Patents

Literature

30results about How to "Optimized gear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

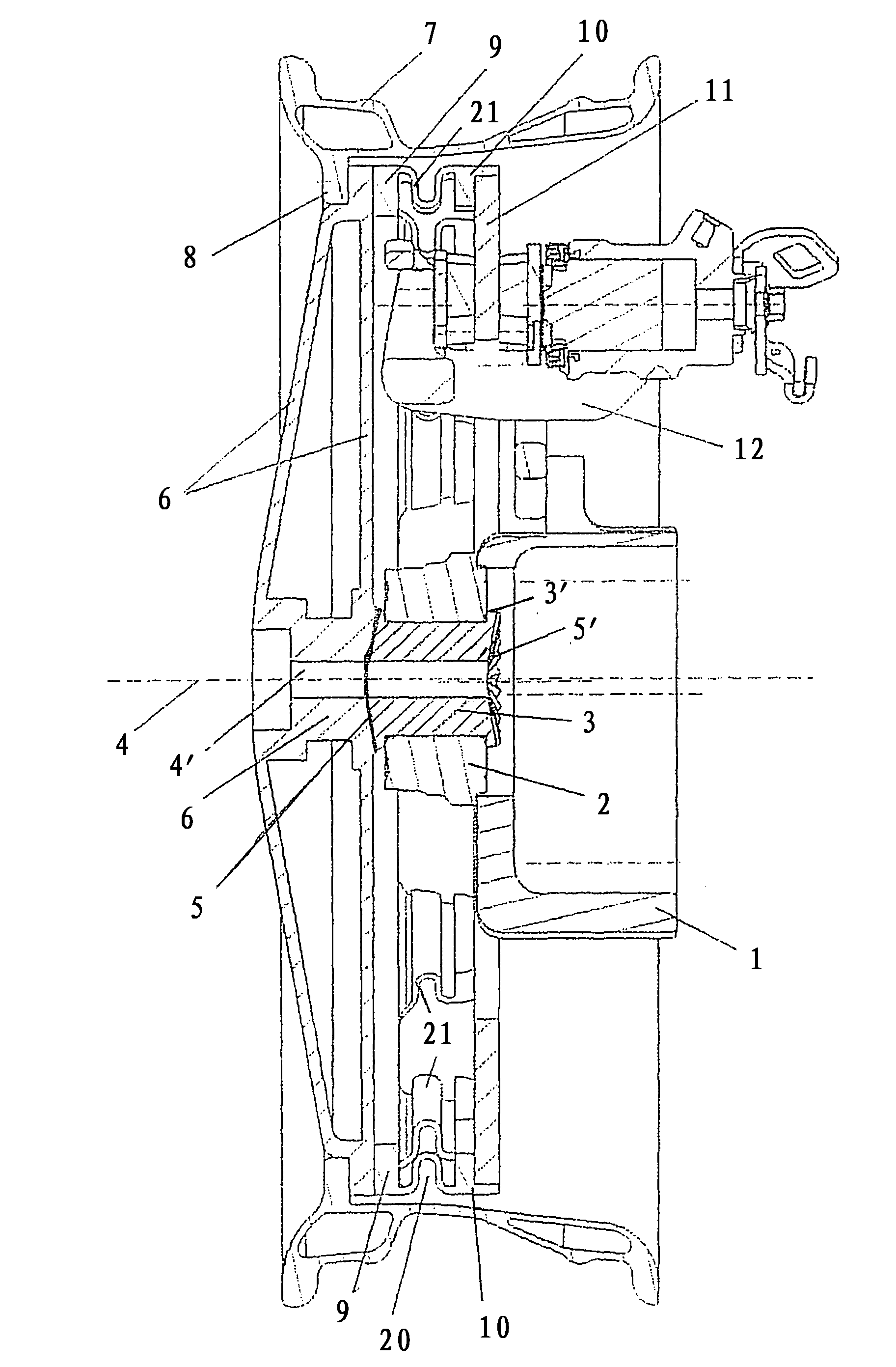

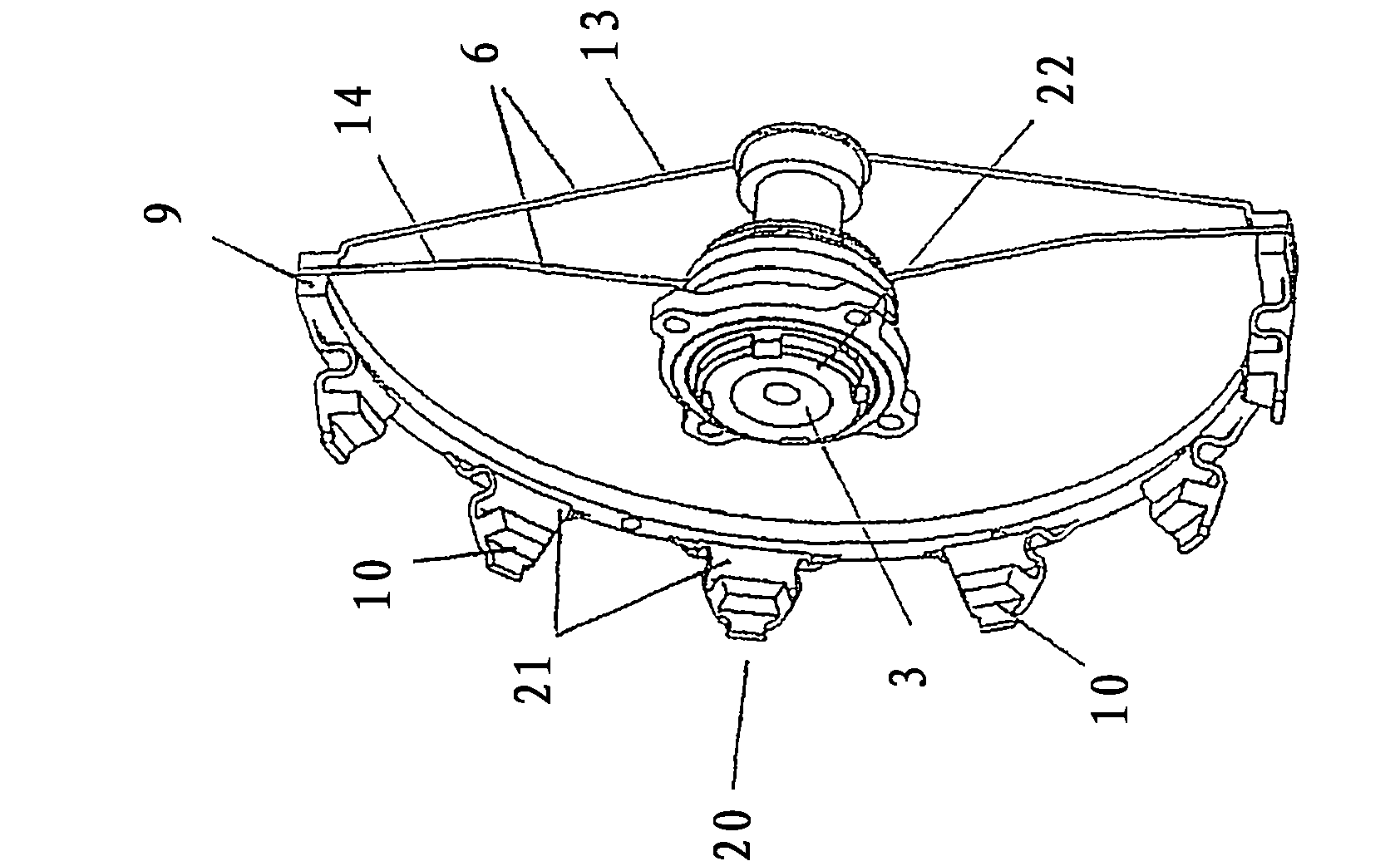

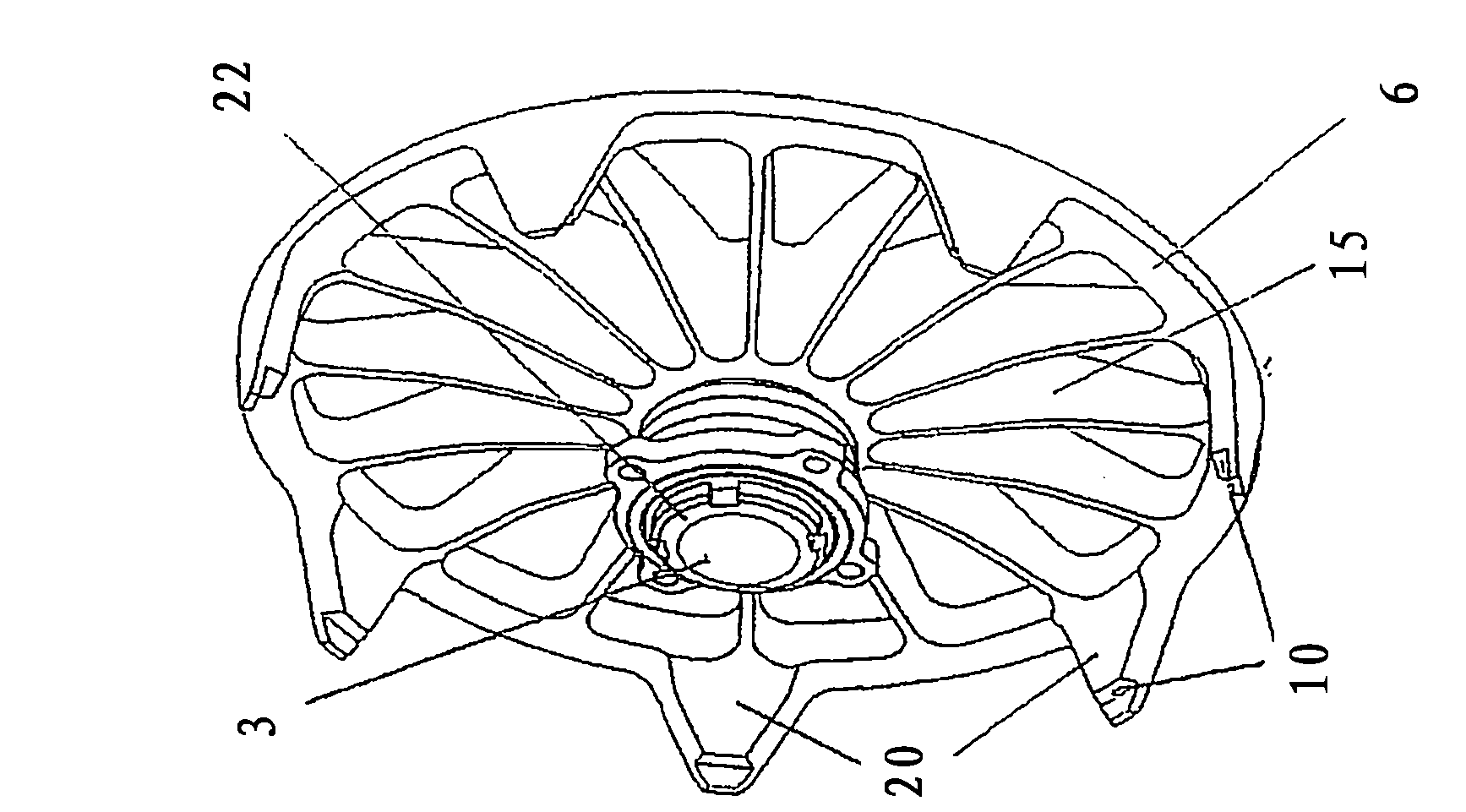

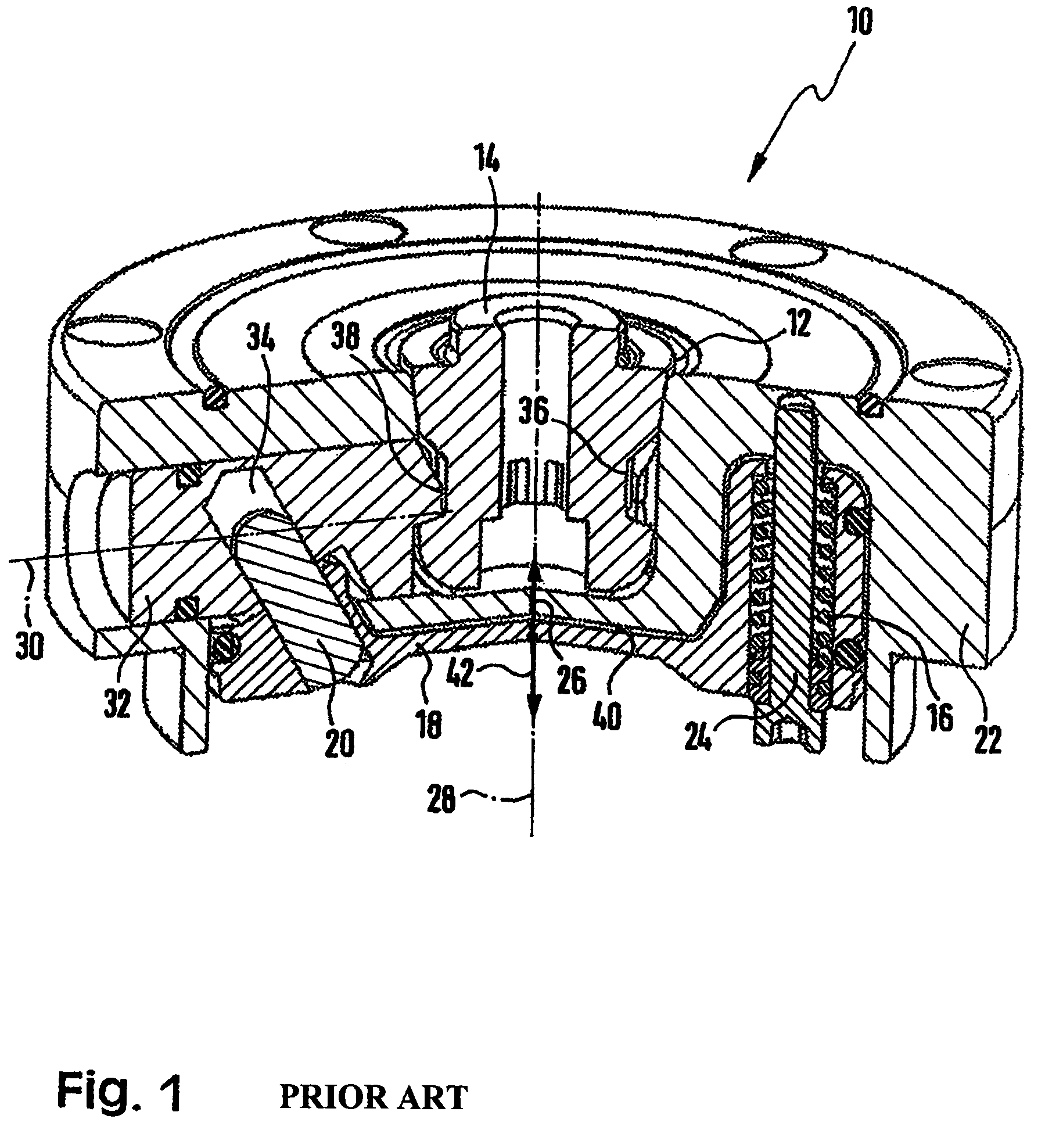

Wheel assembly for motor vehicle

InactiveCN103038070AWeight advantageReduce weightBraking element arrangementsAxially engaging brakesCalipersMotor vehicle crash

The invention relates to a wheel assembly for mounting a motor vehicle wheel on one side, comprising a disk brake brake disk that is fixed to a wheel disk at the outer circumference of said wheel assembly, when seen in the radial direction, in the vicinity of a wheel rim, the brake caliper of said disk brake surrounding the brake disk over the brake disk inner circumference and being fixed to a wheel carrier that supports a stationary ring of a wheel bearing. The rotating ring of said wheel bearing supports a wheel hub that is connected to the wheel disk in a rotationally and axially fixed manner. The invention is characterized in that the connection of the wheel disk to the wheel hub is formed by a press fit or by a plane serration, in particular a Voith Hirth coupling.

