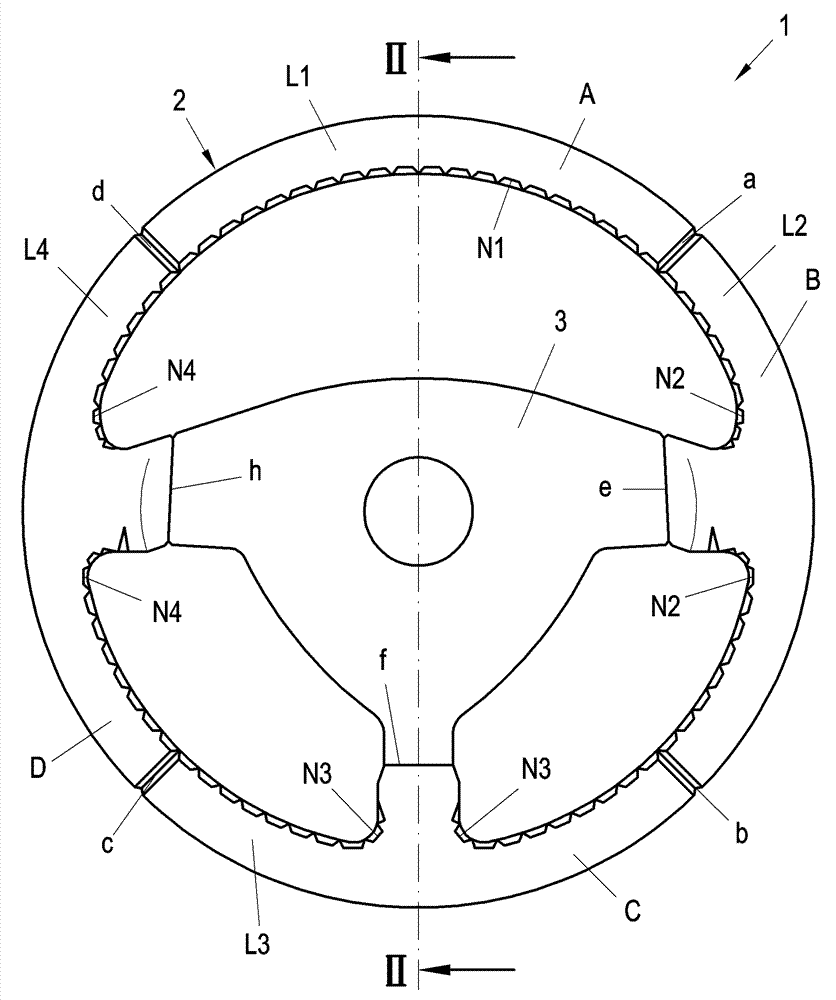

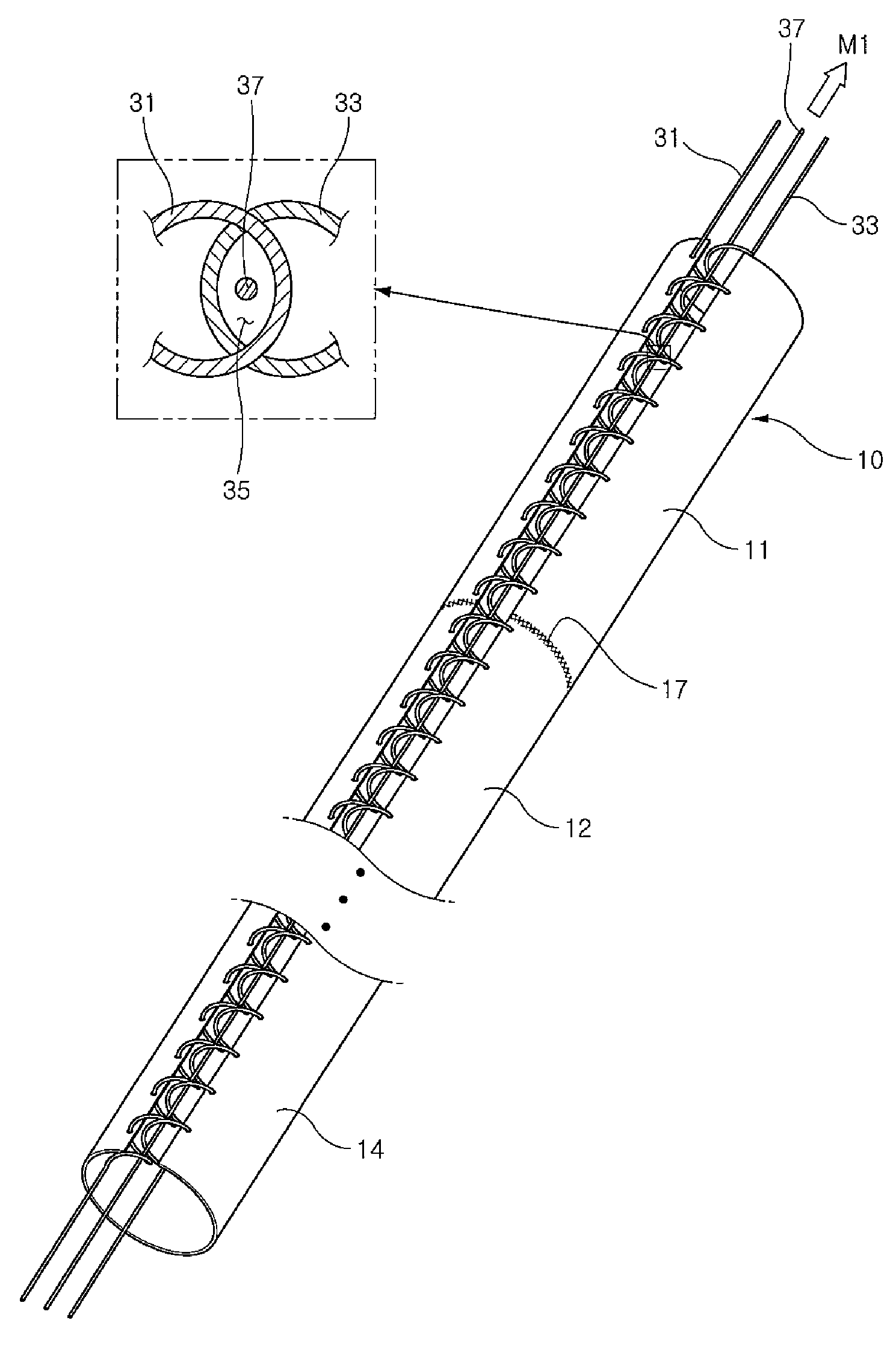

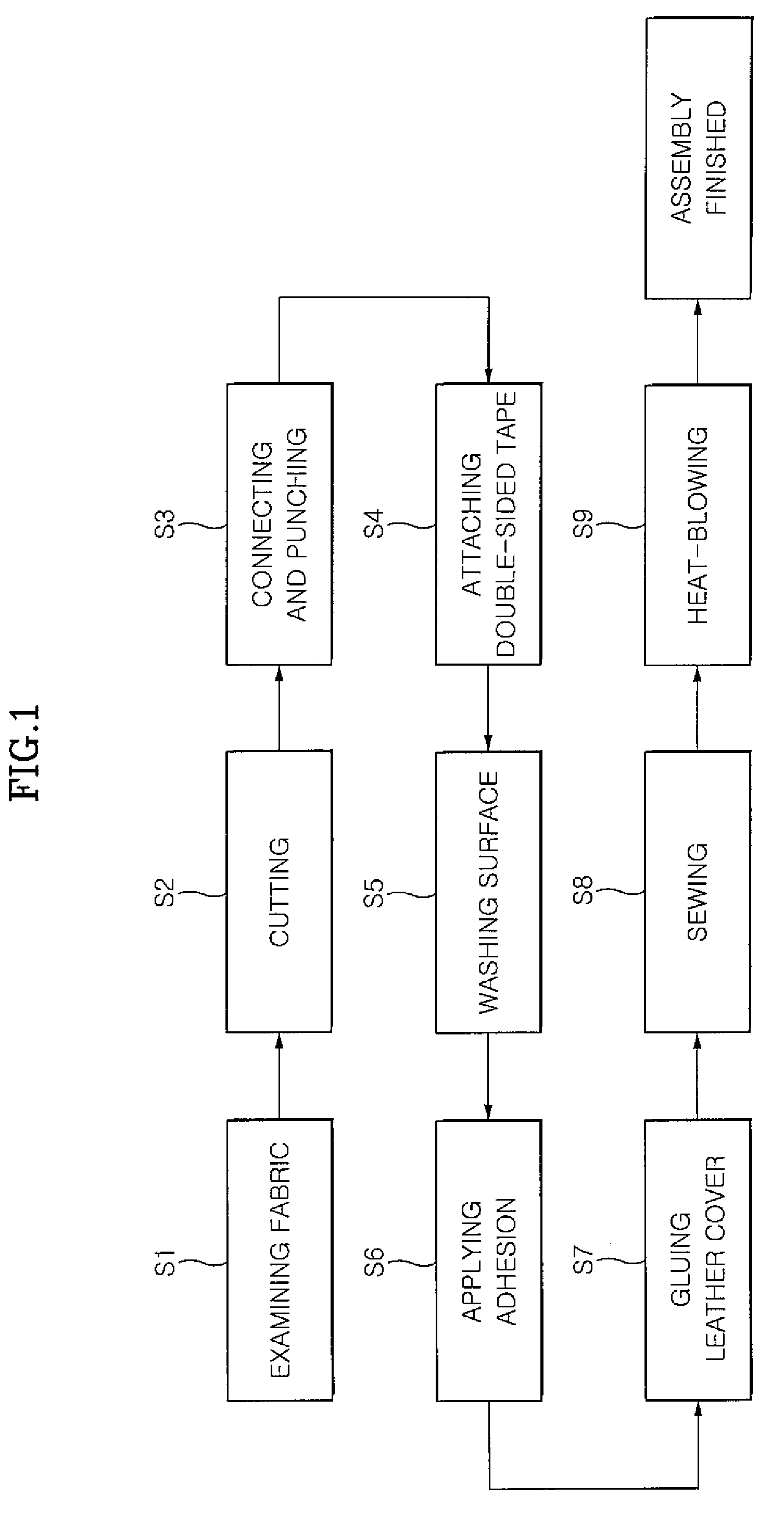

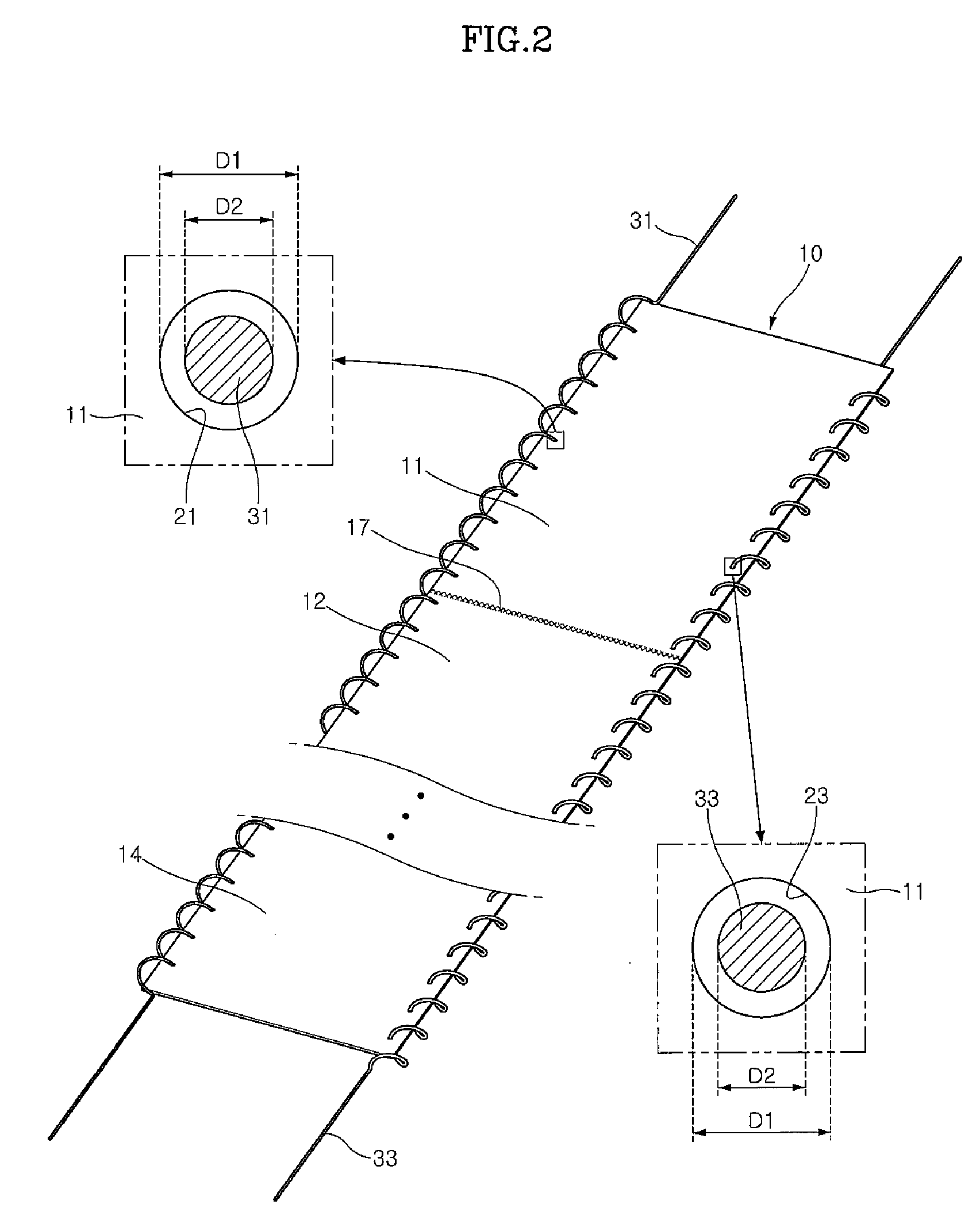

Method of assembling leather cover of steering wheel

InactiveUS20090265937A1Improve productivityLarge amount of cuttingHand wheelsVehicle design optimisationSteering wheelScrew thread

Owner:HYUNDAI MOTOR CO LTD

Leather article and method for its preparation, watch

ActiveCN110817786BImprove waterproof performanceGood weather resistanceBiochemical fibre treatmentLight resistant fibresWeather resistanceAlkoxy group

The invention relates to a method for preparing a leather watch strap, comprising the following steps: providing a leather product body; sequentially soaking the leather product body in a first treatment agent and a second treatment agent for ultrasonic treatment; and soaking the leather product body The leather product body is dried to obtain the leather product; wherein, the first treatment agent is a fluoroacrylate compound with a relative molecular weight of 200-400; the second treatment agent is a fluorocarbon-based trialkoxysilane , the relative molecular weight is 500-800. The invention discloses a leather watch strap and a watch. In the preparation method of the present invention, a structurally complete protective layer is formed on the surface of the leather product body, so that the leather product has good water resistance and has excellent antifouling, weather resistance, friction resistance, deodorization and self-cleaning properties.

