Multistage transmission

A transmission and clutch technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reducing the volume and weight, shortening the axial length, etc., and achieve the effect of shortening the axial length and reducing the sliding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

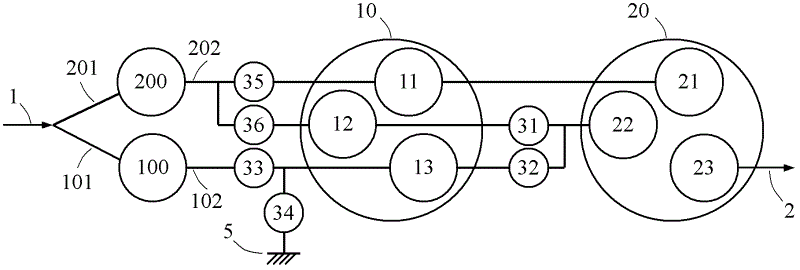

[0036] Embodiment one: if Figure 4 , implemented according to technical solution 1; the transmission shaft connected to the input member 1 of the transmission constitutes the first power transmission mechanism 100; the second power transmission mechanism 200 is composed of a double pinion type planetary gear set 120, and its sun gear The input part 201 constituting the second power transmission mechanism 200, and the ring gear constitute the output part 202 of the second power transmission mechanism 200, and its planet carrier is connected with the transmission housing 5, and the ring gear of the planetary gear set 120 is connected to the input 1 of the transmission. Fixed transmission ratio; the first planetary gear set 10 is a single pinion planetary gear set 10_1, the ring gear of which constitutes the first rotating element 11, the sun gear constitutes the second rotating element 12, and the planetary carrier constitutes the third rotating element 13 ; The second planetar...

Embodiment 2

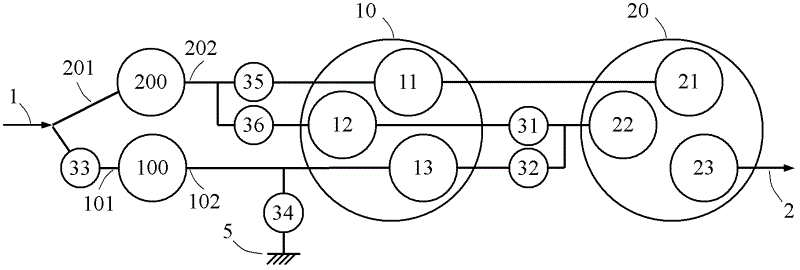

[0040] Embodiment two: if Figure 5 , which is a two-shaft arrangement in Embodiment 1; the first and second power transmission mechanisms 100 and 200 are each a gear set composed of a pair of intermeshing driving and driven gears, and the first and second power transmission mechanisms The driving gears 105, 205 or the connecting shafts of the gears of the transmission mechanisms 100, 200 respectively constitute the respective input components 101, 201 of the first and second power transmission mechanisms 100, 200, and the first and second power transmission mechanisms 100, 200 The respective driven gears 106, 206 or the connecting shafts of the gears constitute the respective output members 102, 202 of the first and second power transmission mechanisms 100, 200; the first and second planetary gear sets 10, 20 and the The first and second clutch shift elements 31, 32 are the same as the first embodiment, and are arranged on the axes of the driven gears 106, 206. The third, fou...

Embodiment 3

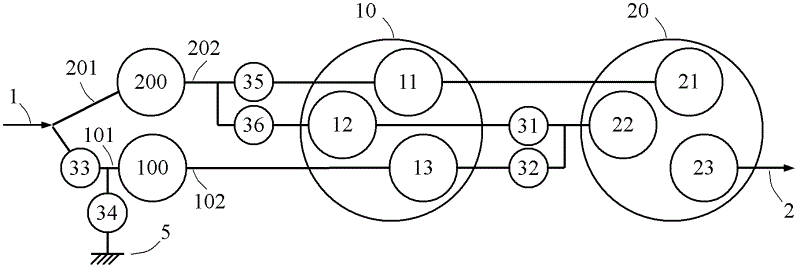

[0041] Embodiment three: as Image 6 , implemented according to technical solution 1; the first and second power transmission mechanisms 100, 200 are the same as the first embodiment; The rotating part 11, the sun gear constitute the second rotating part 12, and the ring gear constitutes the third rotating part 13; the second planetary gear set 20 is a double pinion type planetary gear set 20_2, and its planetary carrier constitutes the first rotating part 21, The sun gear constitutes the second rotating part 22, and the ring gear constitutes the third rotating part 23; each clutch shifting element is also the same as in Embodiment 1; the following is a gear table for each planetary gear set with an appropriate gear ratio:

[0042]

[0043] K 10 =3.600,K 20 =2.333, K 120 =2.250

[0044]Referring to Embodiment 2, this embodiment can also be changed to a two-axis arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com