Owner:BAYERISCHE MOTOREN WERKE AG

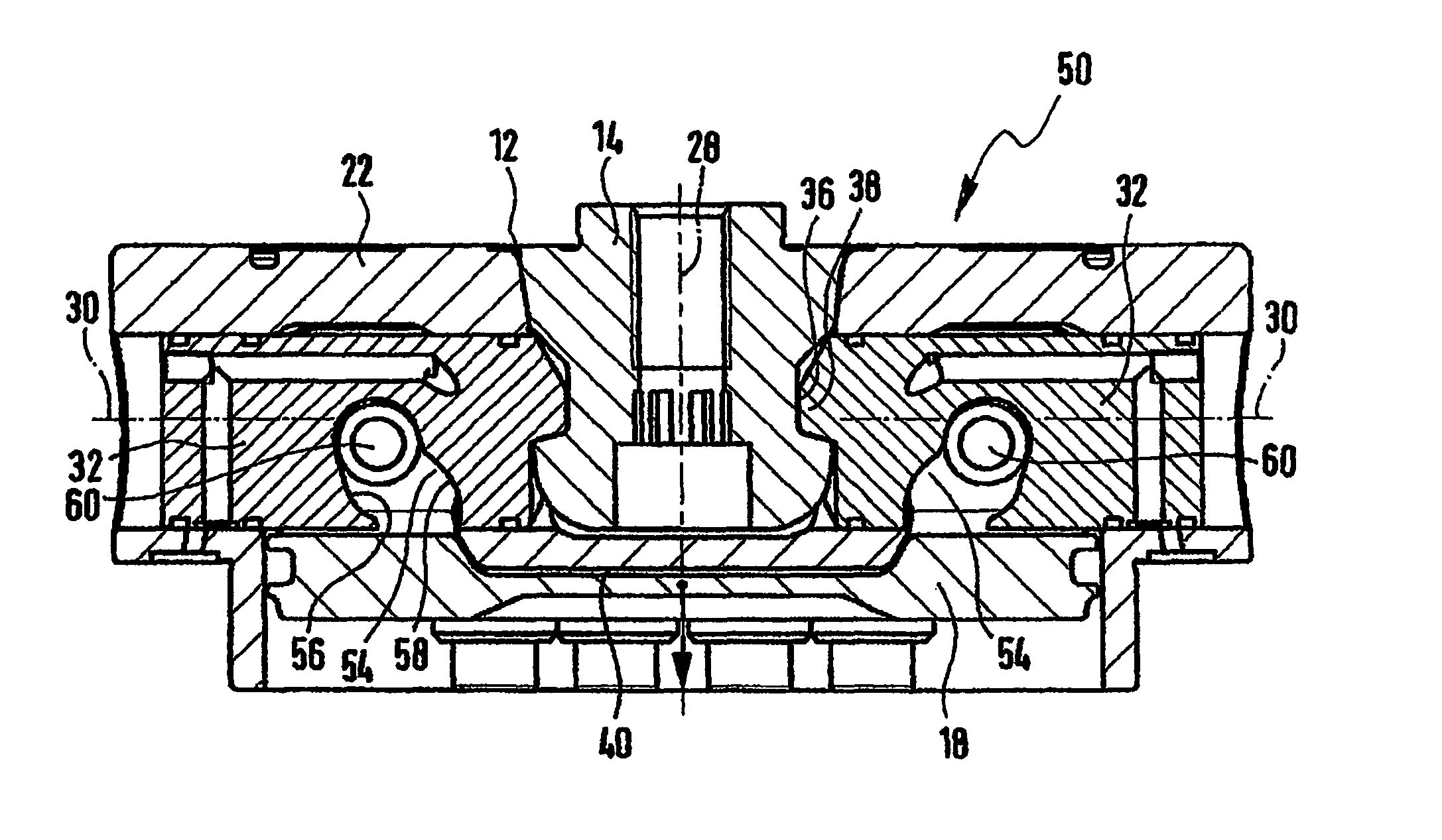

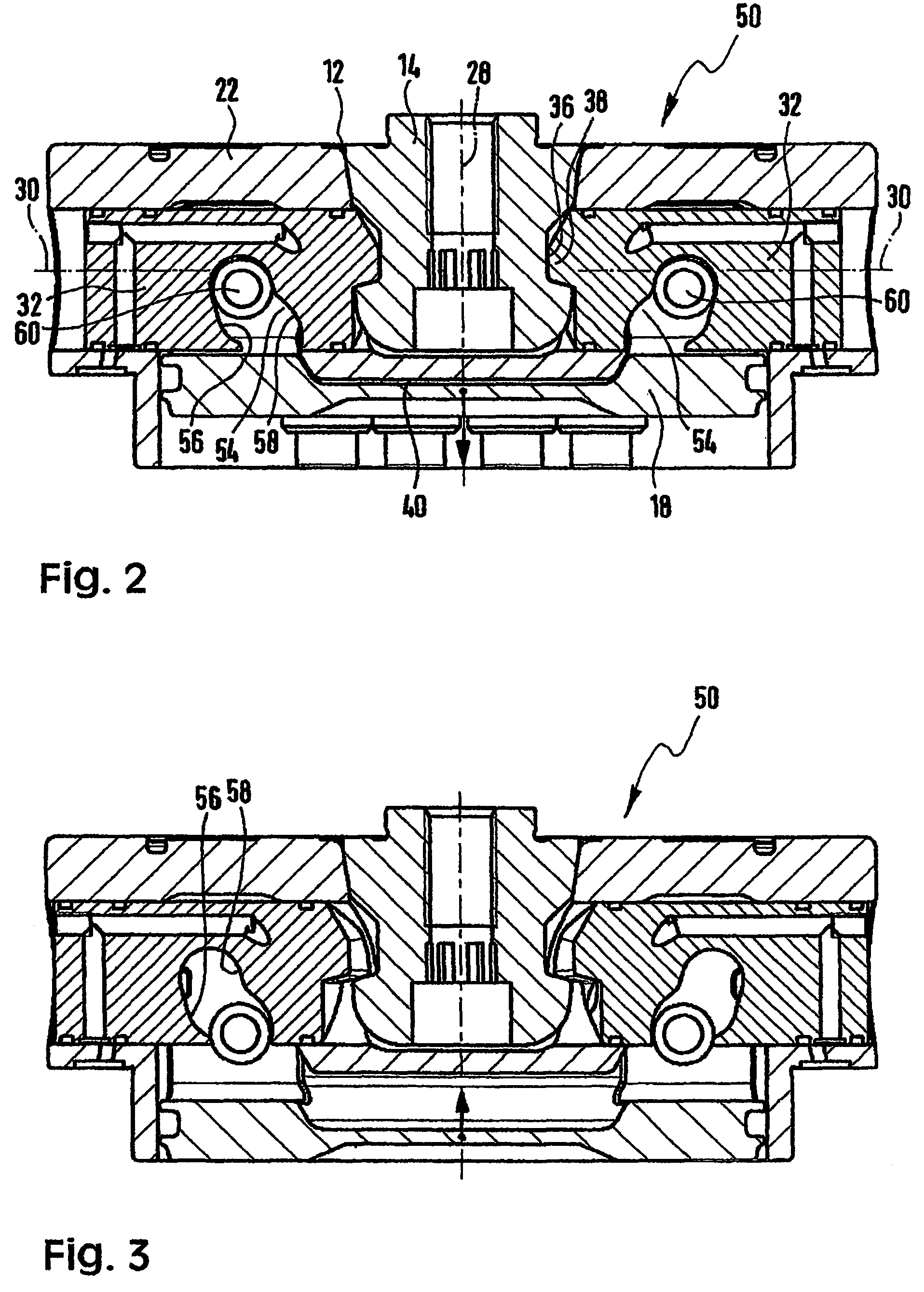

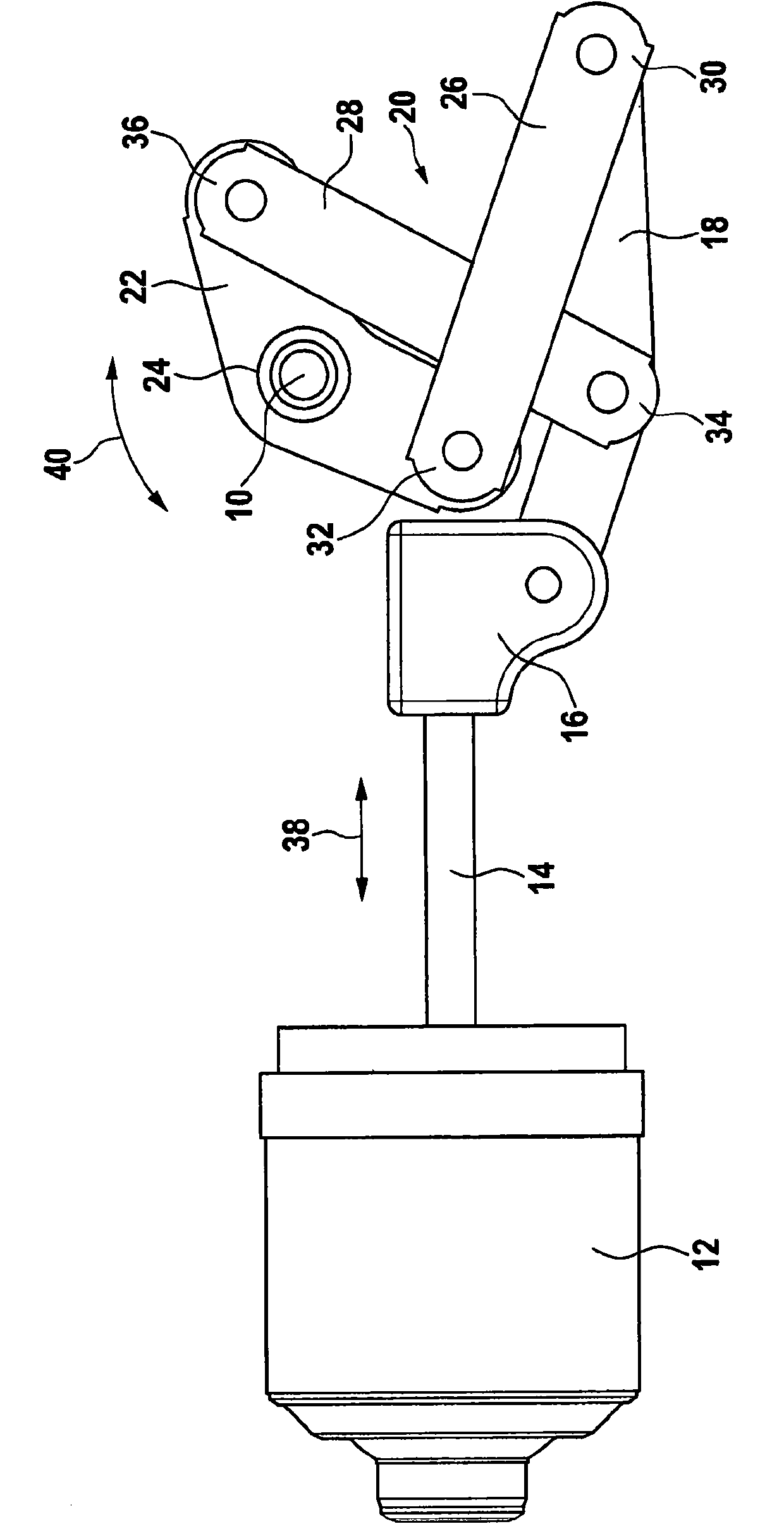

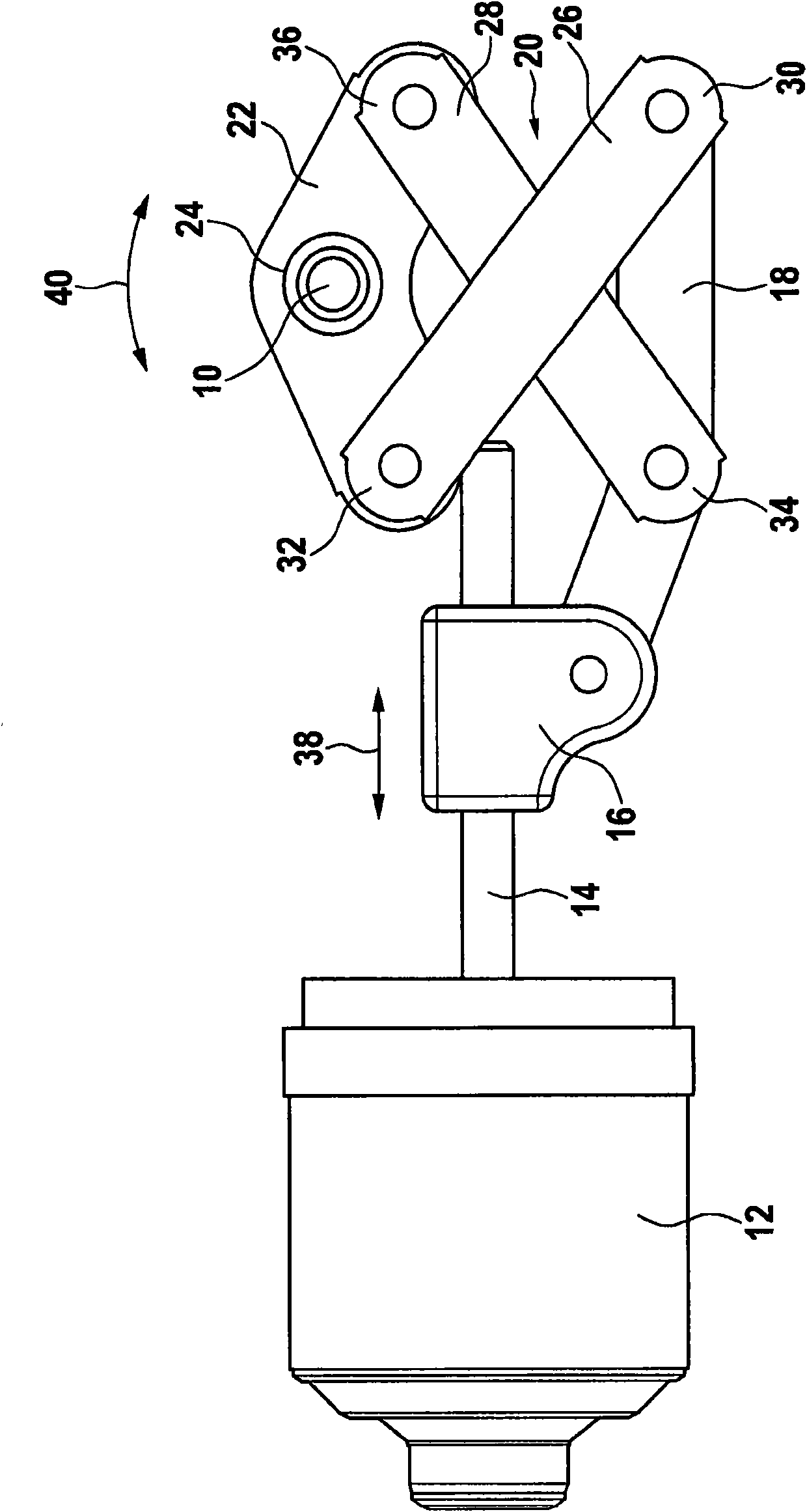

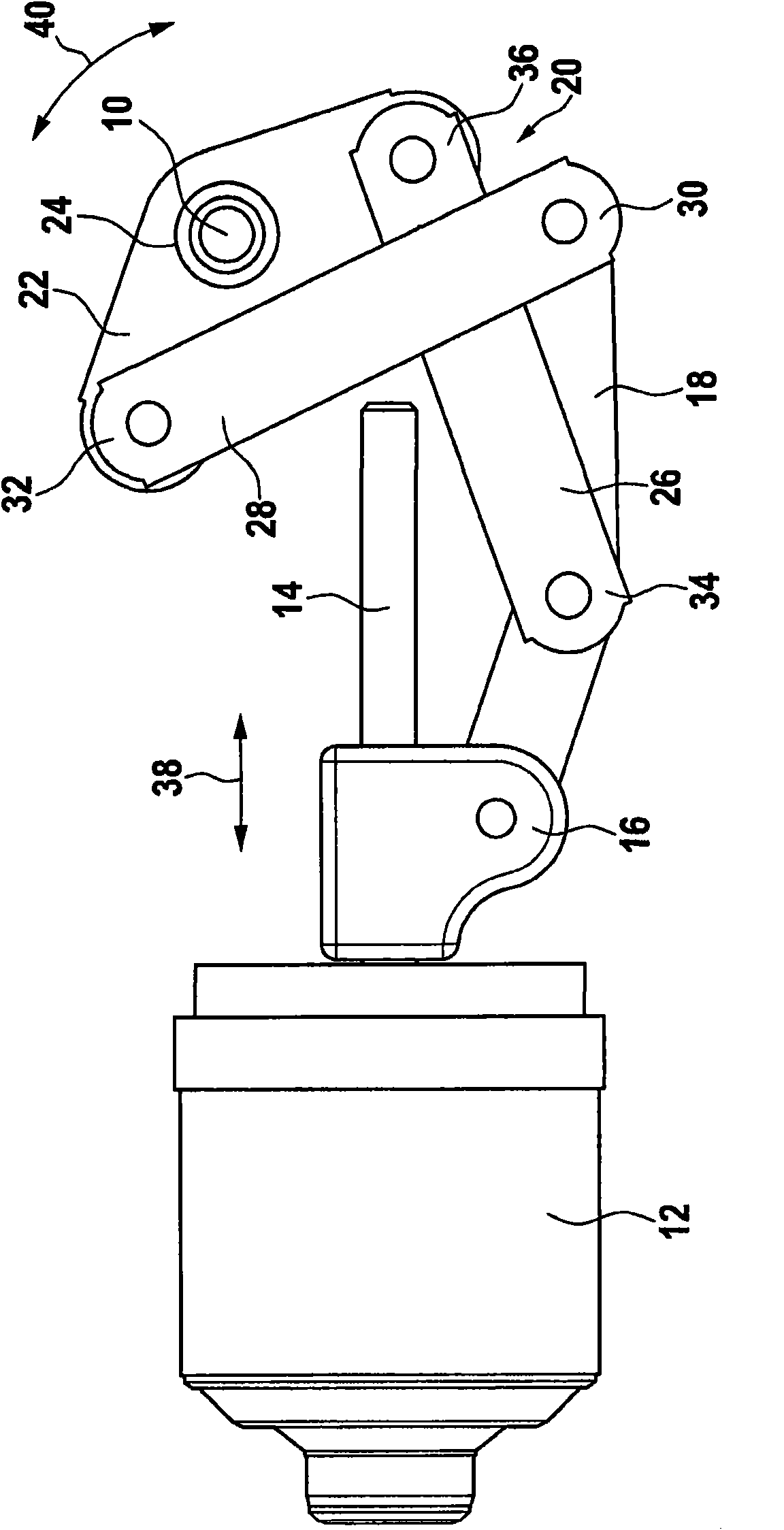

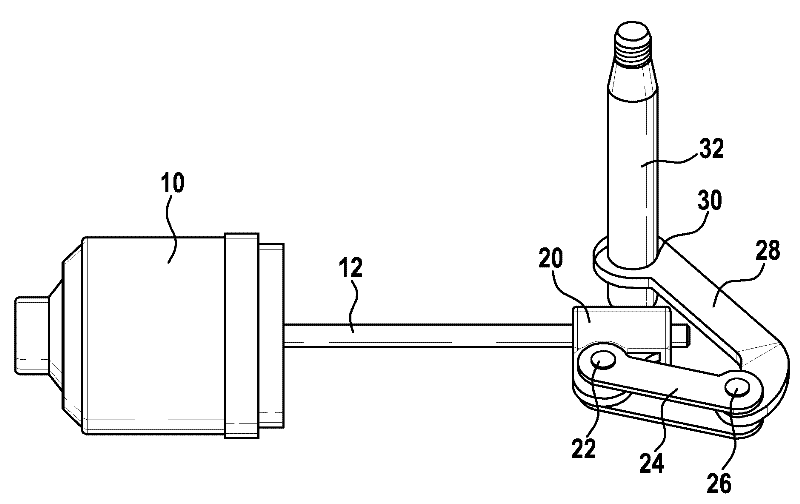

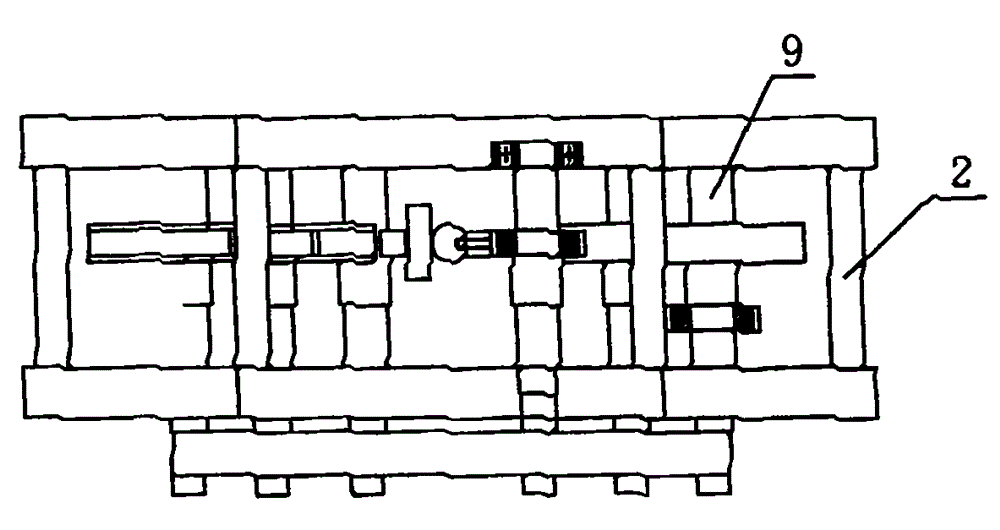

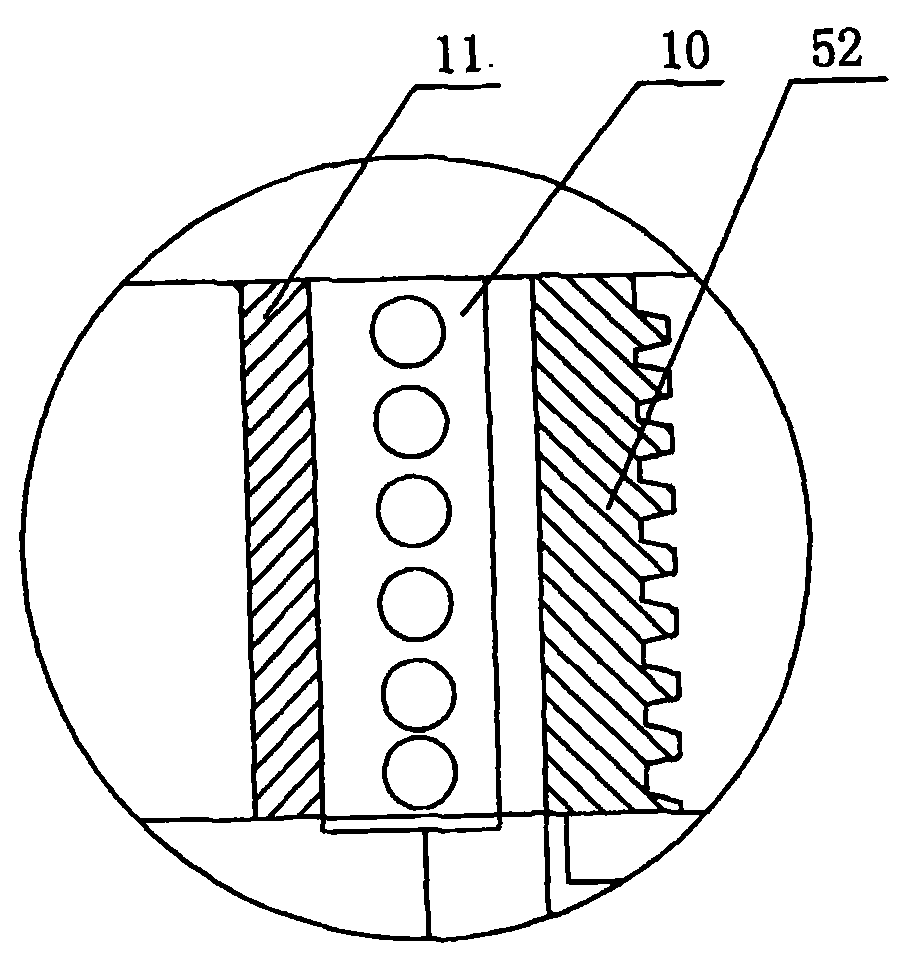

Rapid clamping system

ActiveUS8066289B2Same widthMaximizes clamping forceSleeve/socket jointsLarge fixed membersCouplingEngineering

The invention relates to a rapid clamping system (50), comprising a clamping housing (12), with a piston (18) acted on from one side by springs (15) and which may be pressurised from the other side, with an actuator (60) arranged on the piston (18) to follow the piston movement, with at least one clamping bolt (32) arranged to be displaced perpendicular to the piston axis (28), in a working coupling acting in both directions of displacement with the actuator (60) by means of an inclined guide (52), whereby, with the springs (16) extended, the clamping bolt (32) takes up a locking position for locking a clamping pin (14) which may be introduced in the clamping housing (12) and which adopts an unlocking position for removal of the clamping pin (14) on corresponding pressurization of the piston (18). The invention is characterized in that the inclined guide (52) has an irregular guide contour (54) with varying angles of inclination (α, β, γ, δ) relative to the piston axis (28) to achieve varying translation ratios.

Owner:SCHUNK GMBH & CO KG SPANN UND GREIFTECHN

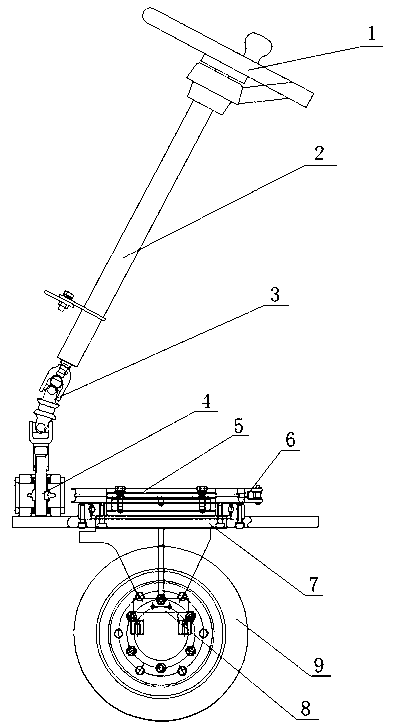

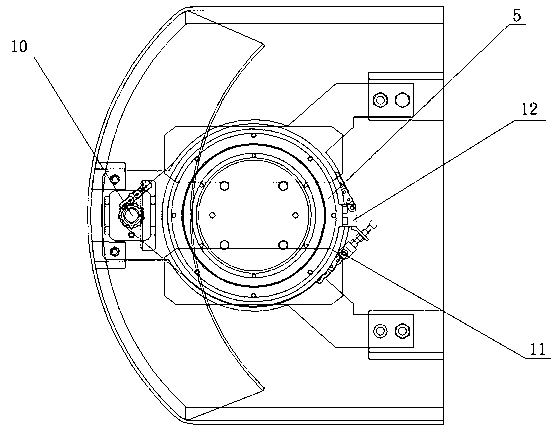

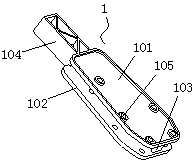

Electric fork-lift truck steering device

InactiveCN102975760AClearance adjustableSmall self-vibrationMechanical steering gearsHand wheelsSteering columnVehicle frame

The invention discloses an electric fork-lift truck steering device which comprises a steering wheel, a steering column, a cardan joint, a steering actuating device, a carframe and a shift wheel, wherein the steering column is arranged below the steering wheel and is connected with the steering wheel. The cardan joint is arranged below the steering column and is connected with the steering column. The steering actuating device is connected with the cardan joint. The carframe is connected with the steering actuating device. The shift wheel is arranged on the carframe. The steering actuating device comprises a chain wheel mechanism and the steering wheel, wherein the horizontally arranged steering is connected with the cardan joint through the chain whell mechanism. The carframe comprises a vertical part and a horizontal part, wherein the horizontal part is connected with the bottom end of the vertical part. The top end of the vertical part of the carframe is fixedly connected with the end face of the steering wheel. The horizontal part of the carframe is provided with the shift wheel. The electric fork-lift truck steering device has the advantages of being simple in structure, convenient to operate and low in cost. In the process of steering, a driver can adjust angles of the shift wheel by constantly steering the steering wheel according to factors such as road surface bending changes and speed changes to maintain steering tracks which a driver wants to reach, and therefore the electric fork-lift truck steering device is reliable in steering, and low in stoppage rate and the like.

Owner:ANHUI HECHA FORKELEVATOR

Automatic transmission capable of transmitting power by aid of shaft and plungers

ActiveCN103206496AImprove powerImprove economyToothed gearingsGearing controlAutomatic transmissionTransmitted power

The invention relates to the field of electronic-control automatic transmissions for vehicles, in particular to an automatic transmission capable of transmitting power by the aid of a shaft and plungers. The automatic transmission is characterized in that semicircular pits are uniformly machined on the radius circumferential surface of the shaft and are matched with the plungers corresponding to the semicircular pits, and the plungers are integrally connected with the shaft under the action of external pressure, so that the power can be transmitted. The automatic transmission with the structure has the advantages that the automatic transmission is simple in structure as compared with the traditional gear transmission, automatic gear shifting can be implemented without cutting off the power, the driving smoothness and the dynamic performance of a vehicle are improved, the economical efficiency is enhanced, and the automatic transmission not only can be used in limousines and light vehicles, but also can be conveniently popularized in trucks and heavy vehicles.