Owner:ZHUHAI ROSSINI WATCH IND

Interior trim panel for a vehicle and method of forming same

PendingCN112622778ALiquid surface applicatorsSynthetic resin layered productsMechanical engineeringAutomotive engineering

An interior trim panel for a vehicle includes a leather layer defining a feature having a radius of less than five millimeters, and a backing layer adhered to the leather layer and providing a support structure for the leather layer. A method of forming the interior trim panel includes clamping the leather layer in a frame to securely fix the edges of the leather layer, positioning the leather layer between compression mold dies defining a complementary surface having a feature with a radius of less than five millimeters, and compressing the leather layer between the dies.

Owner:GM GLOBAL TECH OPERATIONS LLC

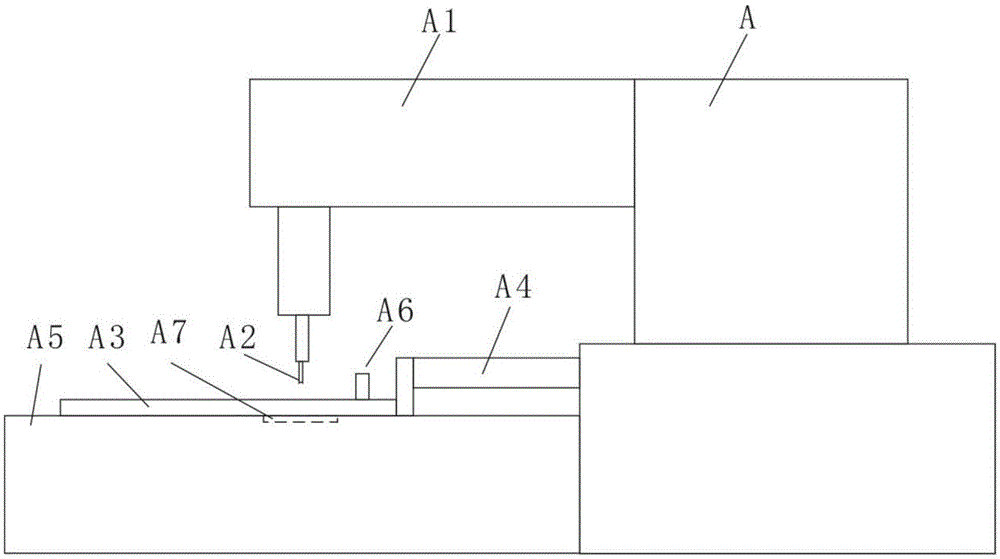

Single template button machine

ActiveCN104082890BEasy to operateIncrease productivityShoemaking devicesLeather articlesFixed framePass rate

The invention discloses a single-formwork button making machine which comprises a mainframe. The mainframe comprises a punch and a fixing frame, wherein the punch is installed on a machine head, and the fixing frame is installed on an X-axis moving frame and a Y-axis moving frame and located below the punch. A working table top is positioned below the fixing frame. A bottom module for being matched with the punch is arranged at the position of the working table top corresponding to the punch. The bottom module is provided with a foot curling bottom die for curling fastener paw parts is arranged on the bottom module, and the fixing frame is provided with a locating hole for locating and fixing a formwork module. Modified parts of the single-formwork button making machine are fewer, and compared with a newly developed button making machine, the single-formwork button making machine greatly reduces cost, saves time and is simple to operate. After the combination with a matched formwork, production efficiency is greatly improved, the fastener position error is 0.1 mm, fasteners are fixed firmly and are vertical and uniform in attitude, the paw parts of fasteners are just completely embedded in leather, the tail ends of paws are fully curled, and the pass rate is almost 100%. A die is provided with 1200-1400 fasteners, and the fasteners can be made in only 5 minutes.

