Patents

Literature

41results about How to "Good transmission precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gear and its production method

InactiveCN1412456AReduce processing costsFacilitate transmissionPortable liftingGearing elementsState of artWhole body

The present invention relates to a gear and its production method. Said gear is made up by using several toothed sheets with identical tooth outline and superimposing them in the mode of aligning tooth profile or alternating them in a certain order, and fixedly connecting them. Its production method includes the following steps: punching thin sheet into toothed sheet, suporimposing toothed sheetsand connecting them together by mechanical process or adhesive process in the mode of aligning their tooth profile and alternating them according to a certain order to form a whole body gear.

Owner:赵永彬 +1

Spiral disc type friction transmission self-adaption automatic speed change drive assembly for electric motor car

ActiveCN105253246ASmooth load changeAchieve balance controlWheel based transmissionDrive shaftEngineering

The present invention discloses a spiral disc type friction transmission self-adaption automatic speed change drive assembly for an electric motor car. The spiral disc type friction transmission self-adaption automatic speed change drive assembly comprises a box body, a transmission shaft, a slow gear transmission mechanism, and a mechanical intelligent self-adaption speed change assembly by utilization of disc type friction transmission; and the slow gear transmission mechanism comprises an overrunning clutch, an inner ring of the overrunning clutch sleeves a transmission shaft sleeve, and an inner circle of the inner ring is provided with a spiral cam used for being cooperated with the transmission shaft sleeve. The spiral cam output structure is adopted by the inner ring of the overrunning clutch, the spiral cam is disposed on the transmission shaft sleeve, use of end cams is reduced, and the spiral cam has good flexibility and is sensitive to resistance. The overrunning clutch has the possibility of multiple cam transmission, sensibility and stability of disengaging and engaging of friction transmission are ensured by utilization of the disc type friction transmission, axial dimension of a speed changer is reduced, and the spiral disc type friction transmission self-adaption automatic speed change drive assembly is suitable for hubs and has relatively good flexibility and high transmission precision during the speed change process.

Owner:SOUTHWEST UNIVERSITY

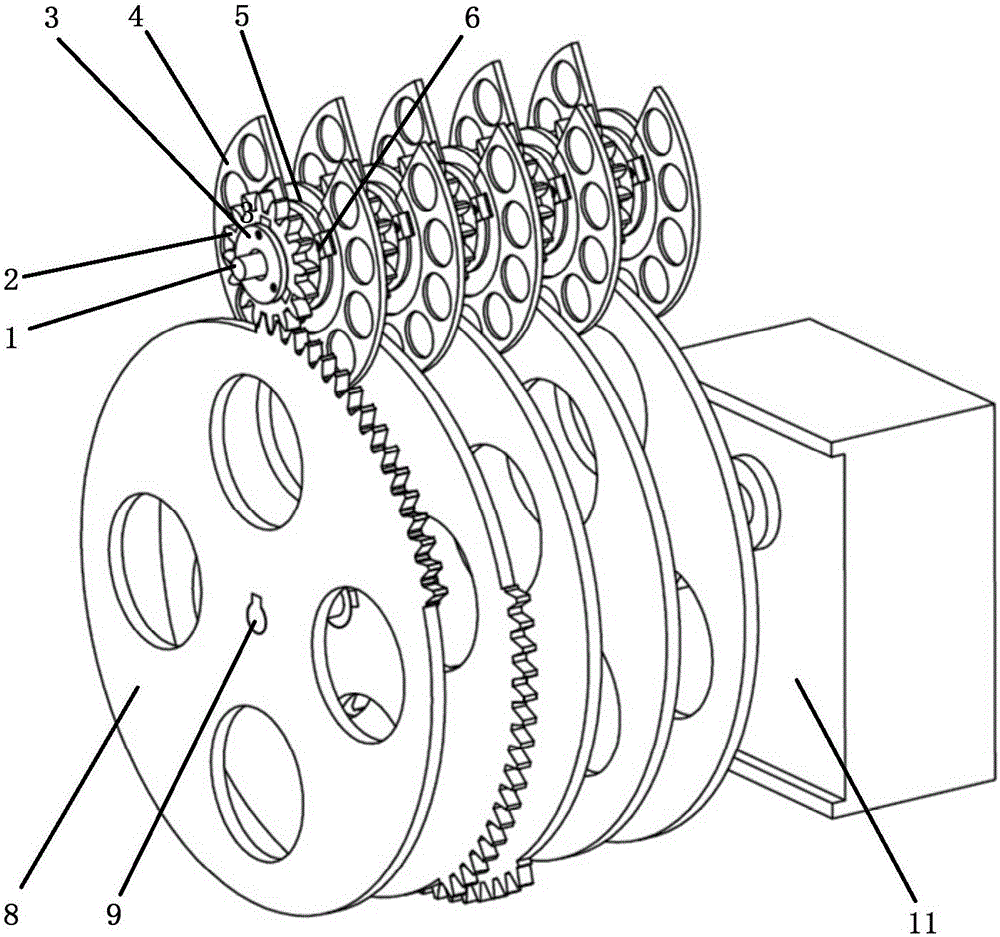

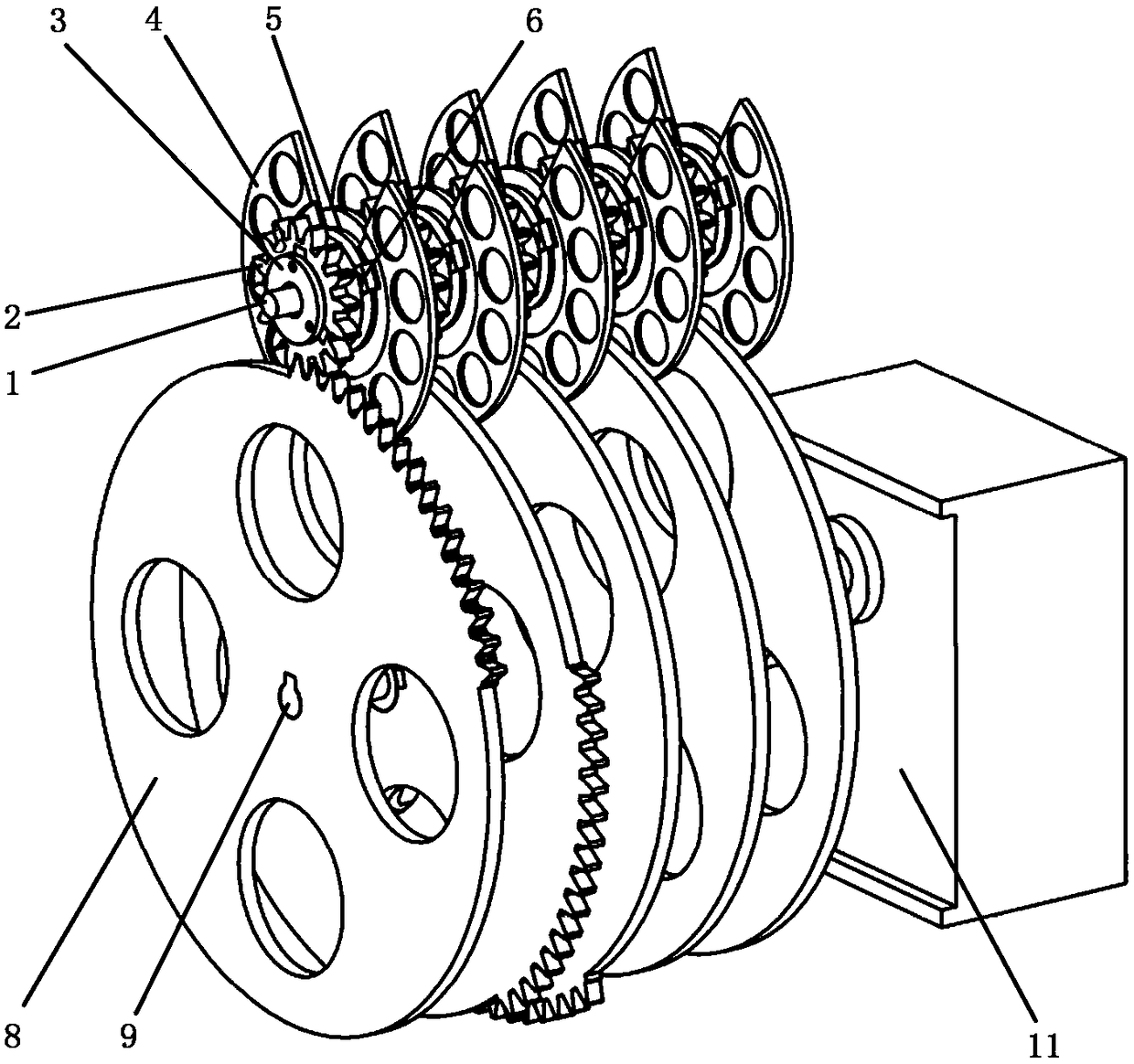

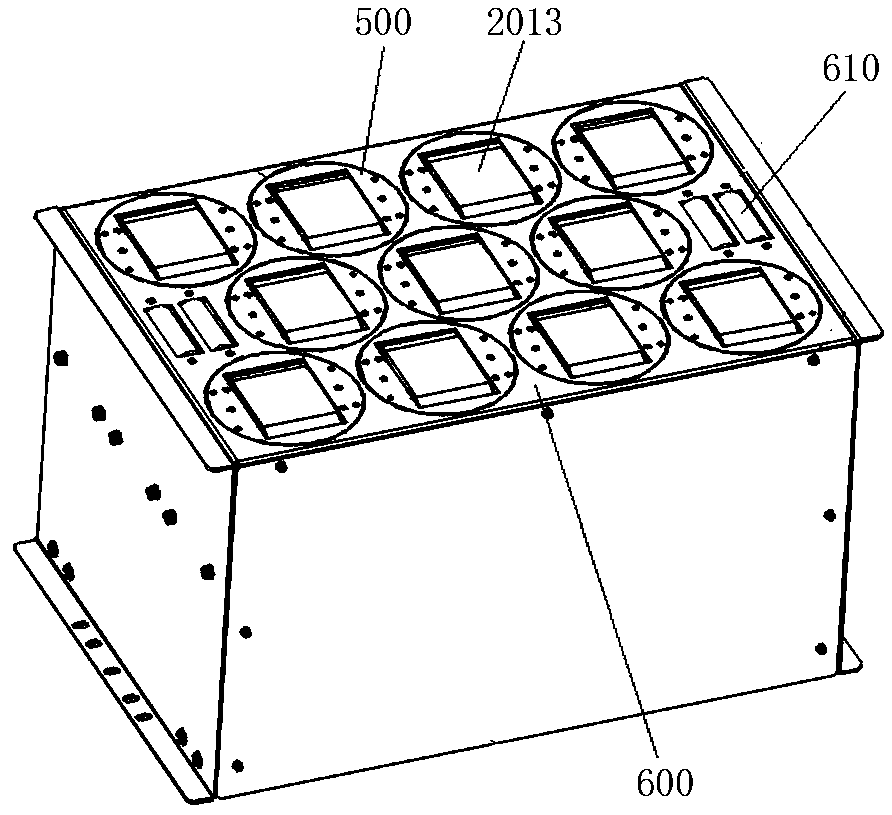

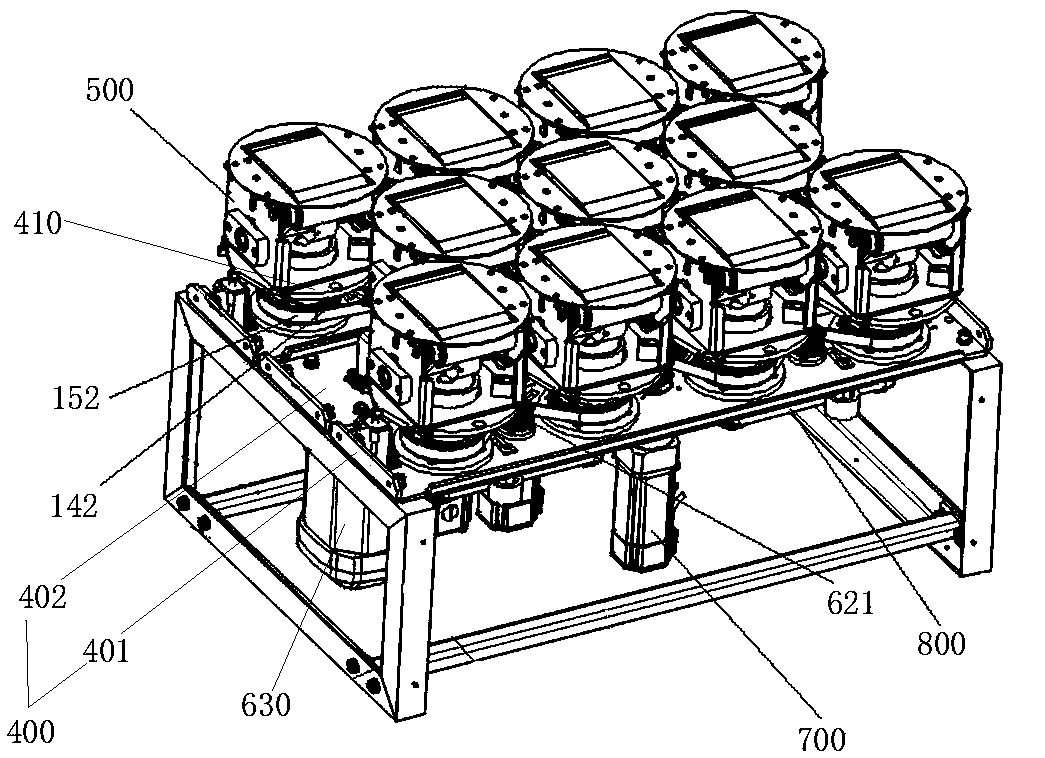

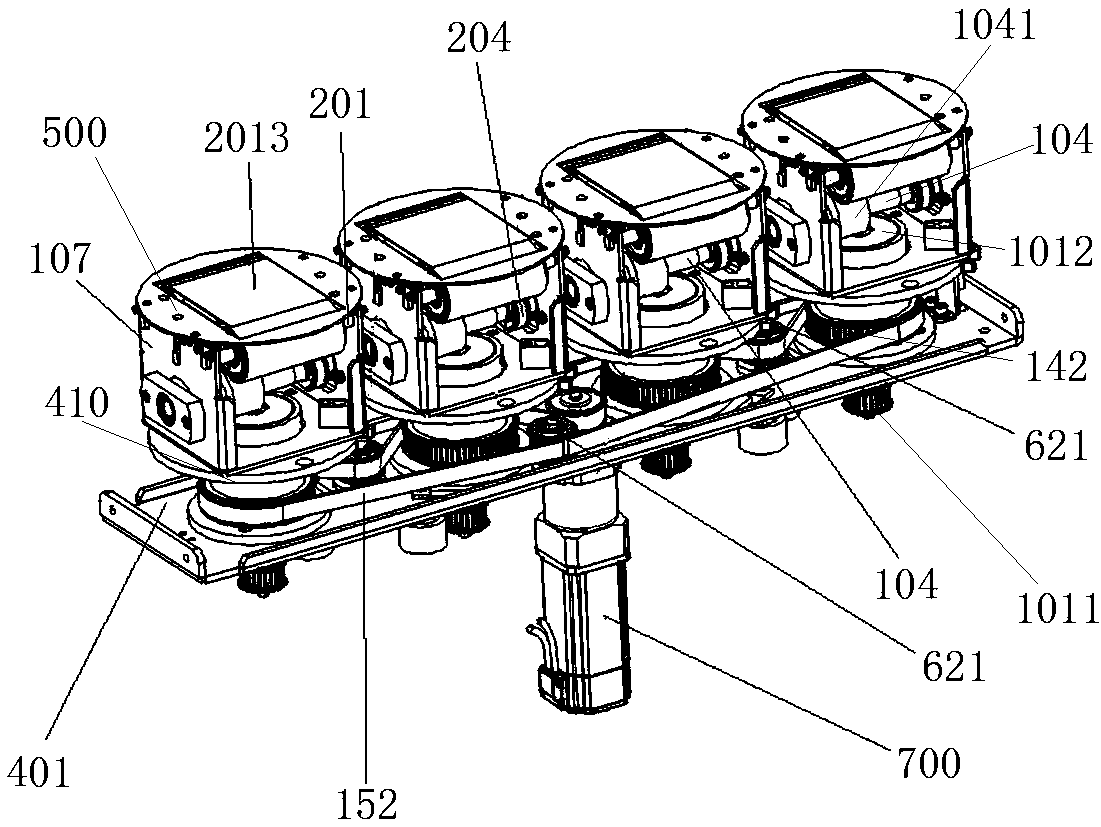

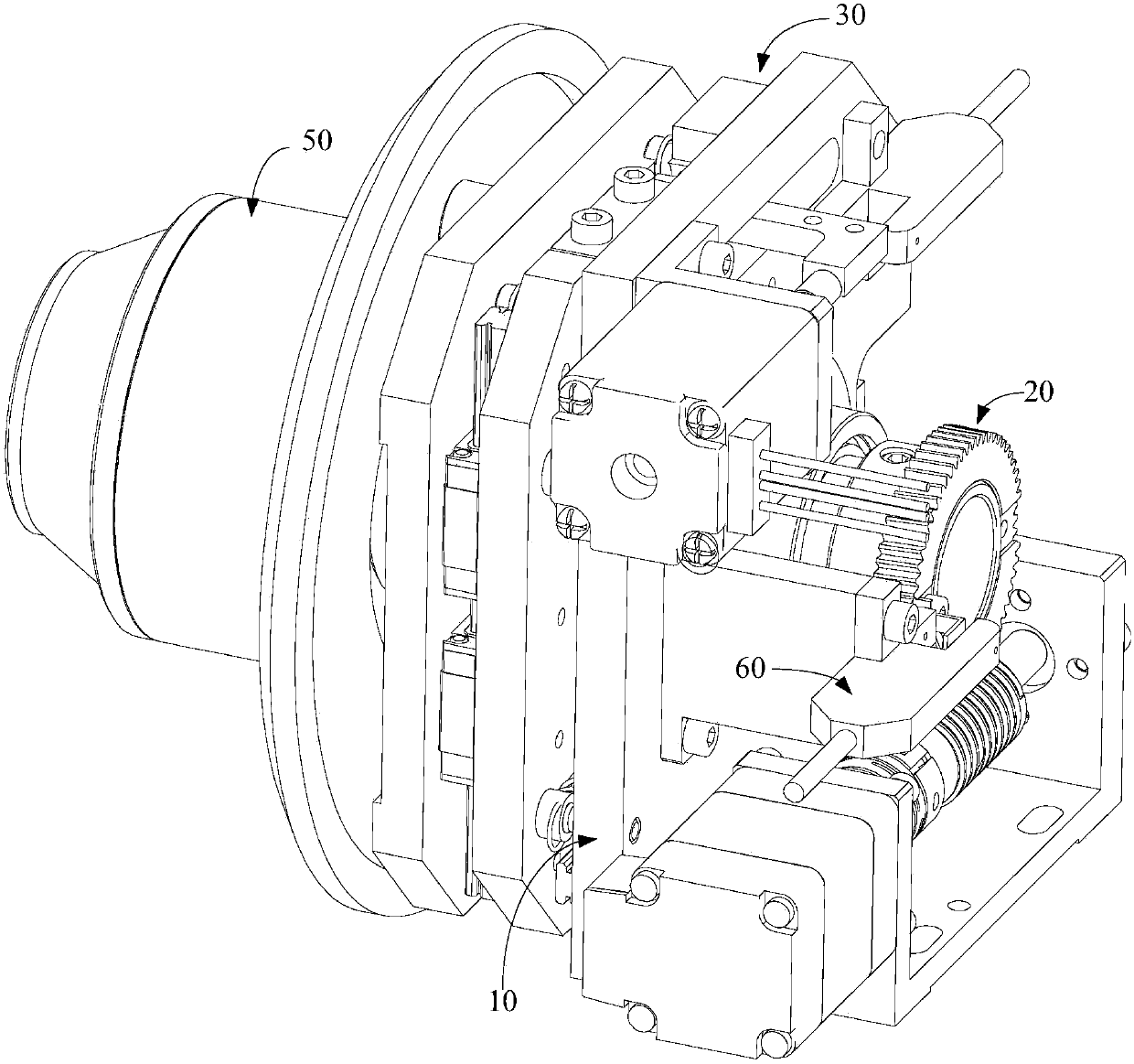

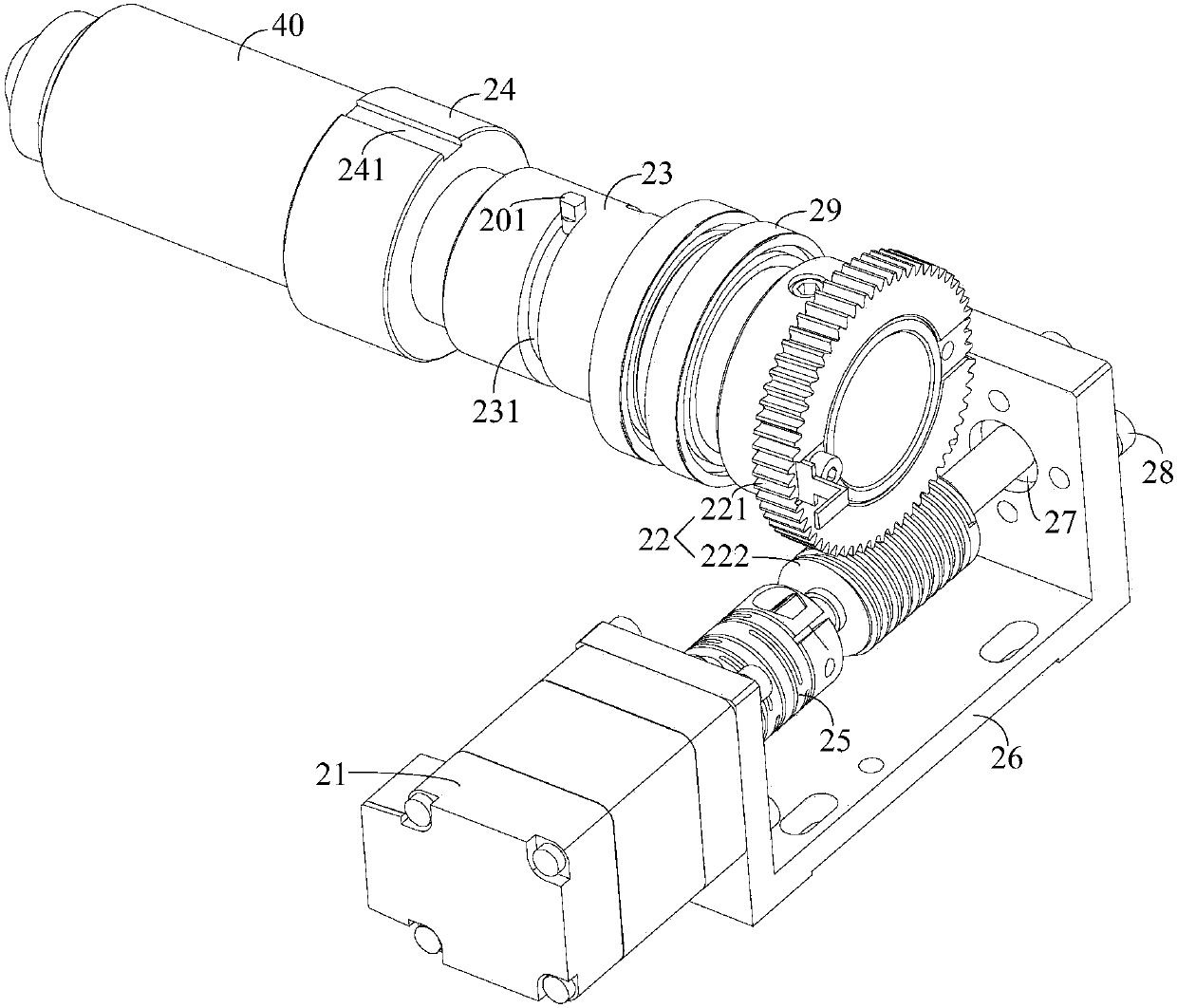

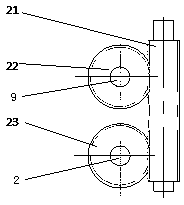

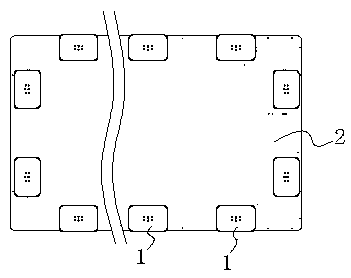

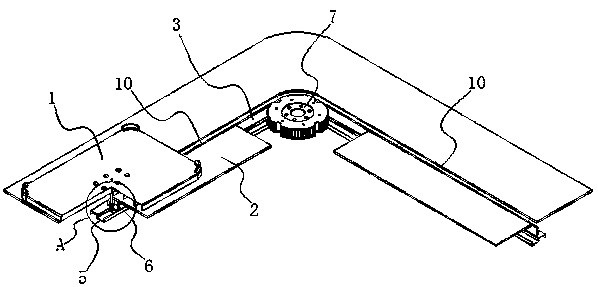

Multichannel combined optical filter wheel

ActiveCN106200213AHigh degree of automationGood transmission precisionCamera filtersMountingsData acquisitionEngineering