Owner:范巨新

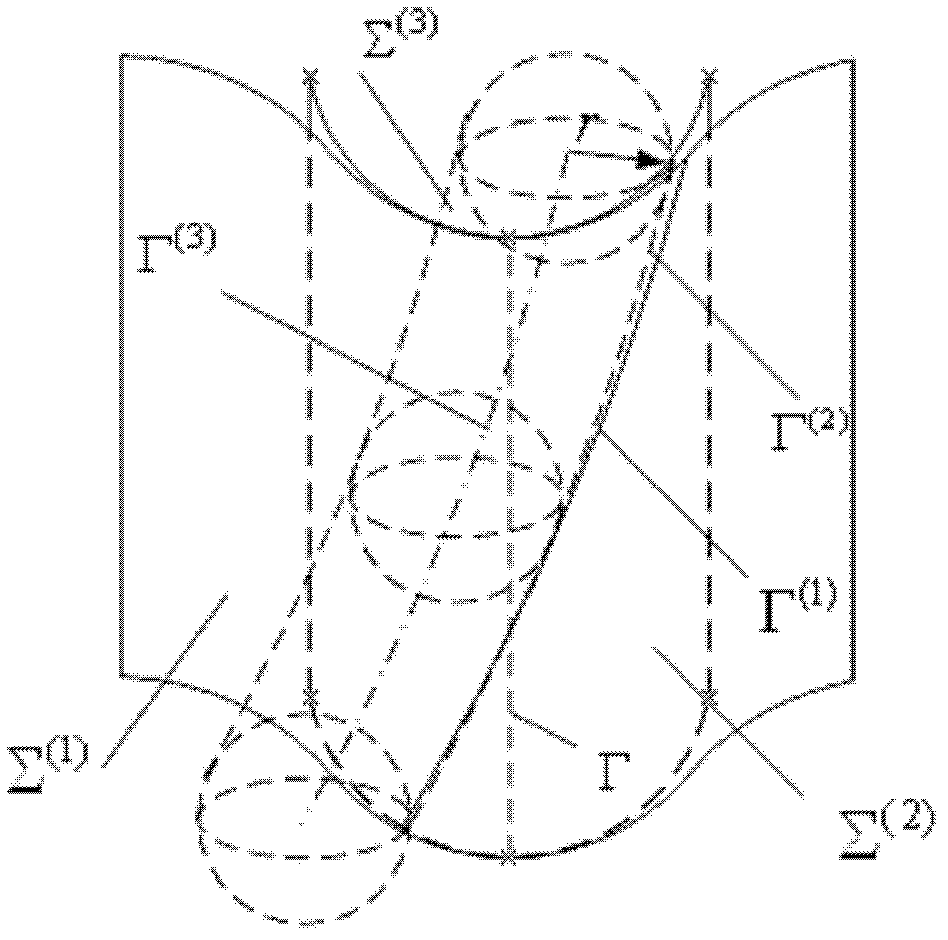

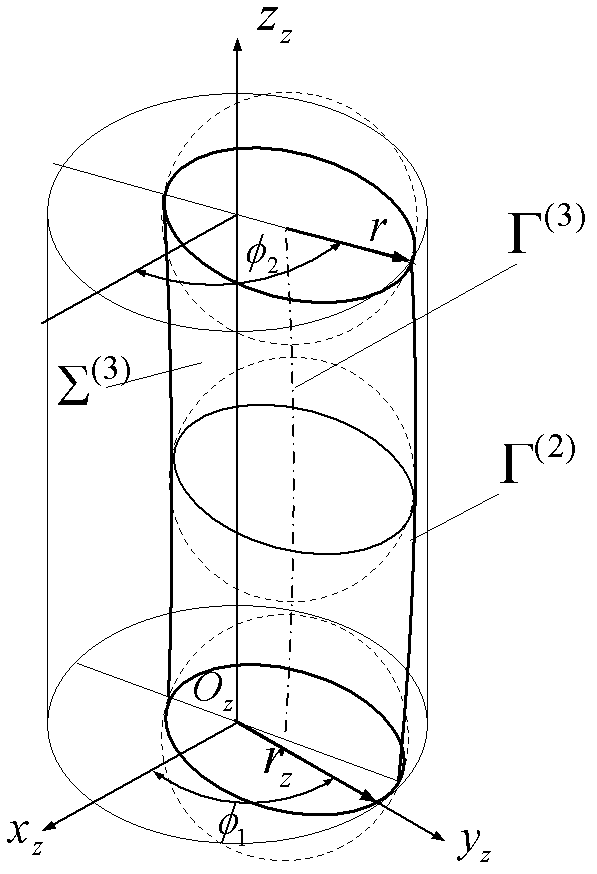

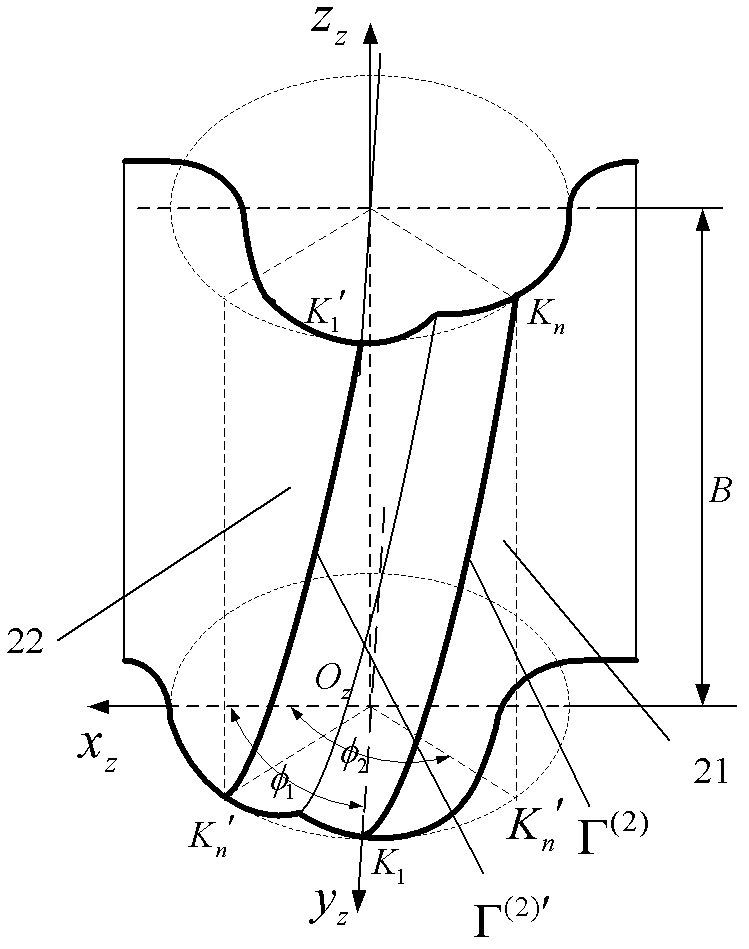

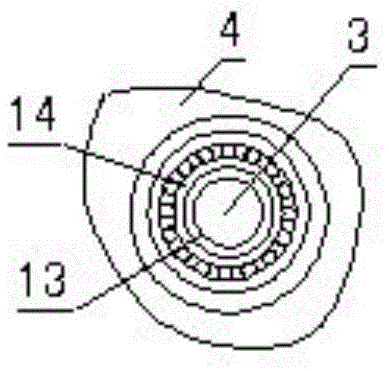

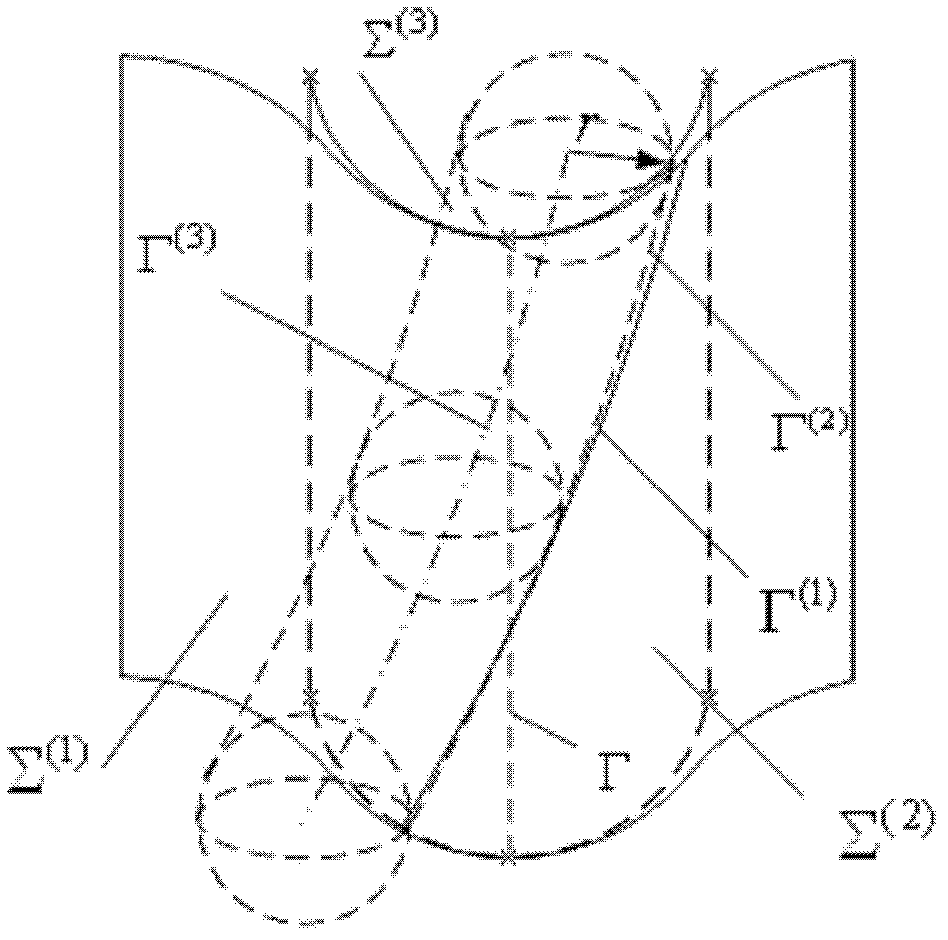

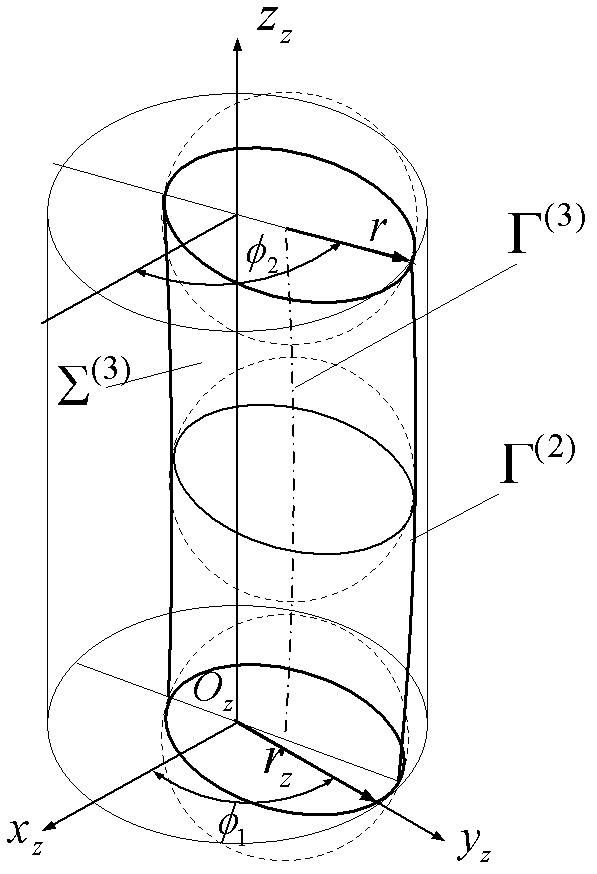

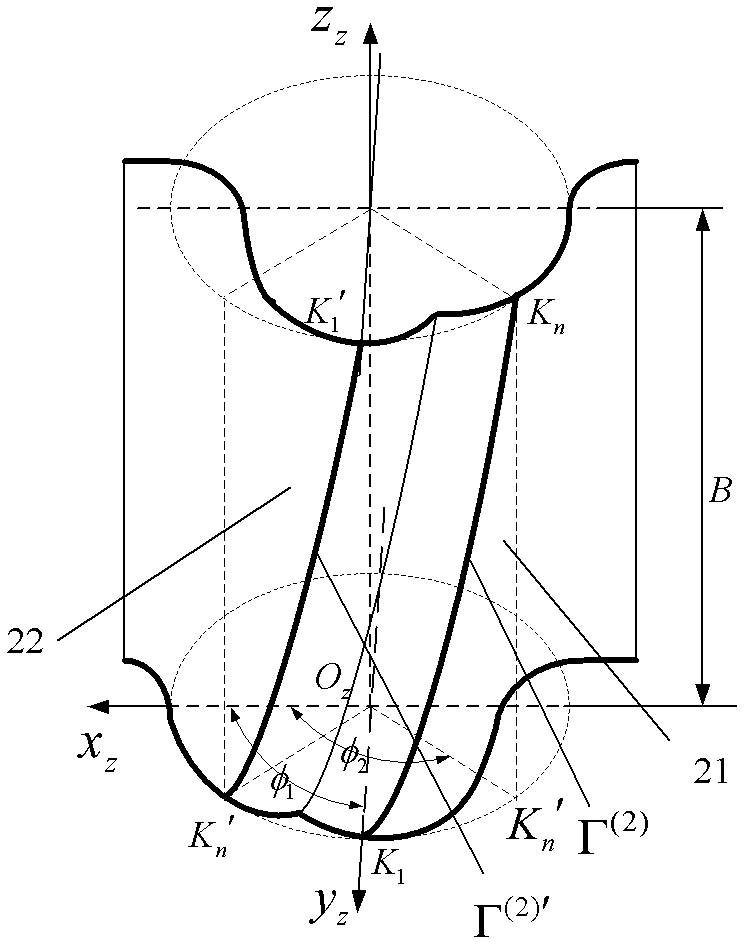

Cycloid planetary transmission gear based on line-surface conjugation

ActiveCN102252058AImprove rigidityGood transmission precisionToothed gearingsPortable liftingEngineeringCycloid

The invention discloses a cycloid planetary transmission gear based on line-surface conjugation, and relates to a cycloid planetary transmission gear which comprises a cycloid pin wheel planetary transmission meshed pair. A smooth curve line inverted L (2) is selected on a gear surface of a gear in the meshed pair, the main normal vector direction is consistent with the normal direction of the gear surface, and the curve line inverted L (2) and the gear surface of another gear in the meshed pair form line-surface conjugation mesh; the gear surface of the gear is a tubular meshed surface which is a sphere family enveloping surface sigma (3) of which the sphere center moves along an equidistant line inverted L (3); the equidistant line inverted L (3) is a smooth curve line which has a distance of r from the main normal vector direction; the spherical radius of spheres in the sphere family is the distance r between the equidistant line inverted L (3) and the smooth curve inverted L (2), and the r is less than the minimum curvature radius of the meshed section of the original gear surface. According to the invention, through changing the cycloid planetary transmission into the line-surface conjugation meshed pair, the meshed process is in the mode of point contact, the transmission ratio is great, the rigidity is good, the structure is compact, the transmission accuracy is high, the mesh can be approximately to pure rolling, the sliding ratio can be reduced greatly, thus the efficiency is improved greatly, the service life is improved, the manufacturing is simple, and the accuracy is high.

Owner:CHONGQING UNIV

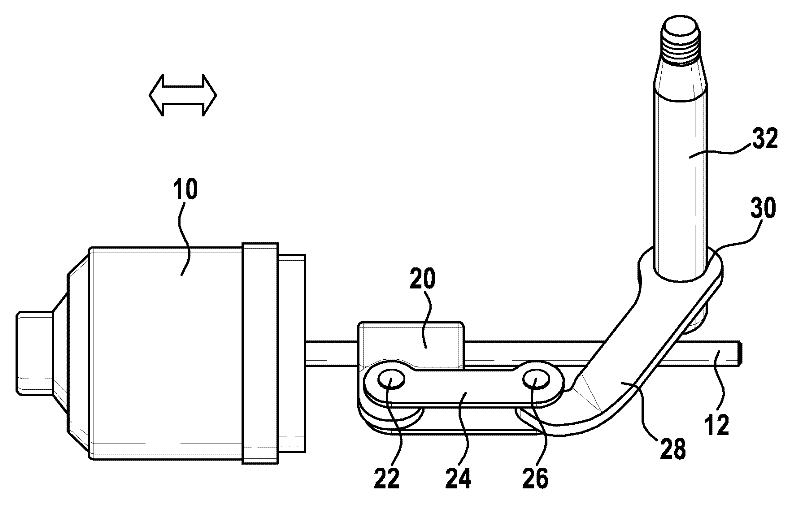

Windscreen installation driving device

InactiveCN102001325ASave construction spaceSmall structure sizeVehicle cleaningLinear motionDrive shaft

The invention relates to a windscreen installation driving device, for making an output shaft (10) move, comprising a drive shaft (14) driven by a motor (12) and a linear motion element (16) integrated with the drive shaft (14) in a torque-proof manner, wherein the linear motion element (16) is connected with the output shaft (10) by a connecting piece (18) and an oscillating arm (22) integrated with the output shaft (10) in a torque-proof manner and a cross guide device (20) is arranged to mutually connect the connecting piece (18) with the oscillating arm (22) in an articulated manner.

Owner:ROBERT BOSCH GMBH

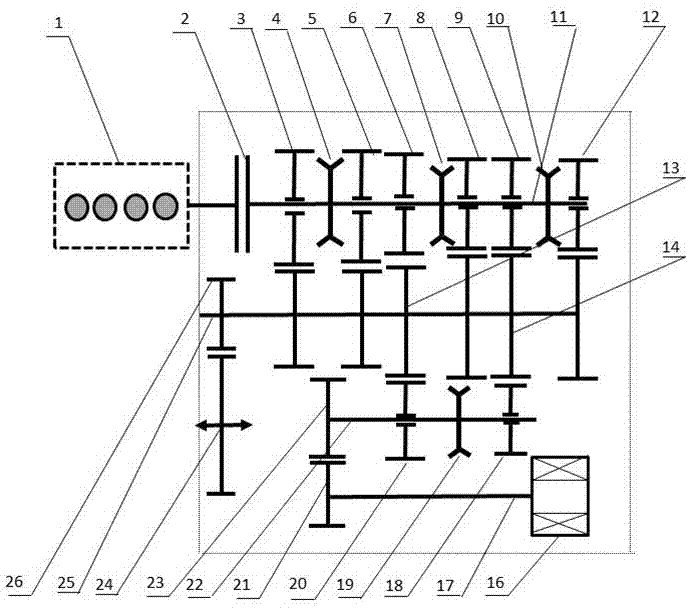

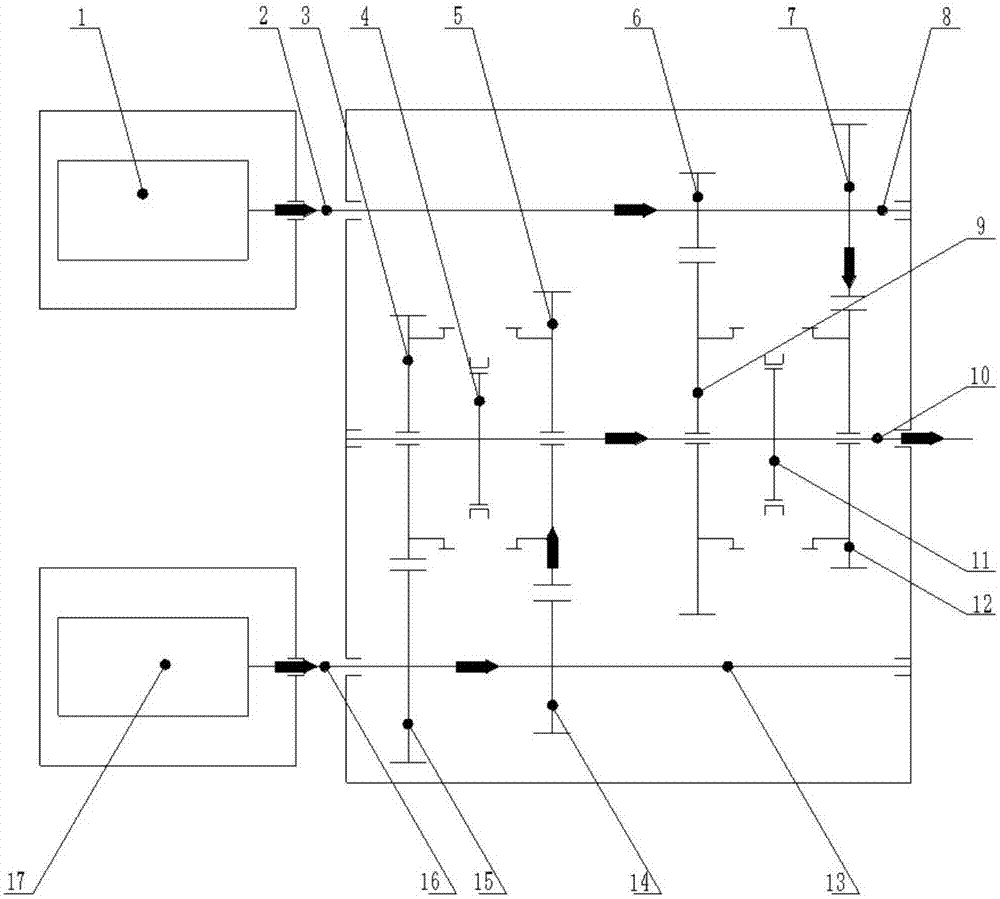

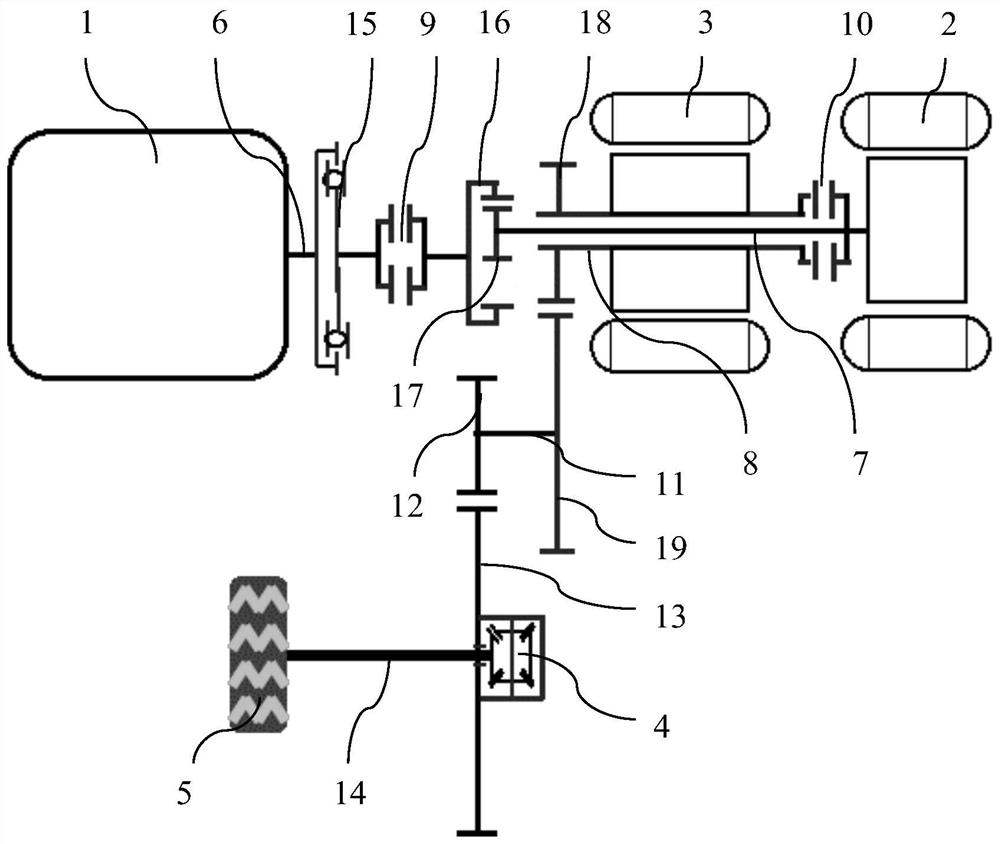

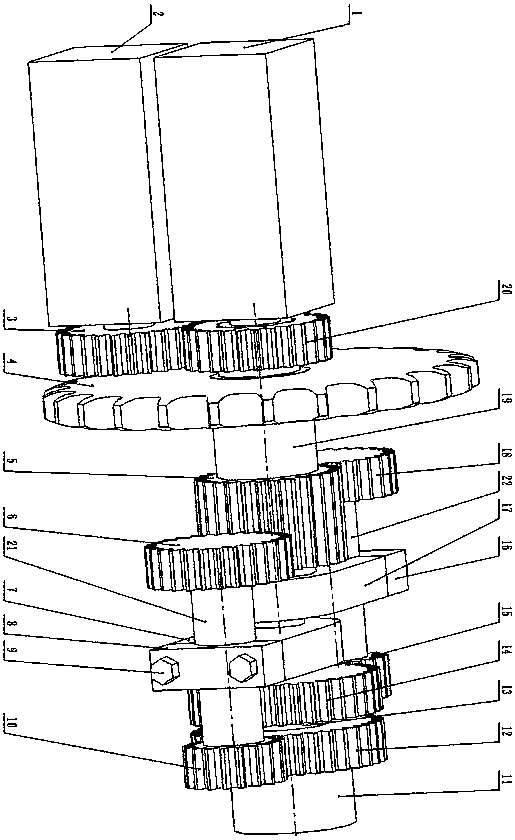

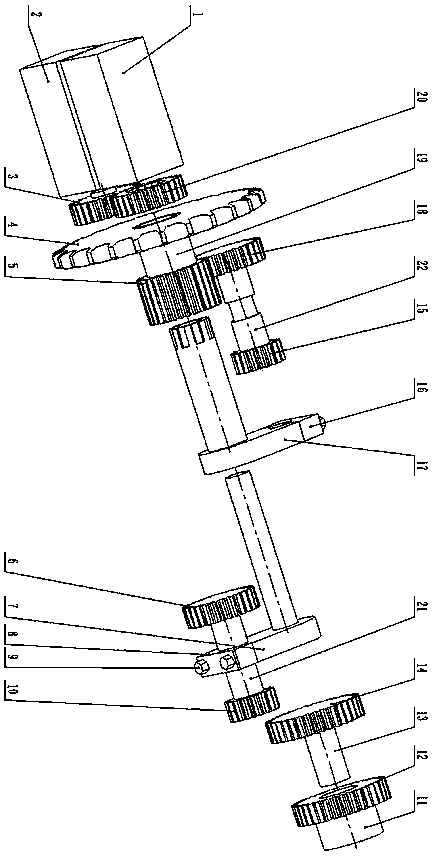

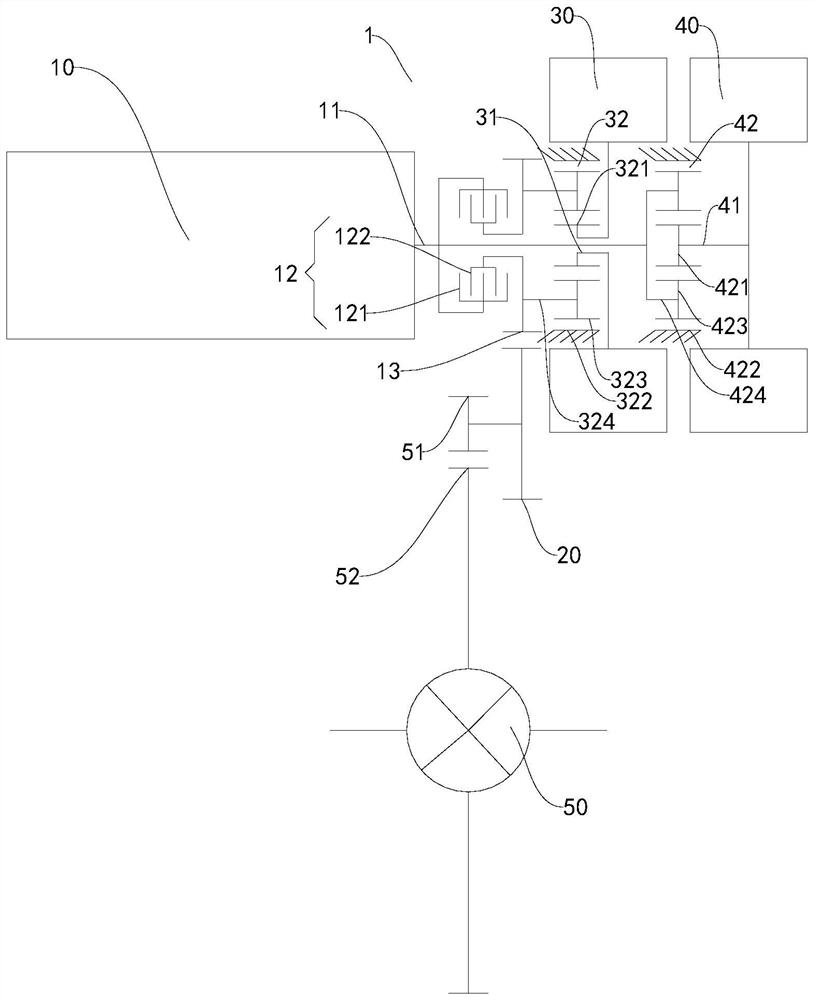

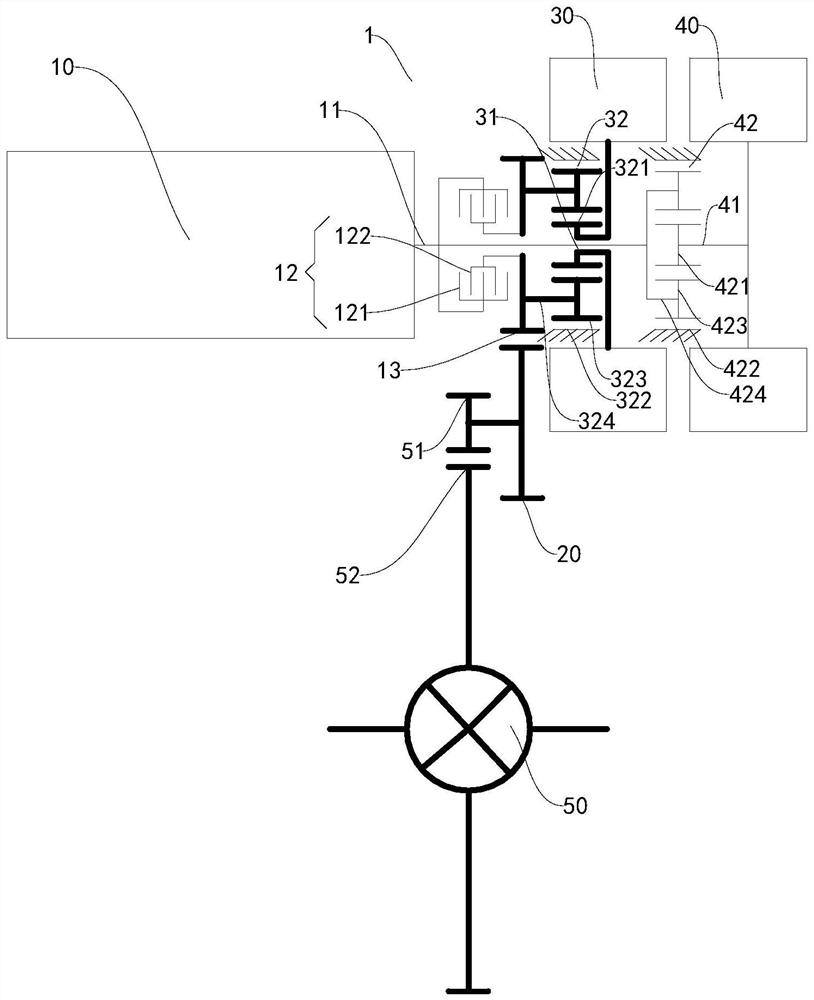

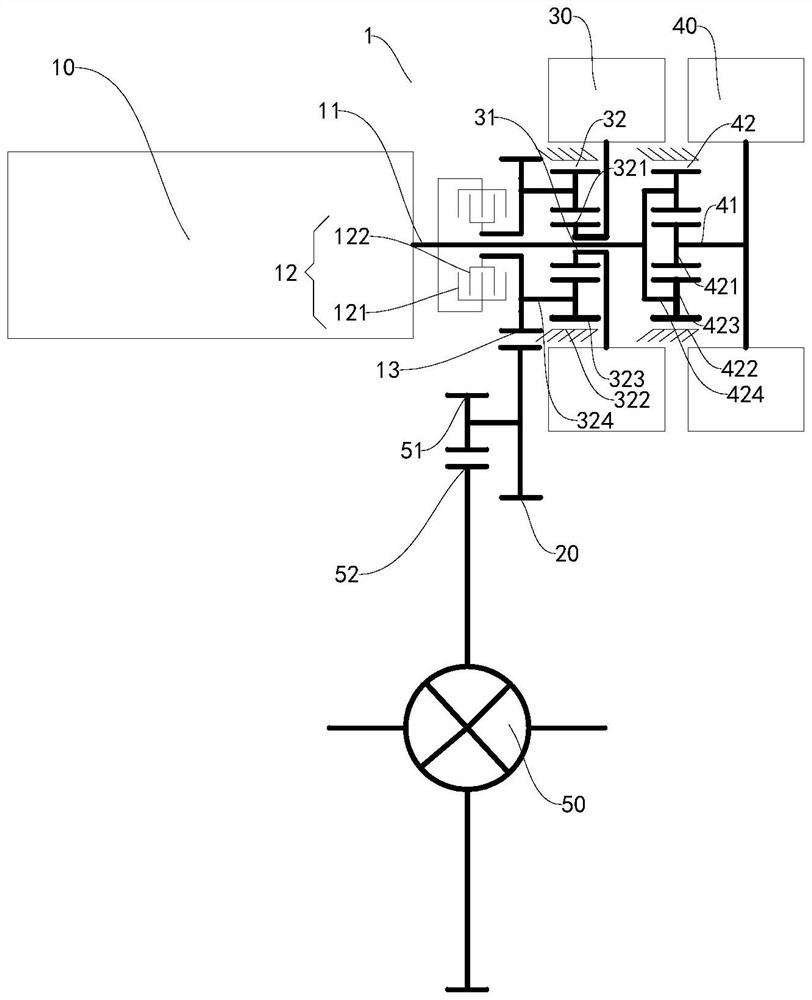

Hybrid coupling device based on mechanical automatic transmission

InactiveCN107187310AEliminates torque interruptionReduced risk of torsional vibrationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingAutomatic transmissionCoupling