Owner:四川非意欧国际皮革制品有限公司

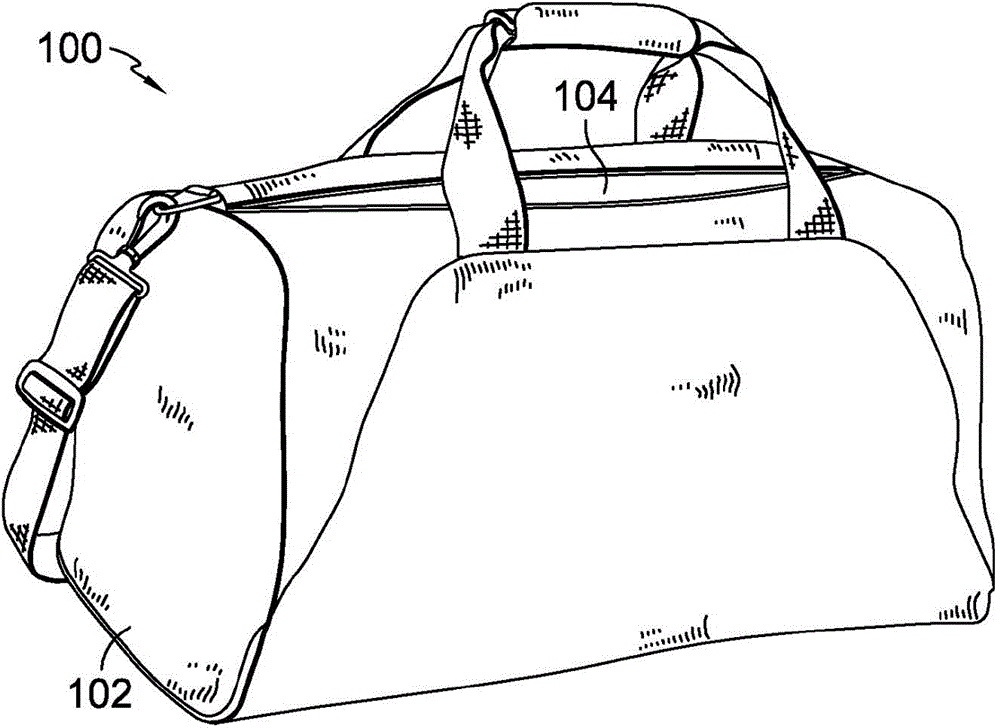

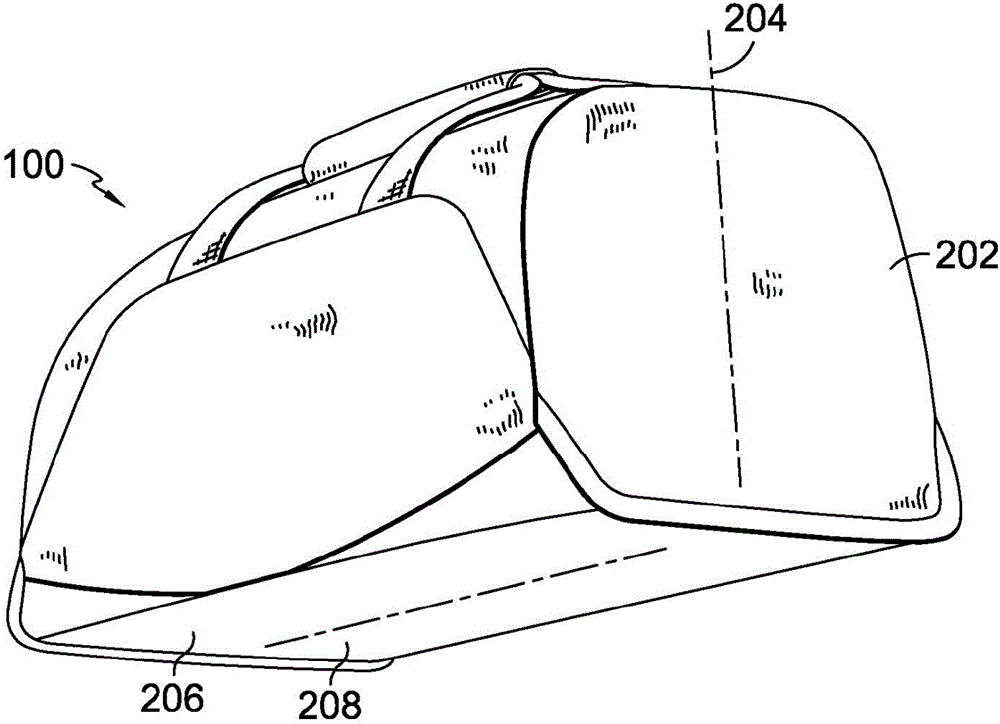

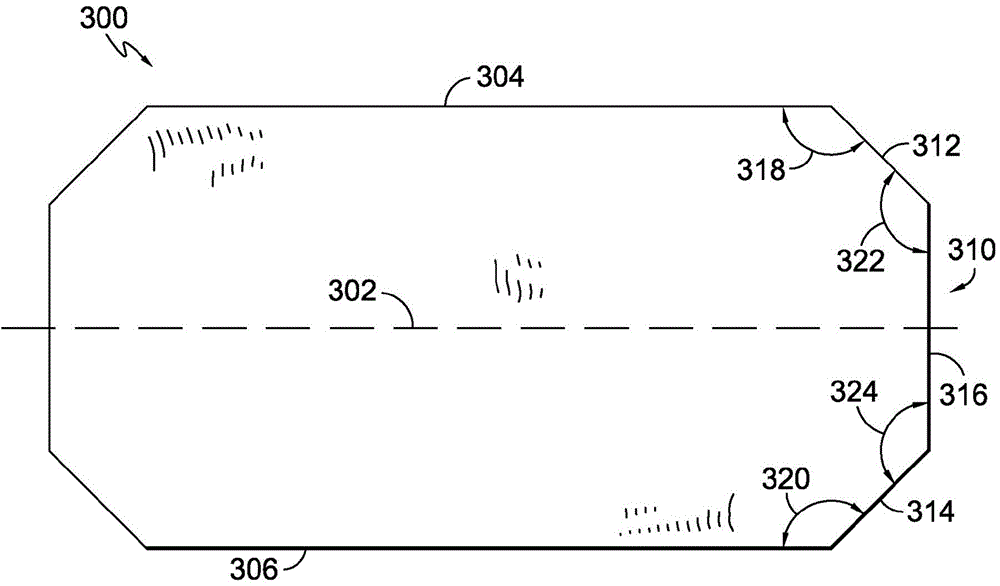

Three-dimensional bag with affixed seams

InactiveCN104582944ABag making operationsFlexible containers manufactureThermoplastic elastomerEngineering

A three-dimensional structure composed of pliable elements and having affixed seams is provided. The structure may comprise duffel bags, backpacks, shoe uppers, etc. The structure has a bottom panel with a first terminal bottom portion and a first end panel with a terminal end portion. As well, the first terminal bottom portion and the terminal end portion are affixed to each other in a flattened, two-dimensional arrangement by a variety of attachment methodologies including a thermoplastic elastomer strip. Two-dimensional construction saves time and helps to reduce manufacturing costs.

Owner:NIKE INNOVATE CV

Vacuum adsorption molding method for realizing continuous production

ActiveCN101830424BRealize continuous productionIncrease productivityLeather articlesProcess engineeringSingle station

The invention discloses a vacuum adsorption molding method for realizing continuous production, which aims to improve vacuum adsorption molding production efficiency. In the method, a baking station and a molding station are separately arranged to form double stations; and rear-section leather can be heated at the same time when front-section leather is molded so as to realize the continuous production and avoid the problem that a single station of conventional vacuum adsorption methods makes sheet heating and vacuum molding required to be sequentially performed to cause a relatively longer period. The method has the advantages of greatly shortening a molding period and improving molding efficiency.

