Case forming method

A molding method and technology of bags, which are applied in the field of bags, can solve the problems of increasing the volume of bags, complicated manufacturing process, and easy dumping of the box body, and achieve the effects of reducing the external volume, stabilizing the central point of the overall structure, and not being easy to dump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

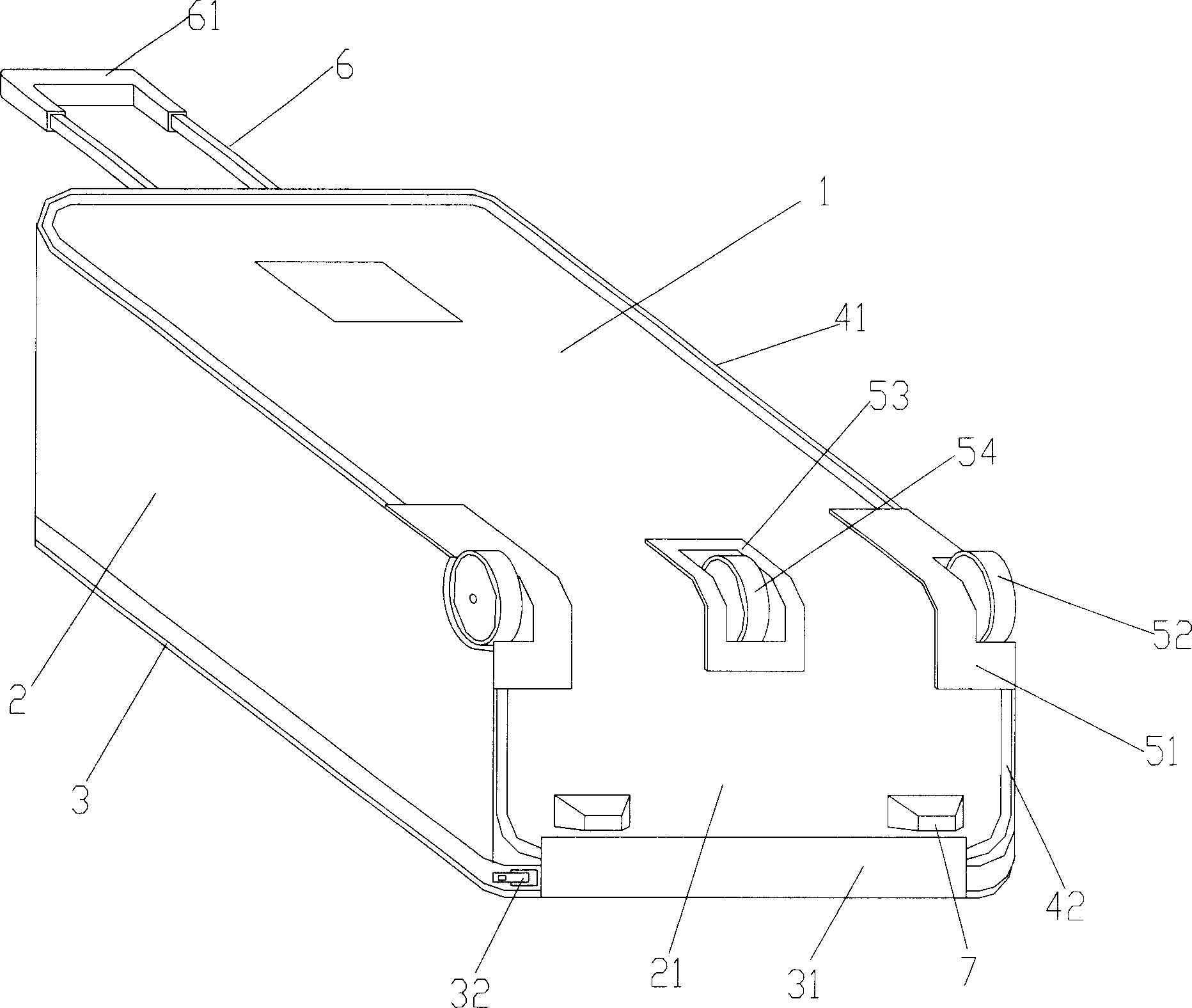

[0010] The invention relates to a luggage molding method, which adopts the method of combining front and rear molding and side molding. The bottom 1 of the box is integrated with one side 21 of the box body 2, and the other three sides of the box body 2 are integrated.

[0011] Such as figure 1 Shown is a schematic structural view of the finished case and bag in a method for forming a case and bag according to the present invention, which includes a case bottom 1, a case body 2 and a case cover 3, and generally uses hard materials to make a skeleton first, and the skeleton is generally a cuboid structure, or basically Rectangular, but all or part of the side and feet are designed with arcs to increase the aesthetic feeling of the entire box. The material is required to be relatively strong and able to withstand a certain extrusion force. After the skeleton and raw materials are ready, it can be stitched and formed. The forming process is to make the lining cloth first, then ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com