The invention discloses a multichannel combined optical filter wheel. A mode of combining a plurality of optical filter wheels is adopted in the scheme, the mature high-precision gear transmission technology is used for realizing the automatic orderly rotation of the plurality of optical filter wheels, the automation degree is high, and the transmission precision is good; furthermore, the structure of the device can be designed according to the required number of the optical filter wheel, the integral volume is optimized, the structure is compact, and the combined optical filter wheel can be placed in front of a focusing face of a multispectral camera, thereby realizing the multi-channel multi-wave spectral data acquisition.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

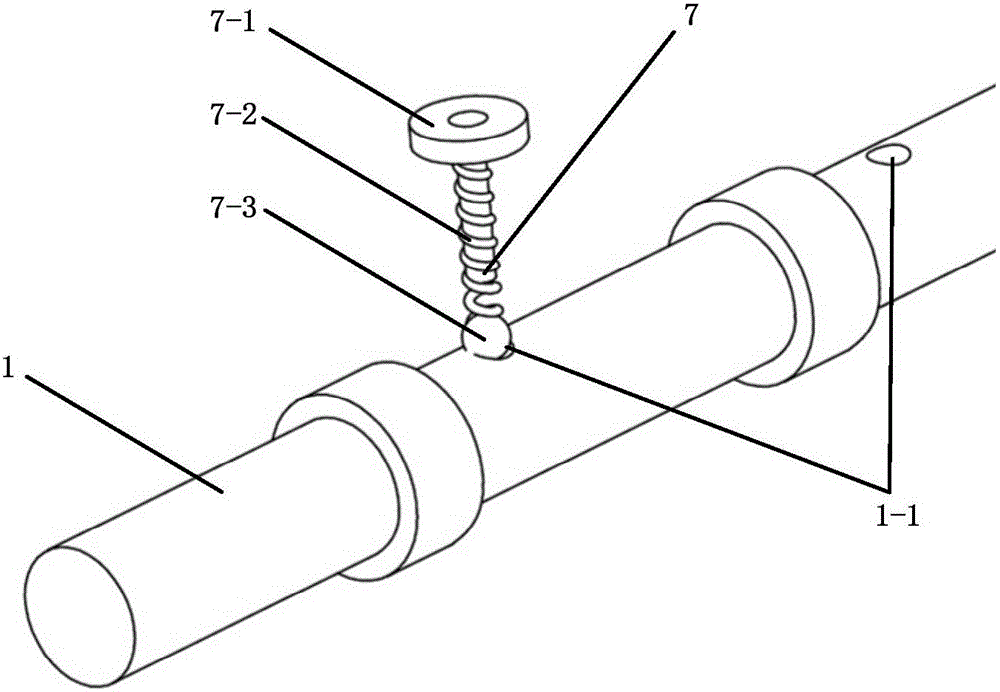

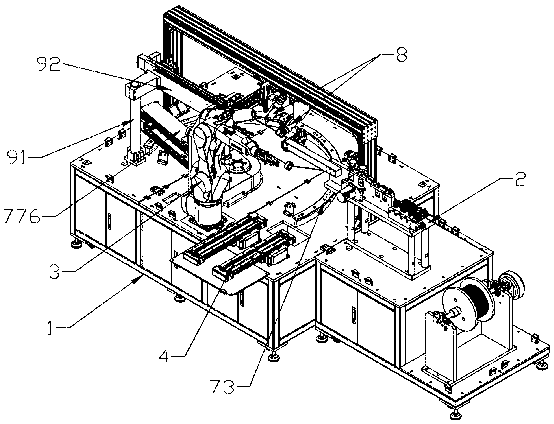

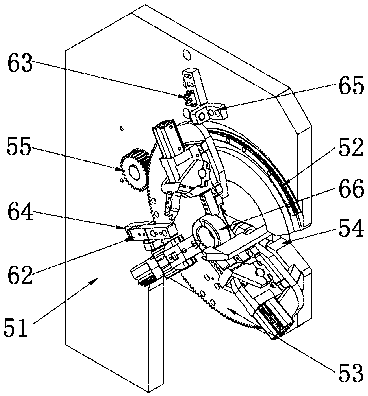

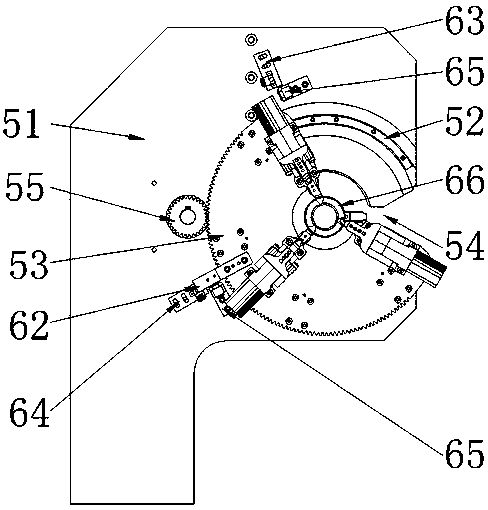

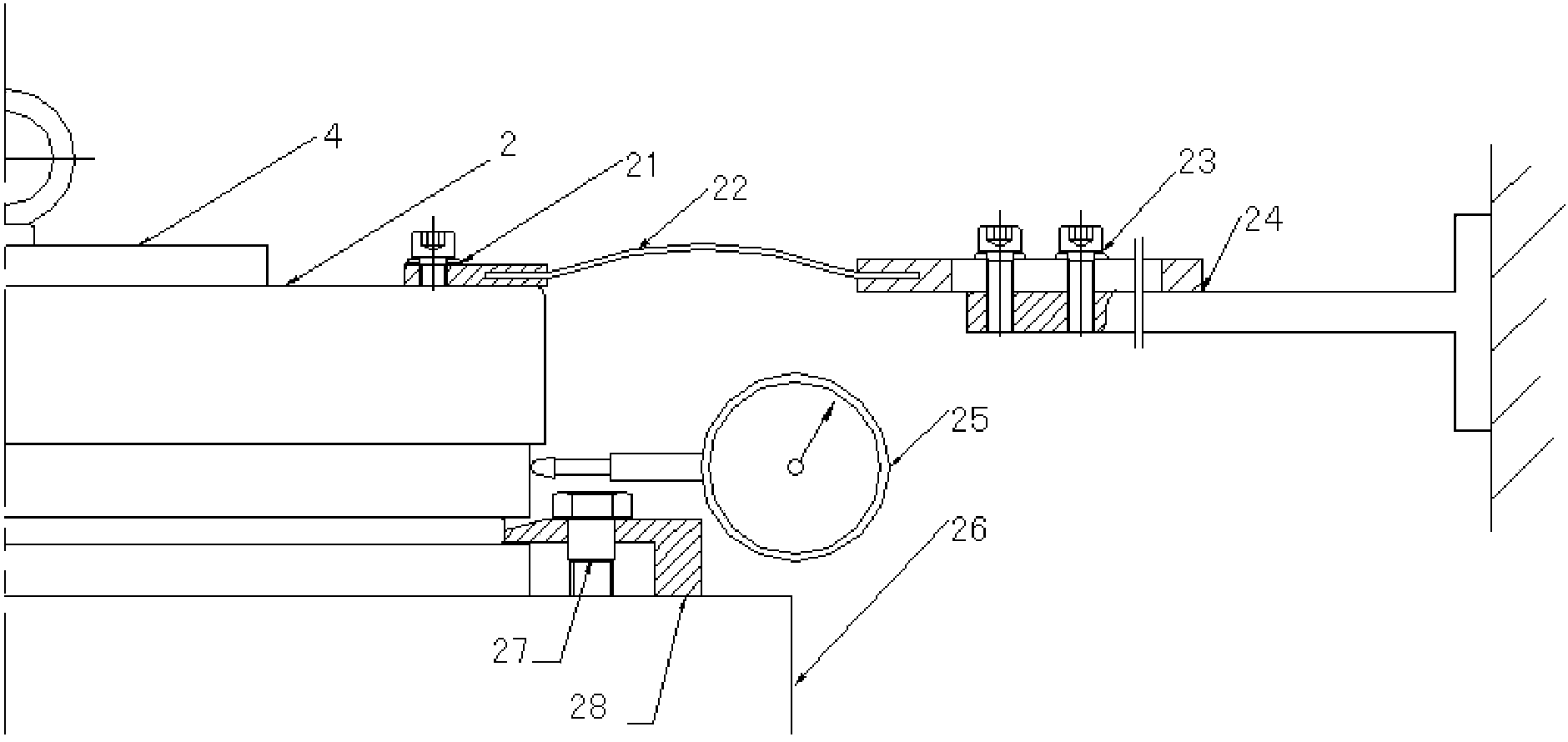

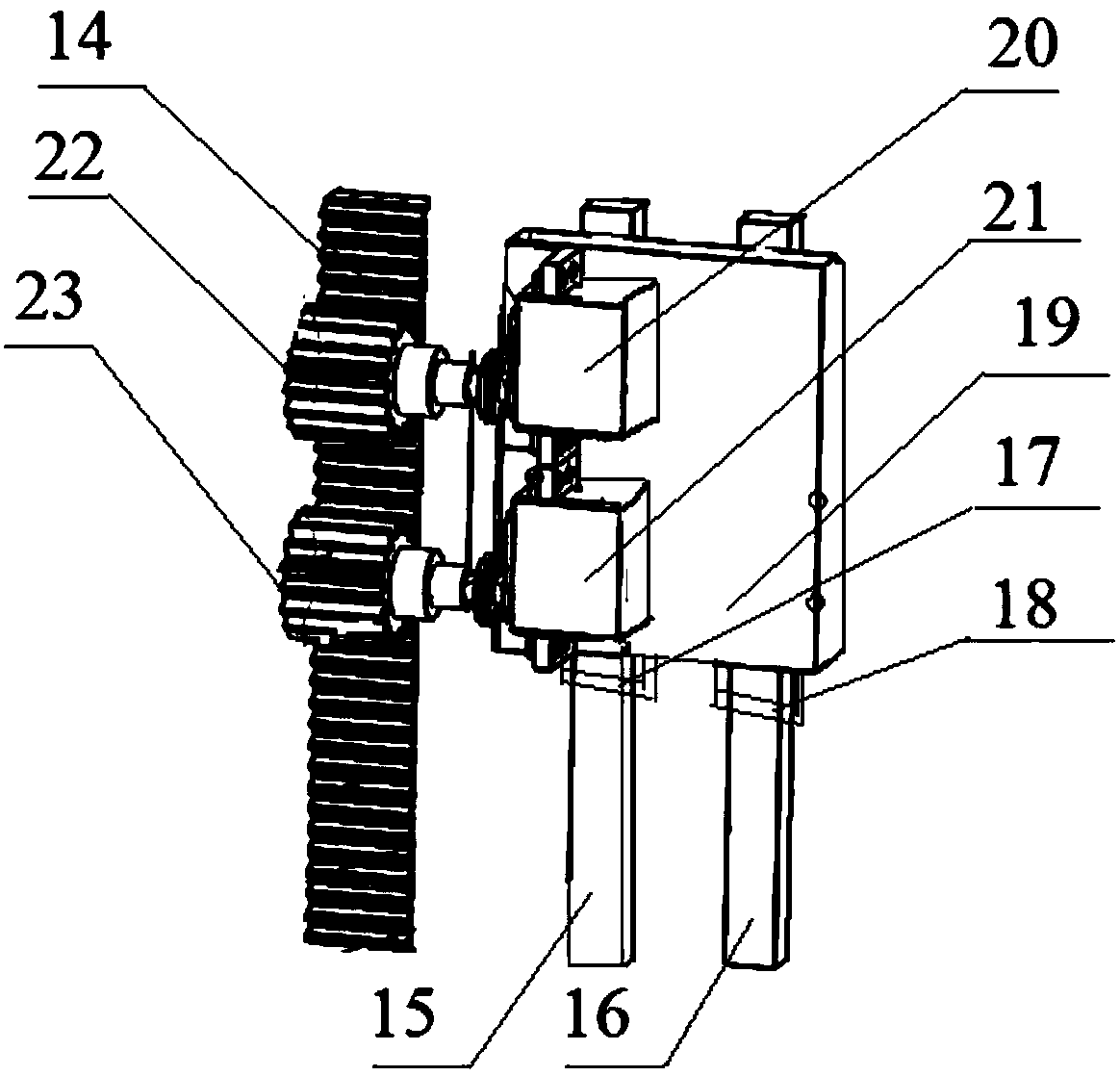

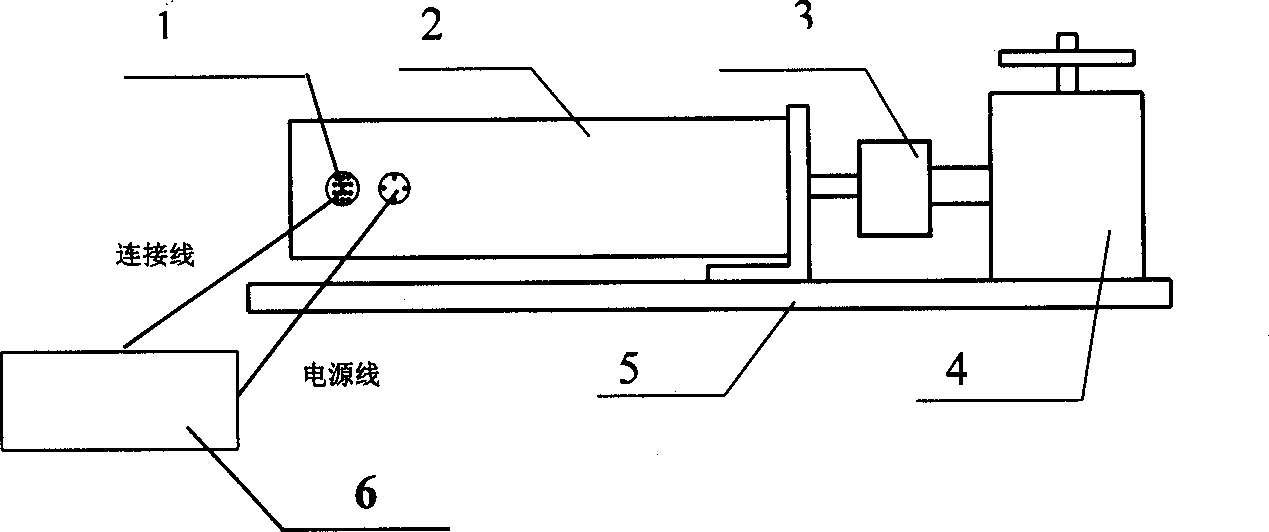

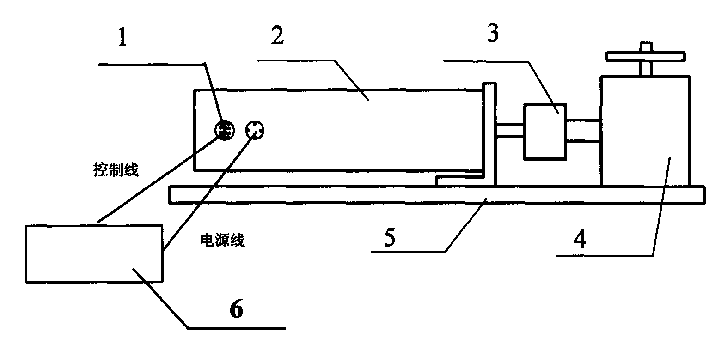

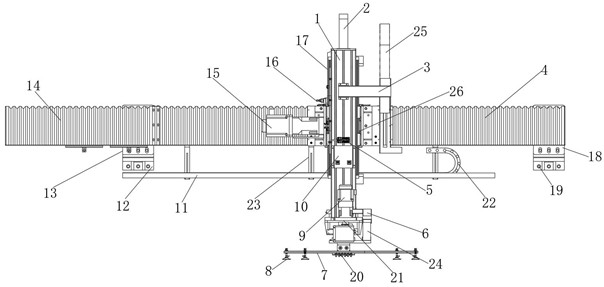

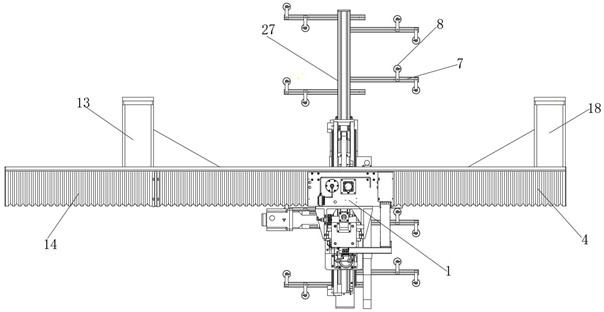

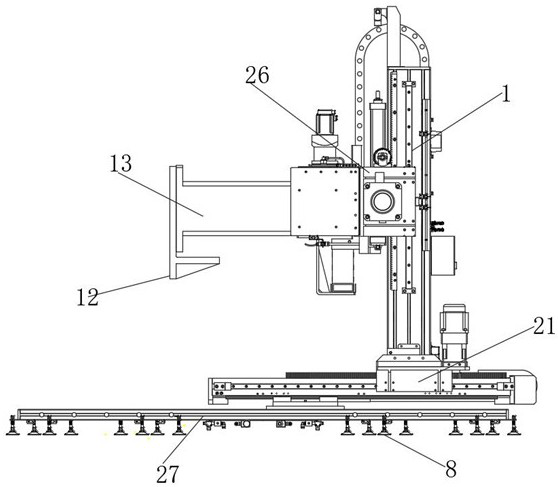

A thick-diameter magnetic loop automatic winding machine and a winding method thereof

ActiveCN109036838AHigh cable work reliabilitySmooth linesCoils manufactureWinding machineEngineering

The invention discloses a thick wire diameter magnetic loop automatic winding machine and a winding method thereof, which have high working efficiency, low labor cost, high working precision, uniformwire arrangement and stable clamping. The automatic winding machine for thick wire diameter magnetic loop coil in the invention comprises a machine table and wire feeder respectively arranged on the machine table, Manipulator, magnetic clip ring indexing device, Cable-clamping device for that first time, wire winding and pulling device, A line cut and clamping arm and a unloading table, the manipulator is arranged between the wire feeder and the magnetic clip ring indexing device, the first cable clamping and pulling device is arranged behind the magnetic clamping ring indexing device, The wire winding and pulling device is arranged at the rear of the magnetic clip ring indexing device and under the first wire clip and pulling device, the wire clipping arm is arranged in front of the magnetic clip ring indexing device, and the unloading table is arranged at one side of the magnetic clip ring indexing device. The invention is applicable to the field of magnetized winding.