The invention discloses a hybrid coupling device based on a mechanical automatic transmission. The hybrid coupling device comprises an engine, a drive motor, a differential, synchronizers, an engine input shaft assembly, an output shaft assembly and a drive motor input shaft assembly, and further comprises a drive motor shift shaft assembly. The hybrid coupling device disclosed by the invention is compact in structure and convenient to use; the engine and the drive motor can provide sufficient power separately or in a matching manner; when outputting power, the engine input shaft assembly and the drive motor input shaft assembly simply need to respectively output power to the same output shaft assembly; the engine and the drive motor can respectively achieve different speed ratios; on the basis of guaranteeing good power output performance, the structural complexity is reduced; technical complexity and performance are well balanced; machining and assembling requirements are relatively low; output without power interruption can be achieved; the impact on parts is small during shifting; and the hybrid coupling device is low in cost input, safe and reliable, energy-saving and cost-reducing and worthy of widespread use in the technical field.

Owner:湖州伊立机械有限公司

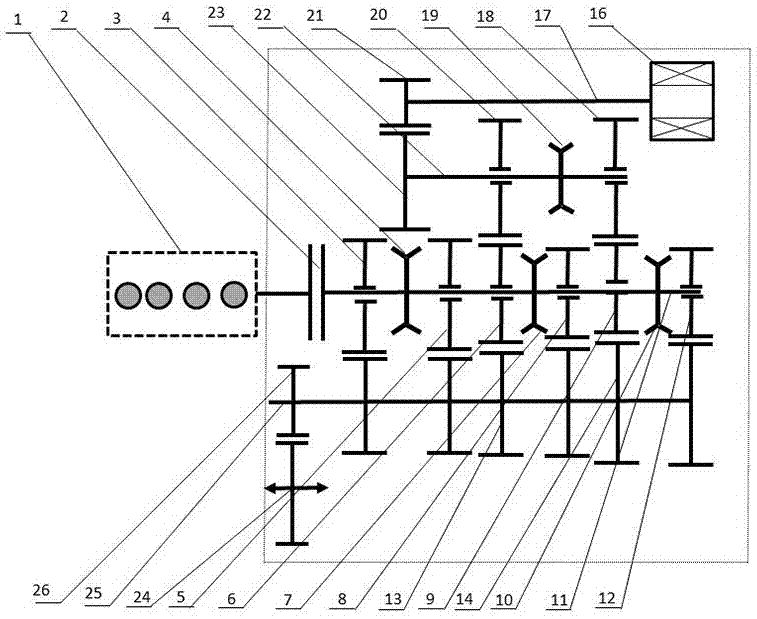

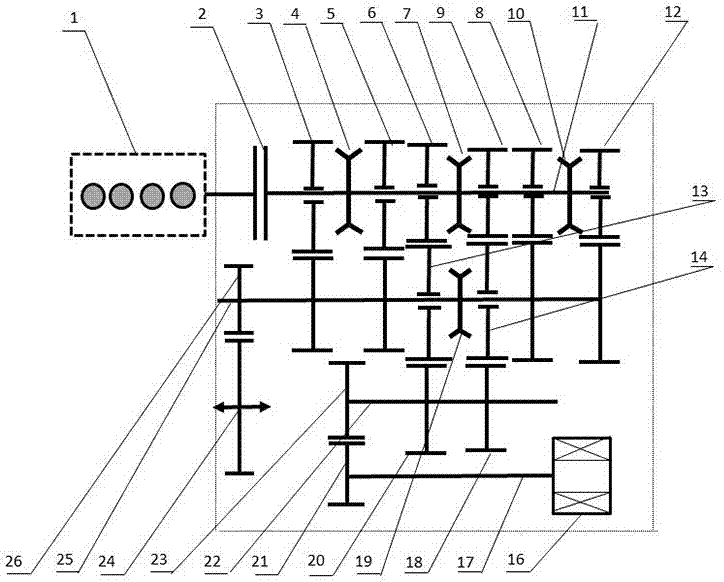

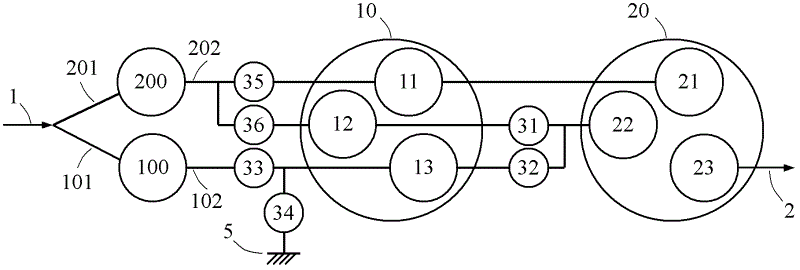

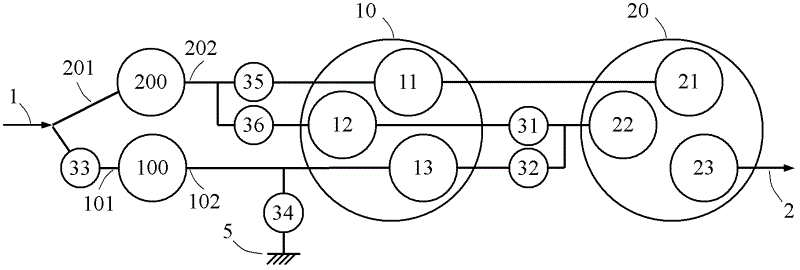

Multistage transmission

InactiveCN101984271AShorten the axial lengthLess sliding lossToothed gearingsAutomatic transmissionVariator

The invention discloses a multistage automatic transmission for a vehicle. The transmission comprises two or three power transmission mechanisms in the front, two planet rows and five or six gear shifting elements; the third rotary component of the second planet row is connected with an output; the first rotary components of the first and second planet rows are interconnected; the first and second gear shifting elements are connected in series between the second rotary component of the second planet row and the second and third rotary components of the first planet row in turn; the third gear shifting element is connected in series on the route of transmitting an input power to the third rotary component of the first planet row from the first power transmission mechanism; the fifth and sixth gear shifting elements are connected in series on the route of transmitting the input power to the first and second rotary components of the first planet row through the second power transmission mechanism or the second and third power transmission mechanisms in turn; and the fourth gear shifting element can selectively brake the third rotary component of the first planet row. The transmission is provided with five or eight forward gears, each gear is combined with three gear shifting elements, and the gears can be arranged on split shafts so that the length of the gears is shortened and the gears are suitable for driving the vehicle forwards.

