Tubular belt transverse stiffness test device

A technology of transverse stiffness and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, instruments, etc., can solve the problems of difficult and inaccurate testing of transverse stiffness, and achieve the effects of adjustable measurement range, reliable measurement data and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

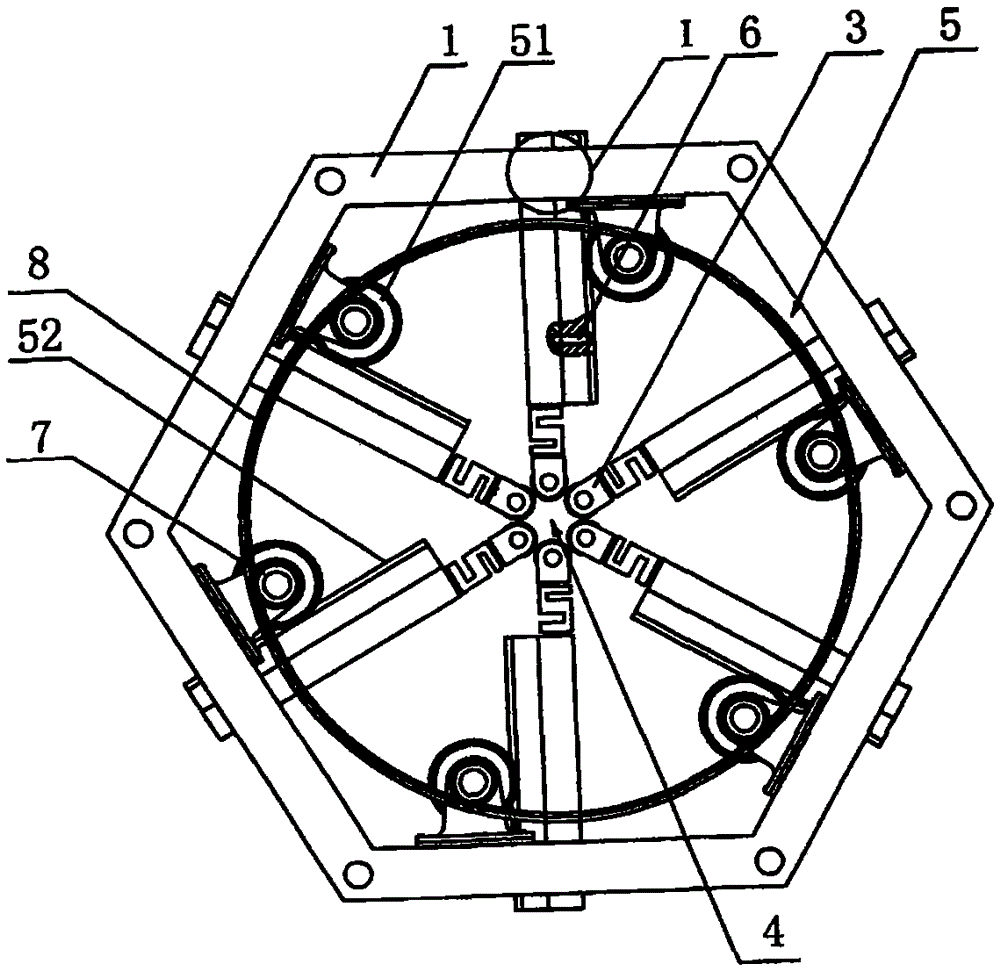

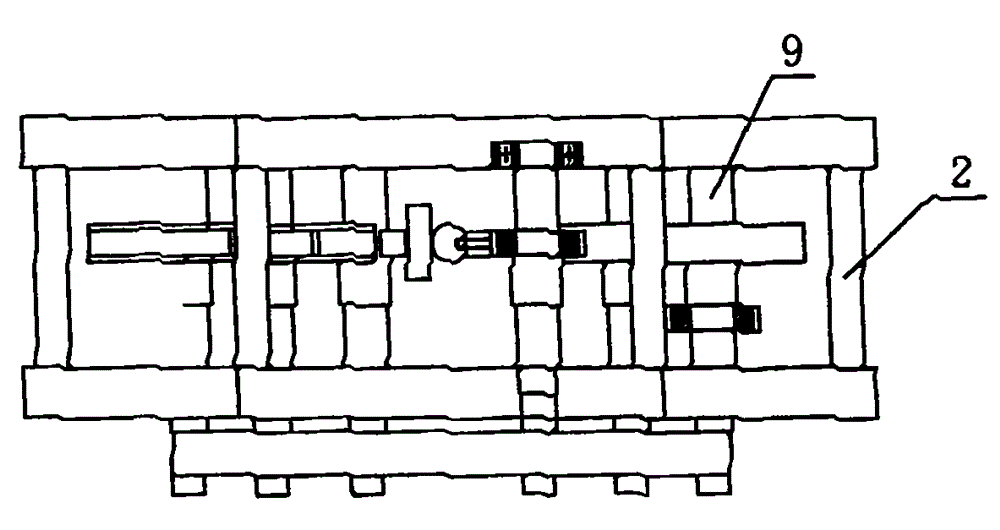

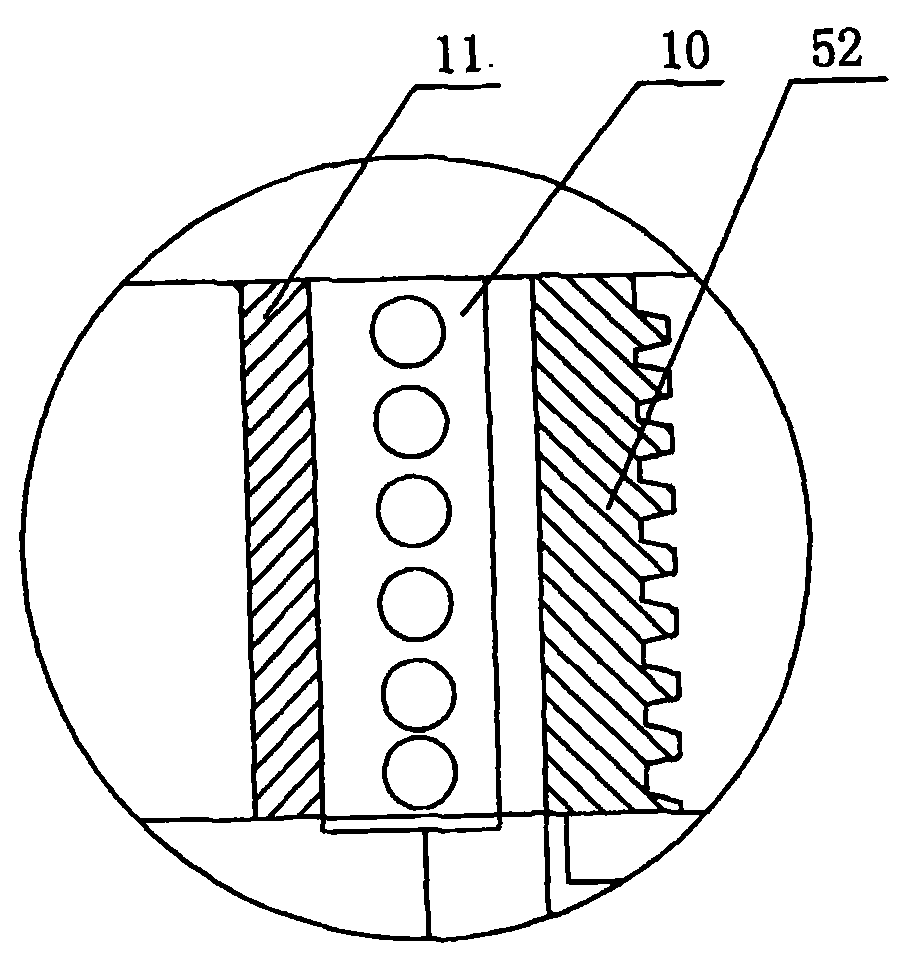

[0014] Such as figure 1 , 2 , Shown in 3, content of the present invention mainly comprises mechanical part and control part:

[0015] Mechanical part: The overall structure adopts a regular hexagonal structure, which can simultaneously measure the transverse stiffness of tubular strips of all sizes within the diameter range of 100mm to 850mm. The mechanical transmission structure realizes the modular structure, and uses six sets of gear transmission and belt transmission to realize the simultaneous measurement of six measurement points.

[0016] Control part: A single motor is used to drive six sets of measuring structures, and pressure sensors are used to measure six-point lateral stiffness. PLC controls the action of the measuring device to achieve synchronization and accuracy of action. The measured pressure signal is imported into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com