Owner:ZHUHAI KLES MACHINE TECH

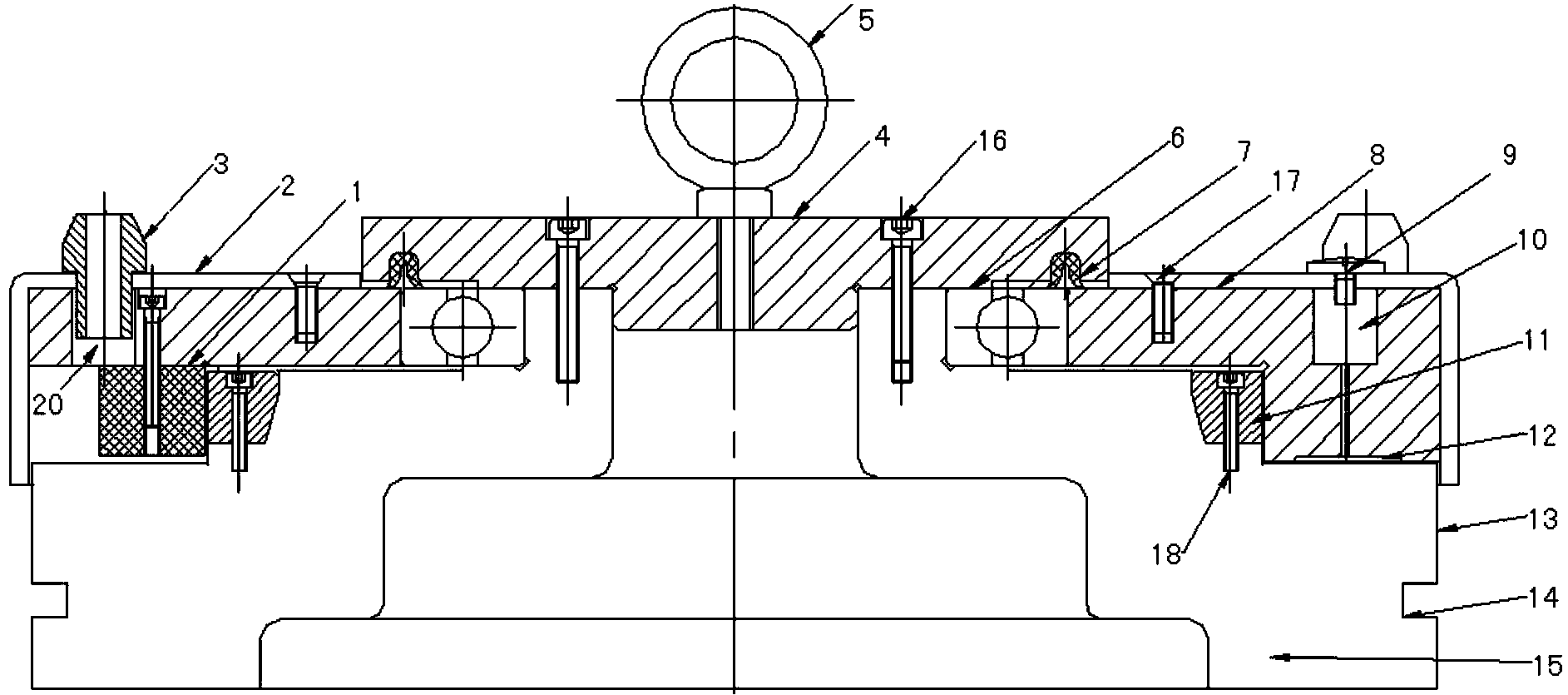

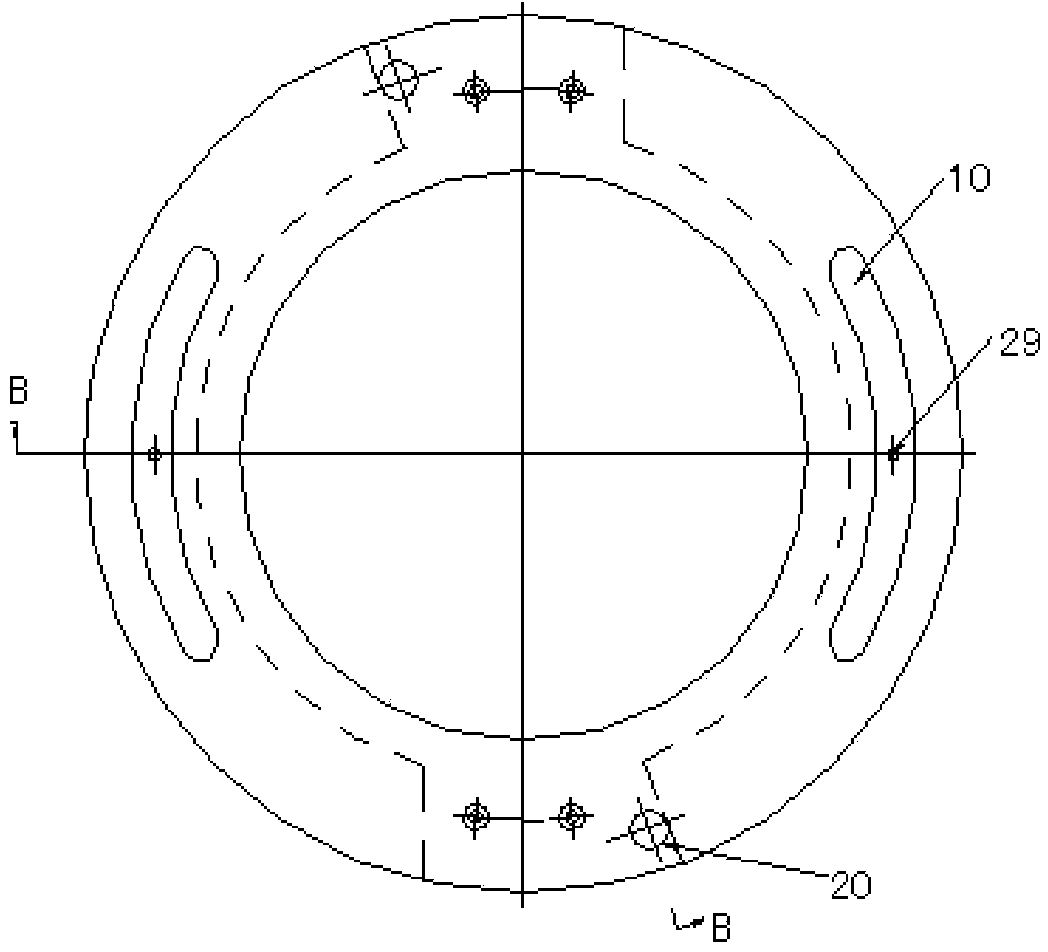

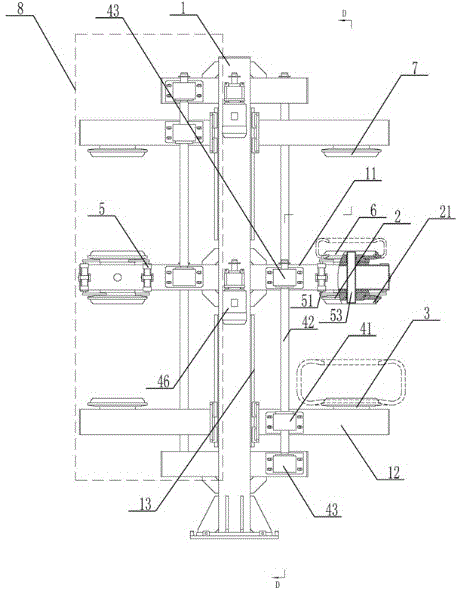

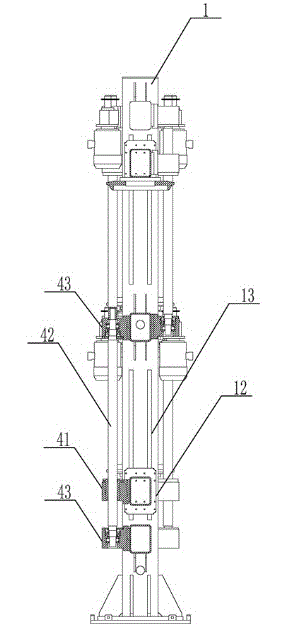

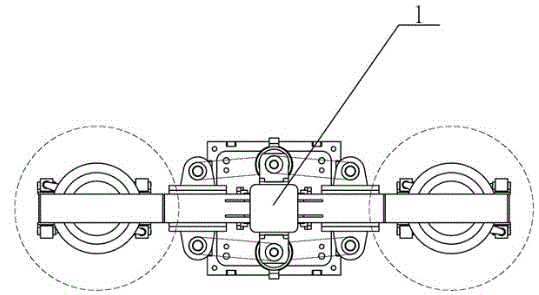

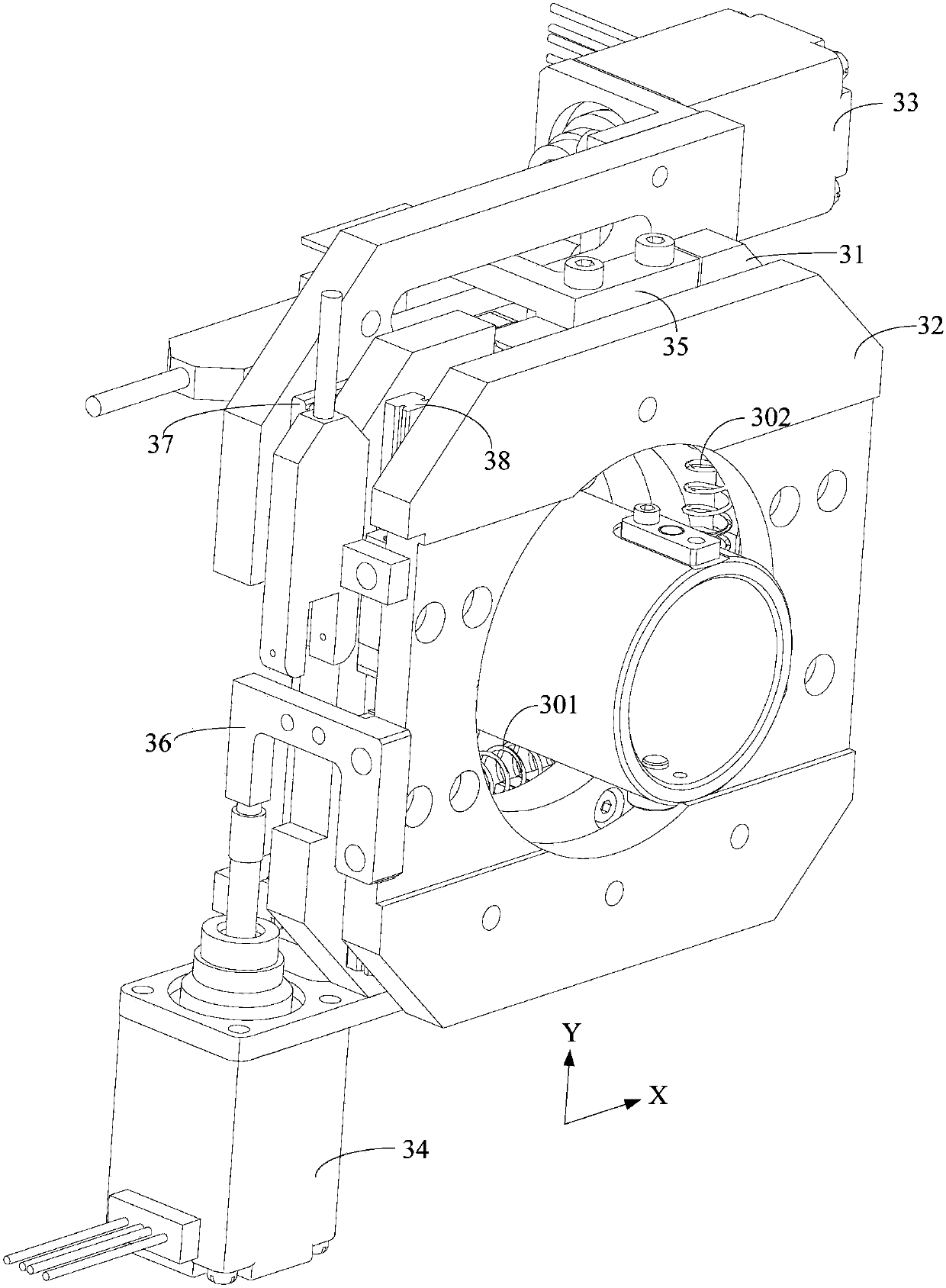

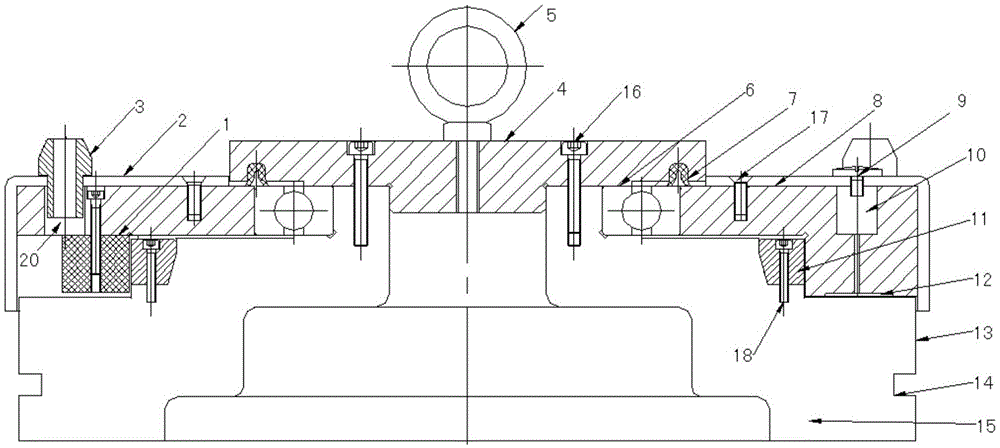

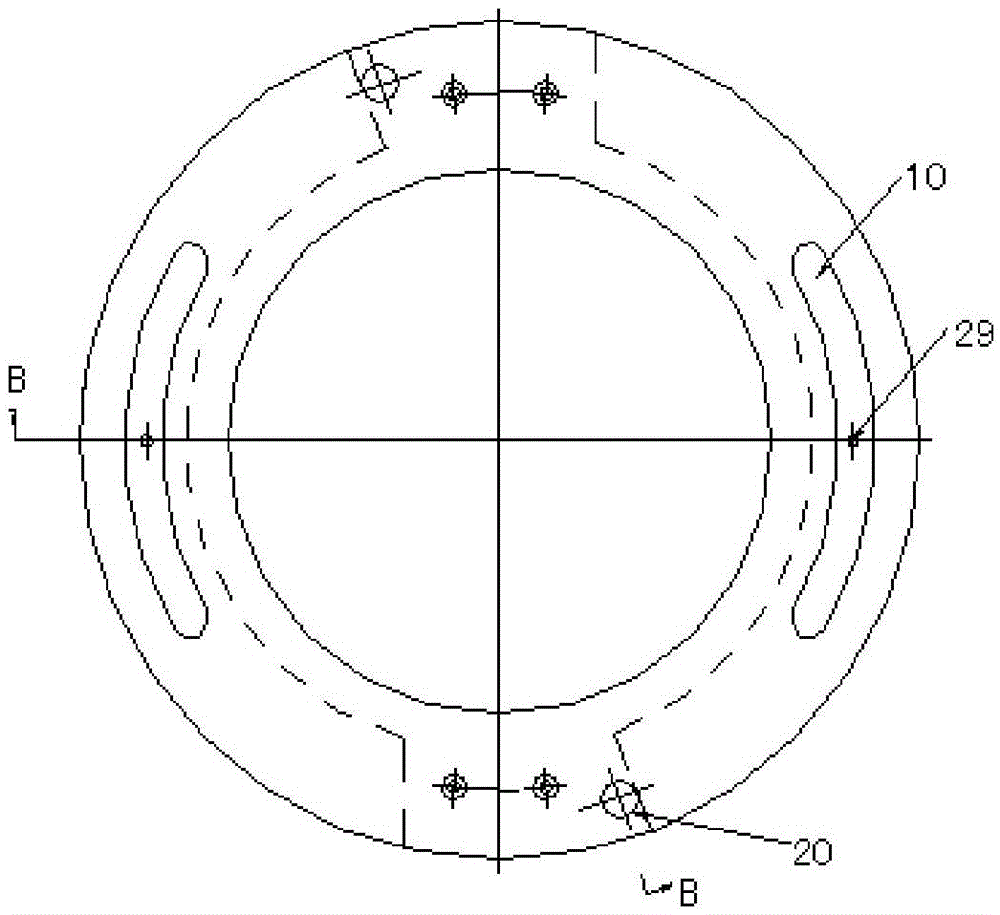

High-precision circular grating assembly device

The invention provides a high-precision circular grating assembly device, and relates to the field of precision instruments. According to the invention, a grating base presses and fixes a rotary platform to be tested; an upper end cap is disposed on the upper part of the grating base and is fastened and connected to the grating base; the upper end cap is wider than the top part of the grating base; the center of the upper end cap is equipped with a lifting ring; a bearing is sleeved on the upper part of the grating base; a reading head turntable is sleeved on the exterior of the bearing; the upper part and the side part of the reading head turntable are covered with cover caps; the reading head turntable employs an oil lubricated ring sliding surface for axial positioning; the inner side of the reading head turntable is provided with a grating reading head; and the radial inner side of the grating reading head is provided with a grating reflection ring which is sleeved on a conical step of the central part of the grating base, wherein the grating reading head presents a non-contact state with the grating reflection ring in a radial opposite direction, and the grating reflection ring is of annular structure of metallic material and has good resistance to mechanical impact.

Owner:CHONGQING MACHINE TOOL GROUP

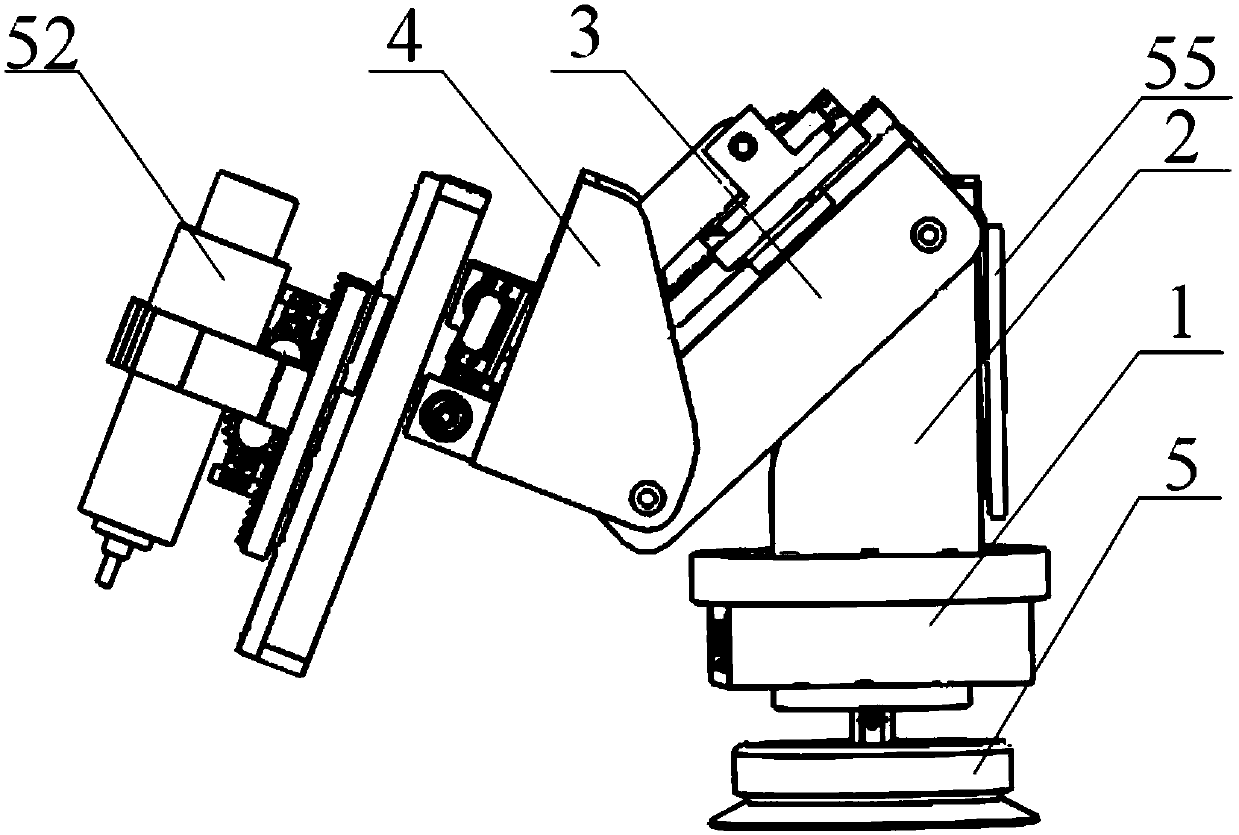

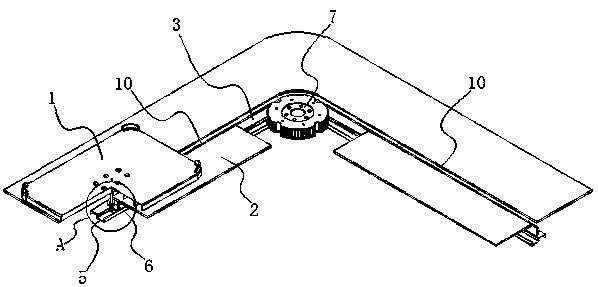

Portable aircraft skin drilling device

ActiveCN108672753AGood transmission precisionReduce volumeFeeding apparatusMetal working apparatusAirplaneEngineering

The invention provides a portable aircraft skin drilling device, and specifically belongs to the field of industrial manipulators. The device comprises a base, a vertical column, an extending arm, a rotating arm and a drilling mechanism, wherein a chuck for fixing is arranged at the first end of the base, and a second rotating platform is arranged at the second end of the base and is fixedly connected to the first end of the vertical column; the second end of the vertical column is movably connected to the first end of the extending arm, and the second end of the extending arm is movably connected to the first arm of the rotating arm; a second rotating platform is arranged on the second end of the rotating arm, and the drilling mechanism is arranged on the second rotating platform and linearly moves on the surface of the second rotating platform. The whole device is compact and small in structure, convenient to operate and carry, and simple in structure, and meets the demand o drillingin the surface of a skin with a complex shape.