Owner:广州科立源机电科技有限公司 +1

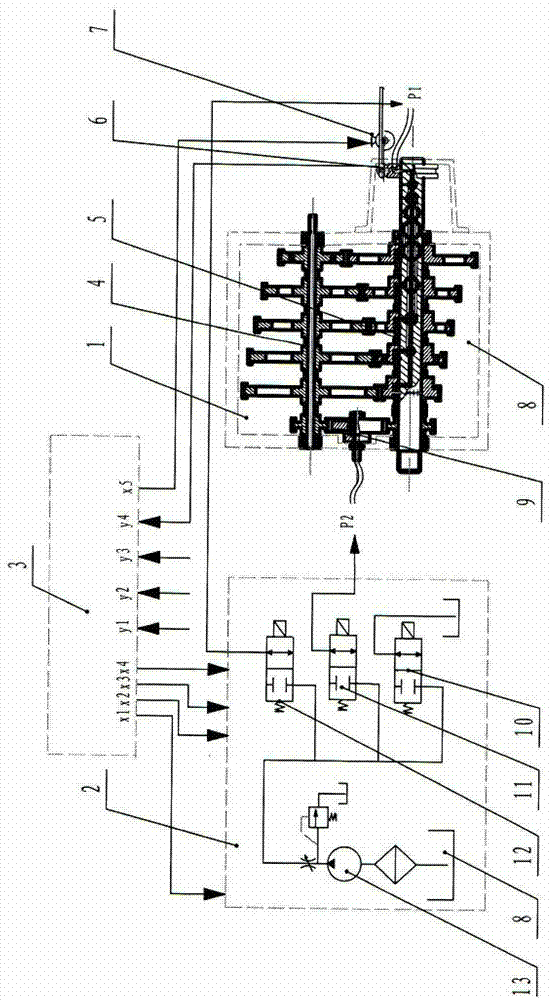

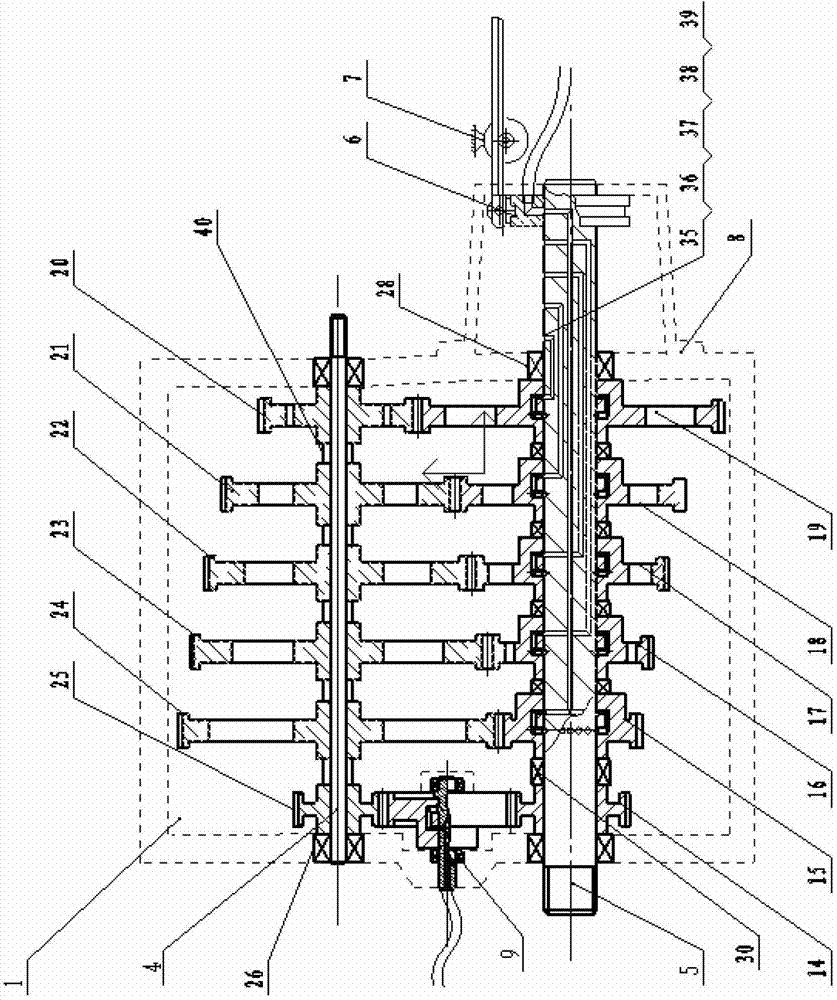

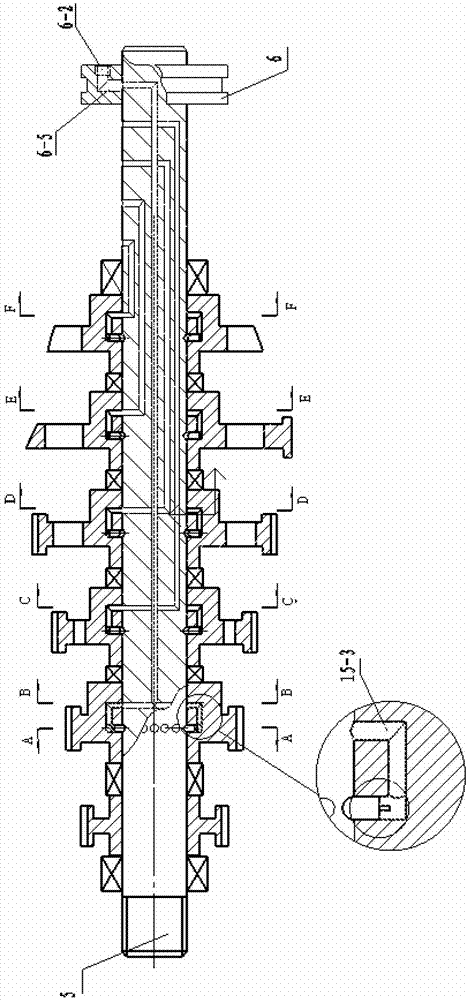

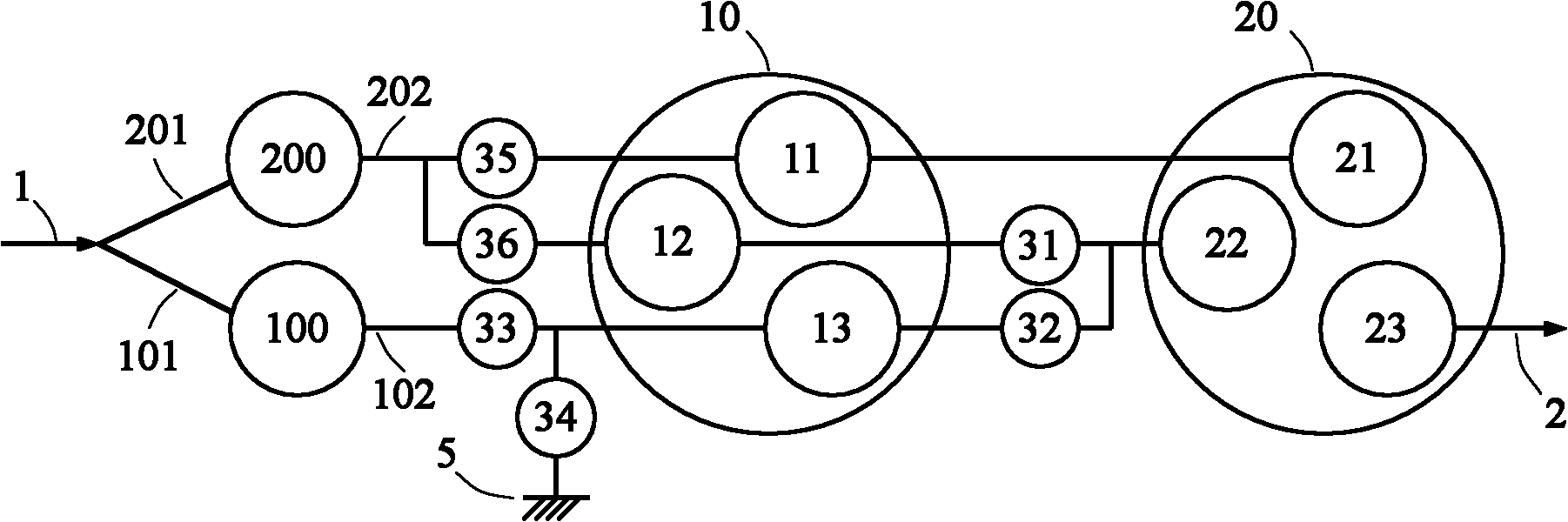

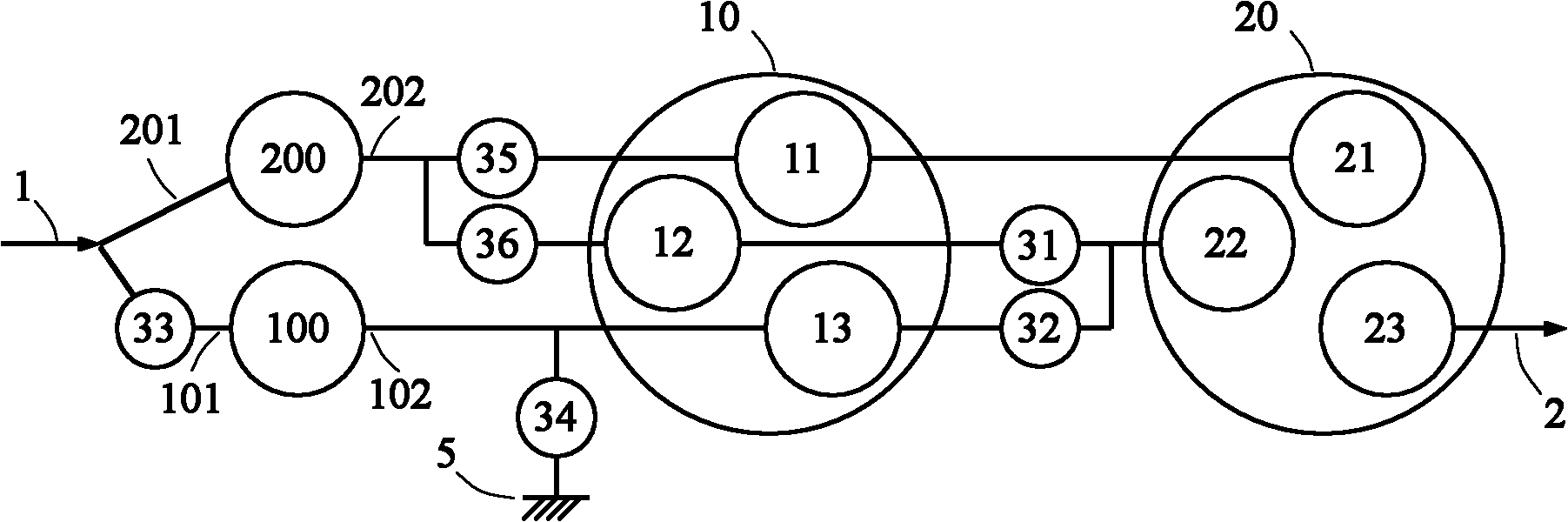

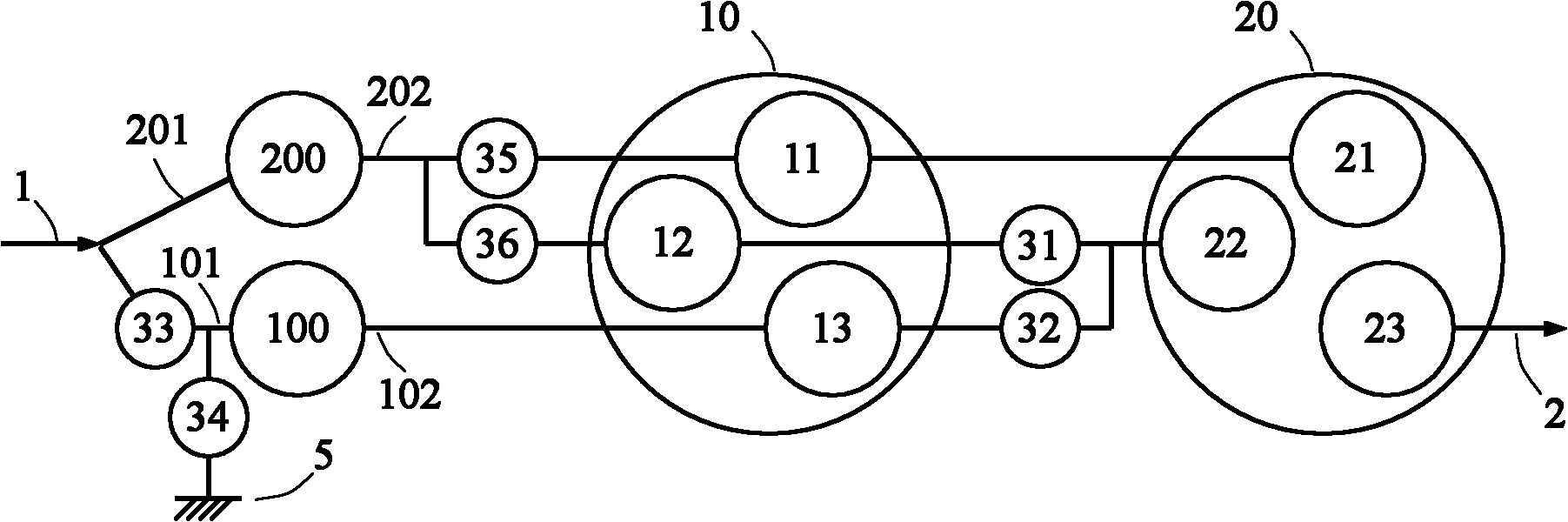

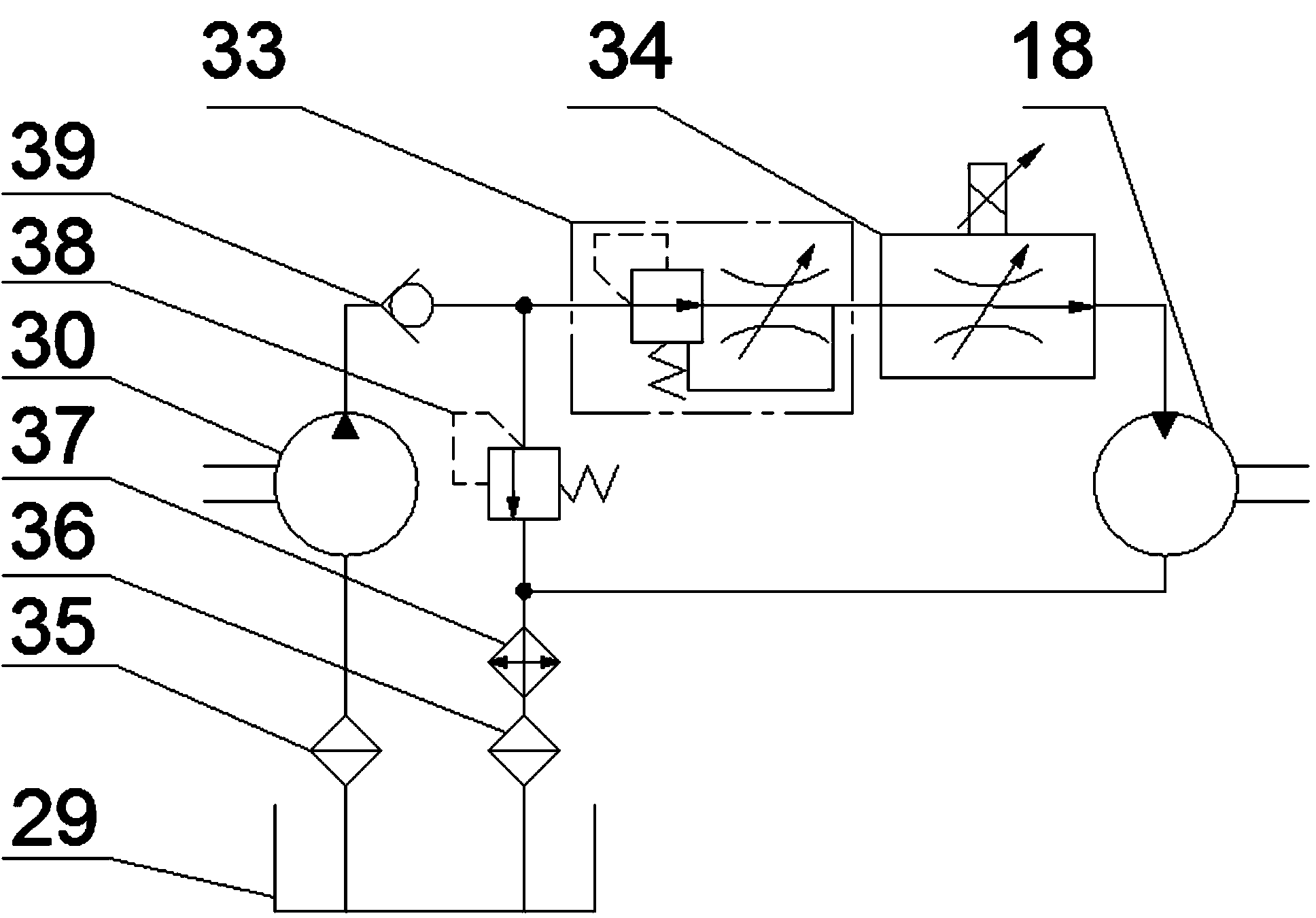

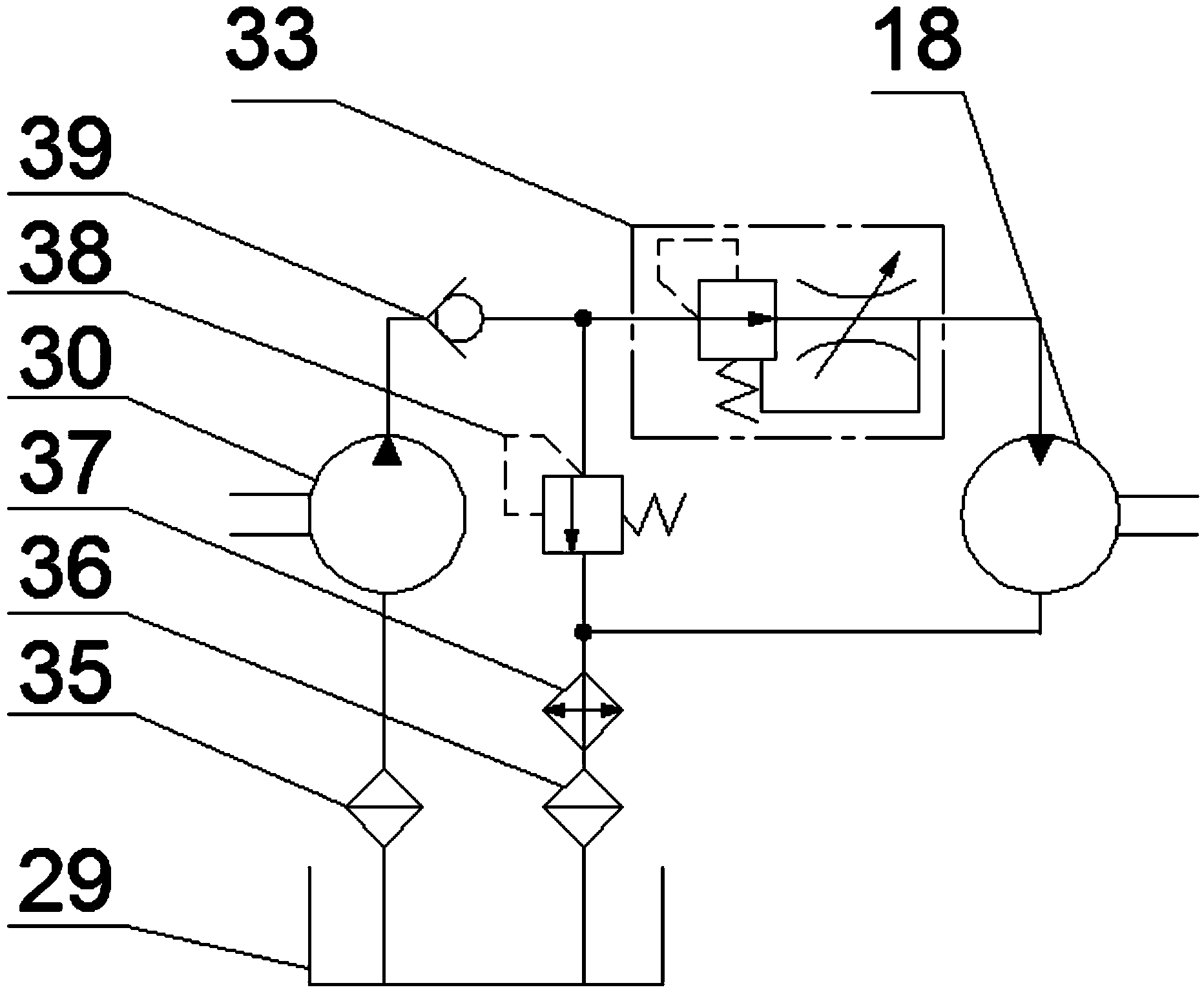

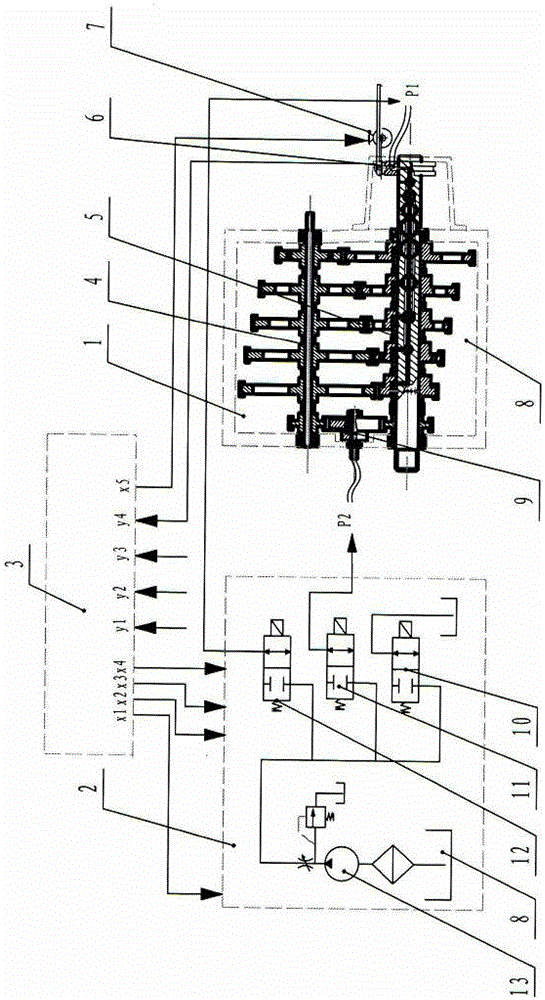

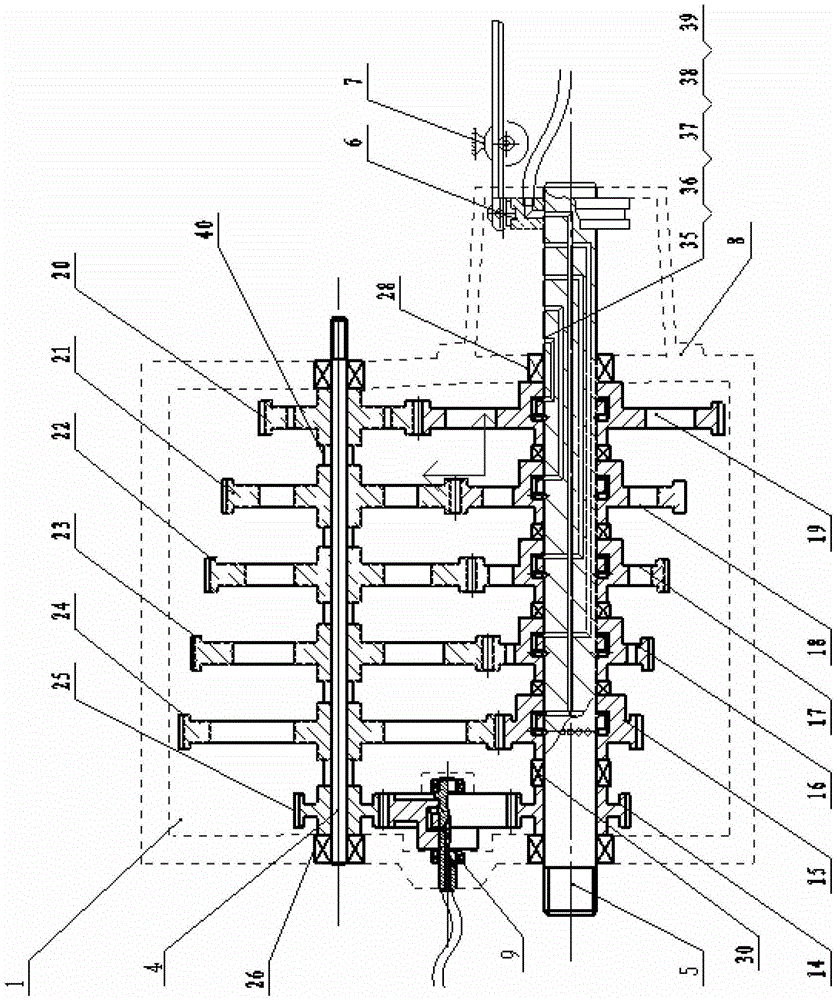

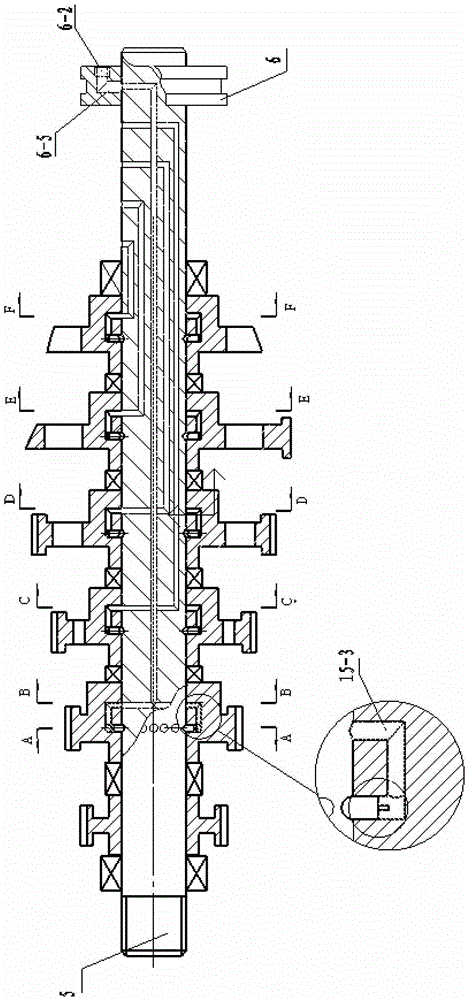

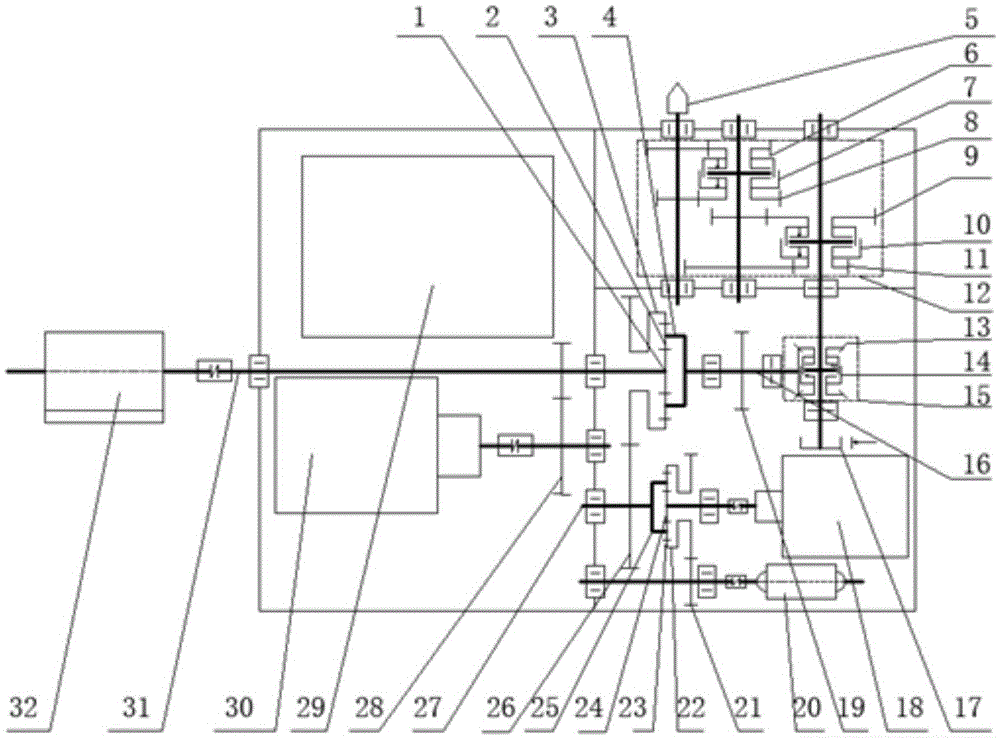

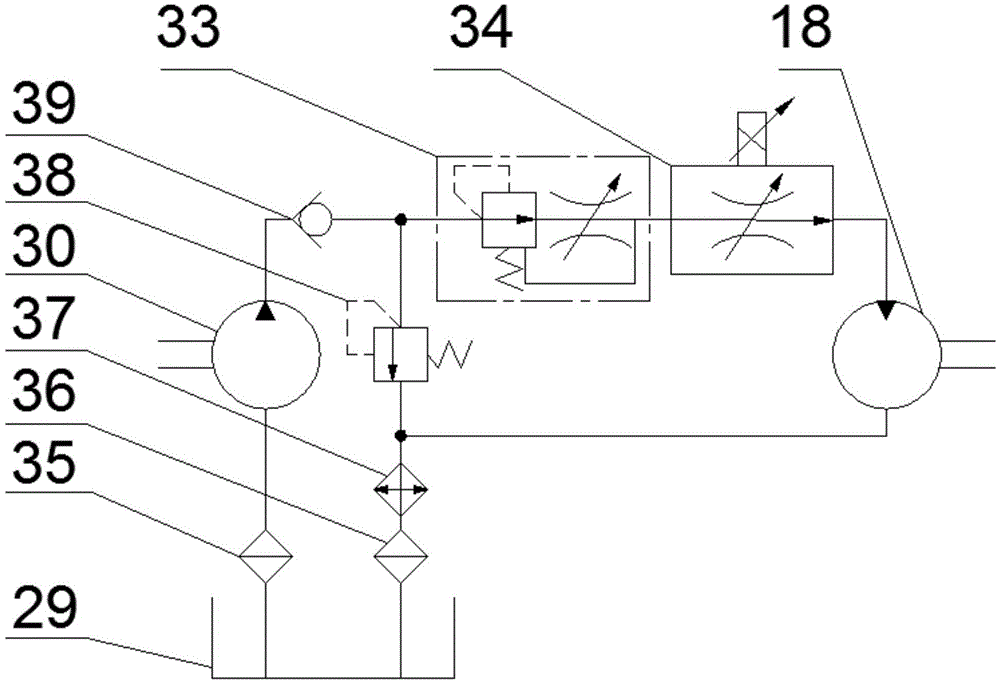

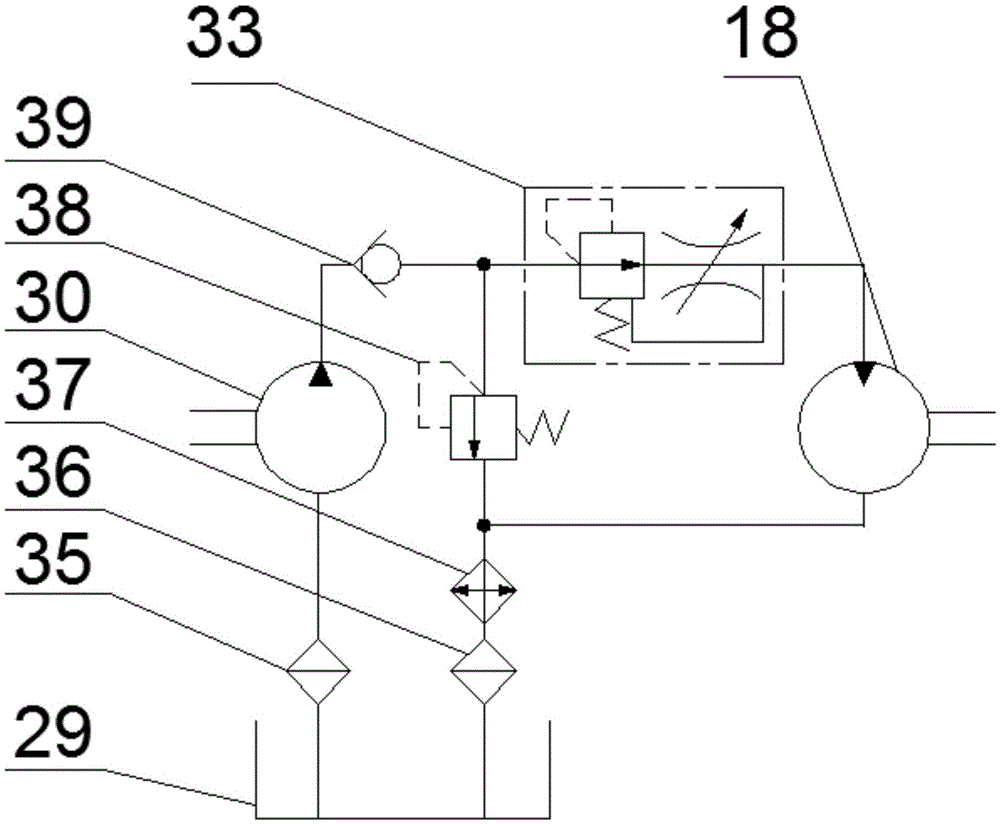

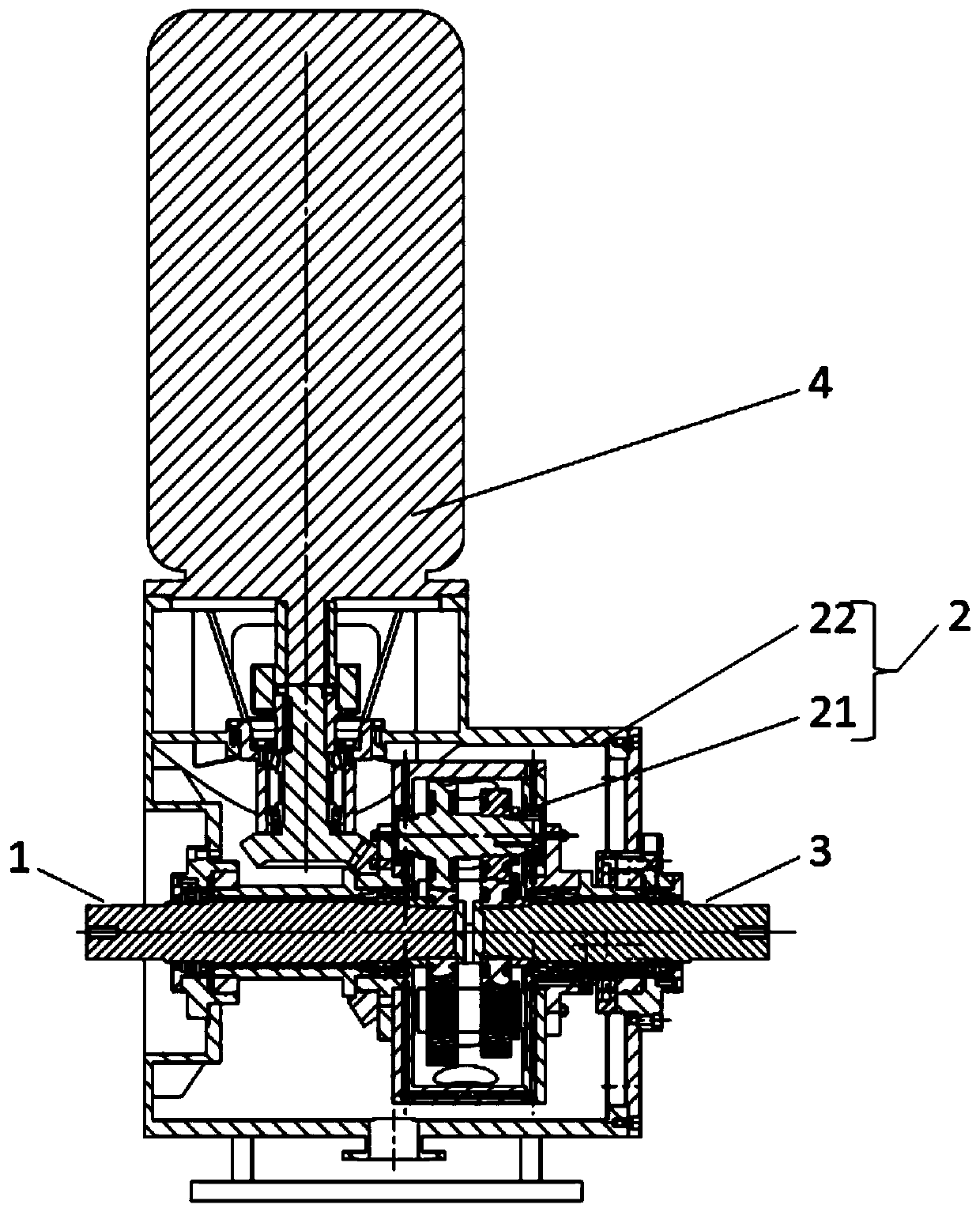

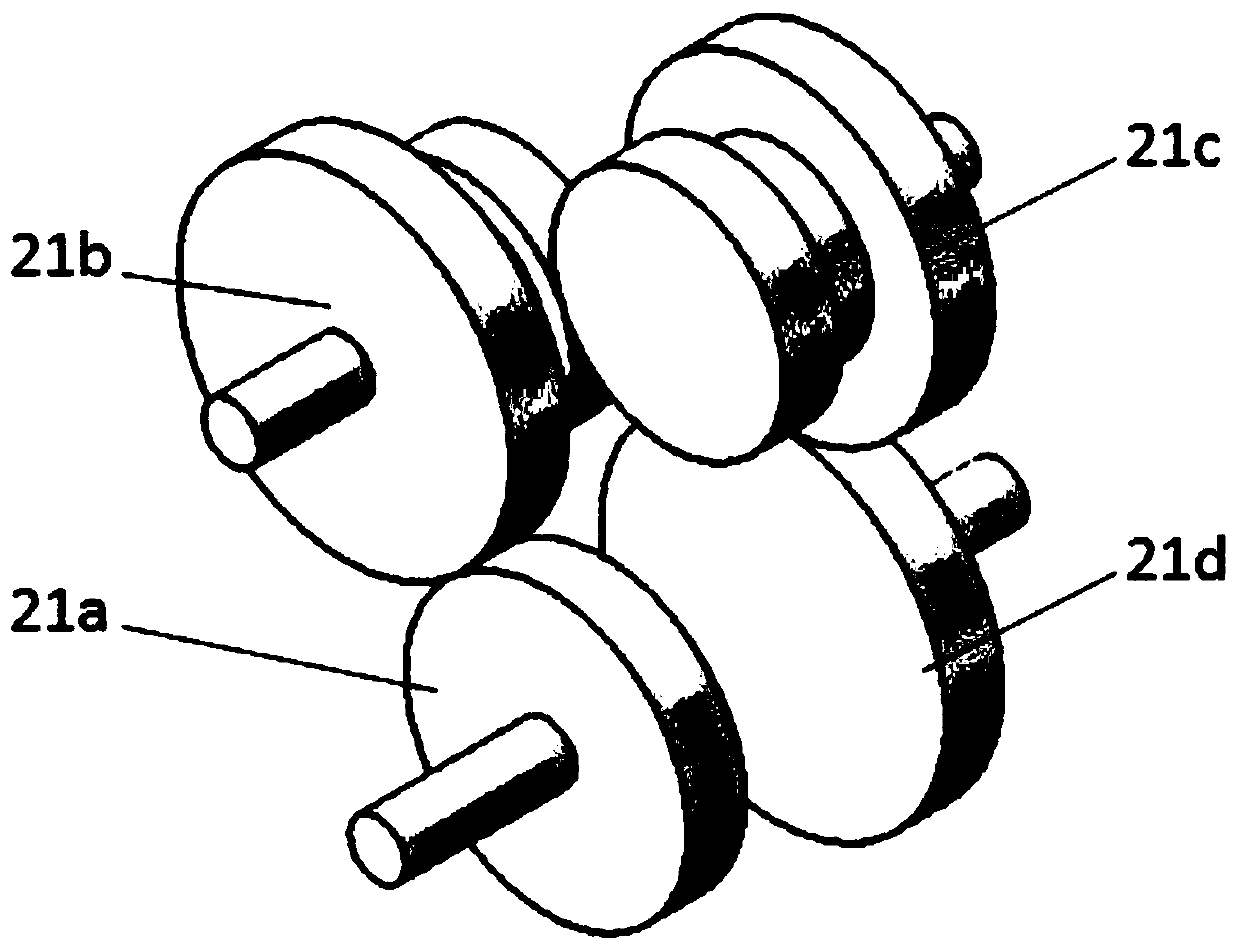

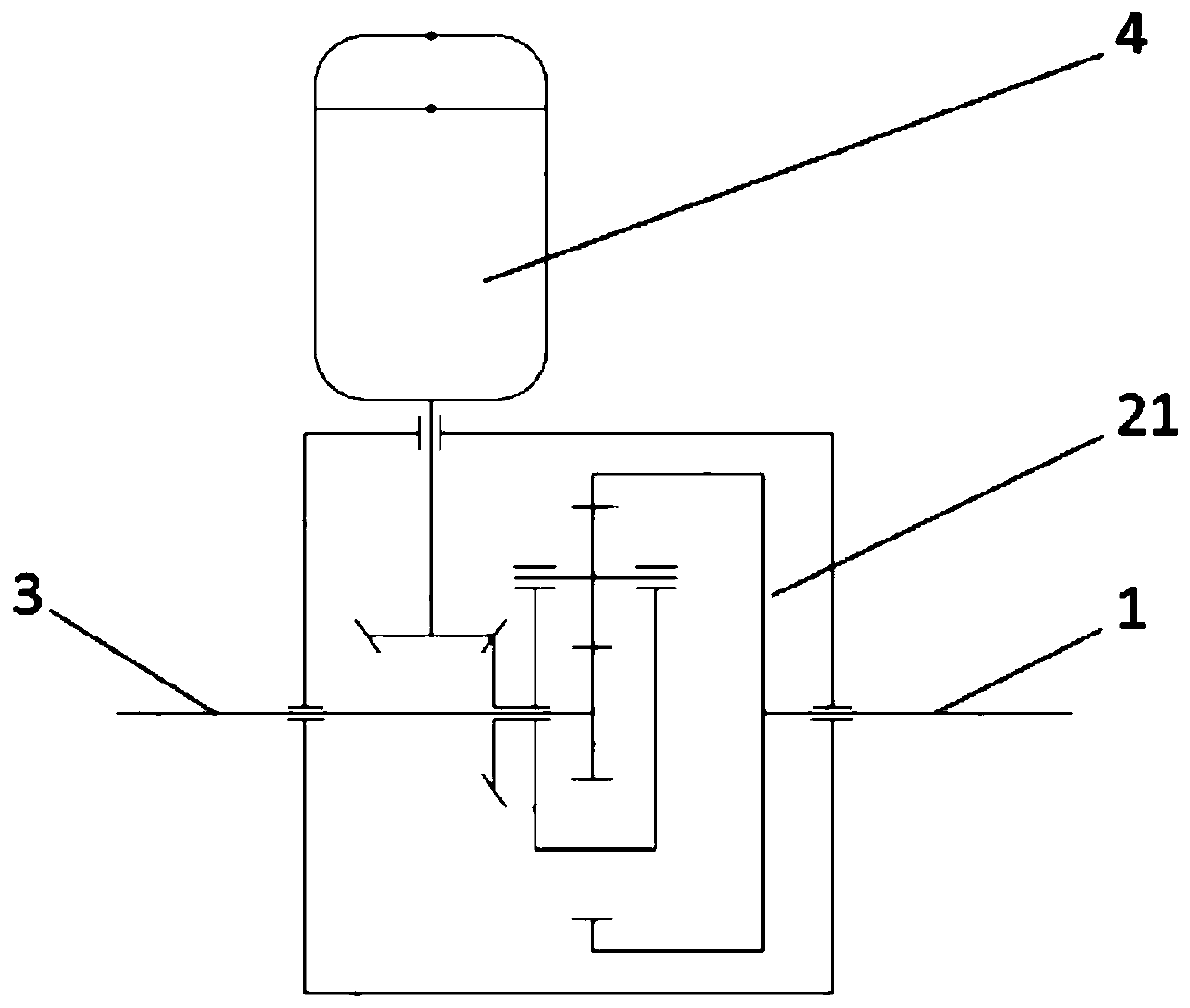

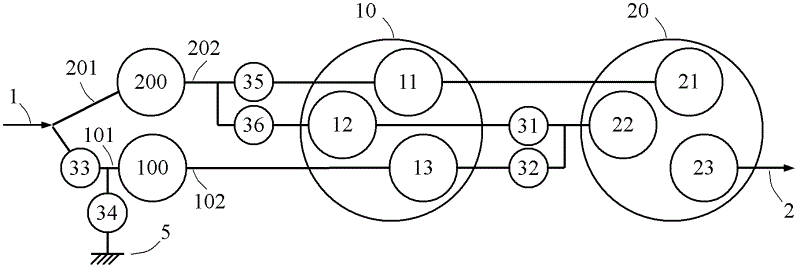

Variable-input and constant-output device adopting hydraulic and servo motor double regulation

InactiveCN104358853AOptimized gear ratioHeavy loadGearing controlFluid gearingsPower flowElectric machine

The invention discloses a variable-input and constant-output device adopting hydraulic and servo motor double regulation. The variable-input and constant-output device comprises a primary differential gear train, a secondary differential gear train, a hydraulic system, a servo motor, a rotating speed sensor, an ordinary gear train step transmission box and a reversing system. Hydraulic and mechanical double power flow transmission is adopted, and output power is large. In a double constant speed regulating scheme, the hydraulic system is used as a main executing system of constant-speed regulation to finish the regulation of large-range rotating speed variation caused by sudden load change, and the small-power servo motor is used as an auxiliary regulation executing system of constant-speed output to rapidly regulate small-range rotating speed fluctuation. In a single constant-speed regulating scheme, the small-power servo motor is used as an executing system of constant-speed regulation to rapidly regulate small-range fluctuating rotating speed. The three functions of constant speed output, stepless transmission and step transmission are creatively combined by the device to meet the requirements of different organizations and different work condition environments on a transmission device.

Owner:JILIN UNIV

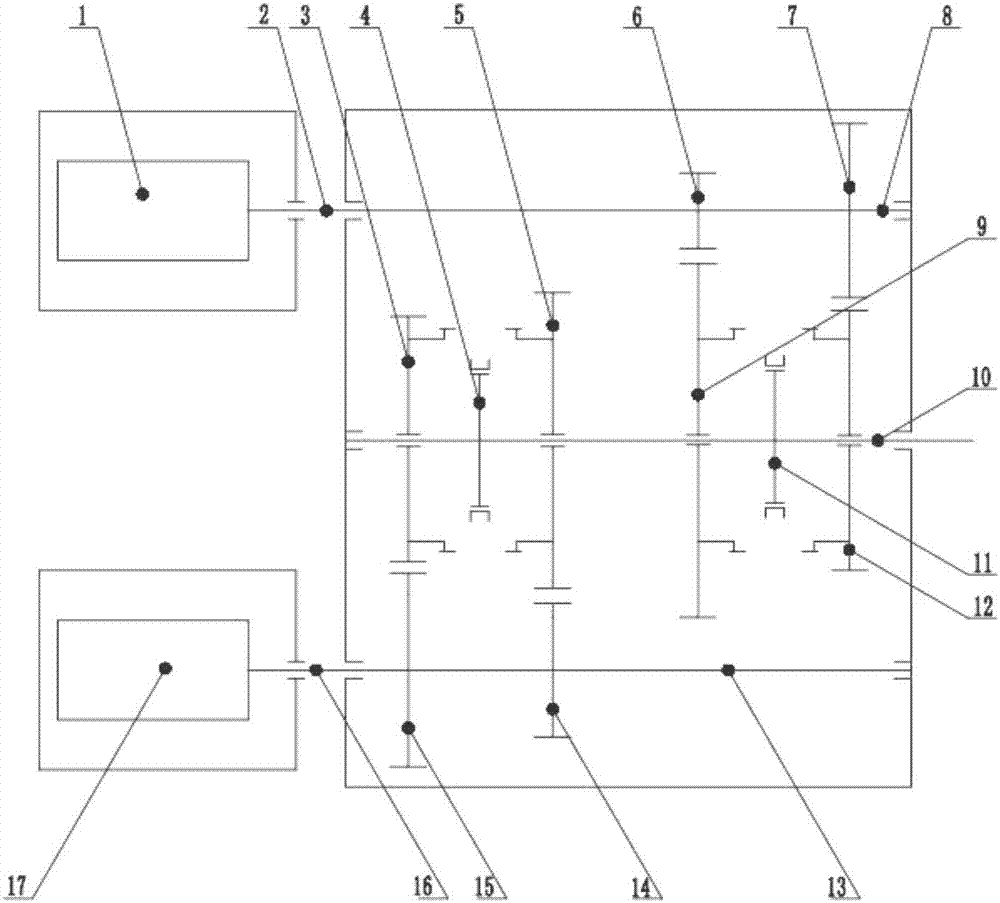

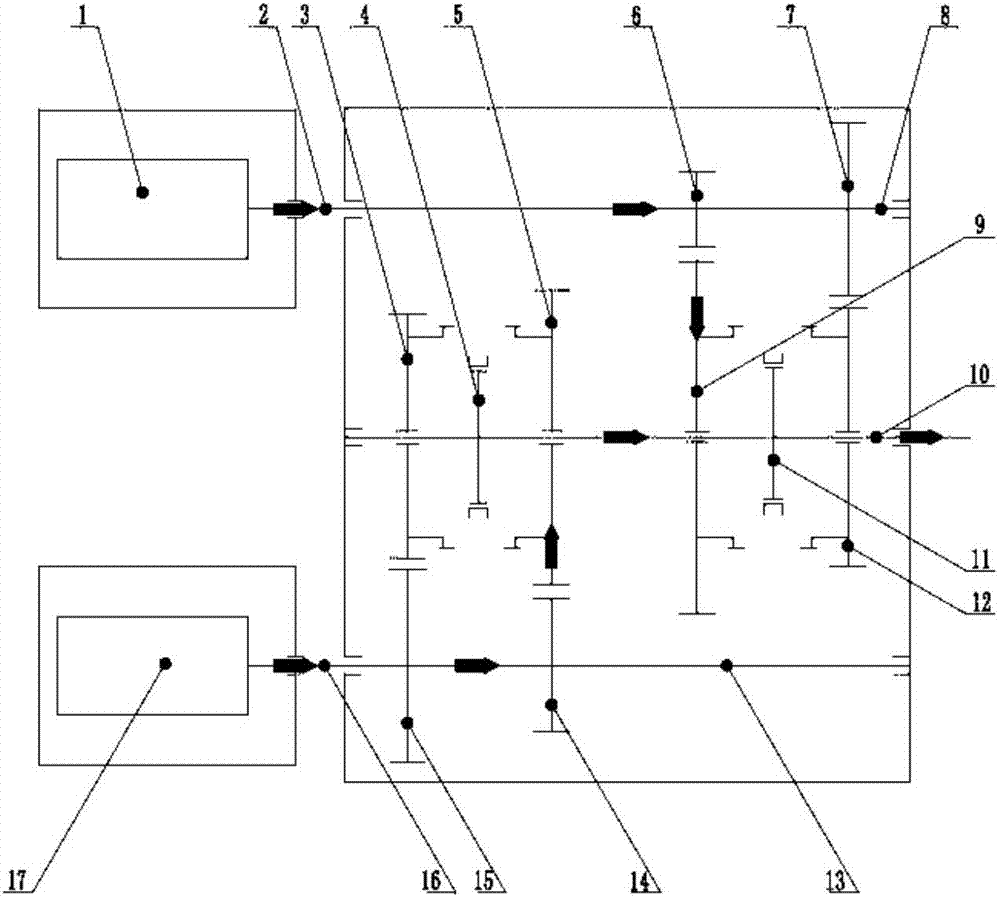

Parallel double-input-shaft transmission system and gear-shifting control method thereof

PendingCN106907433AReasonable space layoutSimple structureBatteries circuit arrangementsToothed gearingsEmbedded systemTransmission system

The invention discloses a parallel double-input-shaft transmission system and a gear-shifting control method thereof. The system comprises a transmission input shaft I, a transmission input shaft II, a transmission output shaft, a first-gear gear set, a second-gear gear set, a third-gear gear set, a fourth-gear gear set, a joint sleeve I and a joint sleeve II. By means of the parallel double-input-shaft transmission system, three-gear switching can be achieved. According to the system, transmission space can be effectively saved, the layout is reasonable, gear shifting can be achieved under the condition that power is not stopped, gear shifting is stable and smooth, the structure is compact, and manufacturing, machining and assembling are facilitated; one-to-one meshing is adopted in all gear-shifting gear sets, shared gears are avoided, the transmission ratio is optimized, and the bearing capacity of the gears is reasonably used; by means of the gear-shifting control method, generated of power needed for maintaining travelling in the gear-shifting process can be achieved; electric energy losses are reduced, and the runtime of a vehicle is prolonged.

