Belt conveyer rectification buffer

A technology of belt conveyors and buffers, applied in the field of deviation correction buffers, which can solve the problems of inability to resist the impact of large materials, unsatisfactory buffering effects, and high rigidity of buffering parts, and achieve simple and reliable buffering process, simple structure, and improved force The effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

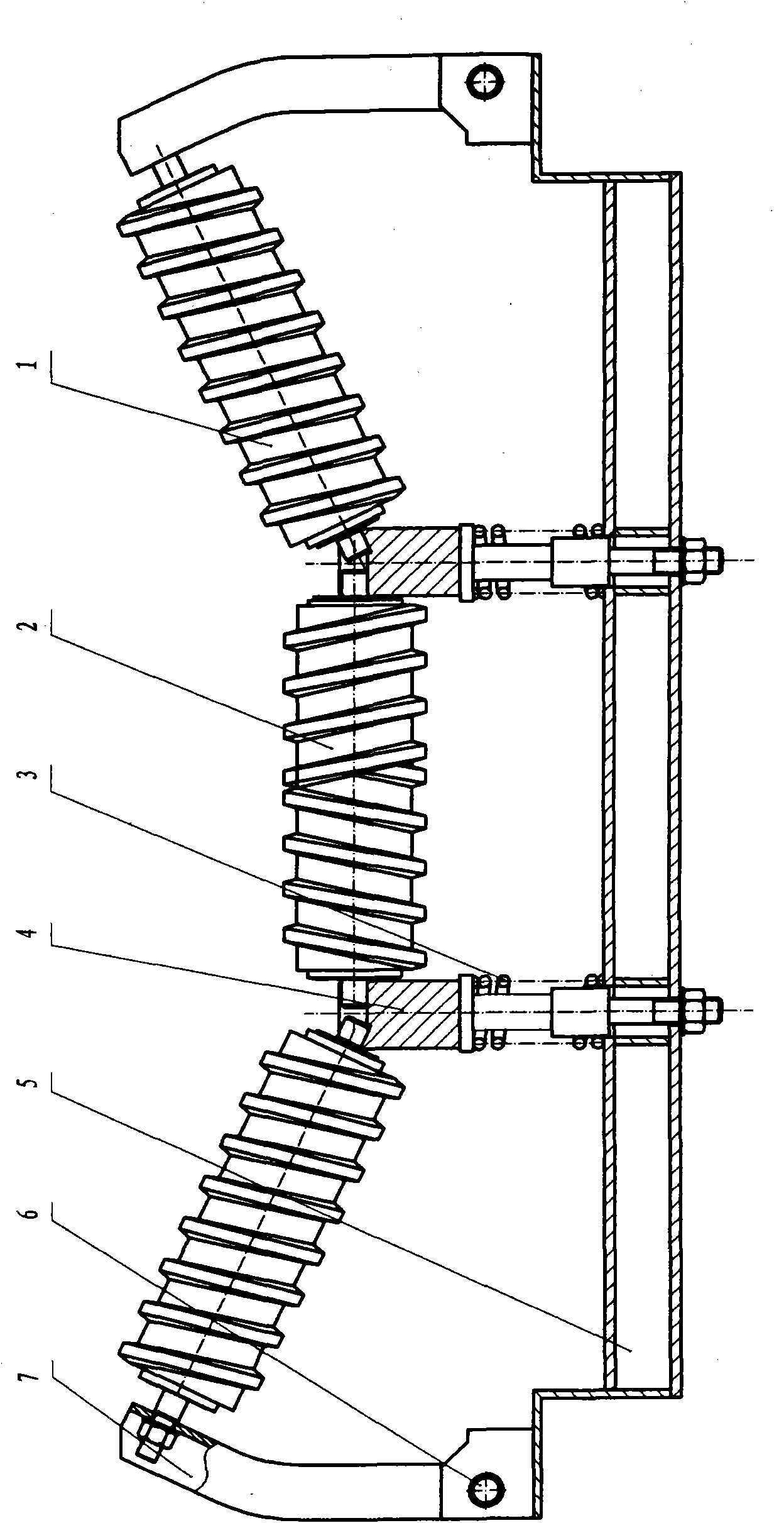

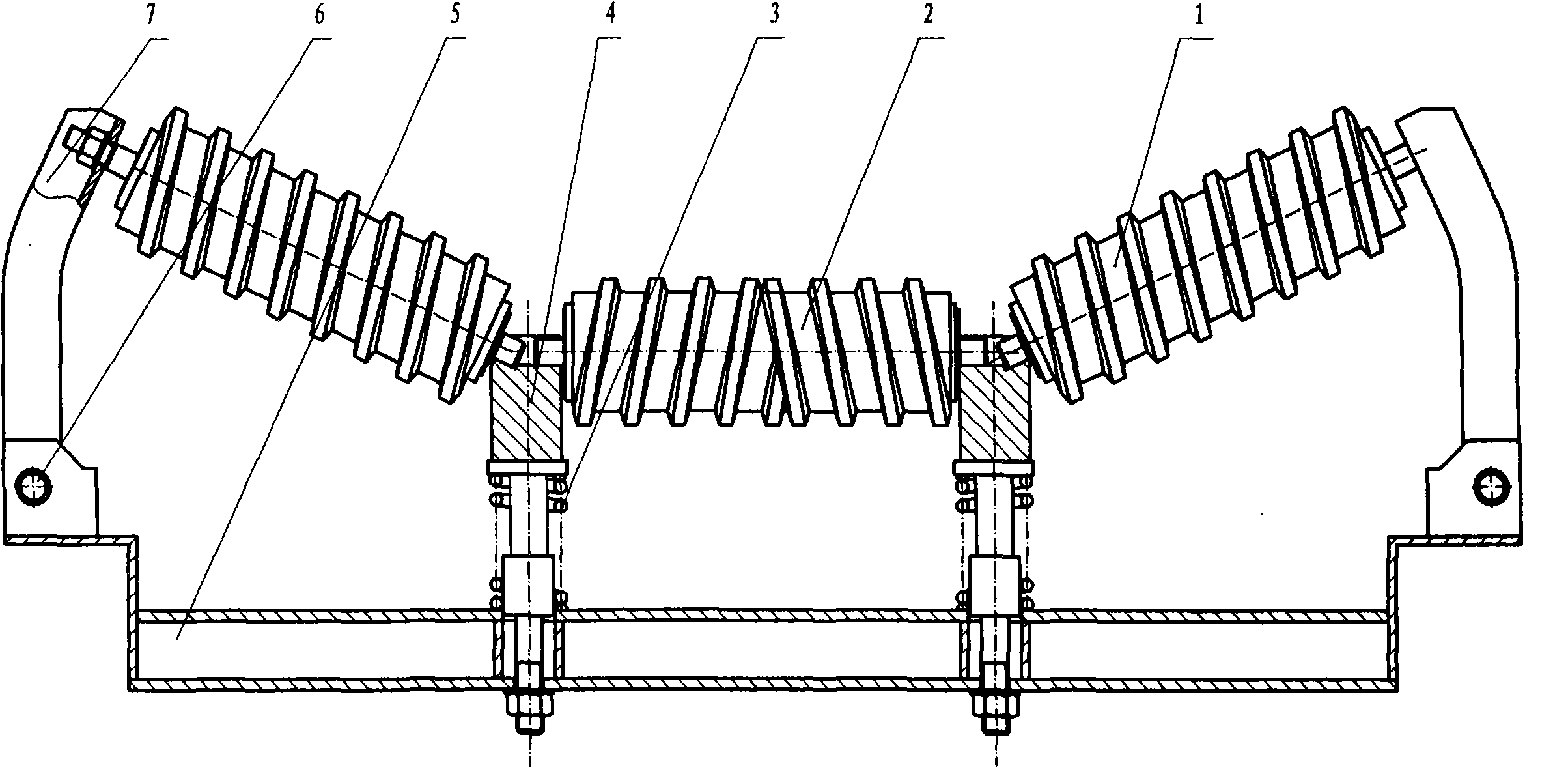

[0018] Such as figure 1 Shown, the present invention is made of a pair of side buffer rollers 1, a middle buffer roller 2, two buffer springs 3, two buffer seats 4, a frame 5, two bearing pins 6, and a pair of side supports 7. The middle buffer roller 2 is installed in the middle of two two buffer seats 4, and the side buffer roller 1 is installed on the side brackets 7 and buffer seats 4 on both sides, and the buffer seat 4 is supported on the frame 5 by the buffer spring 3 , the lower ends of the two side brackets 7 are respectively connected to the two ends of the frame 5 by pin shafts 6, and the side brackets 7 can rotate around the pin shafts 6.

[0019] The side buffer idler 1 is a pair of spiral rubber rollers with opposite rotation directions, and the spiral rotation is opposite, evenly facing the forward direction of the belt; the middle buffer idler 2 is a rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com