Owner:NORTHEASTERN UNIV

Tire post-inflation apparatus having novel transmission structure

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

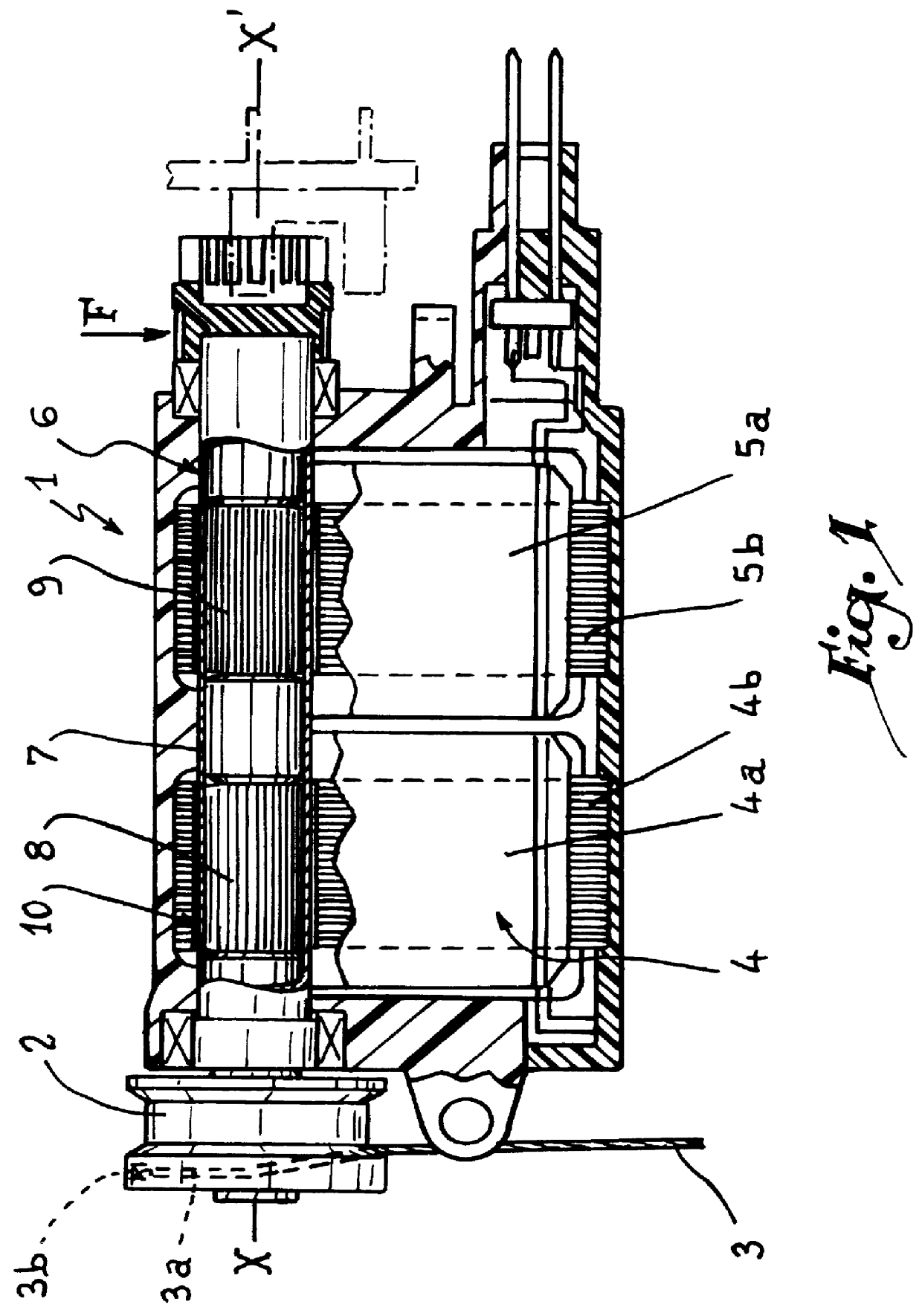

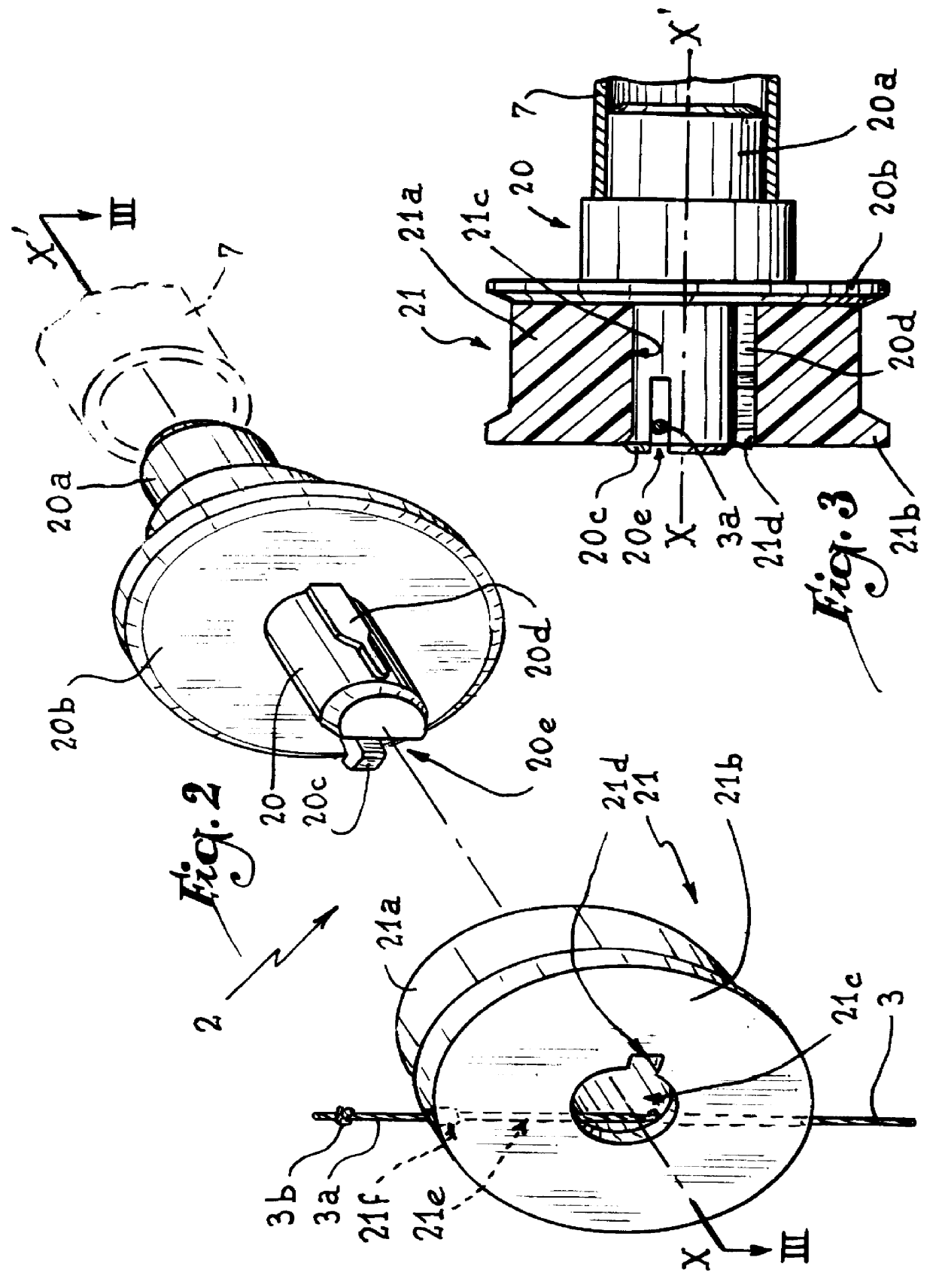

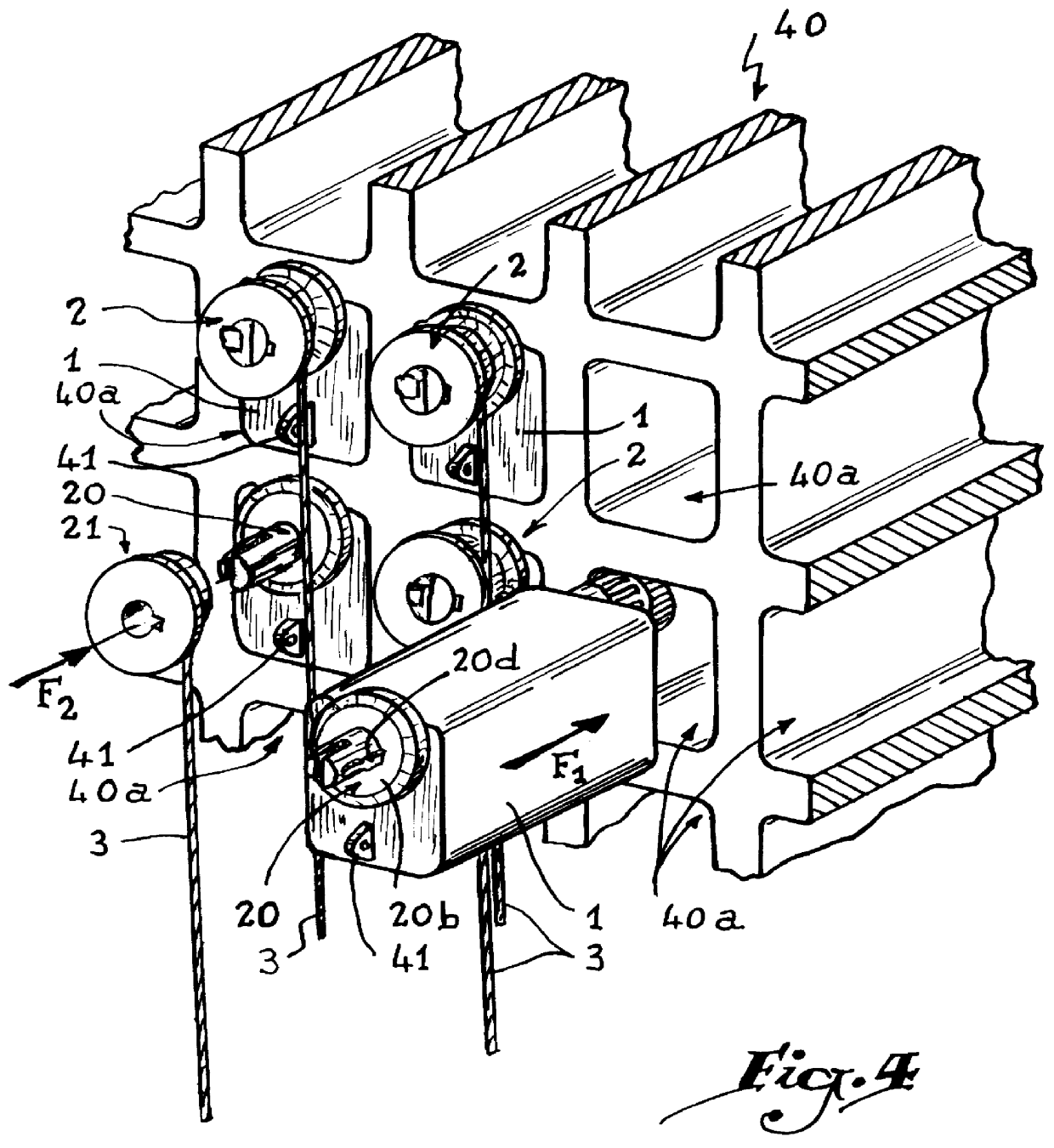

Process and apparatus for mounting a funicular element in a jacquard electrical shed forming device

InactiveUS6092564AEasy to disassembleGood transmission precisionJacquardsOther workshop equipmentEngineeringRotary actuator

A process for mounting a funicular element in a shed forming device of a weaving loom of a Jacquard type wherein at least one end of the funicular element is fixed on a pulley adapted to receive the funicular element and which pulley is driven in rotation by an electrical rotary actuator. A device is provided for removably connecting the funicular element to the actuator.

Owner:STAUBLI FAVERGES SA

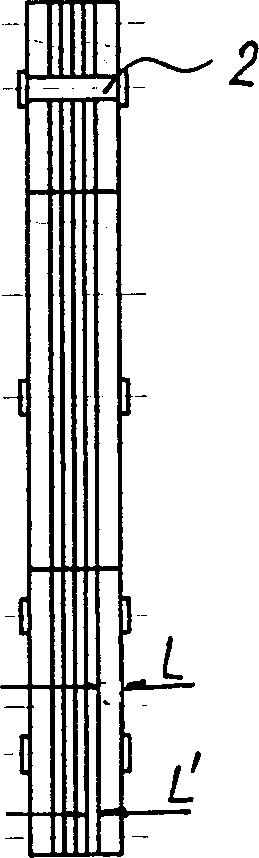

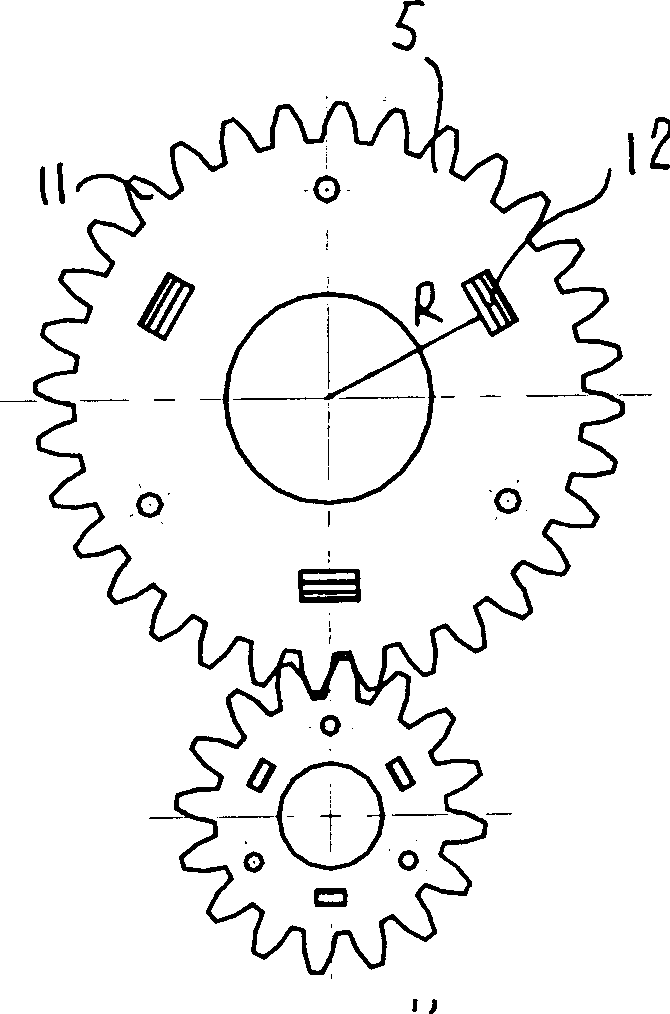

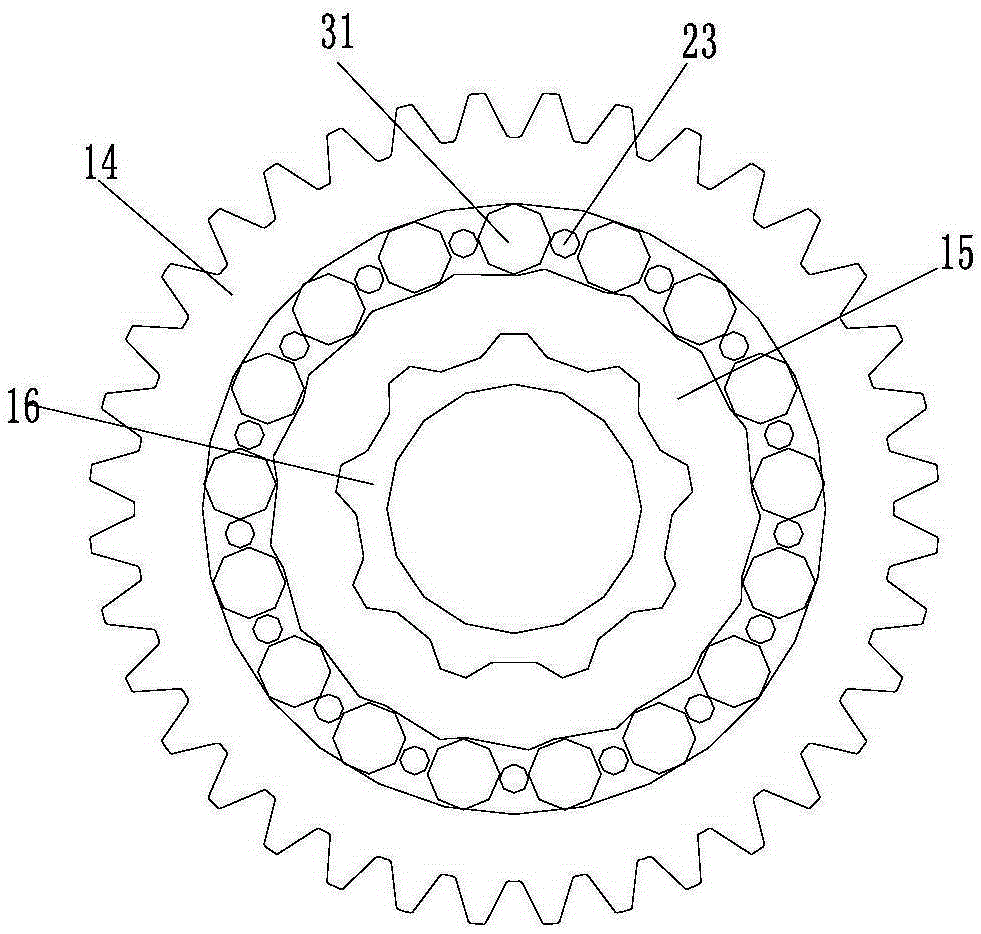

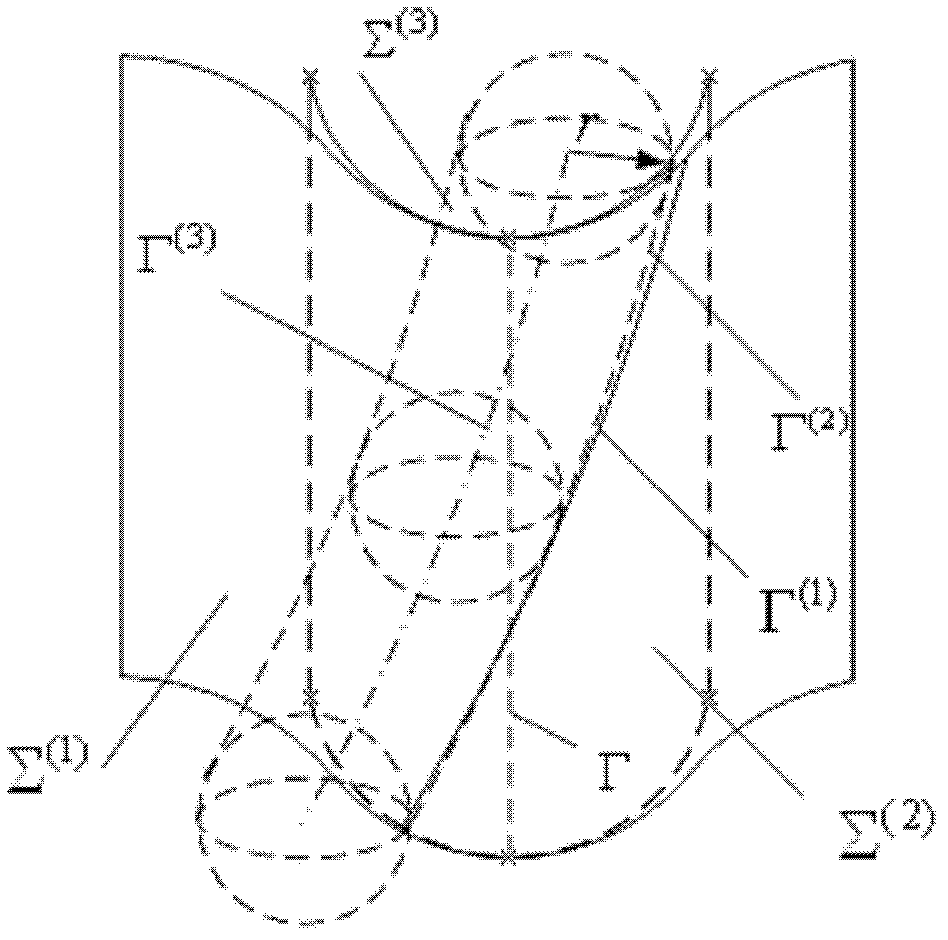

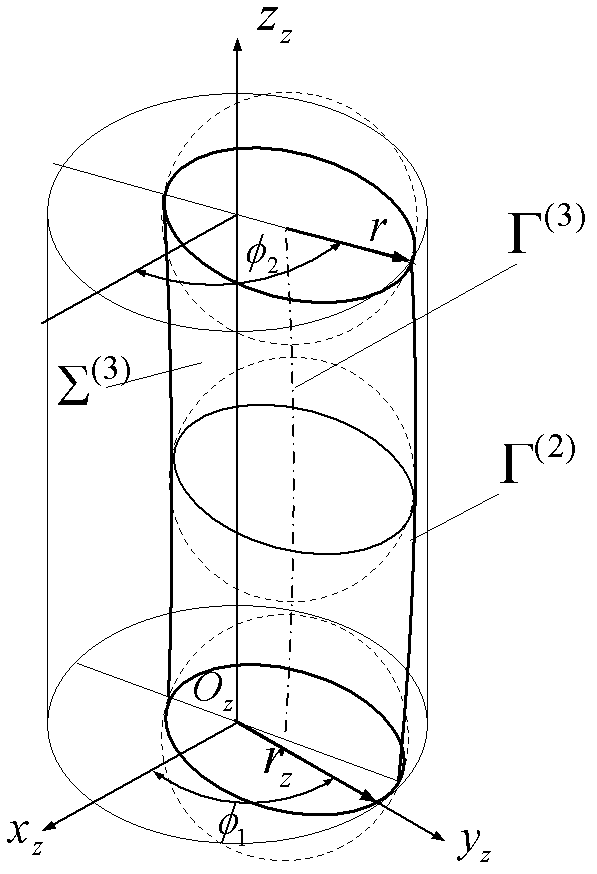

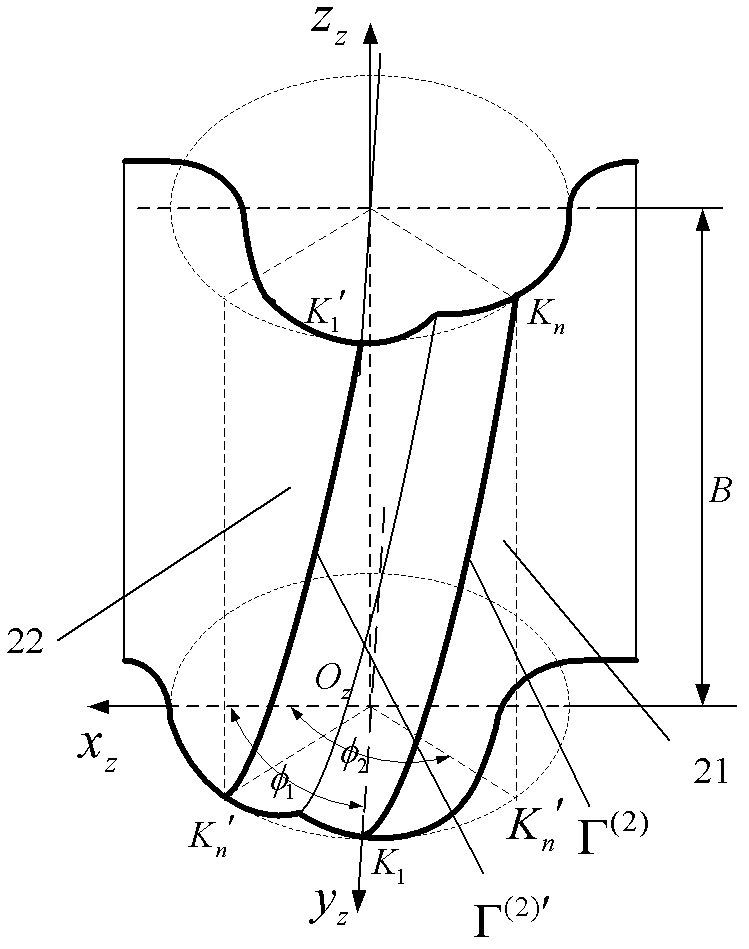

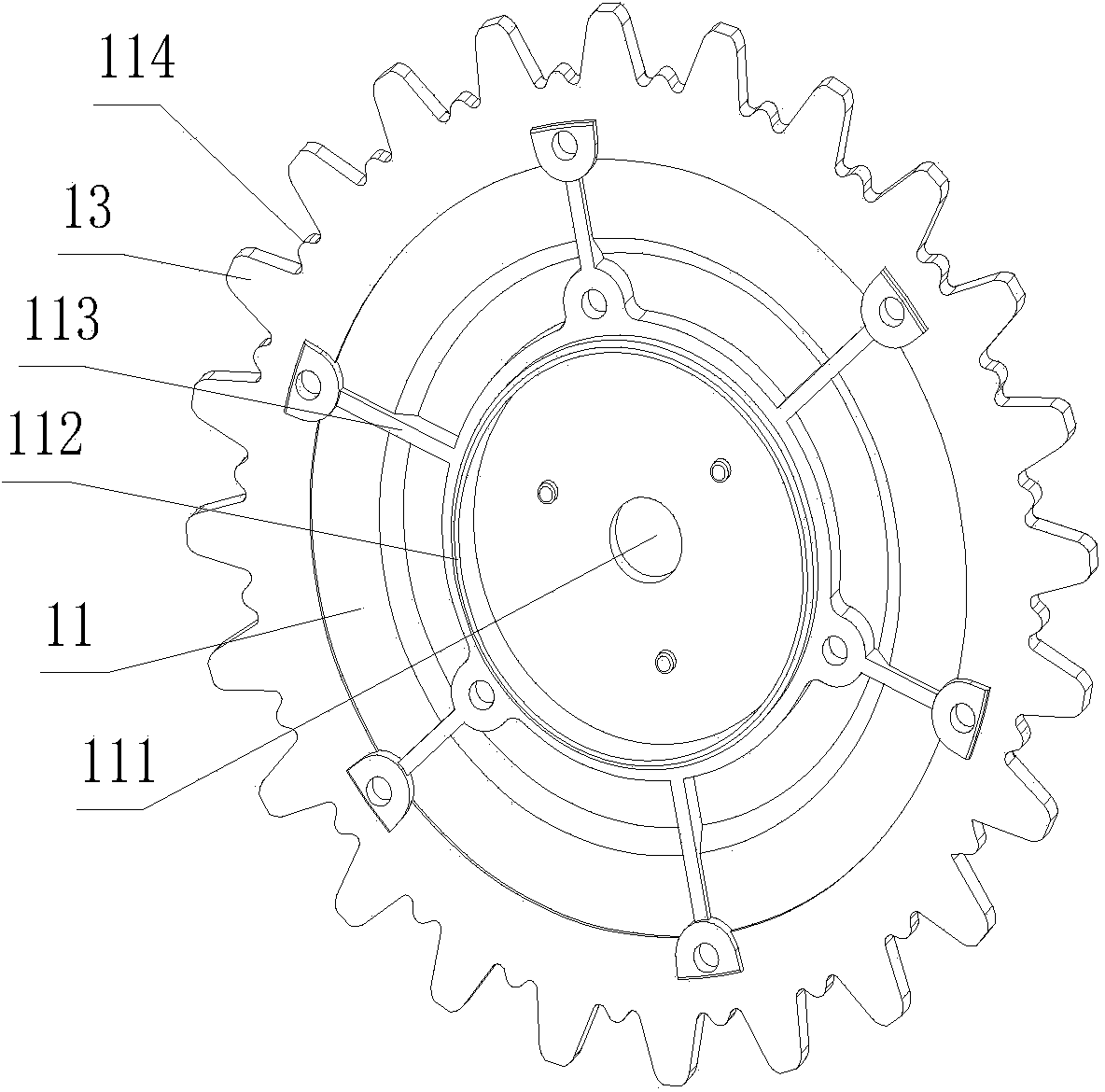

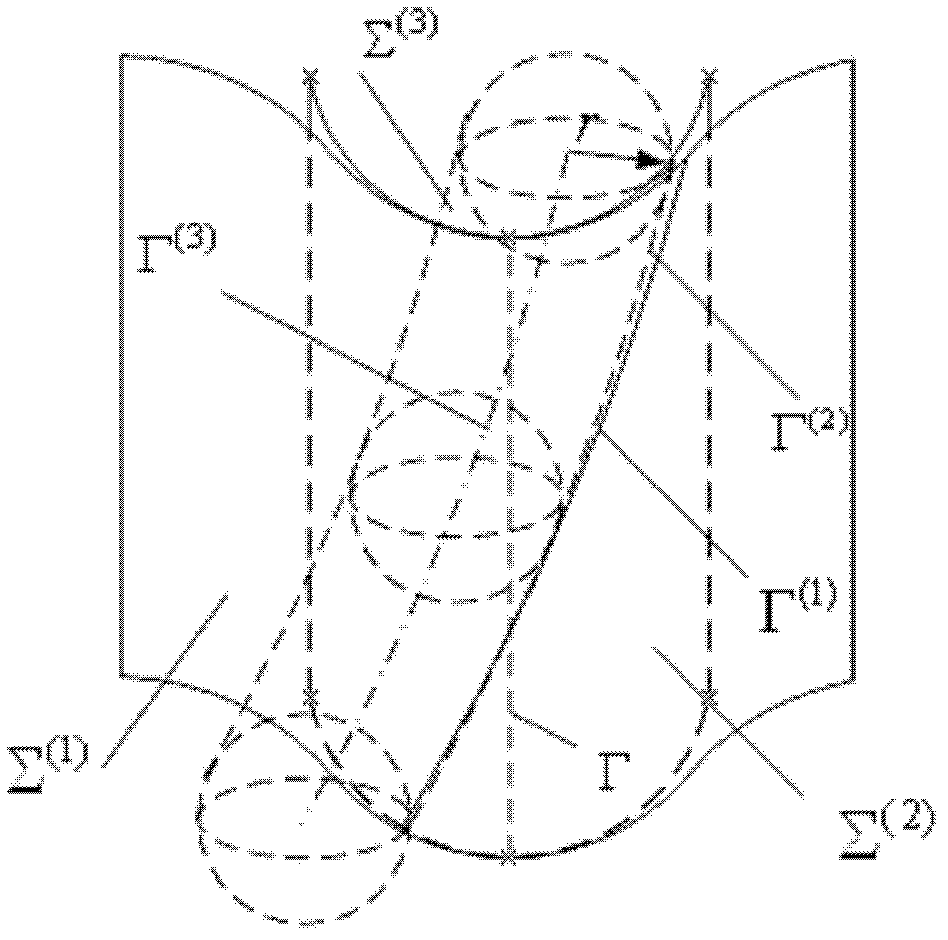

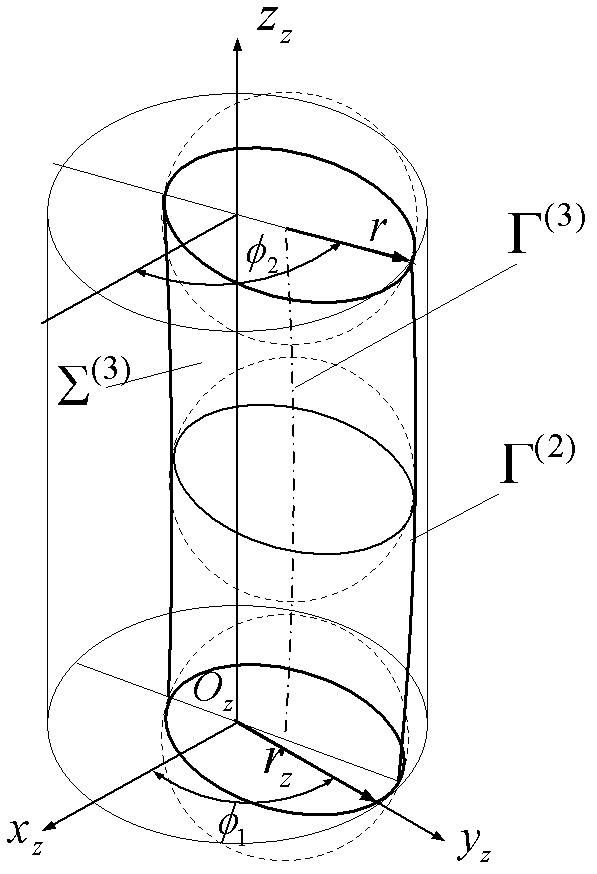

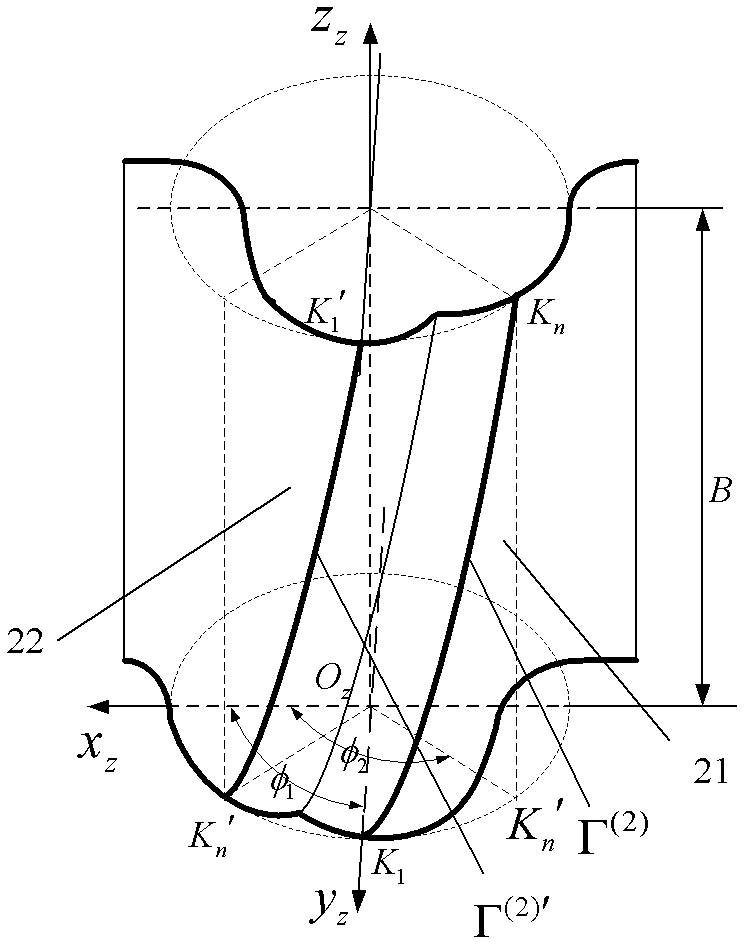

Cycloid planetary transmission gear based on line-surface conjugation

ActiveCN102252058AImprove rigidityGood transmission precisionToothed gearingsPortable liftingEngineeringCycloid