Owner:NANJING YUEBOO POWER SYST CO LTD

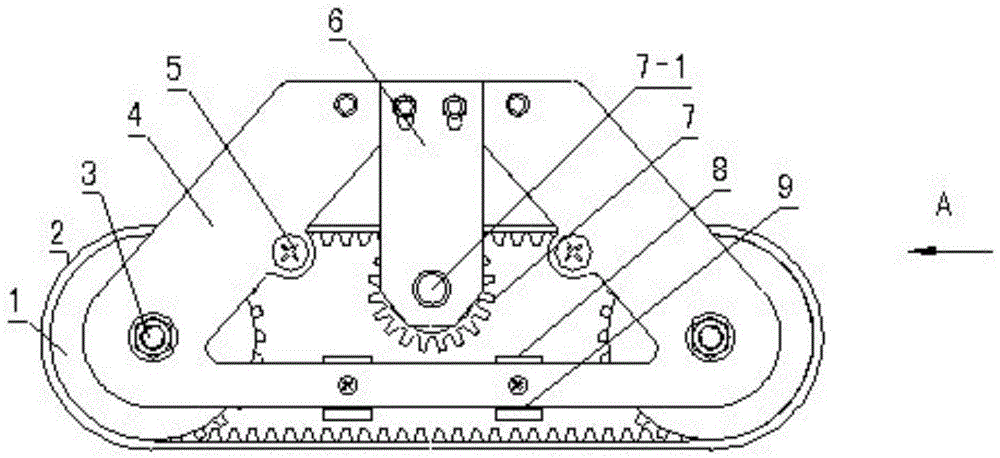

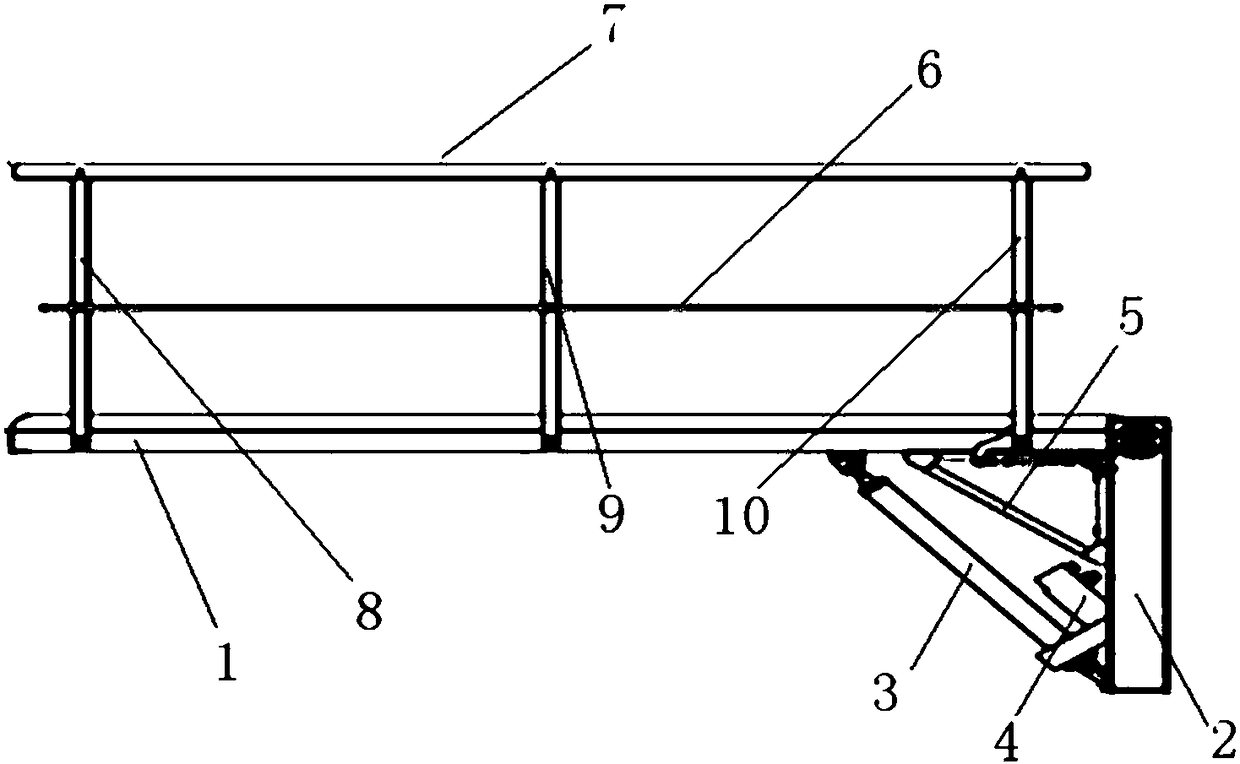

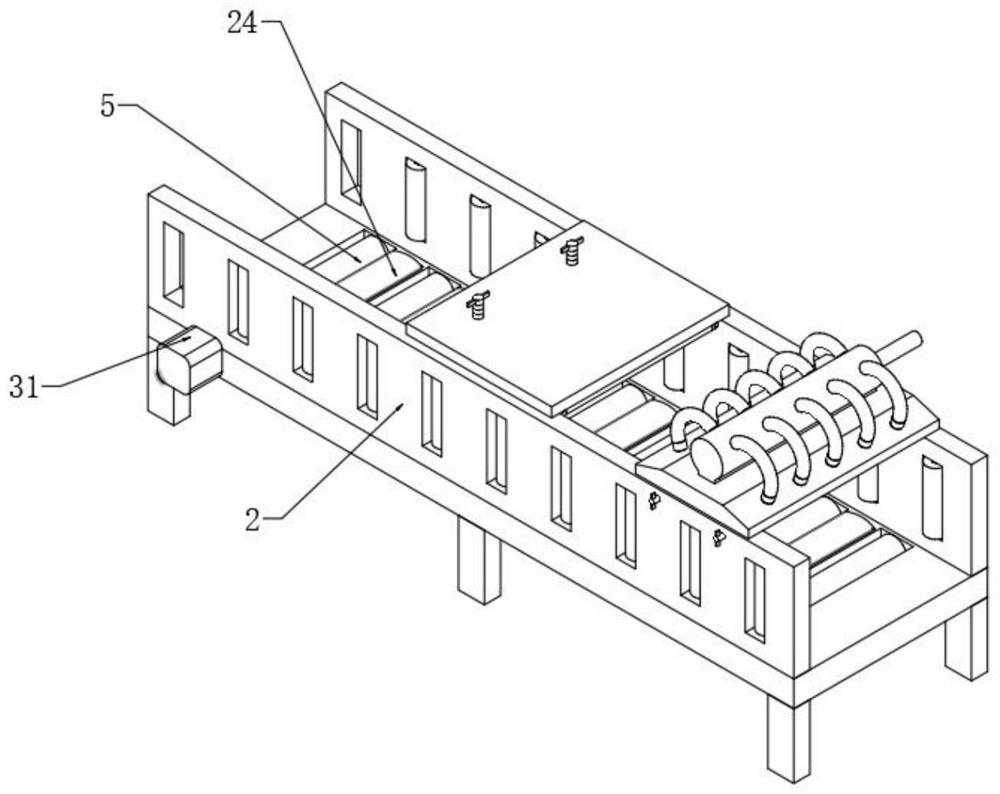

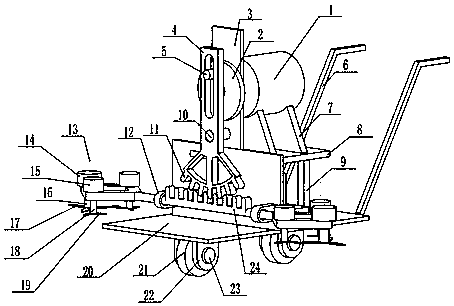

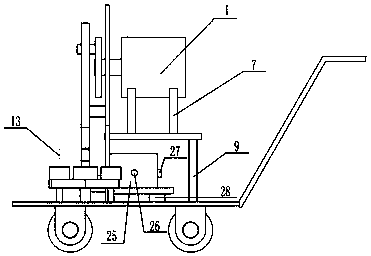

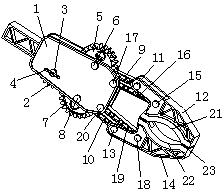

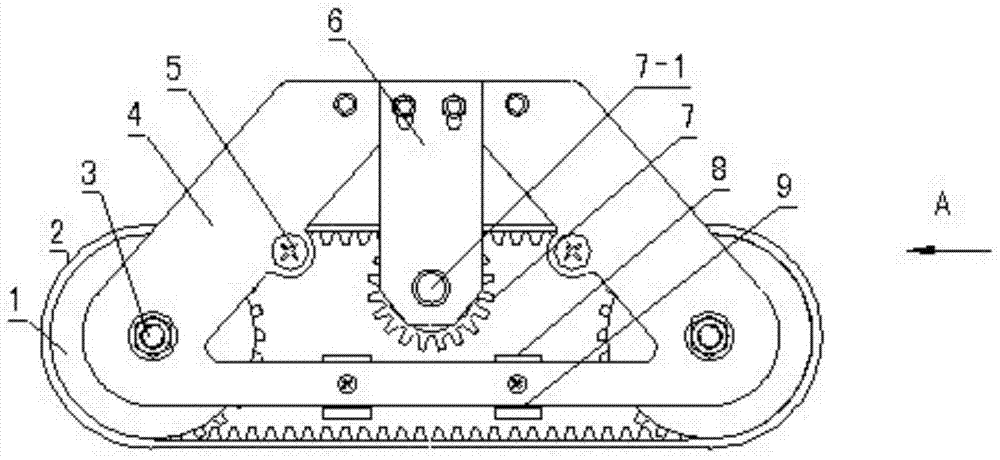

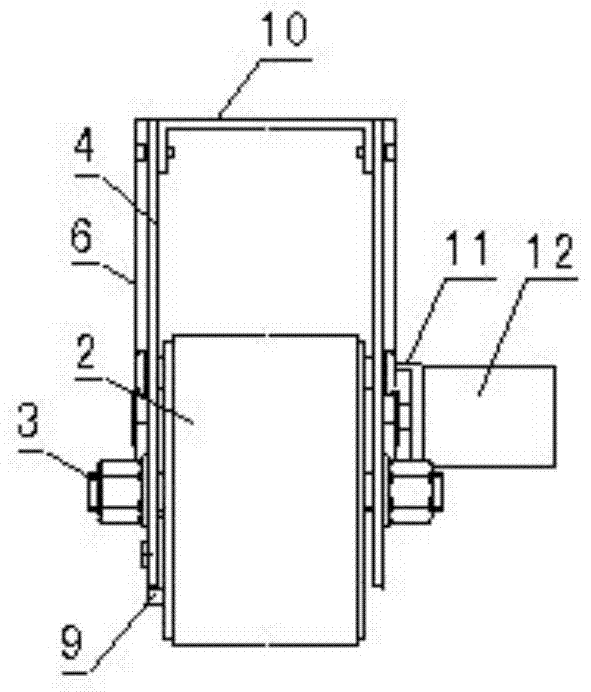

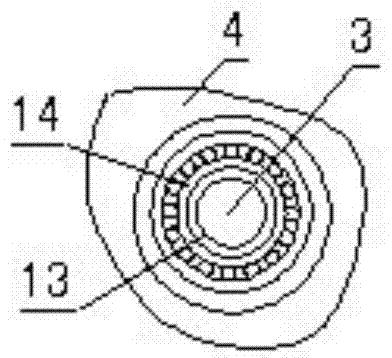

Antiskid wheels for track detecting trolley

ActiveCN104553602ASimple insulation structurePrevent slippingRail-engaging wheelsAuxillary traction increasing equipmentClosed loopEngineering

The invention provides antiskid wheels for a track detecting trolley. The antiskid wheels are characterized in that synchronous belt wheels which are supported through shafts are respectively arranged at two ends of the bottom part of two shaft frame plates which are corresponding to each other in positions; the two synchronous belt wheels are equipped with closed-loop tooth-shaped synchronous belts which engage the two synchronous belt wheels; the outer rubber surfaces of the closed-loop tooth-shaped synchronous belts are jointed with the track surface; a top plate for supporting a trolley body is arranged on the top parts of the two shaft frame plates. According to the antiskid wheels, the jointing area of the outer rubber surfaces of the closed-loop tooth-shaped synchronous belts and the track surface is far more than that of steel wheels and the track surface in the prior art; the frictional resistance between the wheels and the track is relatively large due to the characteristic that the outer surfaces of the closed-loop tooth-shaped synchronous belts are prepared from rubber, and therefore, the slipping of the steel wheels is completely avoided. The antiskid wheels have outstanding advantages of being simple in structure, ingenious in concept and remarkable in performance.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Hybrid power module and hybrid power vehicle

PendingCN111993881ACompact layoutSmall sizeHybrid vehiclesGas pressure propulsion mountingTransaxleElectric machinery

The invention relates to a hybrid power module and a hybrid power vehicle. The hybrid power module comprises an input shaft used for being connected with an internal combustion engine, an output shaftused for transmitting a torque to a drive axle, a first motor, a first rotating shaft, a second motor, a second rotating shaft, a gear ring, a first gear, a second gear, a third gear, a first torquetransmission device and a second torque transmission device, wherein the gear ring and the first gear are meshed with each other; and the second gear and the third gear are meshed with each other. Thesecond rotating shaft is designed as a hollow shaft, and the first rotating shaft is arranged inside the second rotating shaft. The first gear is arranged on the first rotating shaft in an anti-rotation mode, the second gear is arranged on the second rotating shaft in a sleeving mode, the third gear is arranged on the output shaft in an anti-rotation mode, and the first torque transmission devicecan selectively connect the gear ring with the input shaft in the anti-rotation mode. The second torque transmitting device may selectively connect the second rotating shaft with the first rotating shaft in the anti-rotation mode. The hybrid power vehicle comprises the hybrid power module.

