Process for waterproofing leather and leather obtd. by means of said process and shoes containing said leather

A waterproof treatment and leather technology, applied in the waterproof field of leather, can solve the problem of reducing emission performance and achieve the effect of maintaining comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

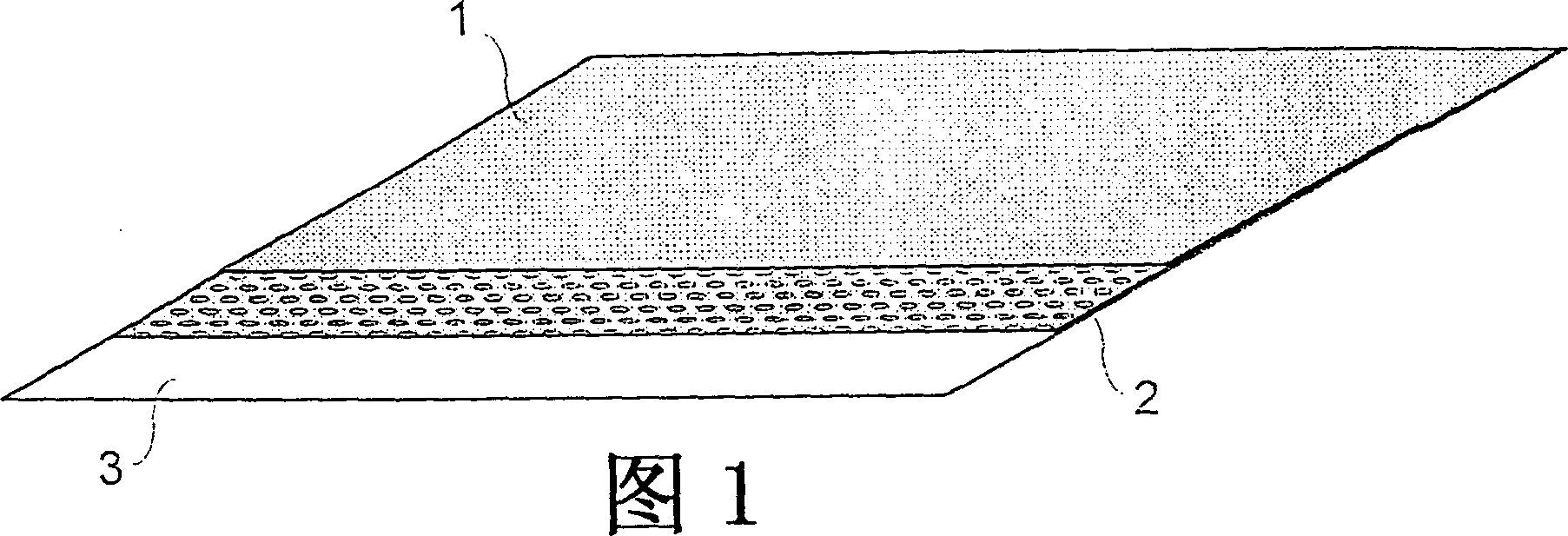

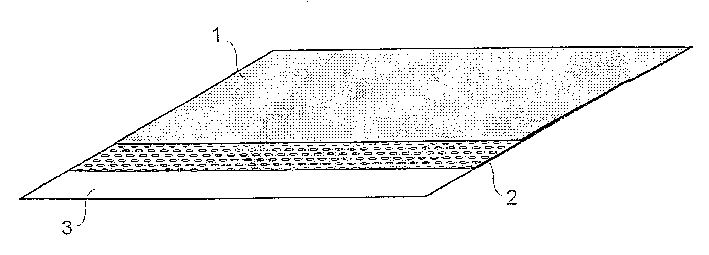

[0026] Other advantages and characteristics of the method of the present invention will become apparent to those of ordinary skill in the art from the following detailed description of one embodiment of the method of the present invention with reference to the accompanying drawings.

[0027] With reference to the figure, said embodiment of the method consists in applying to leather 1 at least one semipermeable membrane 2 completely covering the inner surface of said leather 1 . The application method is carried out by pressing (preferably hot pressing) the entire hide and film with a flatbed or roller press with a heating system. In practice, that surface of the membrane 2 that is in contact with the leather 1 has a pattern of hot-adhesive glue, preferably formed by a number of polyurethane glue dots with a diameter between 0.1 mm and 0.8 mm and a density of 50 points / cm 2 -200 dots / cm 2 . By heating the film 2 during pressing, a good adhesion to the leather 1 is obtained w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com