Leather and leather manufacturing method

A technology of leather and raw materials, applied to leather, steering controls and control devices mounted on cars, etc., can solve the problems of steering wheel appearance deterioration, deterioration, fingertip stuck feel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

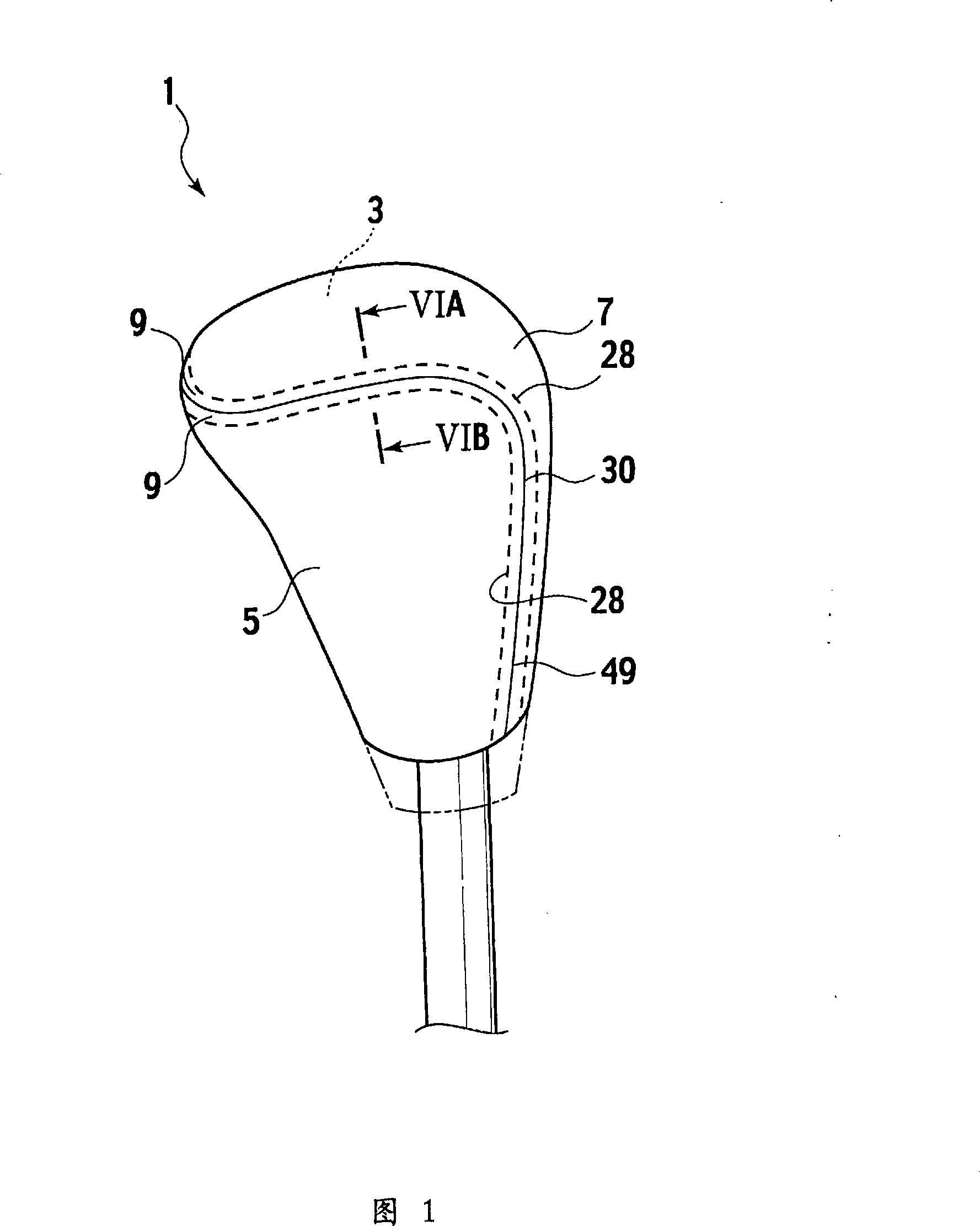

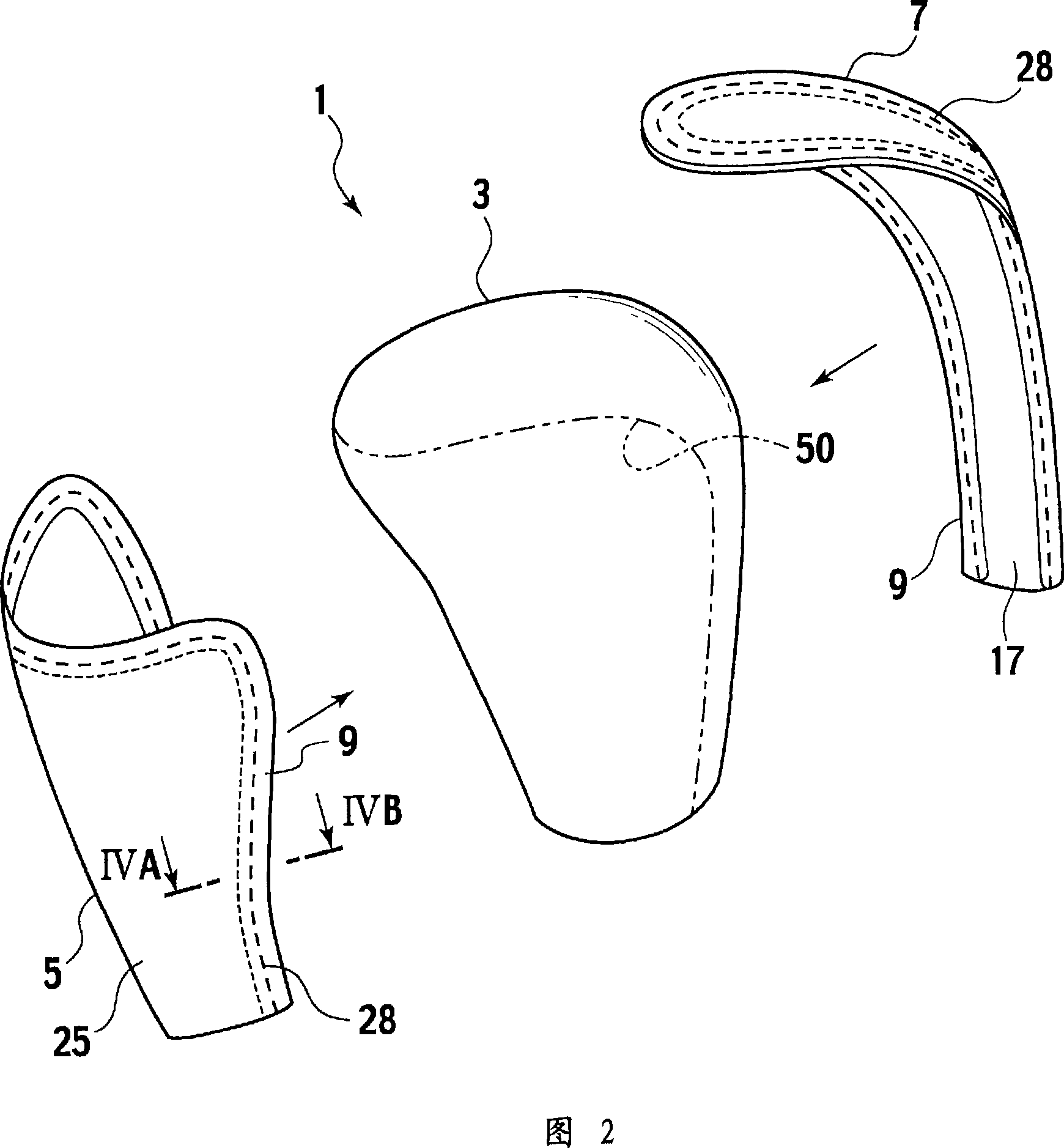

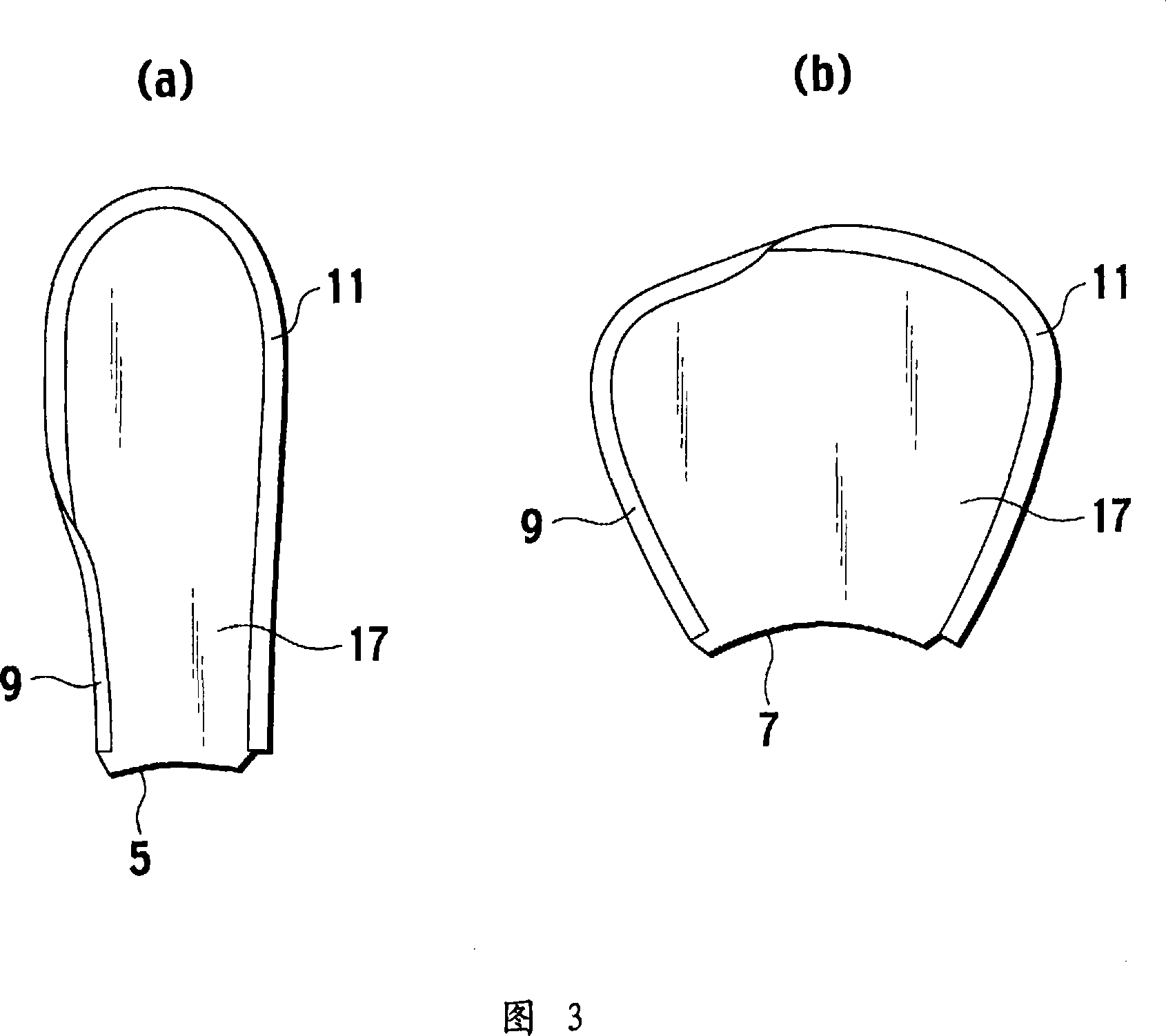

[0040] Fig. 1 is a diagram showing a schematic configuration of a shift lever 1 according to a first embodiment of the present invention, and Fig. 2 is a diagram showing a state in which the shift lever 1 is disassembled.

[0041] The shift lever 1 is, for example, a member used for being attached to the front end of a shift lever of a transmission of an automobile or a front end of an operating lever of a parking brake of an automobile, and has a core material (trunk) 3 constituting a main body, and the above-mentioned core material 3 Cover with leather 5 and leather 7. Moreover, the above-mentioned core material 3 is formed using the existing technology. That is, the core material 3 covers the core shaft with resin such as urethane resin, and the core shaft and the urethane resin are integrally formed.

[0042] In more detail, in a state where the end edges of the leathers 5 and 7 are butted (in contact), the backs of the leathers 5 and 7 (the core material 3 side of the leather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com