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

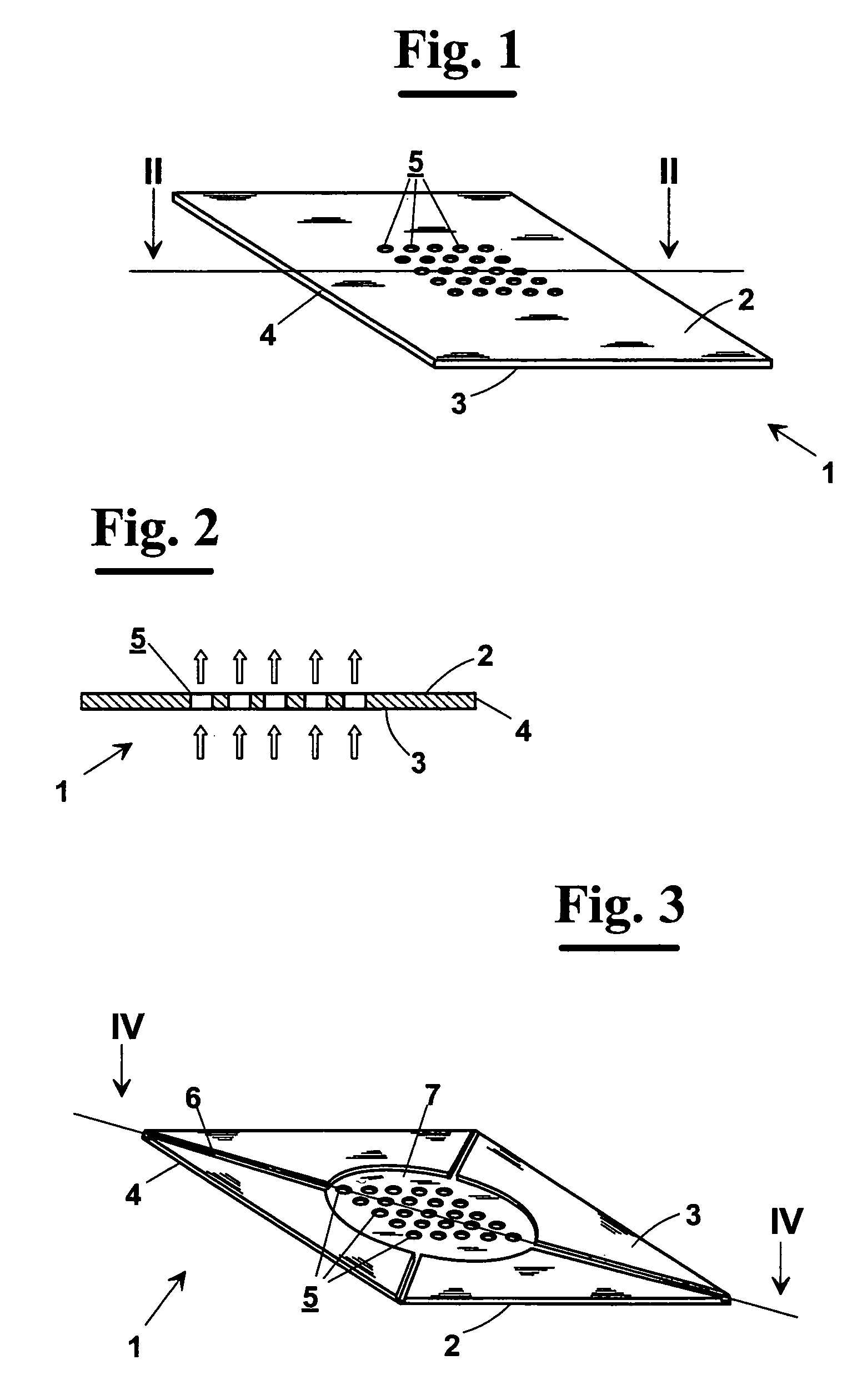

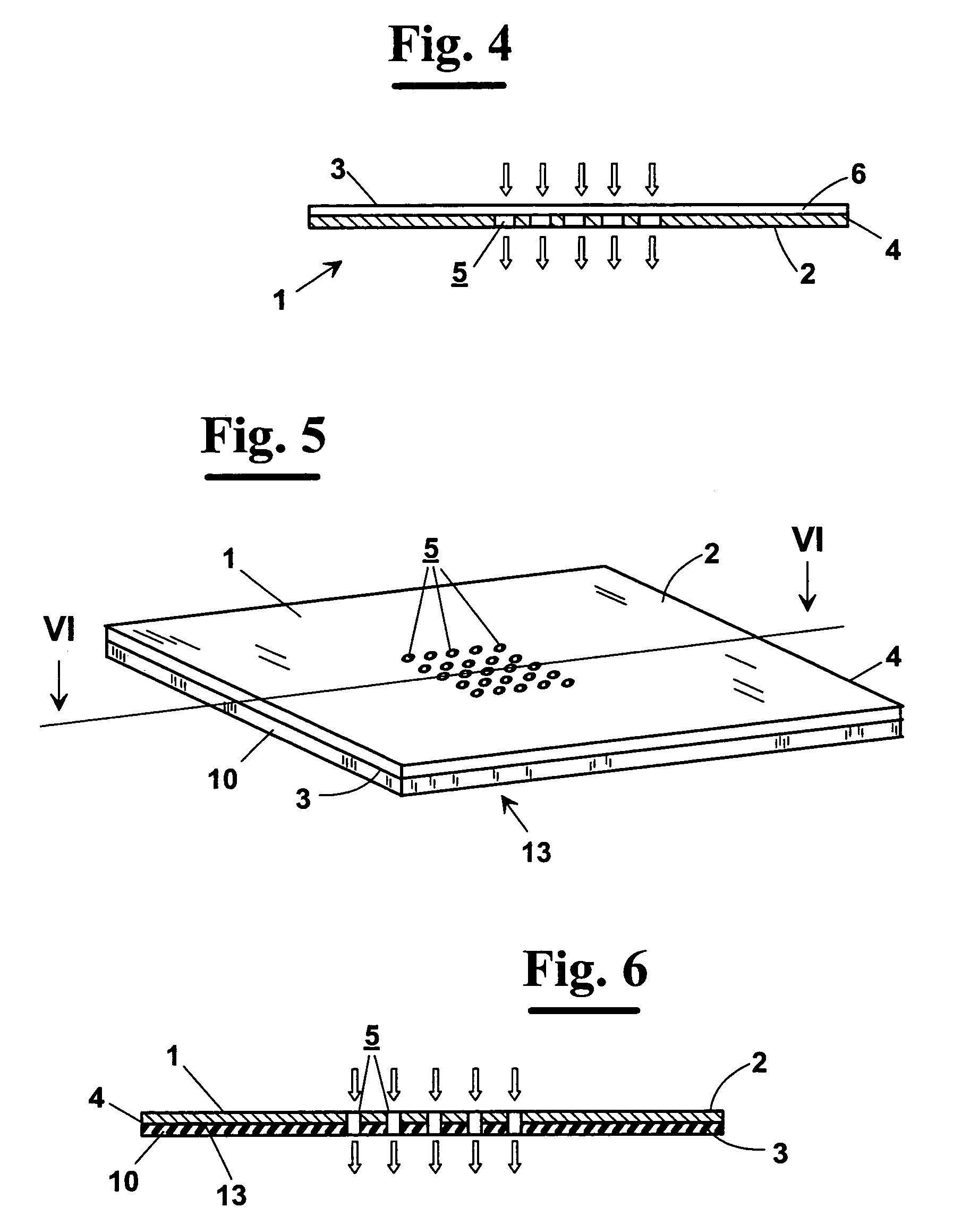

Tiles and method of making same

A tile, made for example of leather, having a first face, a second face, side edges and a plurality of holes that bring into communication first face with second face. In a lining made with such tiles like this, the holes lead the air from below to above the tiles. To improve further the air flow through the tile, on the second face a plurality of grooves are made that extend from a central zone up to the side edges of the tile. This way, an air path is formed between the lining and the floor leading the air to holes and then into the room at the side of first face. A favorable exchange rate through a floor lining made with them is obtained, combined with a heat exchanger embedded in the floor.

Owner:VAGNOLI IVANO

Automatic plush tidying and fur sewing machine

PendingCN112481838AInstalled and disassembledImprove work efficiencyLeather sewingWork-feeding meansEngineeringSewing needle

The invention discloses an automatic plush tidying and fur sewing machine, and belongs to the technical field of sewing equipment. The machine comprises a workbench (1); a material pressing assembly,a sewing needle (28) and a thread picking device (27) are arranged on the workbench (1); the material pressing assembly comprises a material feeding wheel (2) and a material pressing wheel (3) which are arranged on the workbench (1); the material feeding wheel (2) is matched with the material pressing wheel (3); an adjusting device (4) is arranged on the workbench (1); a material guiding device (5) is arranged at the feeding end of the material pressing assembly; the material guiding device (5) is rotationally arranged on the workbench (1); and an automatic plush tidying device (6) is arrangedbetween the material pressing assembly and the material guiding device (5), and comprises a plush shifting device (7) and a driving mechanism (8). The machine has the advantages that plush on the edge of fur is automatically tidied, so that the sewing position of a finished fur product is free of redundant plush, and the quality and attractiveness of the product are improved; and the position ofthe material pressing wheel (3) can be adjusted, so that the flexibility is improved.

