Bag production line

A production line and bag technology, applied to handbags, luggage, leather, etc., can solve problems such as low work efficiency, waste, and many defective products, and achieve the effects of saving labor, improving production efficiency and quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

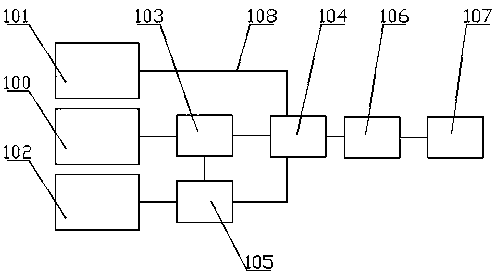

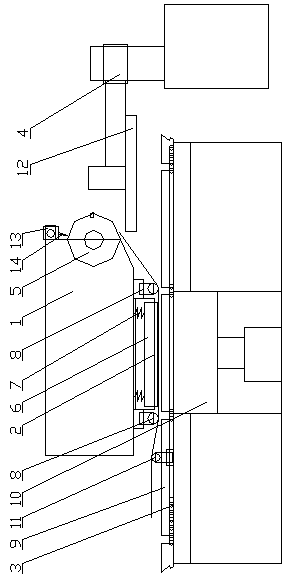

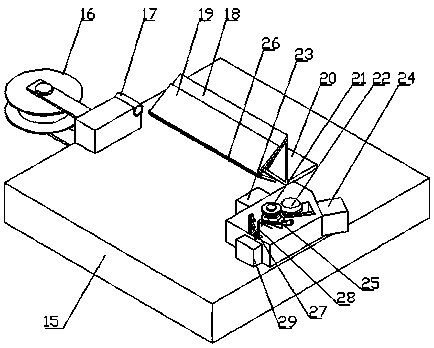

[0022]As shown in the drawings, the present invention includes a fabric die-cutting machine 100, a steel wire skeleton wrapping machine 101, a lining grinding machine 102, a seaming machine 103, a seaming machine 104, a lining sewing section 105, an assembly sewing section 106 and rollers Between the fixed riveting section 107, between the fabric die-cutting machine 100, the overlocking machine 103, the overlocking machine 104, the assembly and sewing section 106, the roller fixed riveting section 107, between the steel wire skeleton wrapping machine 101 and the overlocking machine 104, the inner lining Between the grinding machine 102, the lining sewing section 105, and the hemming machine 104, a belt conveyor 108 is arranged between the seaming machine 103 and the lining sewing section 105; Die 2, chain conveyor 3 and unloading manipulator 4, one end of the hydraulic upper mold base 1 is provided with a side material take-up roller 5, a stripper plate 6 is provided in the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com