The invention discloses a cycloid planetary transmission gear based on line-surface conjugation, and relates to a cycloid planetary transmission gear which comprises a cycloid pin wheel planetary transmission meshed pair. A smooth curve line inverted L (2) is selected on a gear surface of a gear in the meshed pair, the main normal vector direction is consistent with the normal direction of the gear surface, and the curve line inverted L (2) and the gear surface of another gear in the meshed pair form line-surface conjugation mesh; the gear surface of the gear is a tubular meshed surface which is a sphere family enveloping surface sigma (3) of which the sphere center moves along an equidistant line inverted L (3); the equidistant line inverted L (3) is a smooth curve line which has a distance of r from the main normal vector direction; the spherical radius of spheres in the sphere family is the distance r between the equidistant line inverted L (3) and the smooth curve inverted L (2), and the r is less than the minimum curvature radius of the meshed section of the original gear surface. According to the invention, through changing the cycloid planetary transmission into the line-surface conjugation meshed pair, the meshed process is in the mode of point contact, the transmission ratio is great, the rigidity is good, the structure is compact, the transmission accuracy is high, the mesh can be approximately to pure rolling, the sliding ratio can be reduced greatly, thus the efficiency is improved greatly, the service life is improved, the manufacturing is simple, and the accuracy is high.

Owner:CHONGQING UNIV

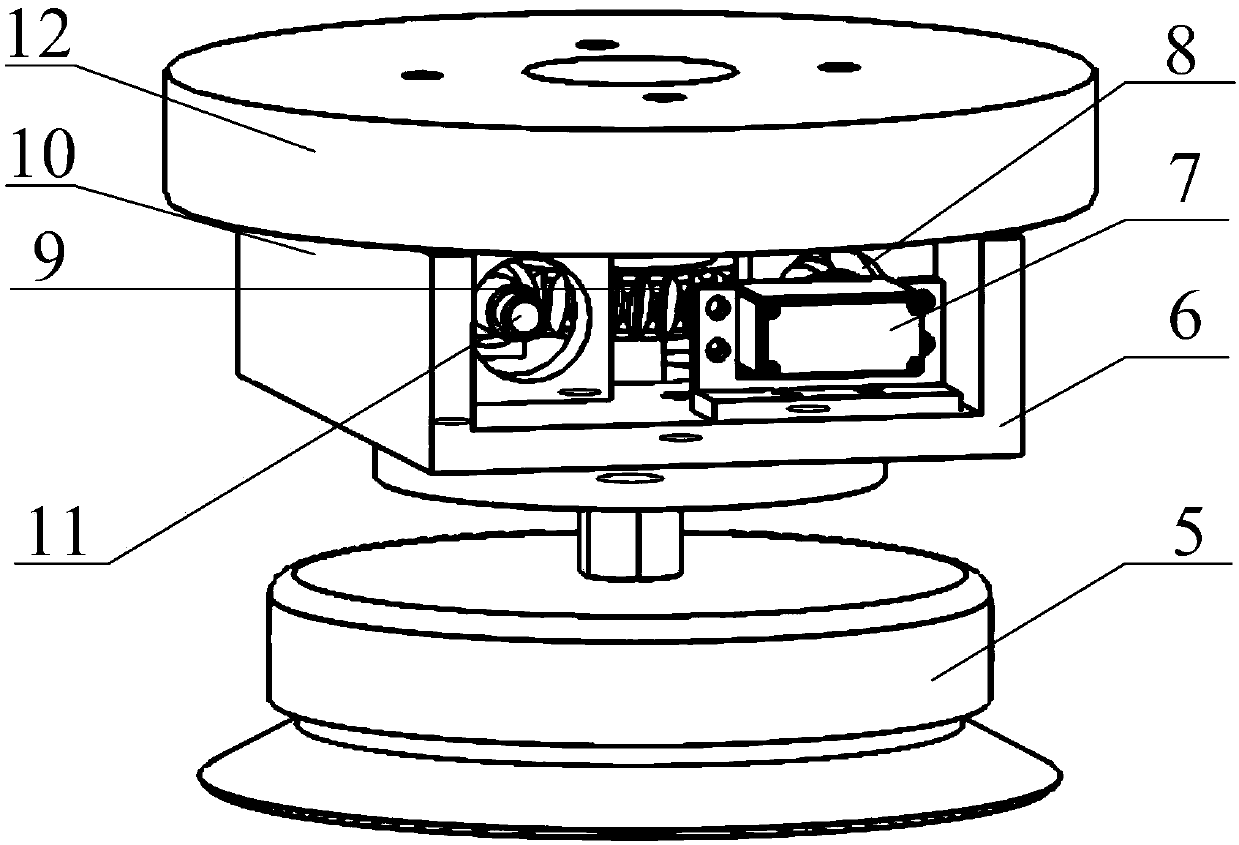

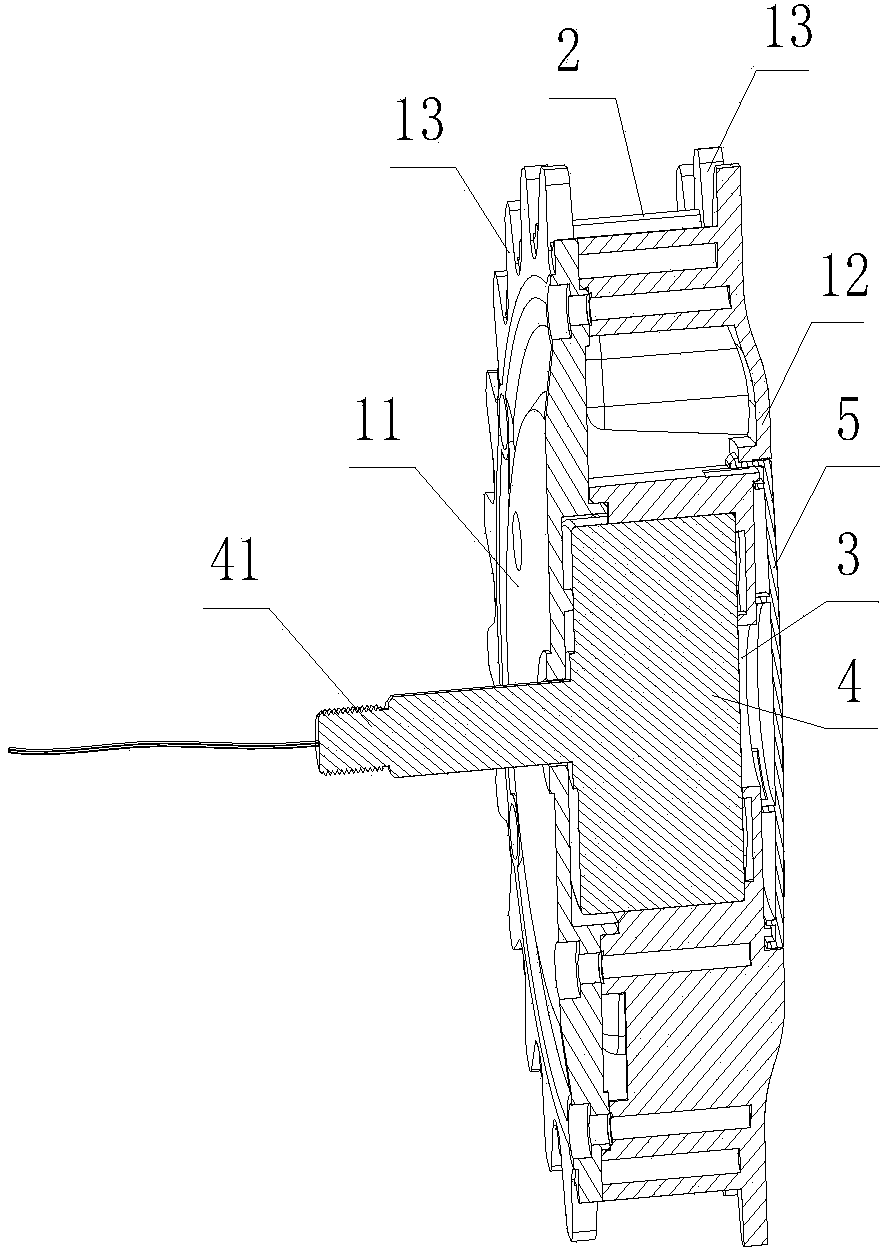

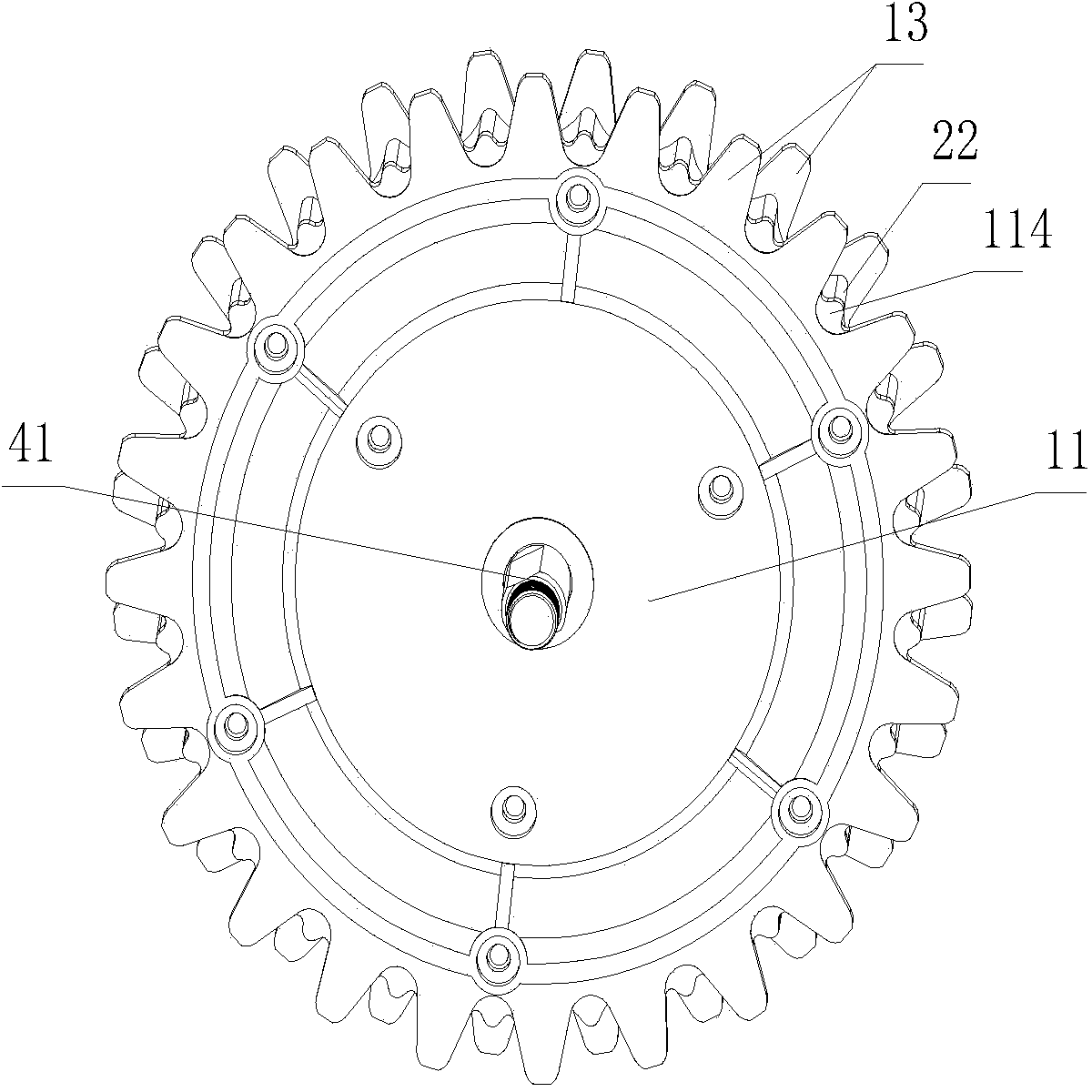

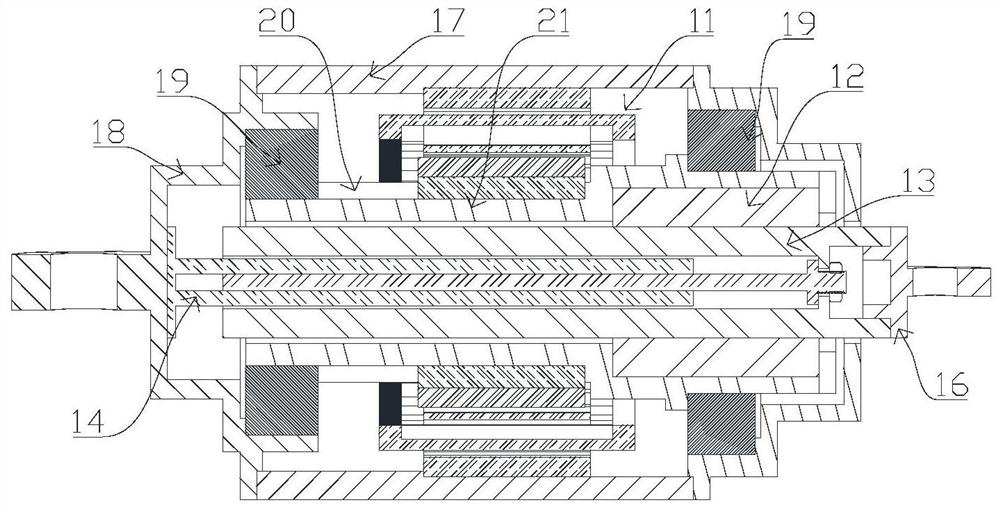

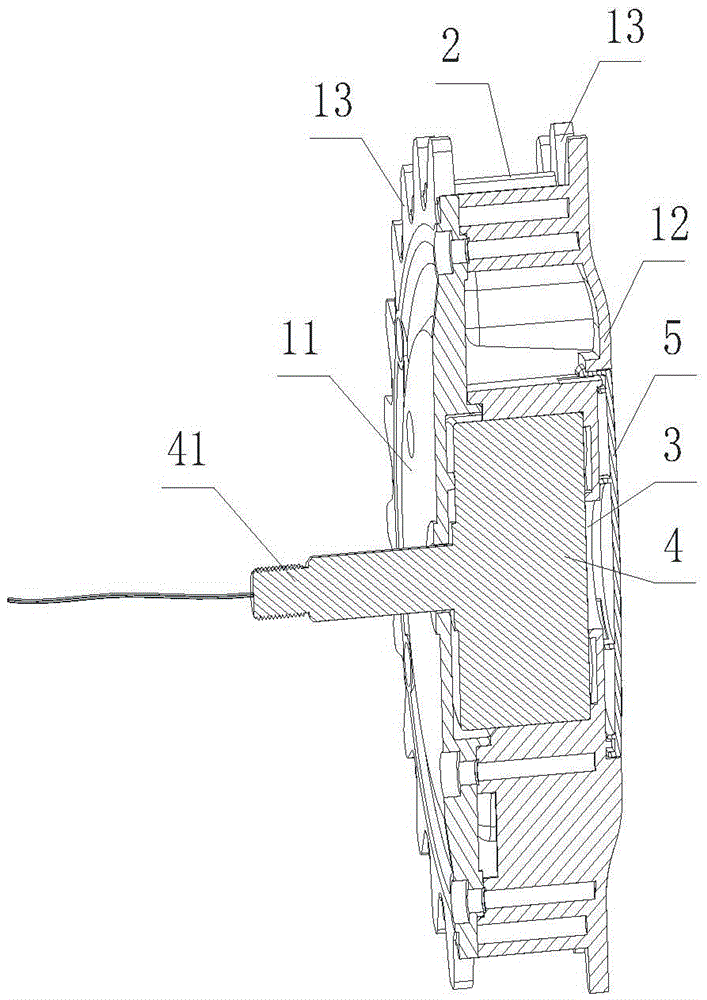

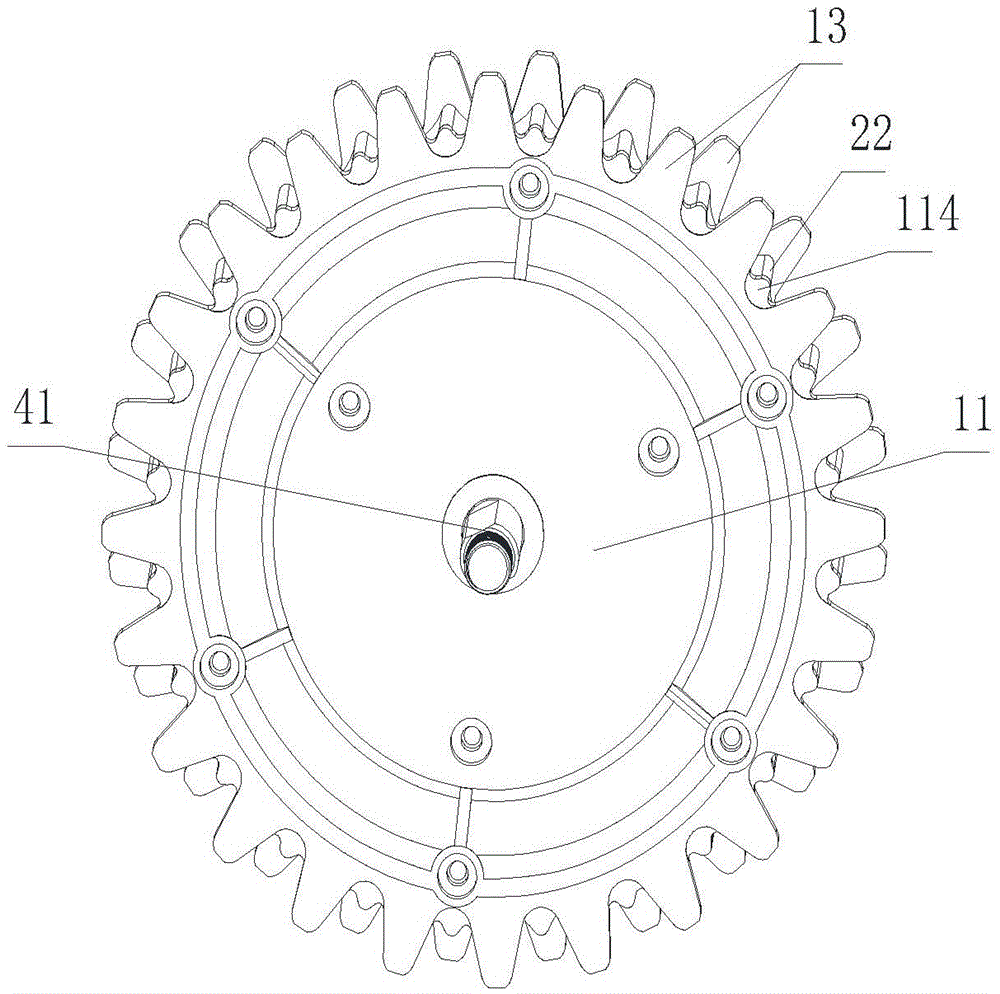

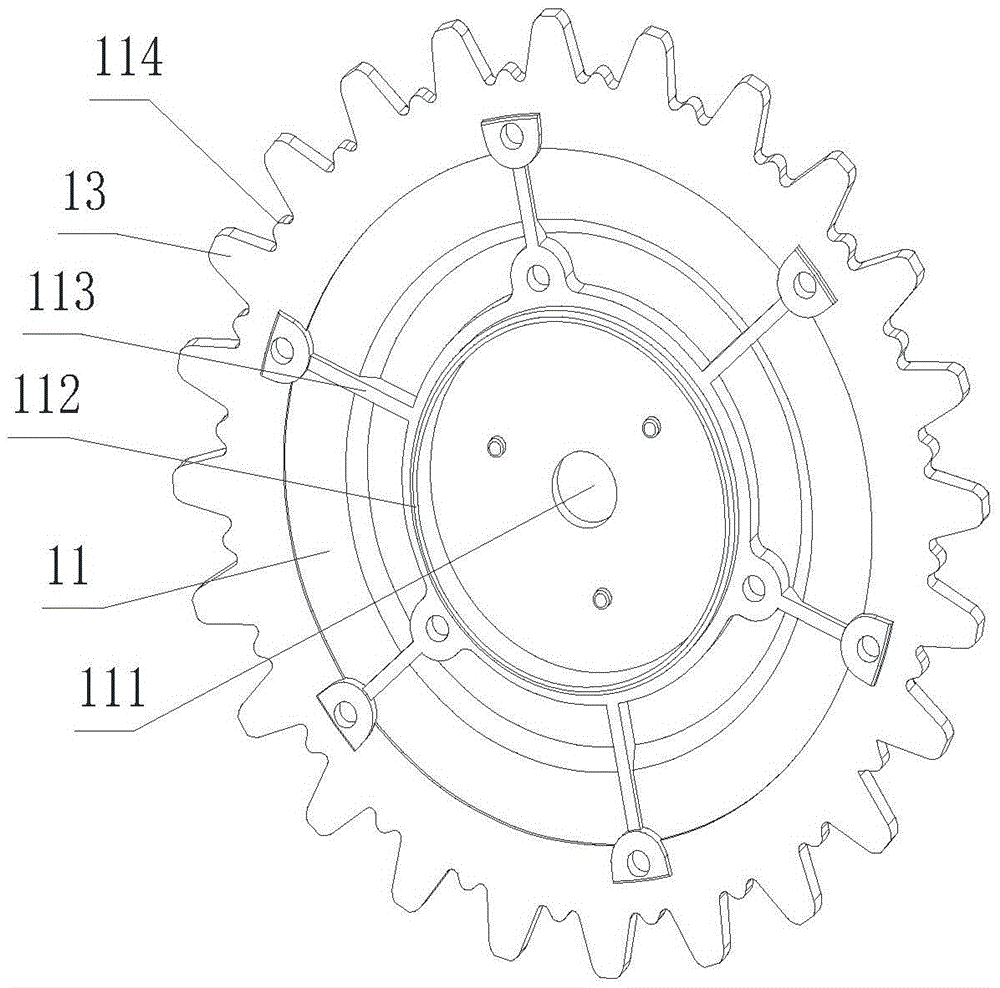

Direct drive mower driving wheel with built-in outer rotor motor and mower

ActiveCN104079113AIncrease the moment of inertiaImprove stabilityLawn-mowersMotor depositionMowerStator