Owner:阮雪福

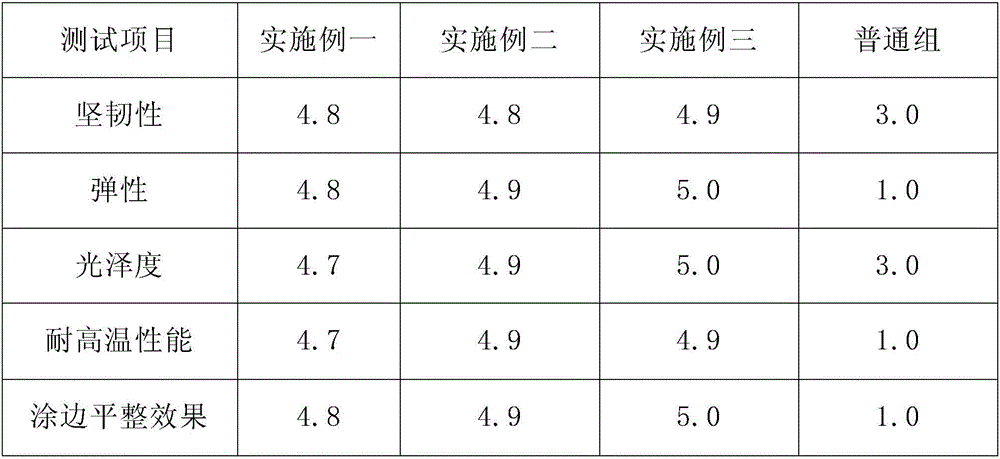

Leather product edge sealing agent and edge sealing method

The invention provides a leather product edge sealing agent and particularly relates to a leather product edge sealing coating. The leather product edge sealing agent comprises two leather layers and an extrusion layer. The extrusion layer is arranged between the two leather layers, the extrusion layer and the leather layers are connected through glue, an edge sealing layer is arranged on the tops of the leather layers, and the edge sealing layer is in an arc shape or is a smooth curve. High-solid-content polyurethane resin has the effects of enhancing the elasticity of the coating and improving toughness and being capable of adjusting the thickness and glossiness of the coating; a high-temperature-resistant slip sense additive has the effect of achieving a smooth and stiff effect after high-temperature edge ironing; a flatting agent has the effect of achieving a smooth effect after edge coating; a defoaming agent has the effect of avoiding bubbles in the edge sealing process; an associating assistant has the effect of being capable of adjusting the viscosity of a product and improving the stability of various substances in the formula; a film drying preventing additive has the effect of being capable of preventing the coating from being sun-cracked during high-temperature edge ironing. The edge sealing time can be shortened through the edge sealing coating, edge sealing is rapider, and the edge sealing process becomes simpler.

Owner:张朋飞

Case forming method

InactiveCN1736697AThe center point of the structure is stableNot easy to dumpBoxes/cartons making machineryLeather articlesEngineering

Owner:NEWCOMER GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com