Hand-knitted bag production method

A production method and hand-woven technology, applied in handbags, woven fabrics, chemical instruments and methods, etc., can solve the problems of low product wear resistance, high product defect rate, and no further processing of leather materials, and achieve good results. , The effect of reducing the defect rate and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

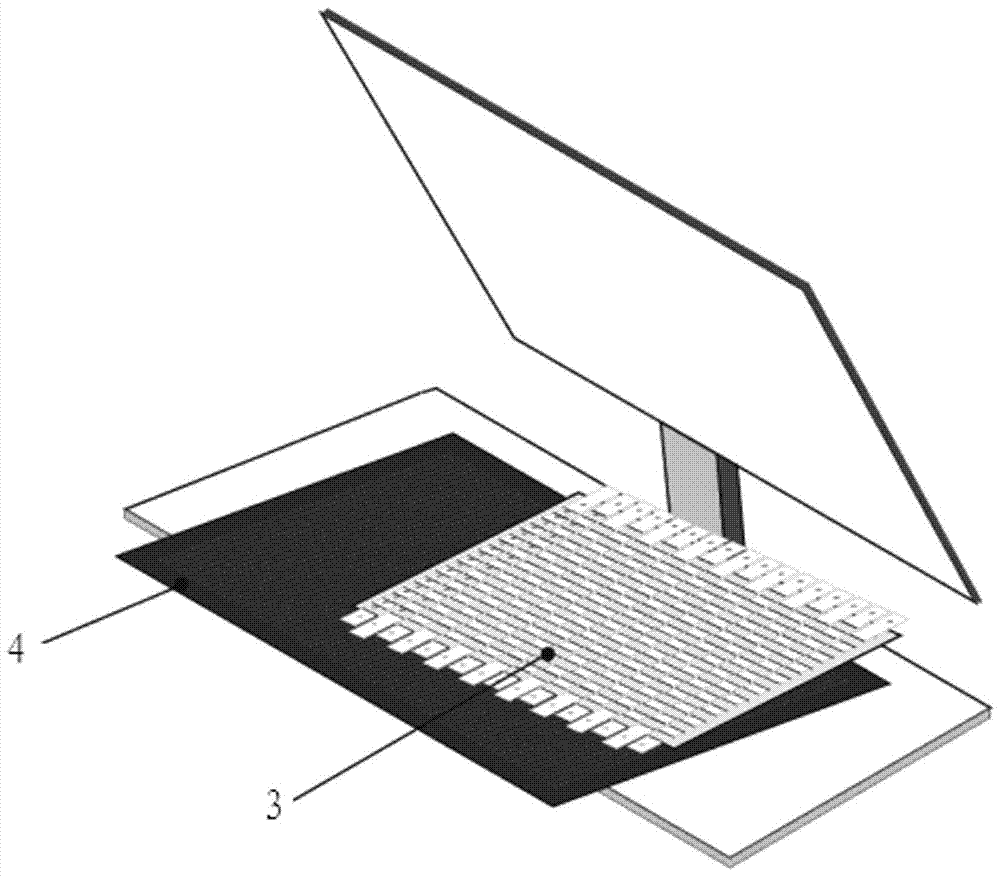

[0025] A method for producing hand-woven bags,

[0026] The first step is to cut the fabric B into strips with a precision slitting machine. If the fabric B is made of leather, it needs to be shoveled before cutting. If the fabric B is made of fabric, you can directly use the precision slitting machine cut into strips;

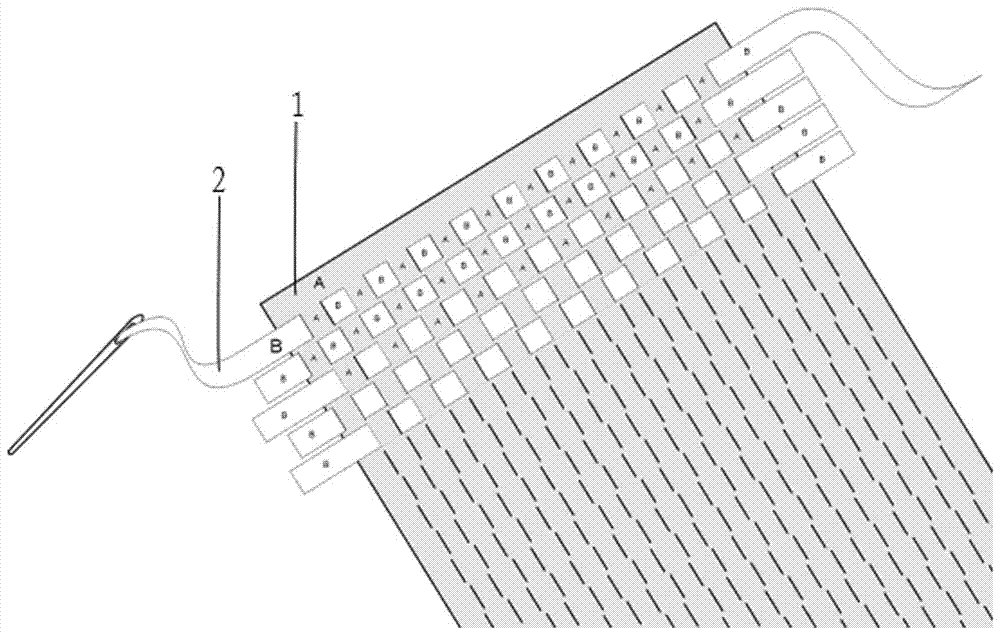

[0027] The second step is to use laser punching to laser out the fabric A with multiple rows of regularly arranged holes;

[0028] In the third step, the holes in each row of fabric A are inserted up and down sequentially through the strip fabric B, that is, the strip fabric B is woven into the fabric A; different from the traditional weaving method, the effect of the traditional weaving method is not ideal. If you don't pay attention to the strength, there will be deformation; if you use this method to weave, the shape is regular and neat;

[0029] The fourth step is to cut the woven fabric A and fabric B into the required shape by cutting with a key knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com