Owner:SCHAEFFLER TECH AG & CO KG

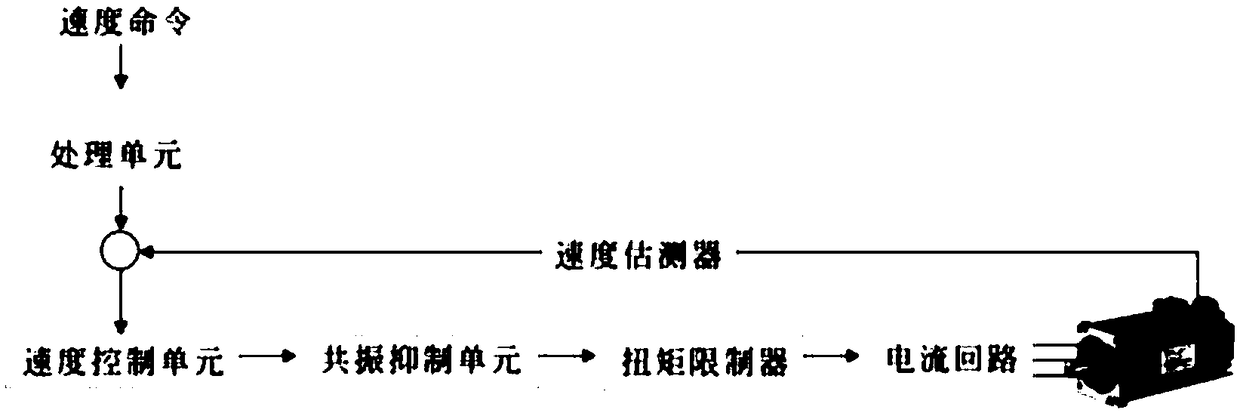

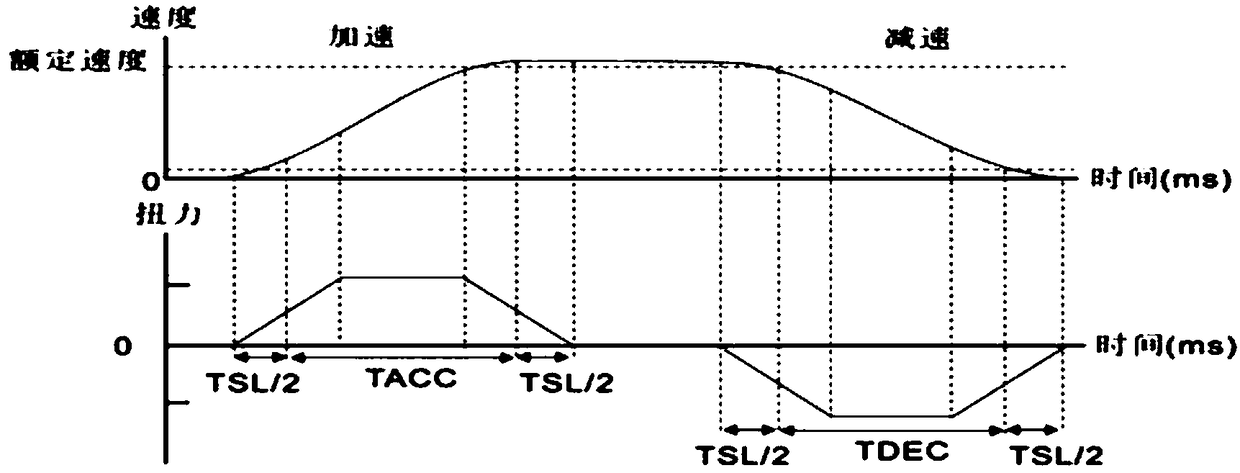

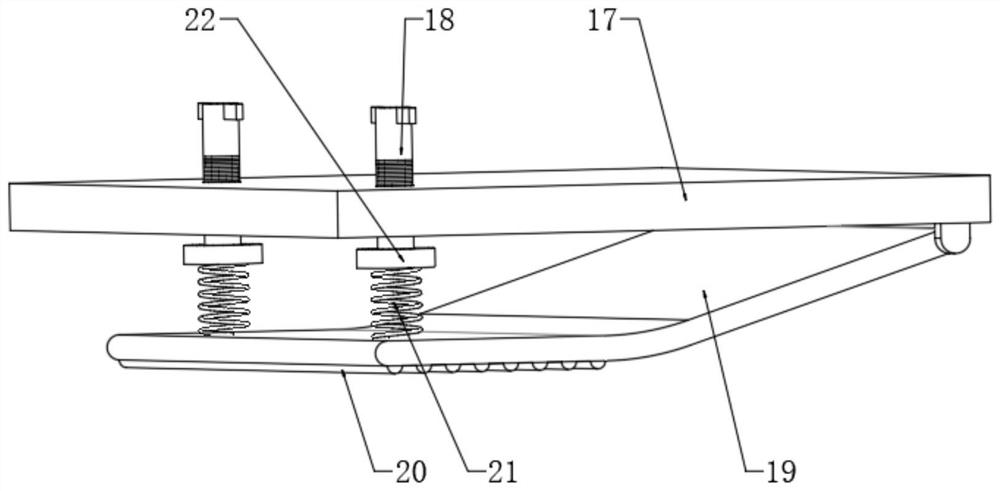

Boarding bridge

The invention discloses a boarding bridge comprising a control device. The control device enables a bridge body to rise or fall through a driving device, the driving device comprises an electric cylinder and a servo motor driving the electric cylinder to work and provided with a contracting brake, and the bridge body comprises a mounting frame. A bridge frame where bridge plates are laid is rotatably arranged on the mounting frame, one end of the electric cylinder is hinged to the bridge frame, and the other end of the electric cylinder is hinged to the mounting frame. The control device comprises a main controller, the main controller is electrically connected with a motor controller, a power source, a contactor and an operating keyboard, and the motor controller comprises a processing unit. The processing unit is sequentially electrically connected with a speed control unit and a speed evaluation unit, the speed control unit is sequentially connected with a resonance inhibition unit,a torque limiting unit and a current loop unit, and the speed evaluation unit and the current loop unit are electrically connected with the servo motor. In the structure, position accurate control can be achieved, operation is stable, the safety is high, meanwhile it is ensured that during operation, noise is small, pollution is avoided, and maintenance is easy.

Owner:北京摩诘创新科技股份有限公司

Motorcycle accelerator handle structure and motorcycle

PendingCN111703533AFlexible layoutIncrease adjustabilityCycle control systemsGear transmissionAutomotive engineering

The invention provides a motorcycle accelerator handle structure which is arranged on a motorcycle body and comprises an accelerator coiled pipe rotatably arranged on the motorcycle body and a transmission unit connected with the accelerator coiled pipe. The transmission unit can be driven by rotation of the accelerator coiled pipe to pull an accelerator zipper. The accelerator coiled pipe comprises a sleeve section which is rotatably arranged on the vehicle body and a a first gear fixedly arranged on the sleeve section in a sleeving mode; the transmission unit comprises a second gear which isrotatably arranged on the vehicle body and can be meshed with the first gear, the sleeve section can bear an external force to drive the first gear and the second gear to rotate, and the acceleratorzipper can be pulled by the rotation of the second gear. The accelerator handle structure of the motorcycle has good control hand feeling.

Owner:河北在路上摩托车配件科技有限公司

Drive device

InactiveCN102177055ASave spaceReduce shaft misalignmentMechanical apparatusVehicle cleaningLinear motionSelf locking

Owner:ROBERT BOSCH GMBH

Cycloid planetary transmission gear based on line-plane conjugation

ActiveCN102252058BImprove rigidityGood transmission precisionPortable liftingToothed gearingsGear wheelEngineering

Owner:CHONGQING UNIV

An automatic transmission that transmits power through shafts and plungers

ActiveCN103206496BImprove powerImprove economyToothed gearingsGearing controlAutomatic transmissionTransmitted power

Owner:范巨新

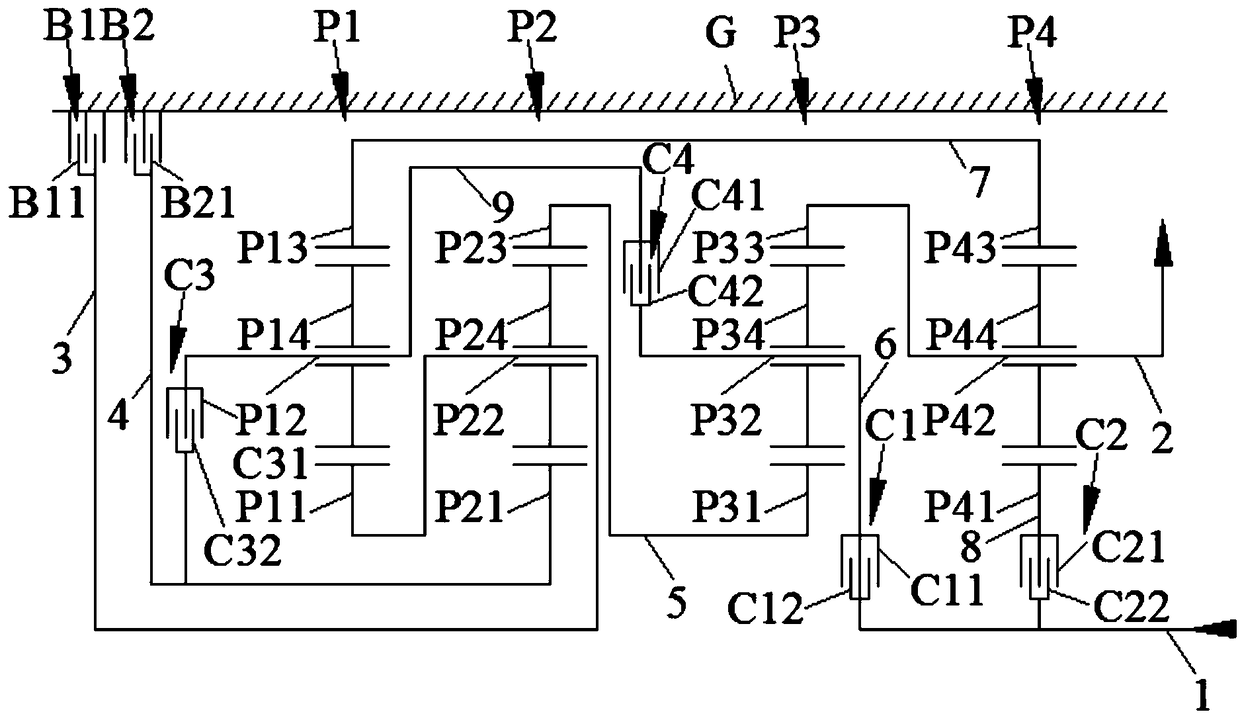

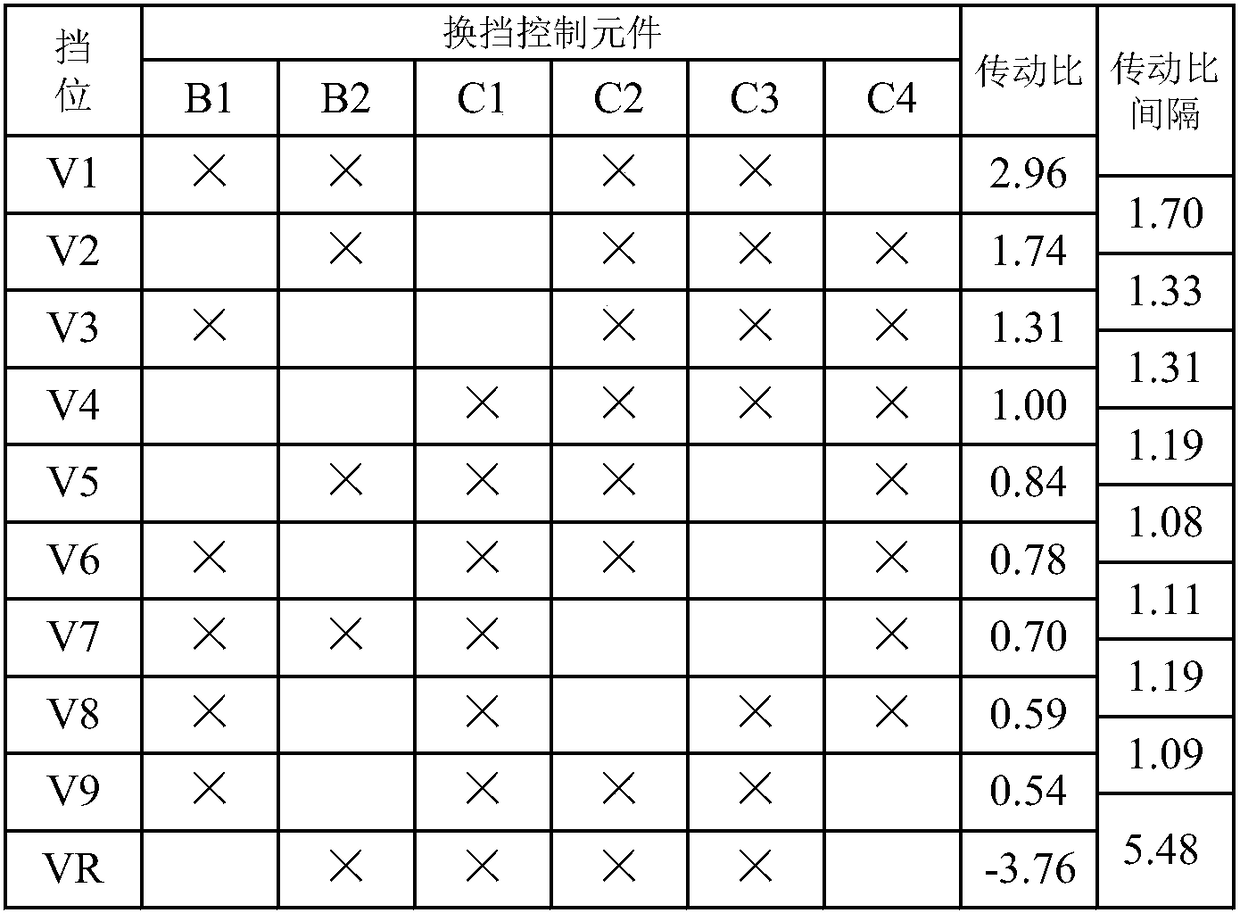

Multi-gear automobile automatic transmission

ActiveCN109340329AReduce loadReduce in quantityToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention discloses a multi-gear automobile automatic transmission, and belongs to the technical field of automatic transmissions. The problems that in the prior art, automatic transmissions are large in component number and complex in structures and cannot provide a slightly progressive and densely classified transmission ratio series and good engagement efficiency especially are solved. Themulti-gear automobile automatic transmission comprises four planet gear sets arranged one behind the other along a main rotation axis, nine rotatable shafts, and six shifting switching elements; the shifting switching elements are allowed to be selectively operated, thus, nine forward gears and a reverse gear are formed between an input shaft and an output shaft of the transmission; the input shaft is connected with a sixth shaft connected to a third planet carrier through a first clutch in a releasable mode and connected with an eighth shaft of a fourth sun gear through a second clutch in a releasable mode; the third shaft is connected with a first sun gear and a second planet carrier and connected to a housing through a first brake; and the output shaft is connected with a third ring gear and a fourth planet carrier.

Owner:ZHAOQING UNIV

Variable speed input and constant speed output device with double adjustment of hydraulic pressure and servo motor

InactiveCN104358853BOptimized gear ratioImprove the lack ofGearing controlFluid gearingsHydraulic motorPower flow

Owner:JILIN UNIV

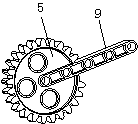

Variable valve timing device

InactiveCN107605561AOptimized gear ratioReduce vibrationMachines/enginesNon-mechanical valveVariable valve timingSprocket

The invention discloses a variable valve timing device. A driven gear is fixed at one end of a camshaft; an upper chain wheel is arranged on one side of the camshaft; the upper chain wheel and a driving gear are fixed to a connecting shaft; the connecting shaft is located on a fixing bracket depending on a bearing, and rotates around the axis of the camshaft; a through hole is drilled in the axisof the connecting shaft; an arm consists of a big end, a small end and screws; the big end of the arm consists of a cylinder and a long block extending in the radial direction of the cylinder; two gears different in reference diameters are fixed to a middle shaft; a section of narrow neck is formed in the middle shaft; two semicircular concave surfaces of the big end and the small end of the arm are clamped in the narrow neck; the big end can be connected with the small end through the screws; and two middle shaft gears are correctly engaged with the driving gear and the driven gear correspondingly. A cylinder of a driving arm controlled by servo motors rotates around the axis of the camshaft, and the position of the middle shaft is changed, so that the phase relation between an input gearand an output gear is changed, and valve timing is changed. By additionally adopting a servo motor, an arm, a middle shaft, middle shaft gears, a driven gear and a transmission gear, the phase of a second shaft rotating around the axis of the camshaft can be controlled.

Owner:陆逸钧

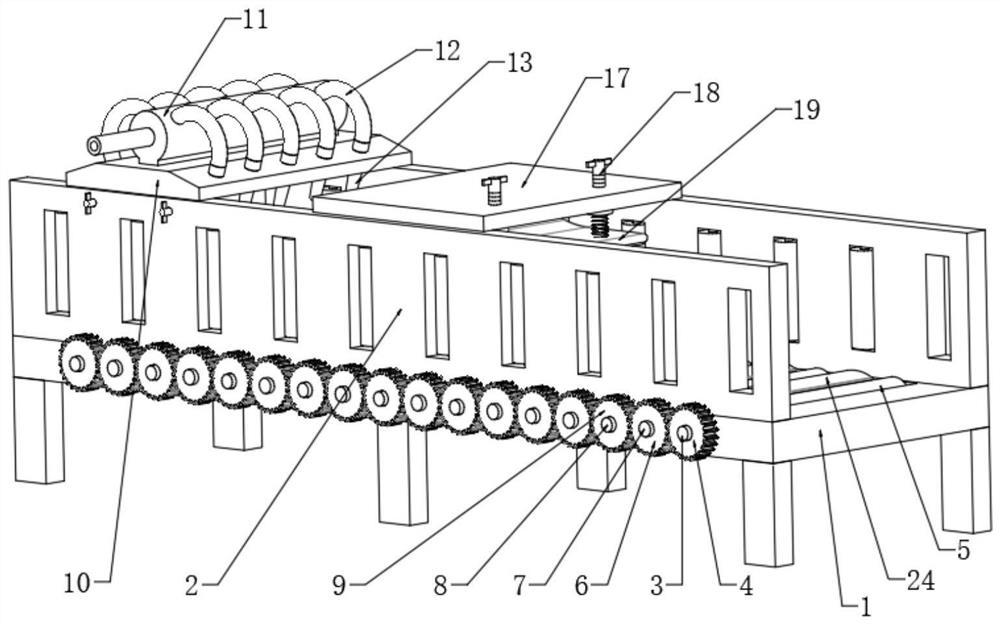

Cleaning device of controller for intelligent equipment and cleaning method thereof

InactiveCN112934788ANot easy to damageEasy to cleanCleaning using toolsCleaning using gasesDrive shaftGear wheel

The invention discloses a cleaning device of a controller for intelligent equipment and a cleaning method thereof. The cleaning device comprises a rack, two side plates are symmetrically and fixedly connected to the top end of the rack, a first transverse mounting hole is formed in one side of the rack, a driving shaft is connected into one of the first mounting holes in a penetrating mode, the outer side of the driving shaft is fixedly sleeved with a rotating cylinder, the outer side of the driving shaft is fixedly sleeved with a driving gear, one side of the rack is fixedly connected with a driving motor, an output shaft of the driving motor is fixedly connected with one end of the driving shaft, a transmission mechanism is arranged on one side of the driving gear, the transmission mechanism comprises a driving gear, a driven gear and an auxiliary gear, and a cleaning mechanism is arranged at the top end of the rack. The cleaning device has the beneficial effects that through the design of the cleaning mechanism and the mode of cleaning the controller through high-pressure gas, dust on the surface of the controller can be well cleaned, and the controller is not prone to being damaged.