The invention provides a direct drive mower driving wheel with a built-in outer rotor motor and a mower. The direct drive mower driving wheel with the built-in outer rotor motor comprises a driving wheel body formed by assembling a wheel lateral cover I, a wheel lateral cover II and a wheel body clamped between the wheel lateral cover I and the wheel lateral cover II, wherein a cavity is defined by the wheel lateral cover I, the wheel lateral cover II and the wheel body, the outer rotor motor is installed in the cavity, an outer rotor part of the outer rotor motor is fixedly arranged relative to the driving wheel body, an inner stator part of the outer rotor motor is provided with a fixing shaft which penetrates through the wheel lateral cover I and extends to the outside of the driving wheel body, and a shaft hole I through which the fixing shaft penetrates is formed in the wheel lateral cover I. According to the direct drive mower driving wheel with the built-in outer rotor motor and the mower, the outer rotor motor is installed inside the driving wheel and directly drives the mower driving wheel, the transmission accuracy and reliability are good, and the inner space of the mower is more reasonable.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

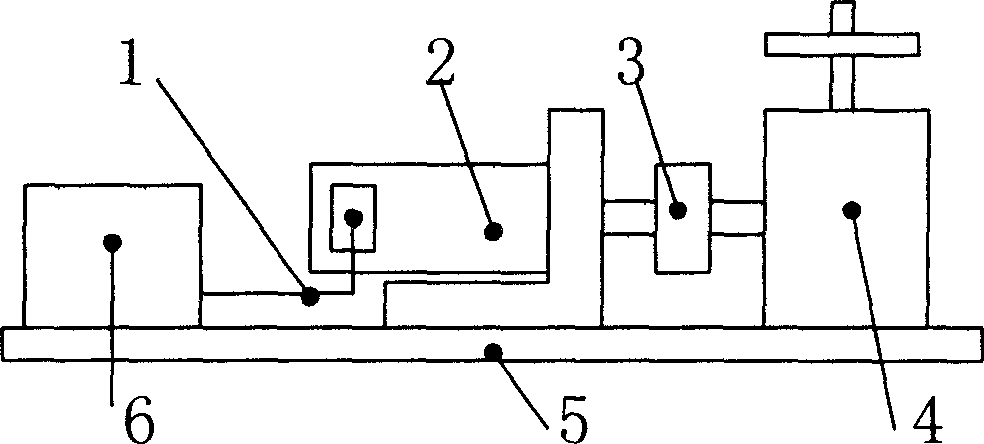

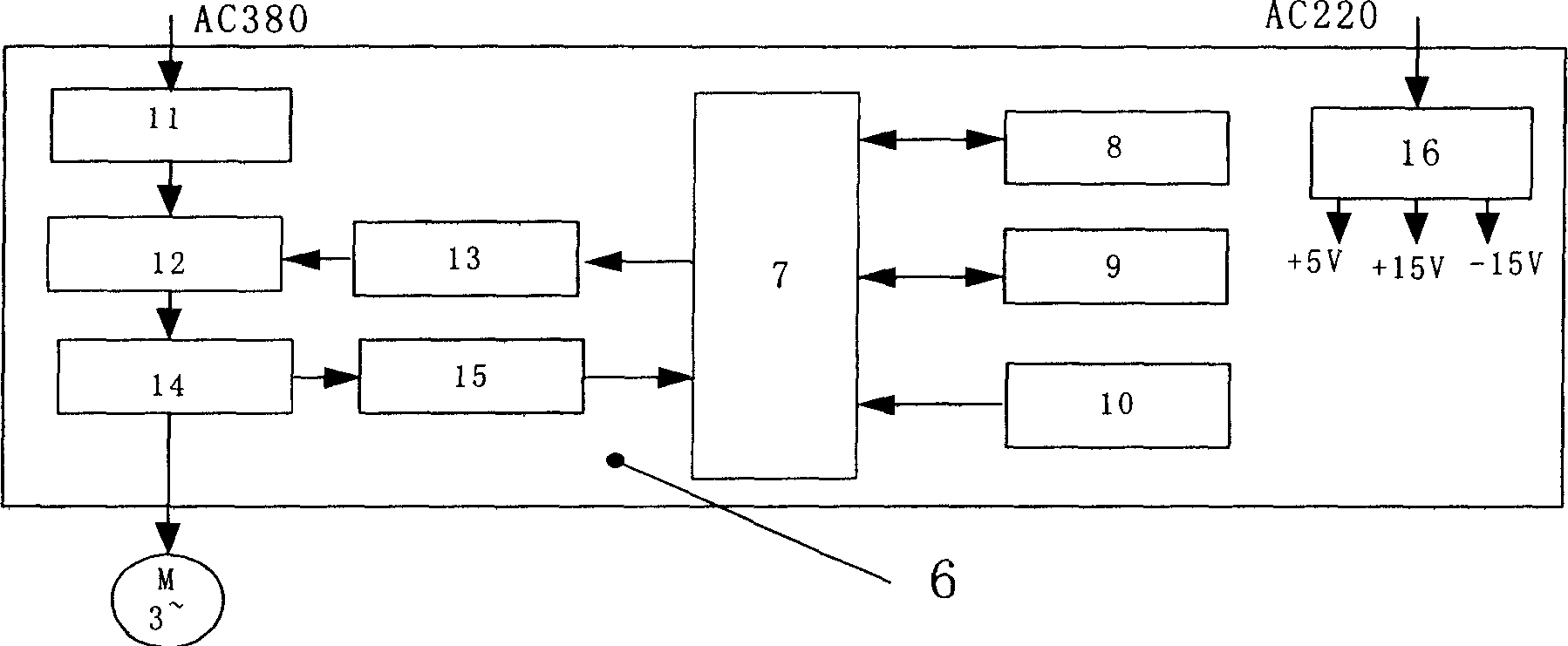

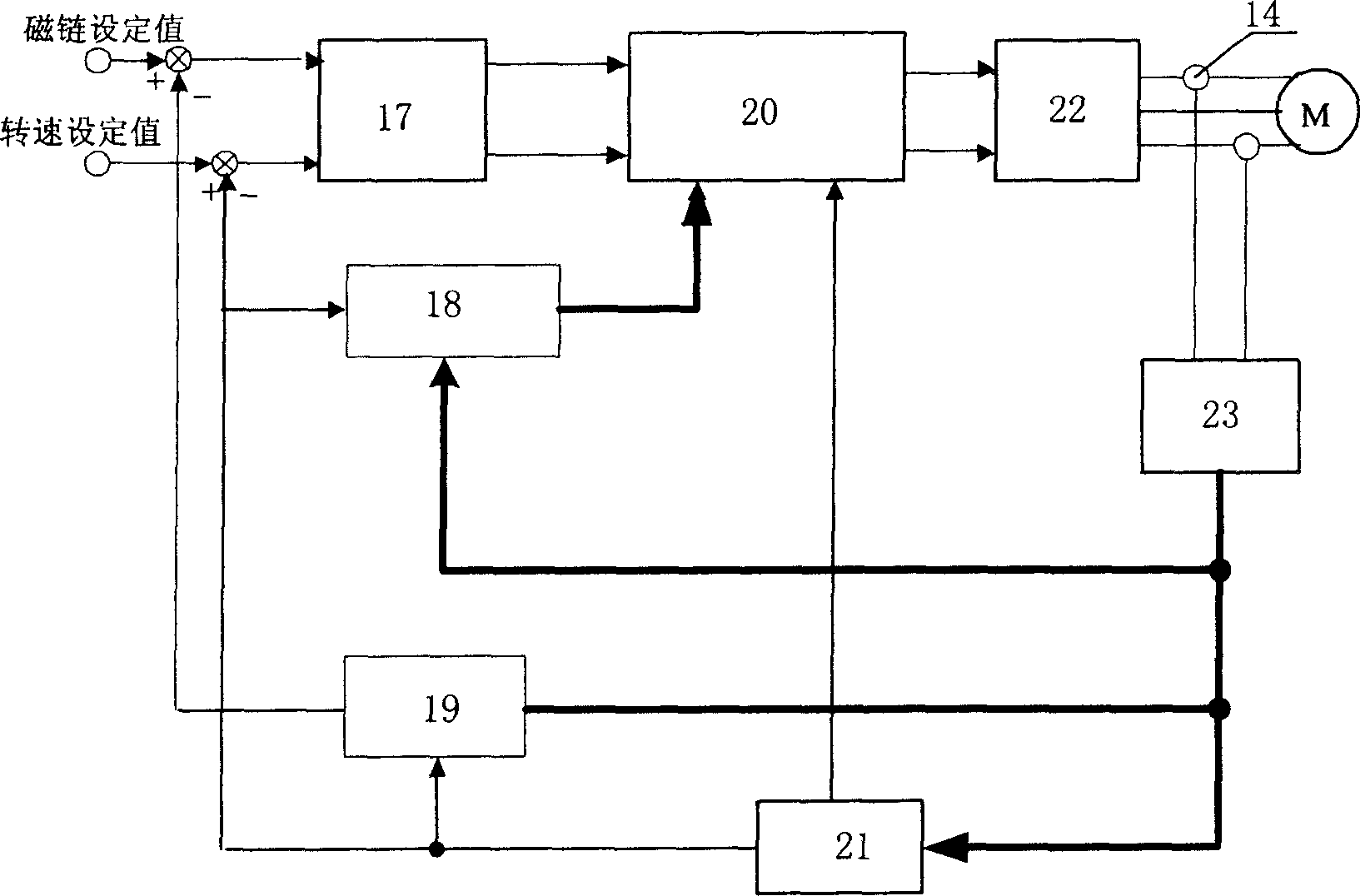

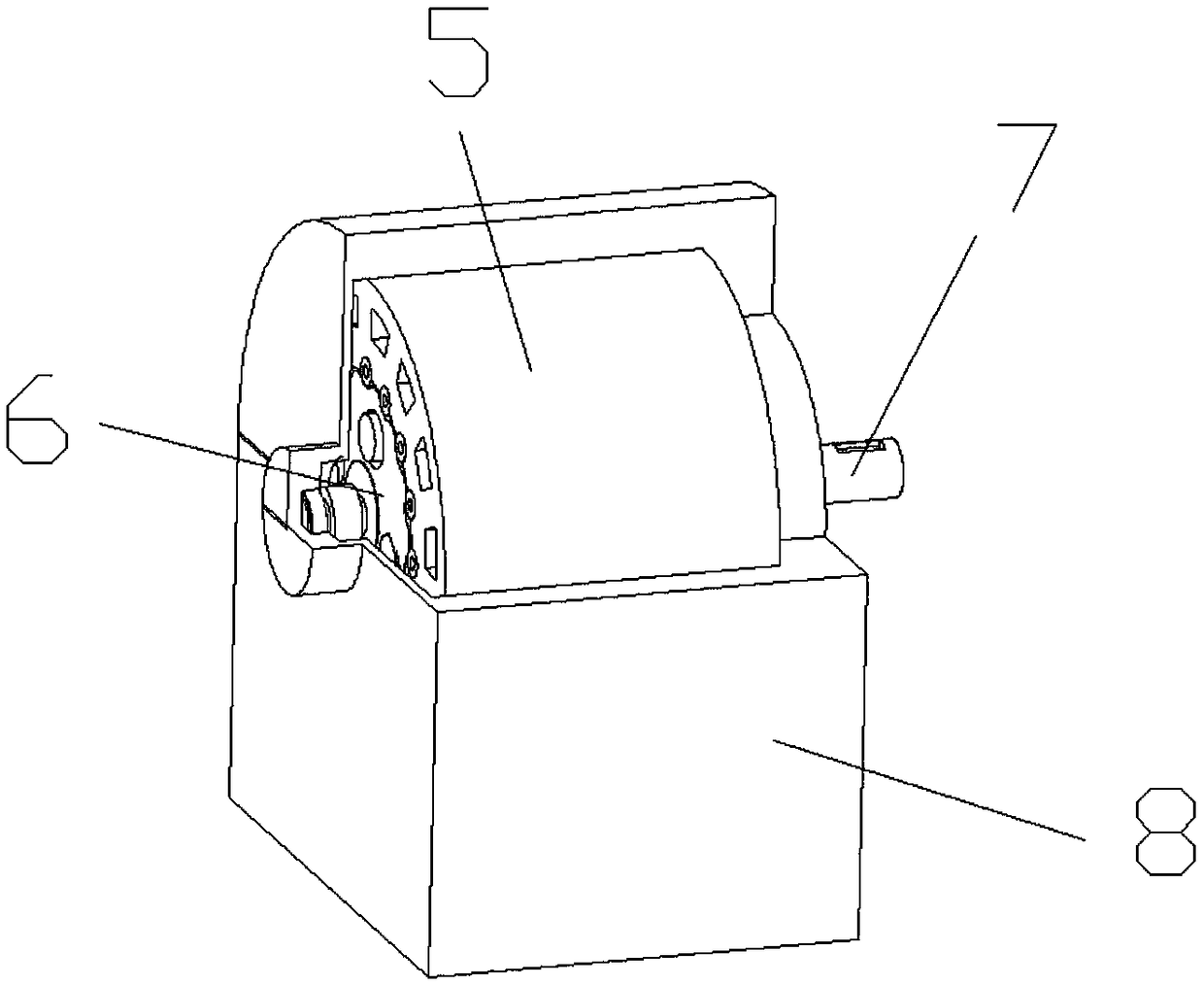

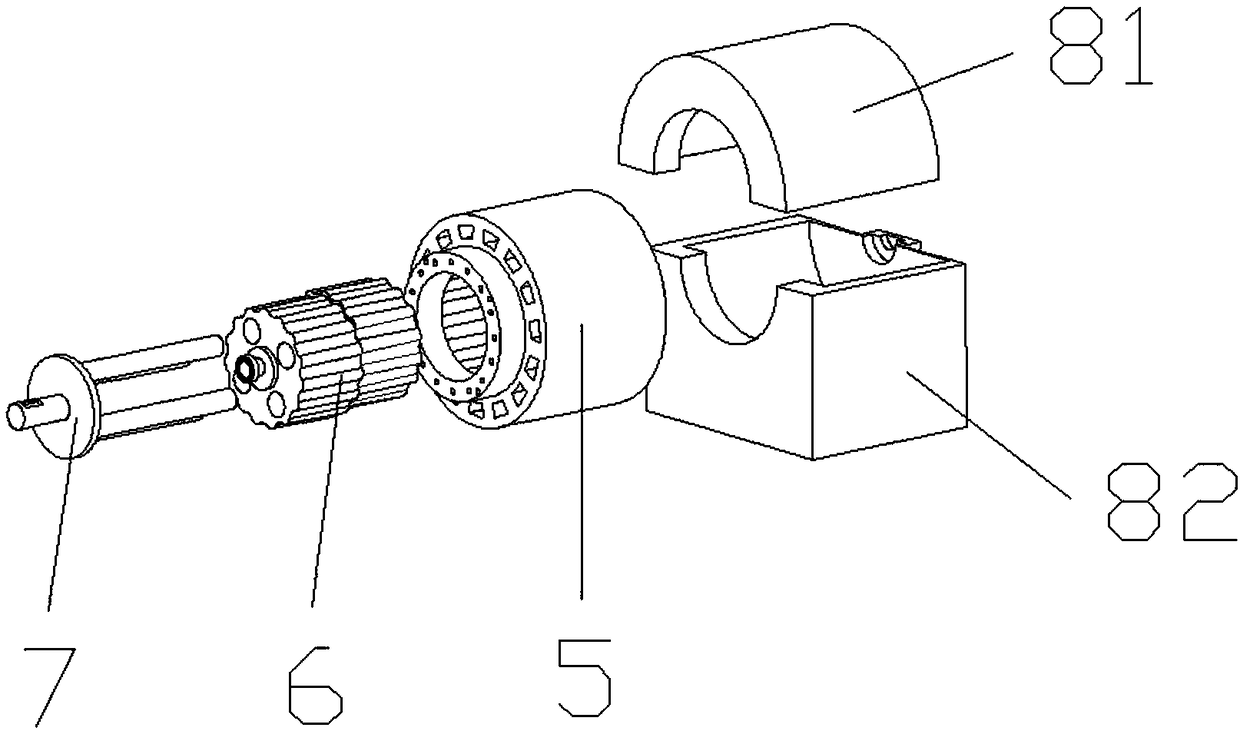

Electromechanical unit and control method for arc indexing cam mechanism

InactiveCN1374467AImprove performanceGood transmission precisionGearingGearing controlCouplingEngineering

The present invention relates to one kind of electromechanical unit and control method for arc indexing cam mechanism. The electromechanical unit consists of mainly motor and its controller, positioncoder, arc indexing cam box, coupling and base. By means of running dynamic torque disturbance compensating algorithm, the motor control is compensated actively to reduce the effect of cam mechanism caused by load change. The present invention can raise the positioning precision of arc indexing cam mechanism and reduce the impact and noise of the arc indexing can mechanism produced in running.

Owner:SHANDONG UNIV

A multi-channel combination filter wheel

ActiveCN106200213BHigh degree of automationGood transmission precisionCamera filtersMountingsGear driveControl theory

The invention discloses a multi-channel combination filter wheel. In the scheme, a combination of multiple filter wheels is adopted, and a mature high-precision gear transmission technology is used to realize automatic rotation of multiple filter wheels in sequence. High, good transmission accuracy; in addition, the structure of the device can be designed according to the number of filter wheels required, the overall volume is optimized, the structure is compact, and it can be placed in front of the focal plane of the multi-spectral camera to achieve multi-channel and multi-band spectra data collection.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

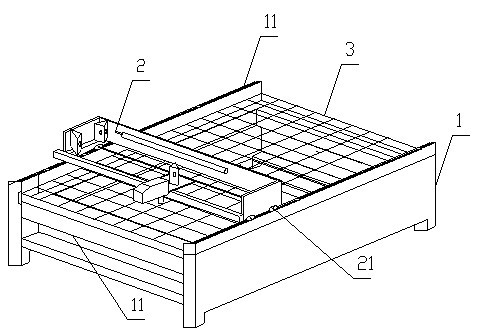

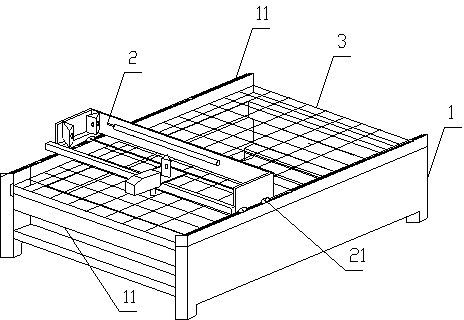

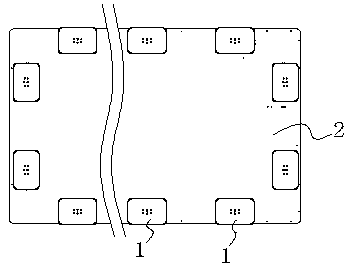

High-speed steering wheel type sorting system

PendingCN110155685AReduce gapHigh degree of integrationConveyorsSortingSteering wheelLogistics management

The invention aims to provide a high-speed steering wheel type sorting system. The high-speed steering wheel type sorting system is used for solving the problems that conveying flexibility is poor, and small packages and soft packages cannot be conveyed due to the fact that mutual gaps between the parts with an effective conveying function are too large in the prior art. The system comprises a support set used for forming the support for component parts and locating the component parts, a driving set used for realizing a steering actuation sorting function of the logistics transportation, a transportation set used for realizing the conveying action of the logistics packages above, and a transmission set used for providing power of the actions for the driving set and the transportation setabove. The high-speed steering wheel type sorting system has the advantages of being high in integration level, small in size, small in the gaps among transportation components and the like, and further has the advantages of being flexible in transportation and steering, high in sorting efficiency, good in conveying stability and not prone to package jamming.

Owner:ZHEJIANG DAMON TECH CO LTD +1

Electromechanical controller and its control method for arc cam indexing mechanism

InactiveCN1684356AImprove performanceHigh positioning accuracyDC motor speed/torque controlMechanical energy handlingCouplingNonlinear decoupling

An electromechanical control device used in a cambered surface cam dividing mechanism includes a motor, a cambered surface dividing cam box, a coupler and a base, it also includes a non-linear perturbed compensation controller fixed on the base together with the motor and the box, the motor is connected with the box by the coupler, the non-linear perturbed compensation controller is connected with the box by a cable. This invention applies the active compensation control to the motor by perturbation observation of a sliding mode transformation structure and a non-linear uncoupling compensation control technology to reduce influence of the load variance to the operation performance of the motor.

Owner:SHANDONG UNIV

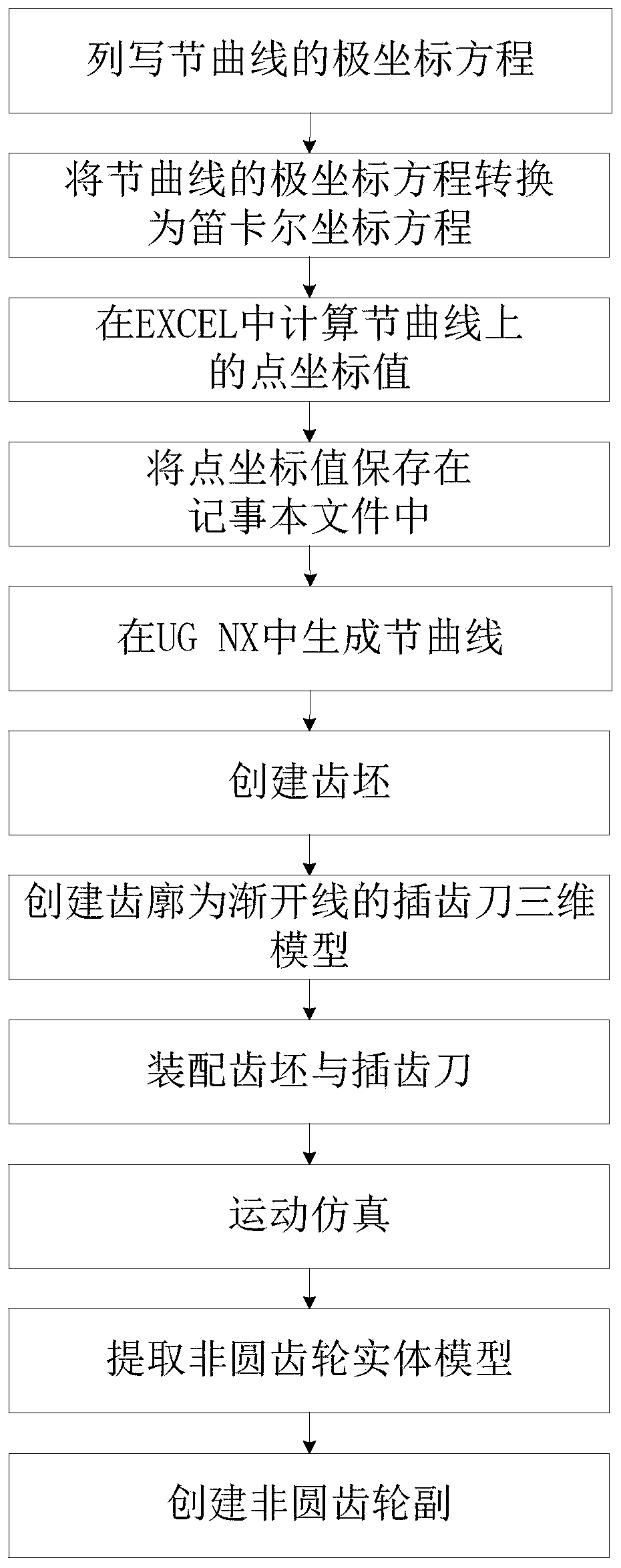

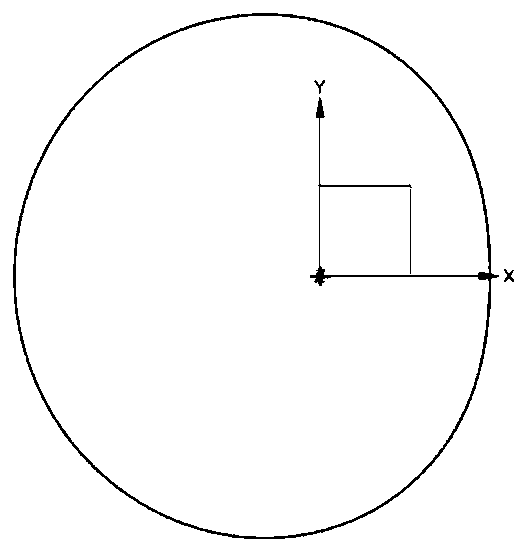

Three-dimensional solid modeling method for non-circular gear pair with involute tooth profile

ActiveCN111539084AThe drawing process is simpleEasy to drawGeometric CADPortable liftingThree dimensional modelModelSim

The invention discloses a three-dimensional solid modeling method for a non-circular gear pair with an involute tooth profile. The method includes: according to a transmission ratio function and a center distance, obtaining point coordinate values on pitch curves of a driving wheel and a driven wheel in the non-circular gear pair in an EXCEL table; importing the point coordinate values into UG NXsoftware to obtain a driving wheel pitch curve and a driven wheel pitch curve, creating a gear blank on the basis of the driving wheel pitch curve and the driven wheel pitch curve, and obtaining a solid model of the non-circular gear by defining the initial positions and relative movement of the gear blank and the slotting cutter model and adopting a motion simulation means, so as to enble the obtained three-dimensional model transmission precision to be superior to that of a tooth profile conversion method. The modeling process is simple, no complex calculation process exists, and the calculation amount is small; a three-dimensional model of the non-circular gear pair is obtained by adopting a UG NX motion simulation technology, programming is carried out without designing an algorithm, and the development difficulty is low.