Owner:WENZHOU UNIVERSITY

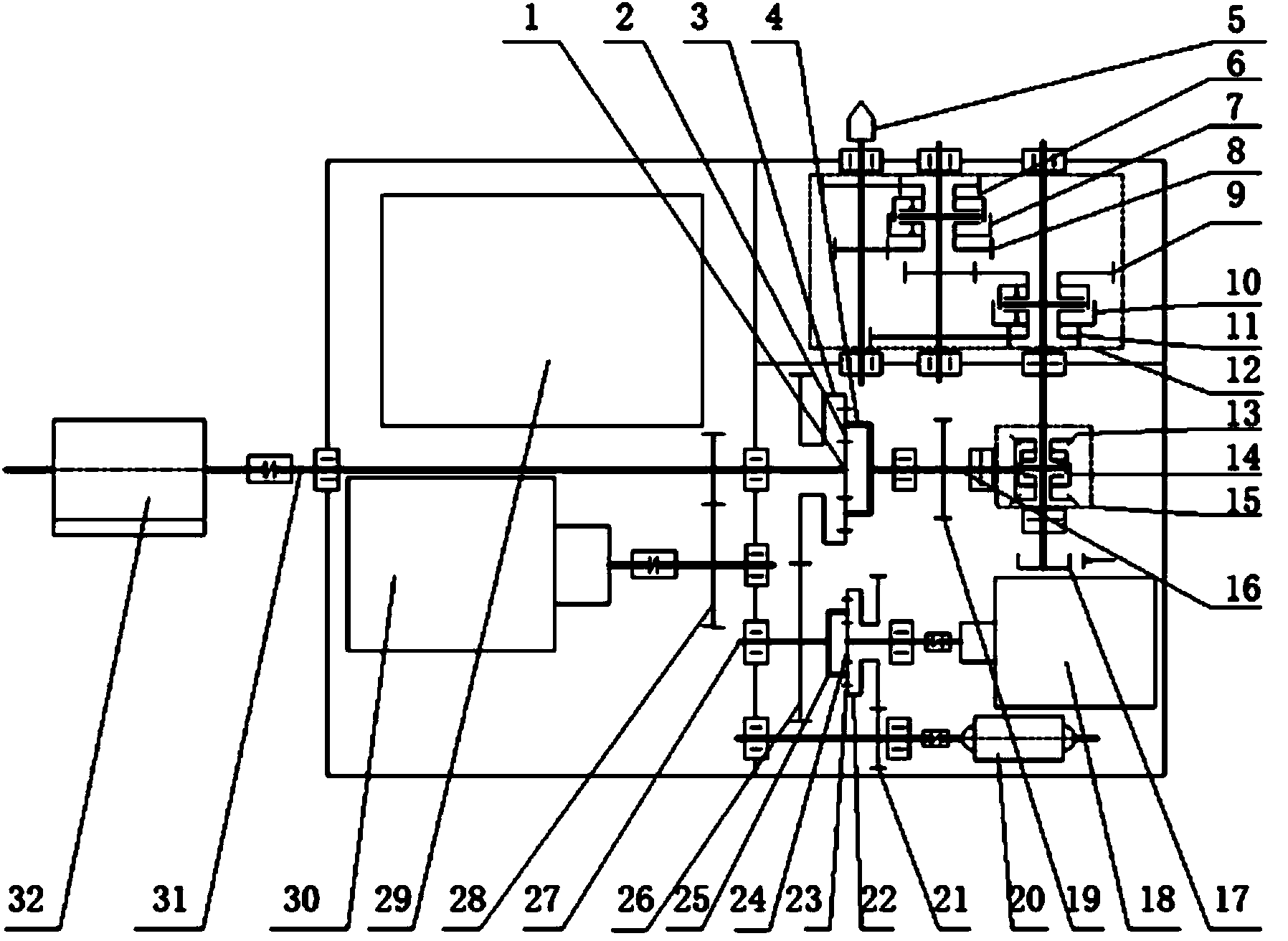

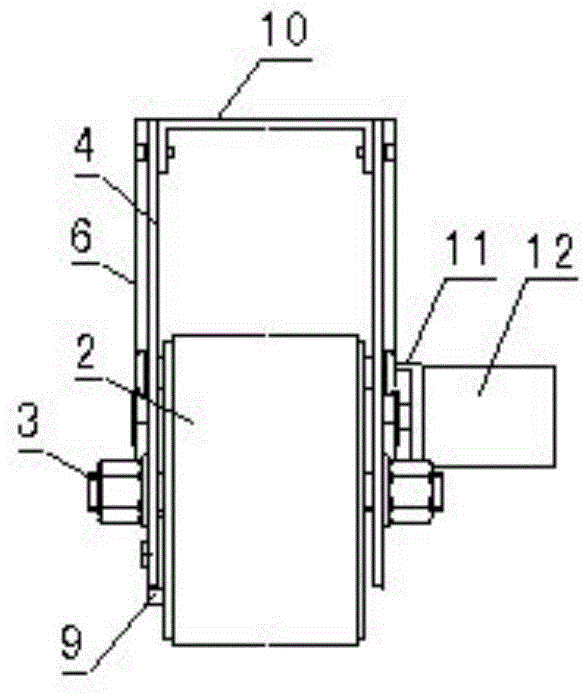

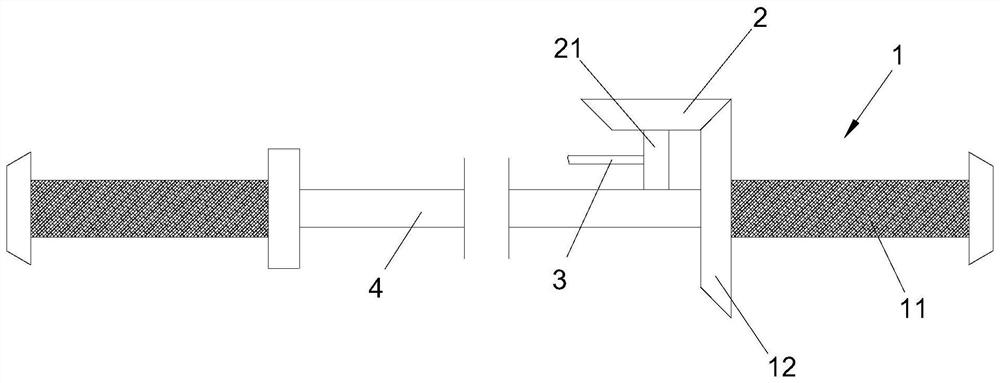

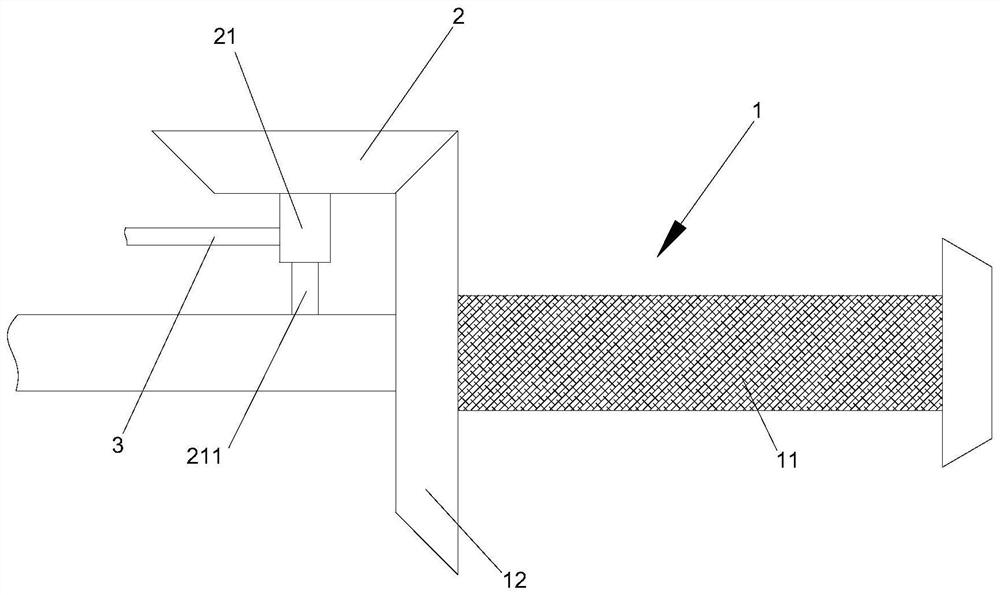

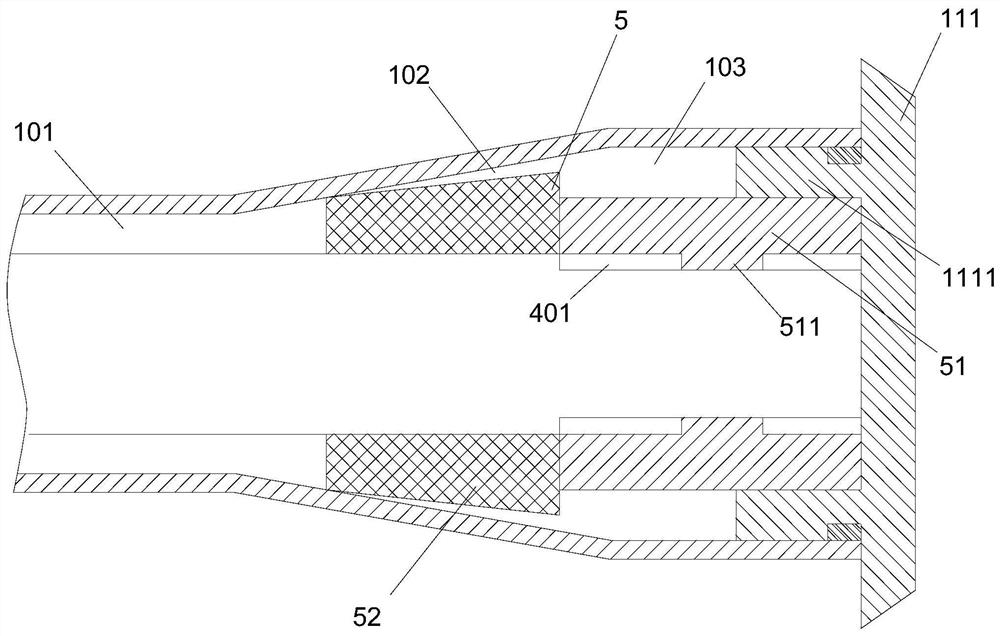

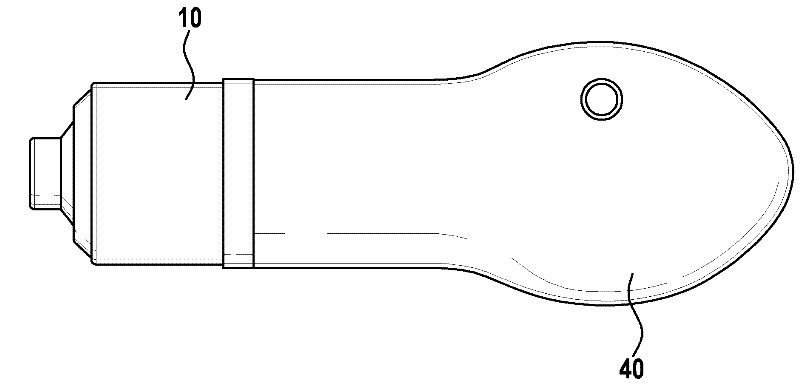

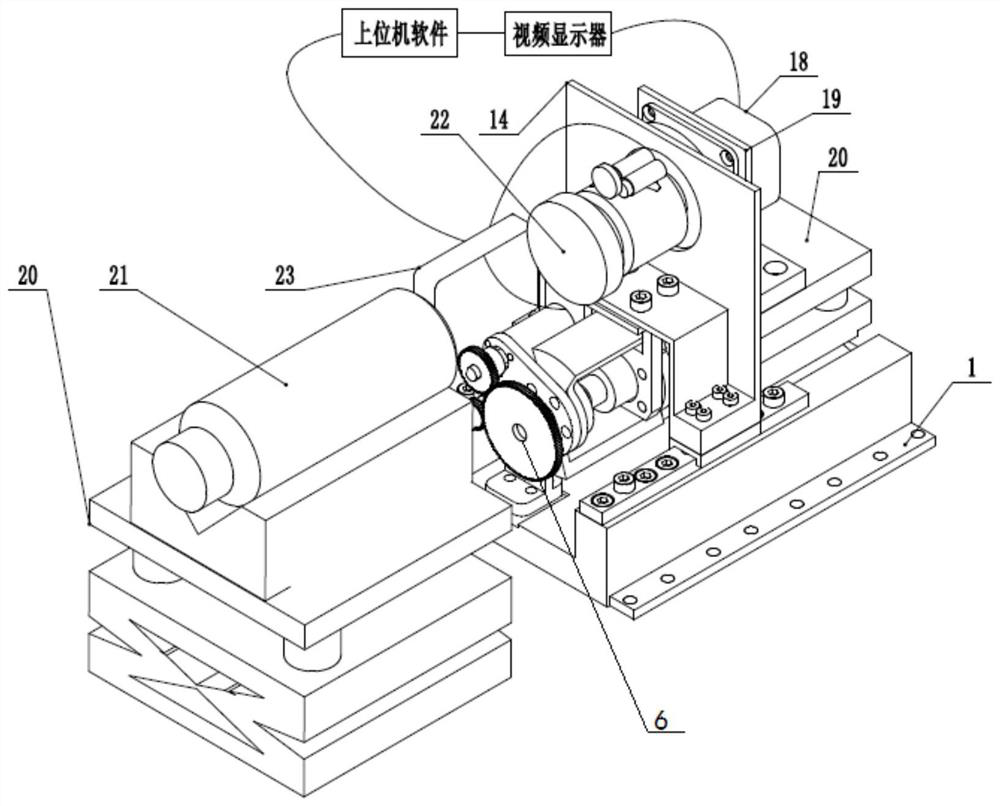

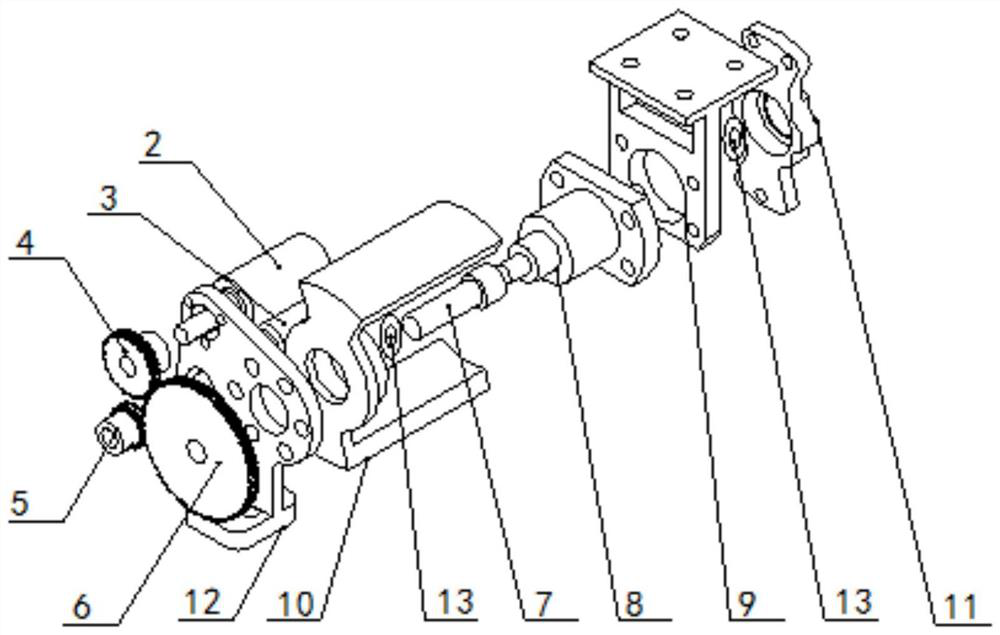

A zoom lens automatic image plane docking and optical axis runout detection system and method

ActiveCN113237634BConsistentAvoid discrimination errorOptical axis determinationLens position determinationOptical axisDisplay device

The invention relates to the field of image plane debugging of aerospace full-spectrum zoom lenses, in particular to a zoom lens automatic image plane docking and optical axis runout detection system and method, which solves the problem that the existing image plane docking method consumes a lot of labor, and different batches of There may be differences in the image plane definition of sub-products and there are individual differences in optical axis jump detection, and the efficiency is not high. The system includes a system support bracket, a drive and feedback component, a guide component, an optical imaging component and a control component. The drive and feedback assembly includes potentiometer, motor, potentiometer gear, motor gear, drive screw gear, coupling, ball screw nut and nut retaining bracket. The guide assembly includes linear guides, moving sliders, and zoom lens mounting brackets. Optical imaging components include imaging components, imaging component mounting brackets, two four-degree-of-freedom optical adjustment platforms, collimator and accessories, and zoom lenses. Control components include control box, upper computer and video display.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Hybrid power system and vehicle with same

PendingCN114103621AReduce volumeReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machinery

The invention discloses a hybrid power system and a vehicle with the same, the hybrid power system comprises an engine, the engine is provided with an engine output shaft, and the engine output shaft is connected with a driving gear through a clutch; and the driven gear is meshed with the driving gear. The first motor is provided with a first motor shaft, and the first motor shaft is in transmission connection with the driving gear through a first transmission assembly; the second motor is provided with a second motor shaft, and the second motor shaft is in transmission connection with the output shaft of the engine through a second transmission assembly; the central axis of the engine output shaft, the central axis of the first motor shaft and the central axis of the second motor shaft coincide with one another. The hybrid power system has the advantages of being small in size, light in weight, low in cost, convenient to adjust the transmission ratio and the like.

Owner:BYD CO LTD

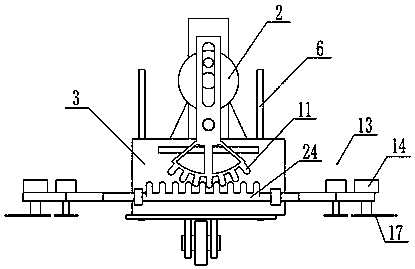

Seedling cutting device special for panax notoginseng

The invention relates to a seedling cutting device special for panax notoginseng, and belongs to the technical field of panax notoginseng water-saving irrigation. The seedling cutting device special for panax notoginseng comprises a frame, a walking mechanism, a power transmission mechanism and a seedling cutting mechanism; the frame comprises a fixed plate, a motor seat, a small support plate, asupport frame, lifting lugs I, a support plate and a cushion block; the walking mechanism comprises handles, wheels, lifting lugs II and pin shafts; the power transmission mechanism comprises a motor,a round disc, a gear plate, a round disc shaft, a fixed shaft, gear teeth; a rack shaft, rack gear teeth and a U-shaped groove; and the seedling cutting mechanism comprises electric wires, a big motor, small motors, a rotating shaft I, main-blade seedling cutting blades, rotating shafts II, secondary-blade seedling cutting blades, a battery pack, a switch and a rhombic frame. The device has highworking efficiency and simple operation, greatly saves manpower, reduces the production cost, is low in manufacturing cost, and can meet the seedling cutting requirements of panax notoginseng in a greenhouse.

Owner:KUNMING UNIV OF SCI & TECH

Conveying device

The invention discloses a conveying device, and belongs to the technical field of maneuvering roller way conveying devices. The conveying device comprises rollers, a transmission chain and a steppingmotor driving device; the rollers support the transmission chain, the stepping motor driving device drives the transmission chain for transmission conveying, the transmission chain is provided with aheat preservation layer and a carbon fiber heating layer, an auxiliary heating device is arranged in the carbon fiber heating layer, the rollers are parallel dual rollers, the dual rollers parallel onthe same horizontal plane are in power connection through the transmission chain, an ARM8 control system is further included, and controls heating of the carbon fiber heating layer and conveying of the maneuvering roller way conveying device, and the thickness of the heat preservation layer ranges from 6 mm to 8 mm. On the premise of ensuring normal conveying, heat preservation and heating of a repair material can be achieved.

Owner:薛飞

Planet gear stepless speed regulation coupler

PendingCN111006003AReduced demand spaceSmall footprintMechanical energy handlingGearing detailsTransverterGear wheel

The invention discloses a planet gear stepless speed regulation coupler. The planet gear stepless speed regulation coupler comprises a main motor, a load and a stepless speed regulation device connected between the main motor and the load, wherein the stepless speed regulation device comprises an input shaft, a planet gear box and an output shaft, the input shaft, the planet gear box and the output shaft are sequentially arranged from the main motor to the load, the planet gear box comprises a gear set and a planet carrier, the gear set is connected to the input shaft and the output shaft, theouter side of the gear set is provided with the planet carrier, the planet carrier wraps the gear set, an auxiliary motor is fixedly arranged on the outer side of the planet carrier, and a frequencyconverter is connected to the auxiliary motor. The invention further discloses a working method for the planet gear stepless speed regulation coupler. The working method utilizes the planet gear mechanism to split the input and output ends, the speed regulation of the load is realized through different states and different rotating speed of the auxiliary motor, on one hand, the power requirement and the occupied space are reduced, the rotating speed of the load is high, the damage is not easy, on the other hand, addition and subtraction operation can be used, the speed regulation range is enlarged, and the flexibility and the practicability of the device are improved.

Owner:YANGZHOU UNION TRANSMISSION TECH

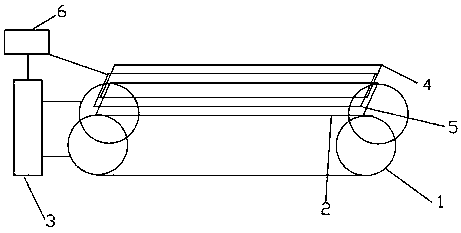

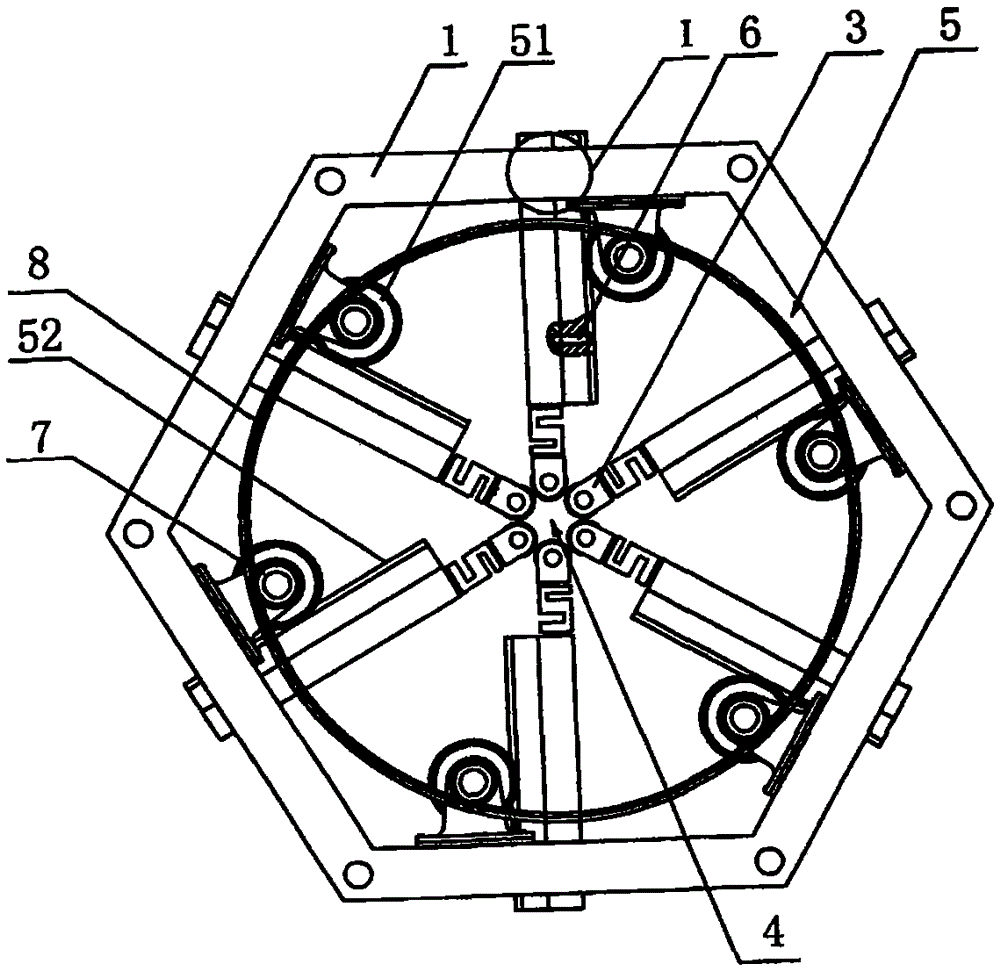

Tubular belt transverse stiffness test device

InactiveCN102967501BNovel structureSafe and reliable structureStrength propertiesComputer control systemTransport system

The invention discloses a testing system capable of automatically testing the lateral rigidity of tubular conveying belts. The testing system comprises a bracket mechanical structure, a mechanical transmission part, a pressure sensing structure, a data transmission system, a computer control system, and the like, wherein the mechanical part carries out sis-point measurement by adopting a regular hexagon structure; the transmission part adopts synchronous belt transmission and can automatically measure tubular conveying belts with different diameters; a control and data transmission part adopts a PLC (Programmable Logic Controller) and the special data transmission system; and the computer control system processes data. The testing system disclosed by the invention mainly has the functions of placing the tubular conveying belts to be measured into the bracket mechanical structure of the testing system, measuring the lateral rigidity values of the tubular conveying belts with different diameters through a pressure sensing mechanism, transmitting the measured lateral rigidity values to the computer control system for data processing, outputting and editing the measured lateral rigidity values and directing the use and production of the tubular conveying belts by acquiring the changing curve of the lateral rigidity values with time.

Owner:QINGDAO UNIV OF SCI & TECH

Multistage transmission

InactiveCN101984271BOptimized gear ratioShorten the axial lengthToothed gearingsAutomatic transmissionVariator

Owner:广州科立源机电科技有限公司 +1

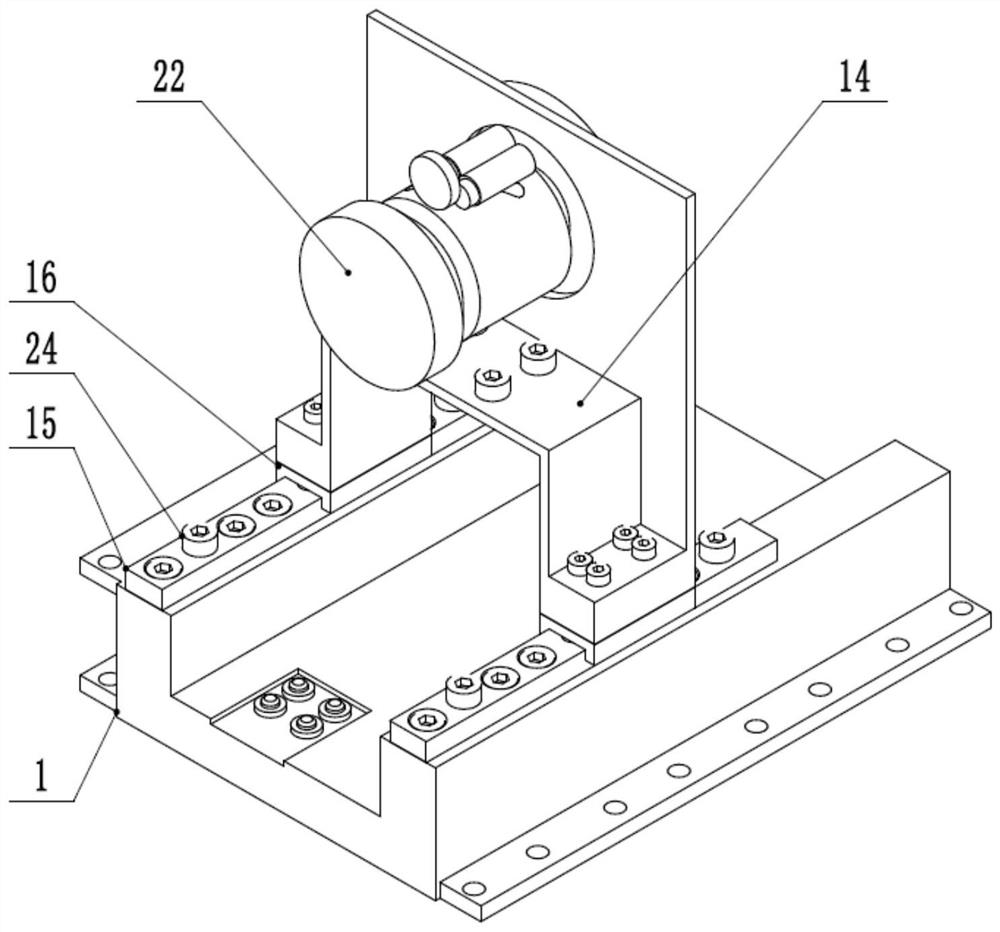

Clamping device based on gear transmission

InactiveCN108115603ASmooth transmissionOptimized gear ratioToothed gearingsWork holdersGear transmissionEngineering

The invention discloses a clamping device based on gear transmission. The clamping device comprises a clamping base. A gear A is mounted in the clamping base through a movable shaft A. A rotating knobis mounted on the movable shaft A. A gear B is mounted in the clamping base through a movable shaft B. A gear C is mounted in the clamping base through a movable shaft C. A first connection rod is mounted on the gear B, and a second connection rod is mounted on the gear C. The other end of the first connection rod is mounted on a first clamping arm through a movable shaft D. The other end of thesecond connection rod is mounted on a second clamping arm through a movable shaft E. A first clamping rod is mounted on the first clamping arm through a movable shaft F. The other end of the first clamping rod is mounted on the clamping base through a movable shaft G. A second clamping rod is mounted on the second clamping arm through a movable shaft H. The other end of the second clamping rod ismounted on the clamping base through a movable shaft I.

Owner:桐城市湃腾机械设计有限公司

Anti-skid wheels of track inspection trolley

ActiveCN104553602BSimple insulation structurePrevent slippingRail-engaging wheelsAuxillary traction increasing equipmentRubber materialEngineering

The present invention is an anti-skid wheel of a track detection trolley. The bottom ends of the corresponding two shaft frame plates are respectively equipped with synchronous pulleys supported by shafts. The rubber outer surface of the synchronous belt is joined with the surface of the track, and the top of the two axle frame plates is provided with a top plate supporting the main body of the trolley. The rubber outer surface of the closed-loop toothed synchronous belt of the wheel and the joint area of the track surface are far greater than the joint area of the steel wheel and the track surface in the prior art, and the characteristics of the rubber material on the outer surface of the closed-loop toothed synchronous belt cause this The friction resistance between the wheel and the track is relatively large, which completely overcomes the slipping phenomenon of the steel wheel. The invention has the outstanding advantages of simple structure, ingenious conception and superior performance.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com