Owner:XIAN AERONAUTICAL UNIV

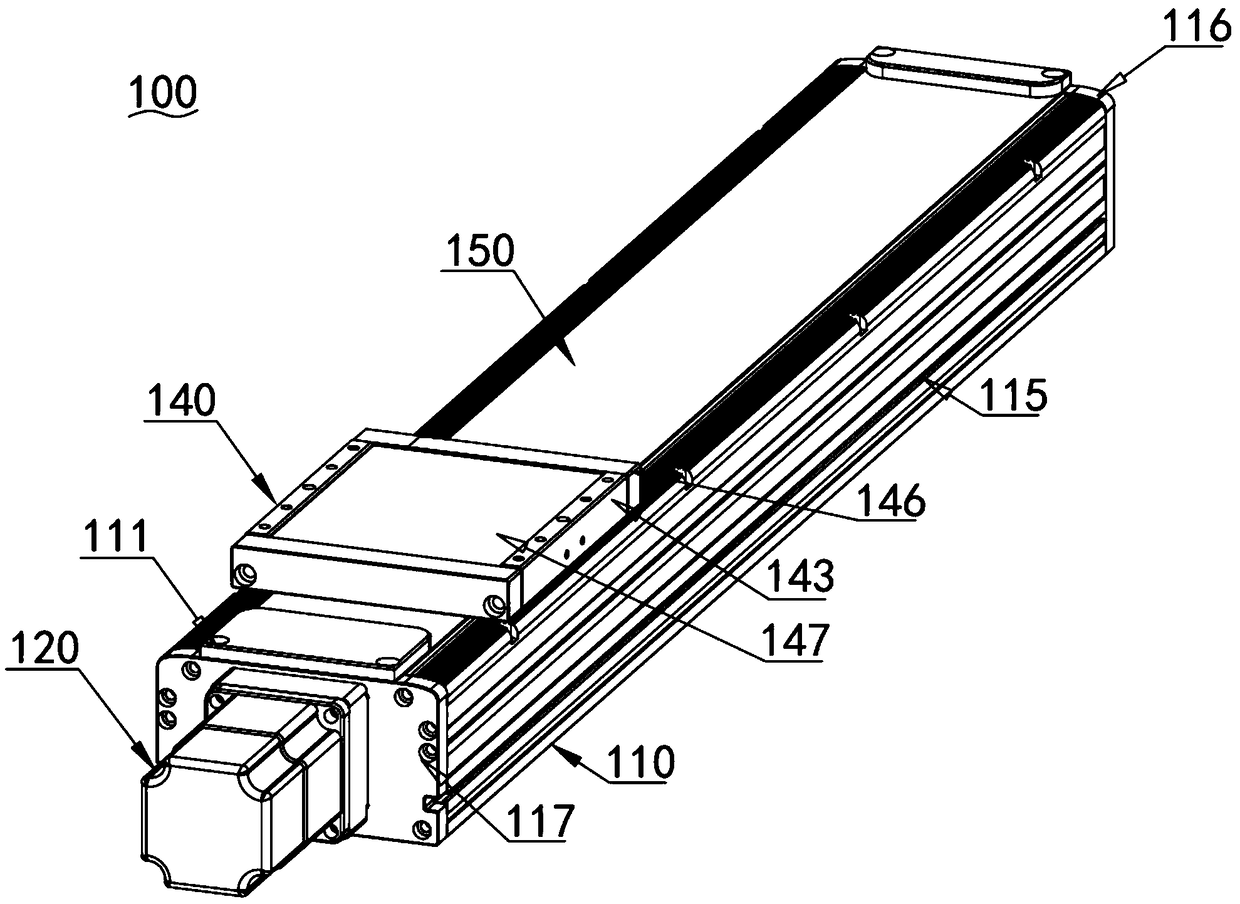

Totally-enclosed type linear module

The invention relates to the technical field of linear transmission, in particular to a totally-enclosed type linear module. The totally-enclosed type linear module comprises a base, a driving component, a transmission assembly and a transmission seat, wherein the driving component is arranged at one end of the base, the transmission assembly is arranged inside the base and is in driving connection with the driving component, the transmission seat is movably arranged to the transmission assembly, the side, provided with the transmission seat, of the base is provided with a sealing steel piece,two ends of the base are provided with pressing plates to fix the sealing steel piece to the surface of the base, the surface of the base is provided with positioning grooves, each positioning grooveis provided with a blocking edge, the blocking edge sides are provided with magnets to adsorb the sealing steel piece, the sealing steel piece penetrates into the transmission seat, the transmissionseat is internally provided with a lever to support the sealing steel piece up, and the positions, located on two sides of the lever, of the transmission seat are provided with roller shafts to pressthe sealing steel piece. According to the totally-enclosed type linear module, by means of the arrangements of the positioning grooves and the absorption actions of the magnets, the sealing steel piece is adsorbed to realize sealing transmission, the fact that the sealing steel piece keeps stable transmission in the high-efficiency transmission process can be guaranteed, the transmission efficiency is high, the stability is good, and the sealing strength is high.

Owner:东莞希思克传动科技有限公司

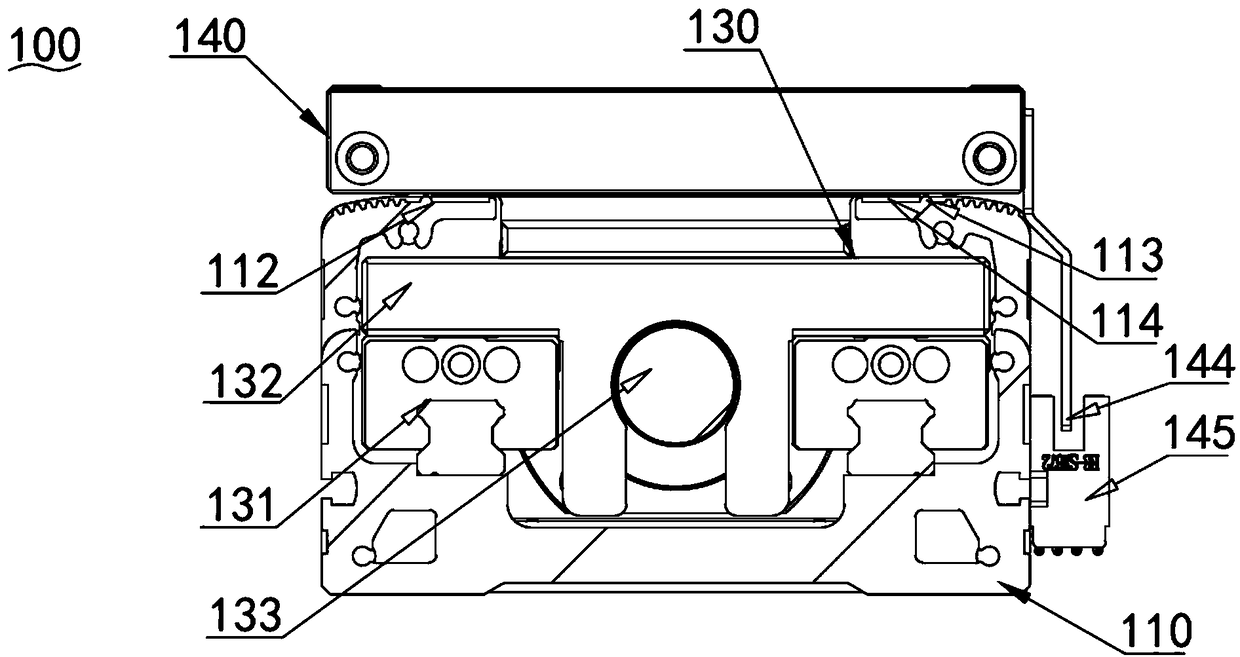

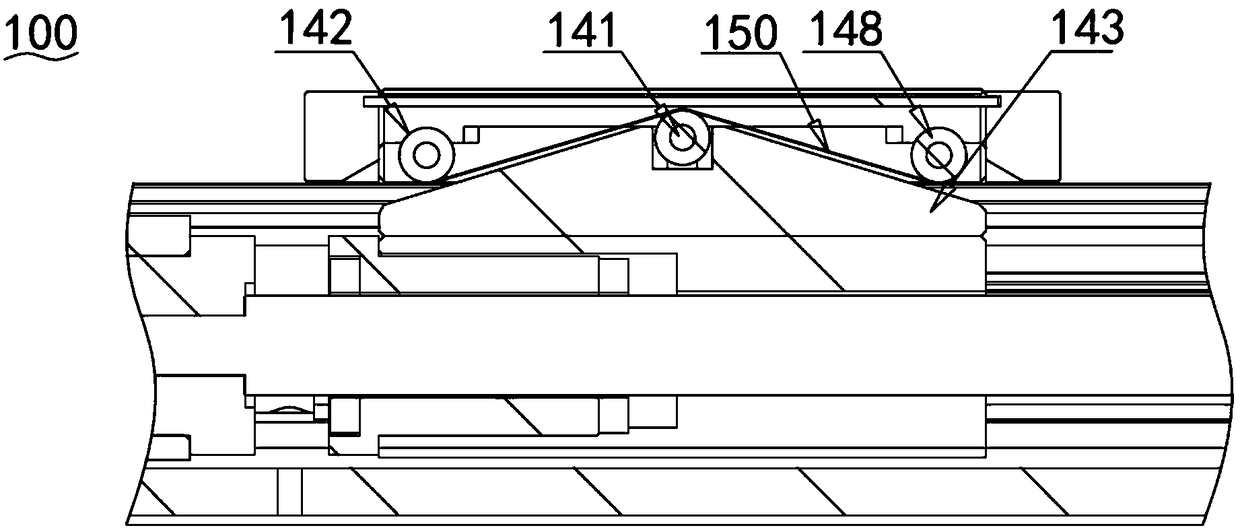

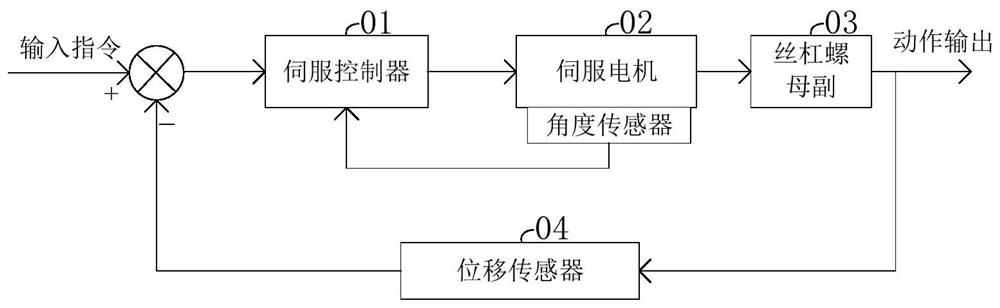

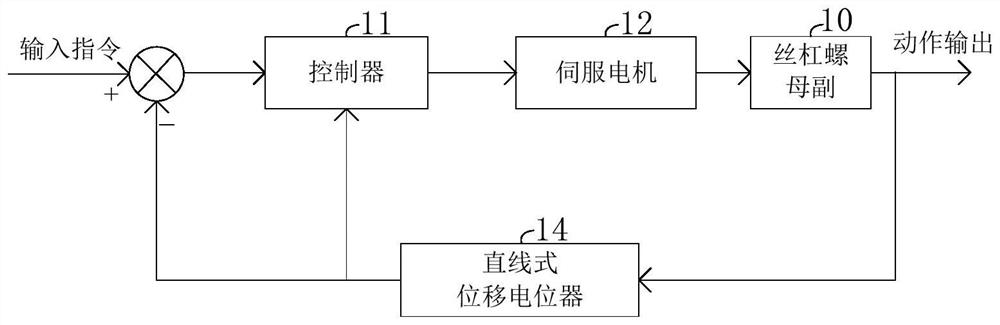

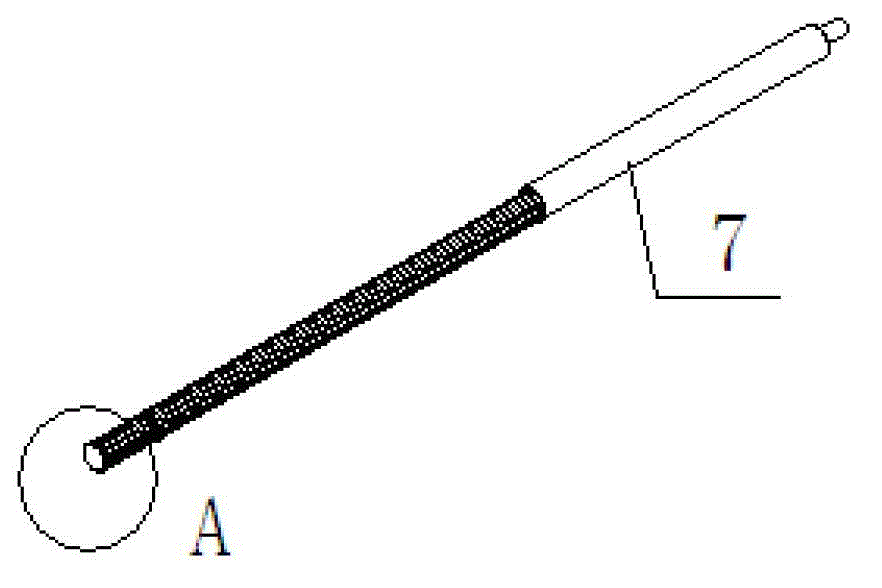

Servo control lead screw transmission device and control method

ActiveCN113636069AReduce failureImprove detection accuracyWithout power ampliicationControl signalControl engineering

The invention provides a servo control lead screw transmission device and a control method. The transmission device comprises a servo motor, a lead screw nut pair, a linear displacement type potentiometer and a controller. The lead screw nut pair comprises a lead screw nut and a lead screw; the servo motor is used for driving the lead screw nut to rotate and the lead screw to translate relative to the lead screw nut; the linear displacement type potentiometer is used for generating a feedback signal representing the current position of the lead screw; and the controller is used for determining the current position of the lead screw and the current rotating position of the servo motor according to the feedback signal, and generating a control signal for controlling the servo motor to rotate according to the current position, the current rotating position and the input instruction. According to the servo control lead screw transmission device provided by the invention, the current position of the lead screw and the current rotating position of the servo motor are determined only by using the linear displacement type potentiometer, a special angle detection sensor does not need to be arranged in the servo motor, the structure is simplified, and transmission device faults caused by problems of the angle sensor are also reduced.

Owner:BEIJING MECHANICAL EQUIP INST

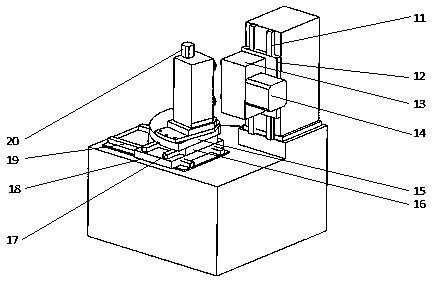

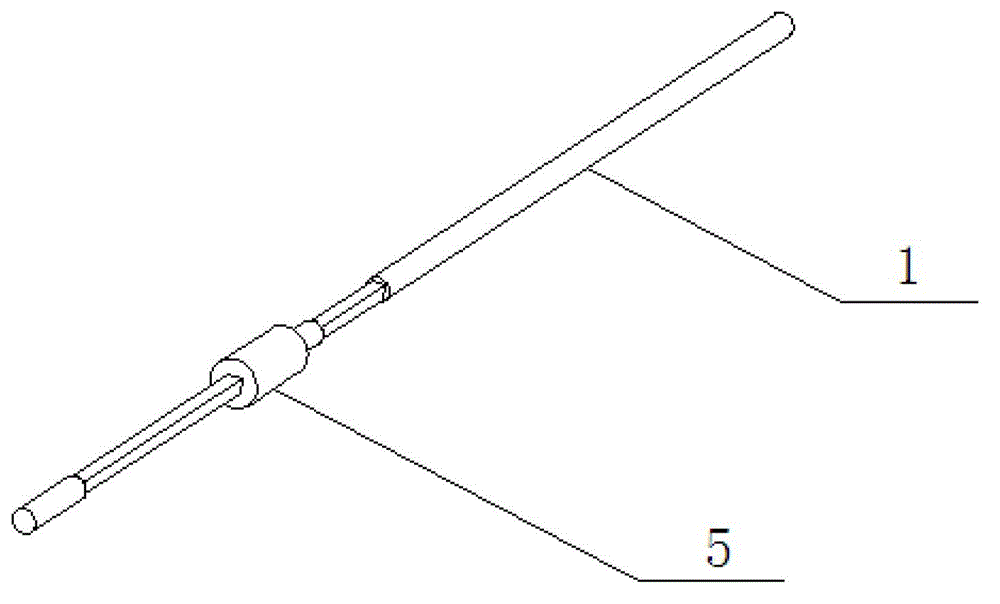

Confocal microscope for large-field tomography

InactiveCN107589537ALower the altitudeHigh-quality tomography resultsMicroscopesEngineeringTomography

The invention discloses a confocal microscope for the large-field tomography, and the confocal microscope comprises an axial motion mechanism and a lateral motion mechanism, wherein a first drive mechanism of the axial motion mechanism drives a worm and gear mechanism to operate so as to drive a cam groove sleeve to rotate. A rotation limiting pin is inserted into a cam groove of the cam groove sleeve, and then is fixed in the cam groove sleeve. An objective lens is fixed at an end part of an axial groove sleeve, and a clamping groove screw is fixed relative to a substrate, and is inserted into an axial groove on an external sleeve wall of the axial groove sleeve, so as to convert the circumferential rotation of a worm gear into the axial motion of the objective lens, and to achieve the tomography. The lateral motion mechanism is disposed on the substrate, and a nasal tube is disposed on the lateral motion mechanism. The objective lens is disposed in the nasal tube, and the lateral motion mechanism is used for adjusting the position of the nasal tube relative to the substrate in the first and second directions perpendicular to the axial direction of the objective lens, so as to achieve the large-field imaging.

Owner:吉林亚泰中科医疗器械工程技术研究院股份有限公司

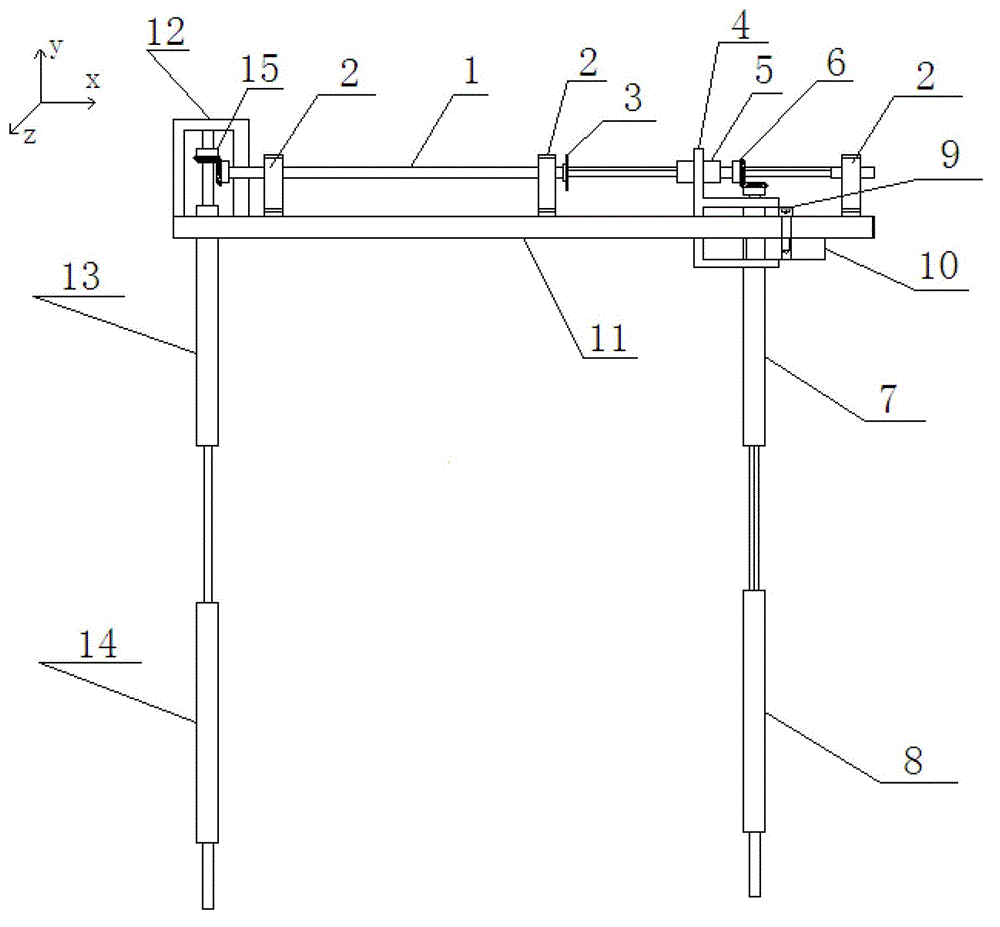

Laser cutting machine

InactiveCN102658437AEfficient cutting operationMeet different needsLaser beam welding apparatusSheet steelEngineering

The invention relates to a laser cutting machine. The laser cutting machine comprises a frame, a laser cross beam and a cutting mesh plate, wherein the cutting mesh plate is arranged on the frame in a sliding manner through a sliding track arranged on the frame. The cutting mesh plate is a steel plate cutting mesh plate or a cloth cutting mesh plate, wherein support points are arranged at mesh nodes of the steel plate cutting mesh plate. Transmission racks are arranged on the two sides of the frame, and a gear meshed with the transmission racks is arranged on the laser cross beam. A plurality of reinforcing rods are arranged at the middle part of the frame. According to the laser cutting machine disclosed by the invention, the cutting mesh plate is arranged on the frame in the sliding manner for facilitating the drawing and replacement of the cutting mesh plate, so that the different needs for cutting steel plates and cloth can be met; simultaneously, the laser cross beam adopts rack-gear transmission, thereby having better transmission precision; and furthermore, the plurality of the reinforcing rods are arranged on the frame, thus the frame is more stable during cutting operation and the need of performing faster cutting operation can be further met.

Owner:江苏大华激光科技开发有限公司

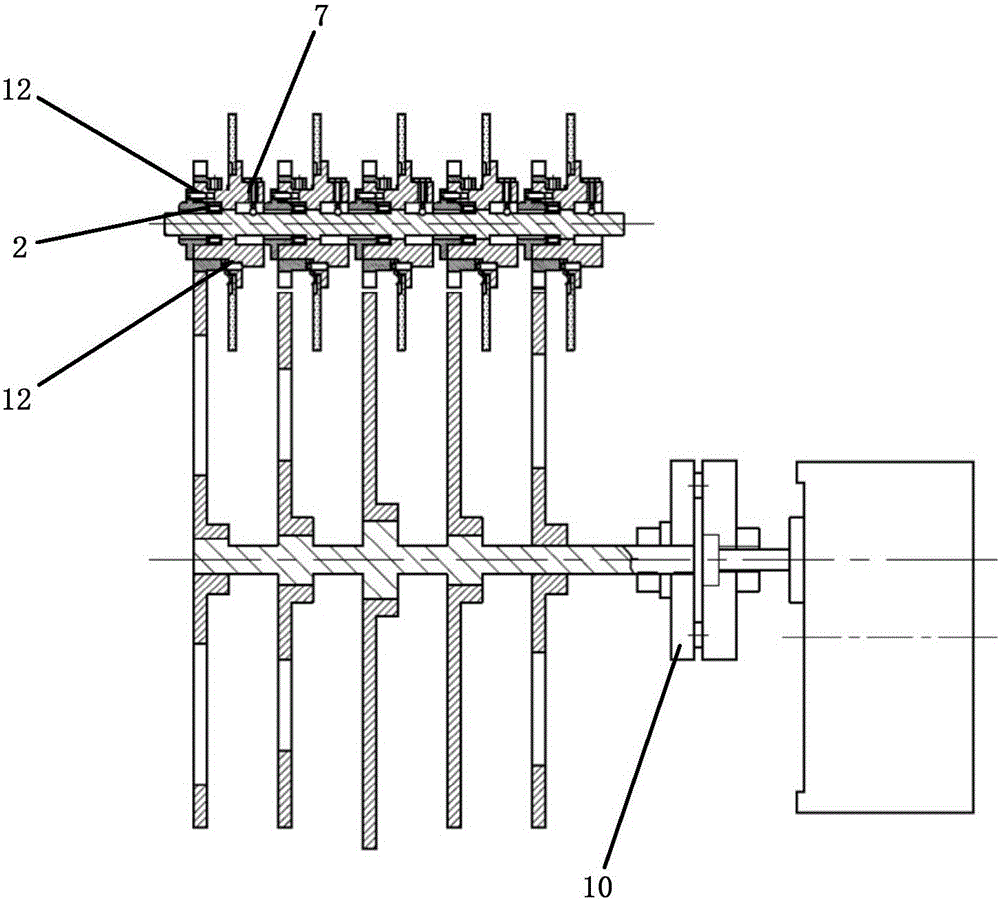

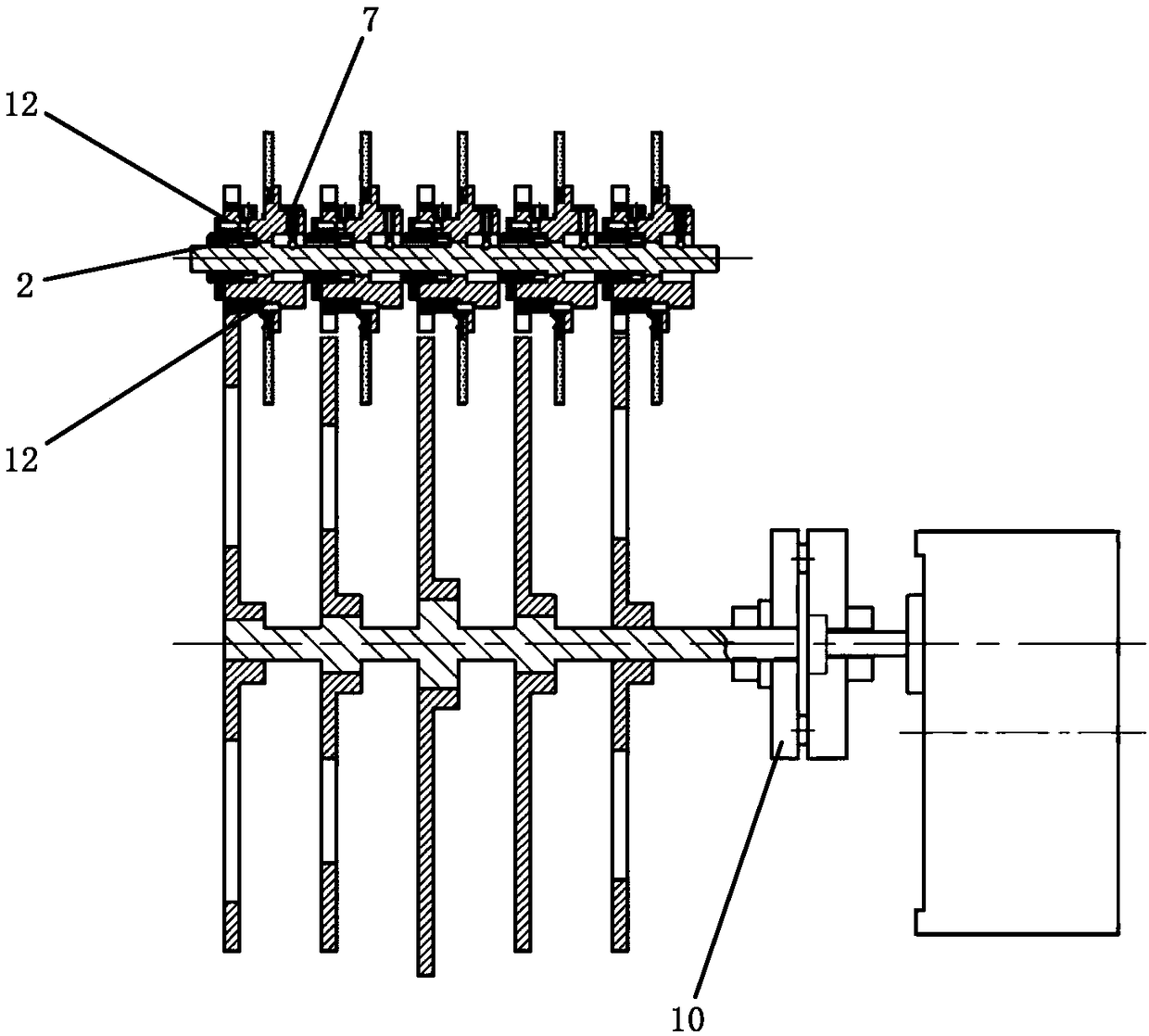

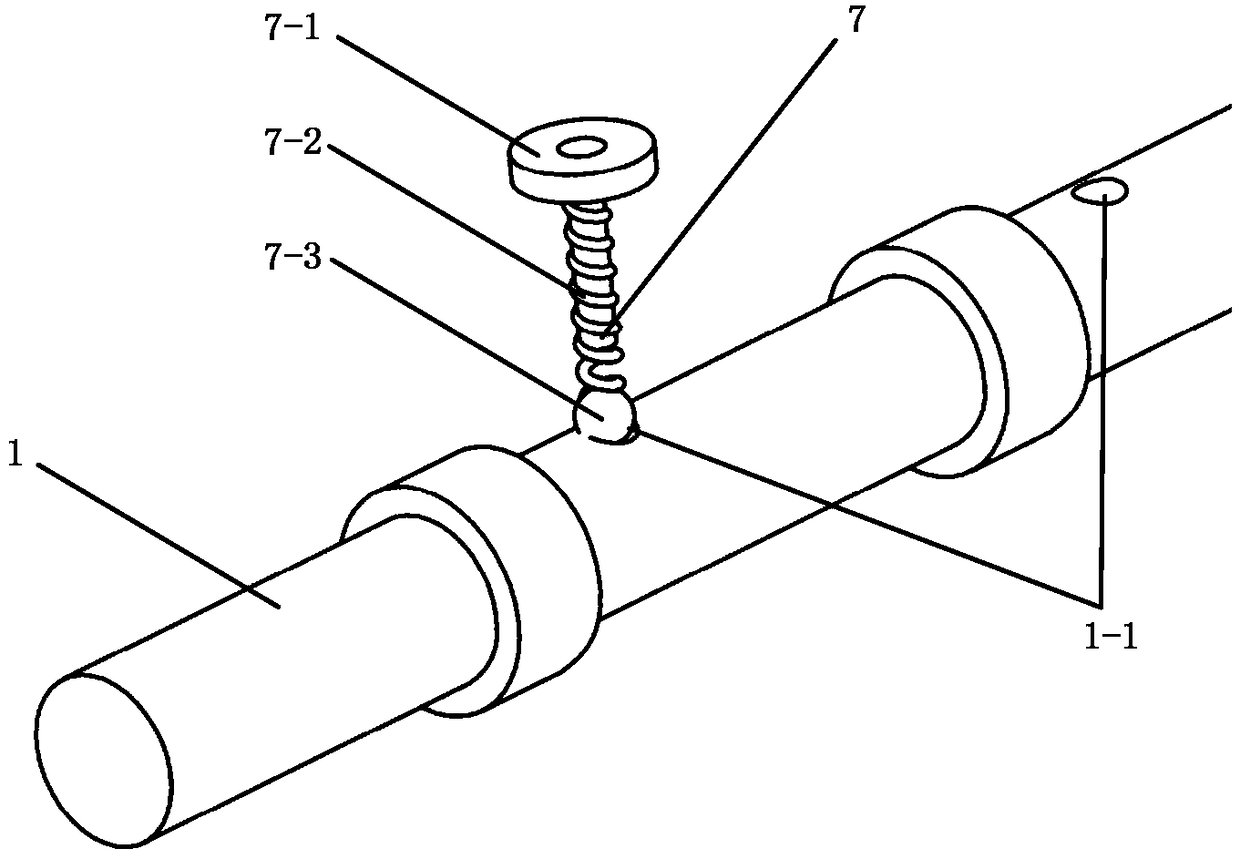

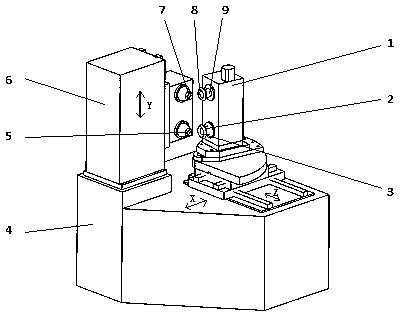

Machining machine tool for spiral bevel gears

PendingCN110421216AReduce in quantityThe overall structure is simpleGear-cutting machinesGear teethMotor driveEngineering

The invention provides a machining machine tool for spiral bevel gears. The machining machine tool comprises a workpiece box and a tool box. M workpiece spindles which stretch in parallel and are usedfor mounting workpieces are sequentially arranged and integrated in the workpiece box, a workpiece motor is fixedly arranged on the workpiece box, and the workpiece motor drives the M workpiece spindles to synchronously rotate through a workpiece synchronous transmission mechanism. N tool spindles which stretch in parallel and are used for mounting machining tools are sequentially arranged and integrated in the tool box, a tool motor is fixedly arranged on the tool box, and the tool motor drives the N tool spindles to synchronously rotate through a tool synchronous transmission mechanism. M is equal to N, and N is 2 or 3. The sequential distribution direction of the M tool spindles is equal to that of the N workpiece spindles, the adjacent intervals of the M tool spindles are equal to those of the N workpiece spindles, thus, the M tool spindles correspond to the N workpiece spindles one to one, and then the M spiral bevel gears are simultaneously machined.

Owner:HENAN UNIV OF SCI & TECH

Transmission method and transmission structure for circulating conveying trays

ActiveCN107934422AGood load bearingHigh transmission precisionMechanical conveyorsEngineeringMechanical engineering

Owner:LILING LVYUAN COMML & TRADING CO LTD

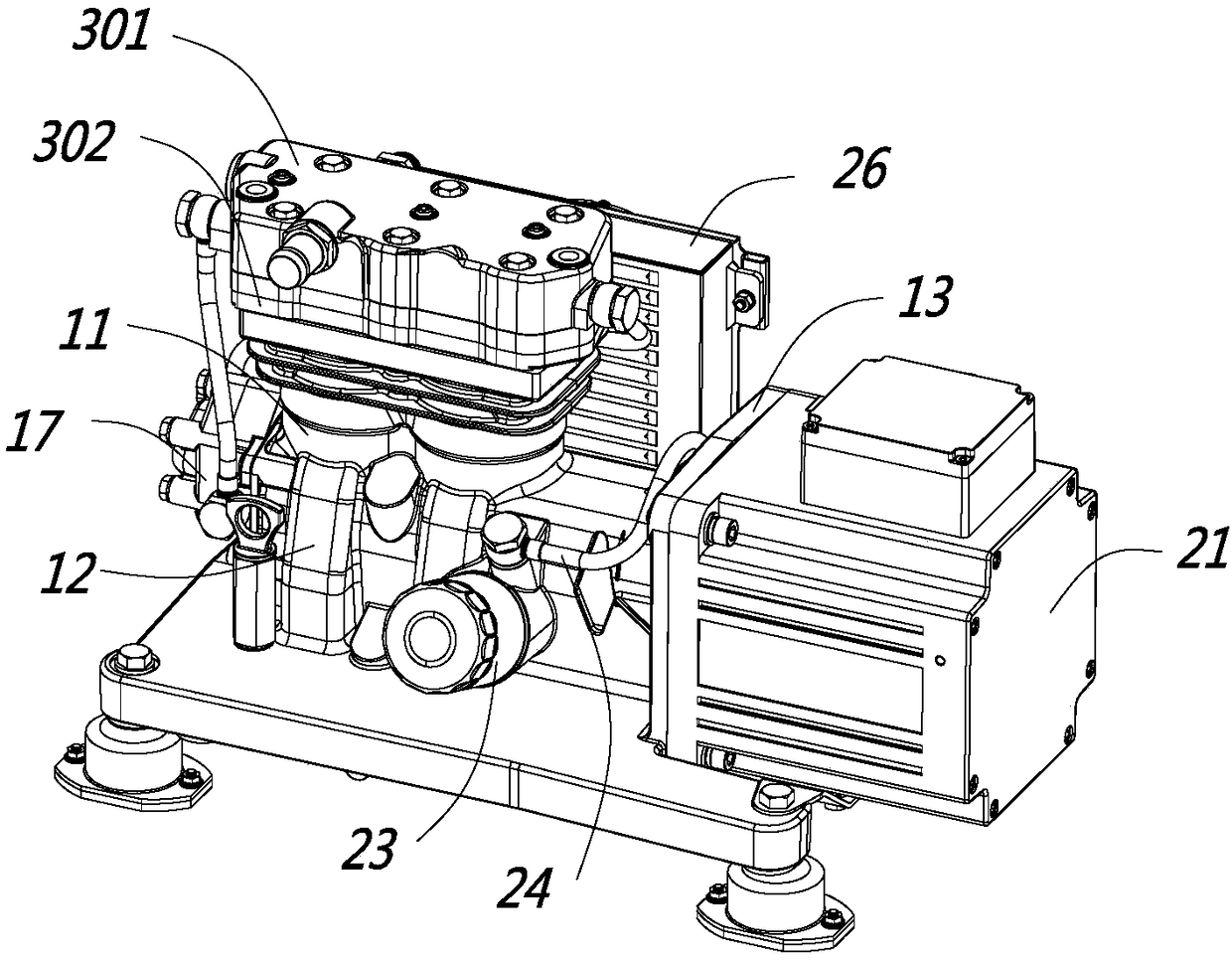

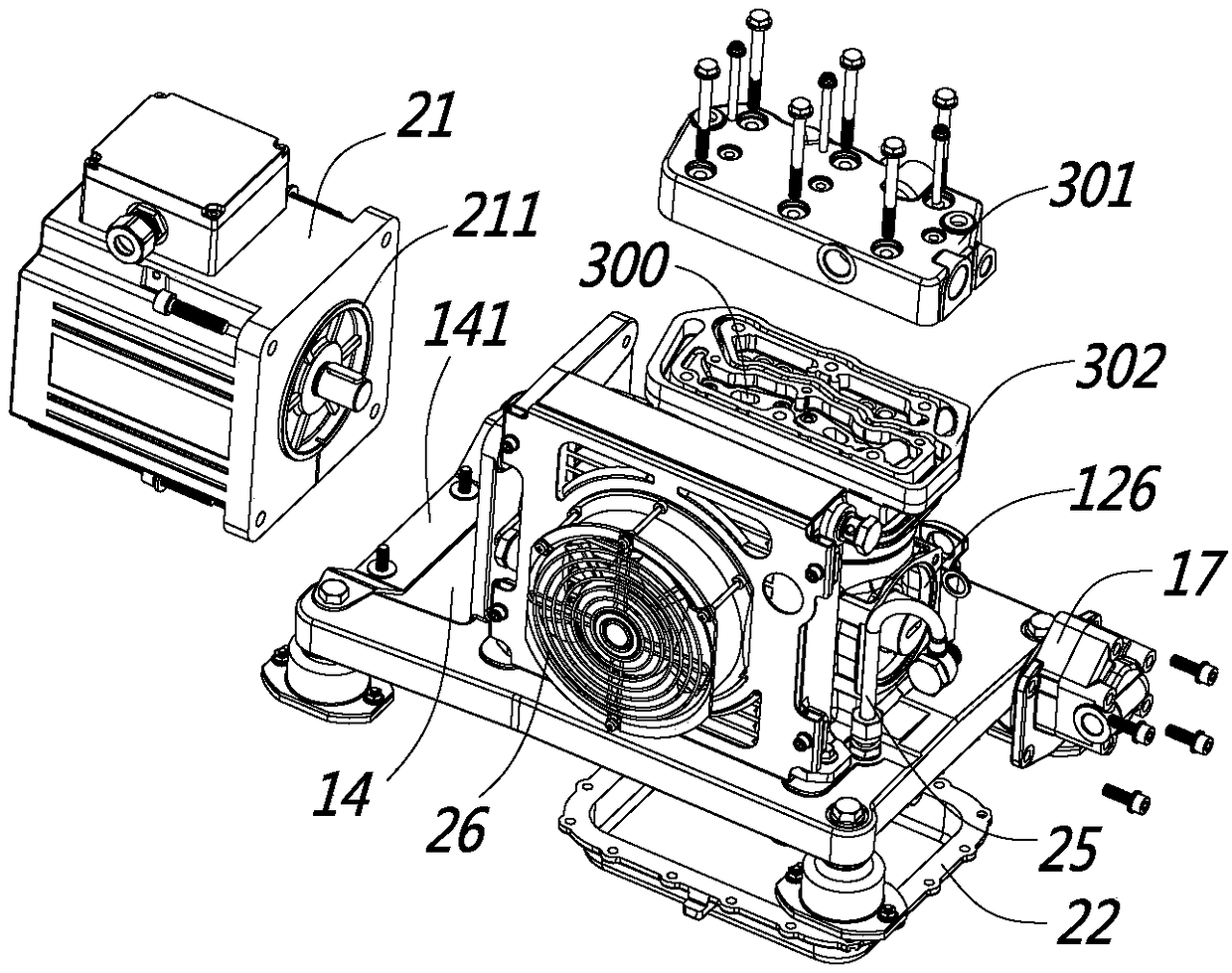

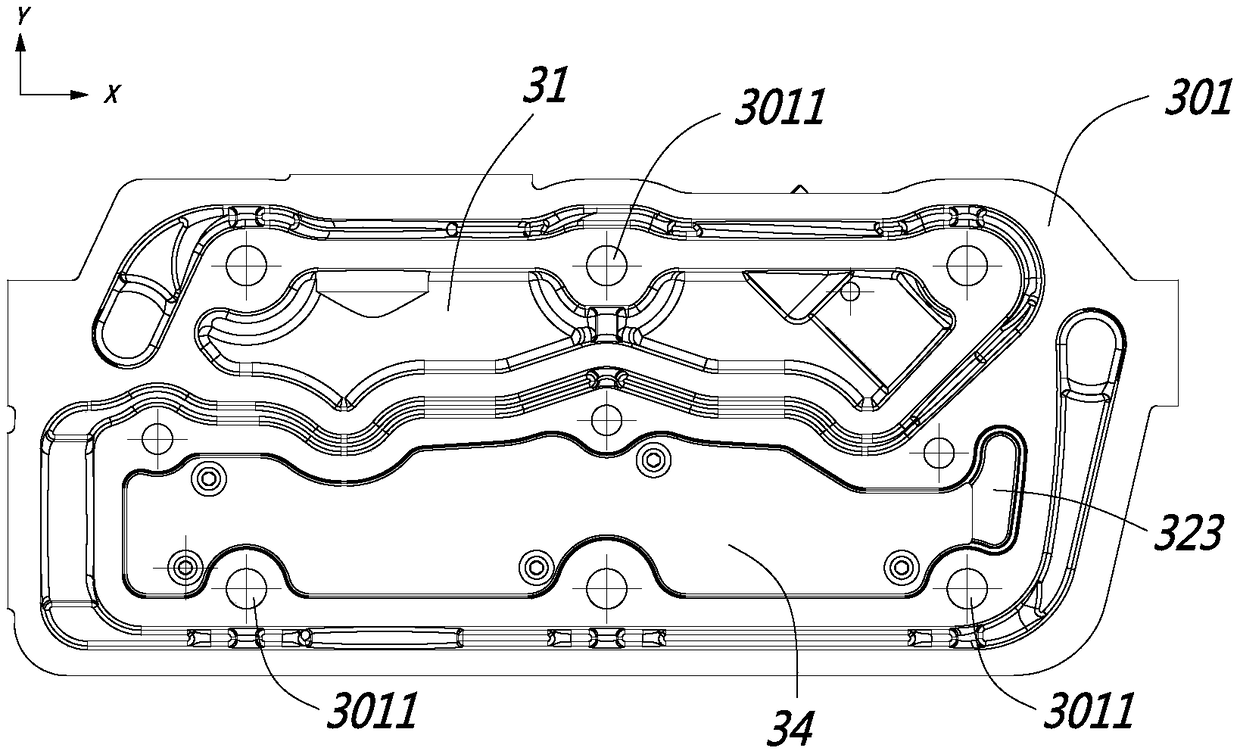

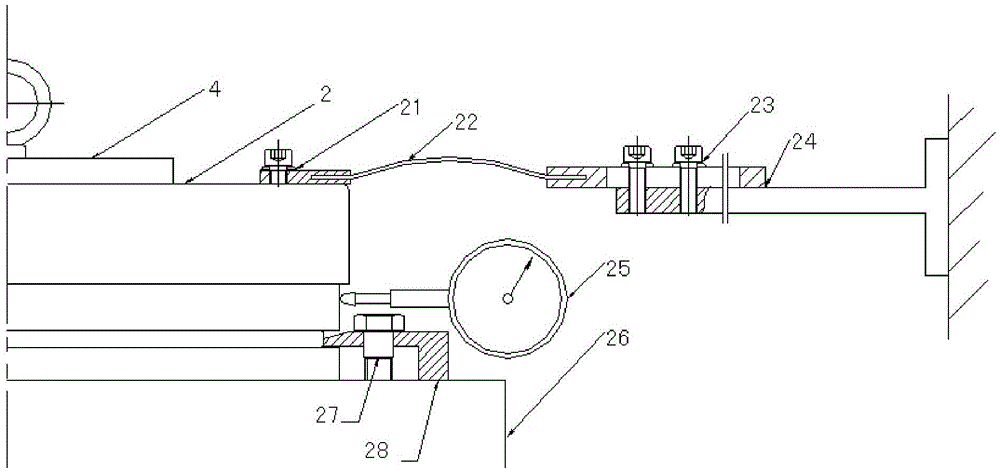

Electric air compressor

PendingCN108915988AGuaranteed normal transmissionImprove coaxialityPositive displacement pump componentsPiston pumpsGas compressorAir compressor

The invention discloses an electric air compressor, and belongs to the field of air compressors. The electric air compressor comprises a machine body and a cylinder cover arranged on the machine body.The cylinder cover is provided with an air inlet cavity and an air outlet cavity which is connected with an exhaust port. An air cylinder body, a crank case and a motor support are included. A flow guiding plate is arranged in the air outlet cavity and divides the air outlet cavity into an upper exhaust channel and a lower exhaust channel. A middle circulation hole communicates between the upperexhaust channel and the lower exhaust channel. The exhaust port communicates with the upper exhaust channel. Compressed air inflows from the lower exhaust channel and enters the upper exhaust channelafter passing through the middle circulation hole, and then the compressed air is exhausted from the exhaust port. The air cylinder body, the crank case and the motor support are of an integrated structure, and the center axis of a crank cavity and the center axis of a motor rotation shaft cavity are coaxially arranged. The electric air compressor has the beneficial effects that the work noise ofthe air compressor can be effectively lowered, and coaxiality of a transmission system is guaranteed.

Owner:浙江万安其弗汽车零部件有限公司

A high-precision circular grating assembly device

The invention provides a high-precision circular grating assembly device, and relates to the field of precision instruments. According to the invention, a grating base presses and fixes a rotary platform to be tested; an upper end cap is disposed on the upper part of the grating base and is fastened and connected to the grating base; the upper end cap is wider than the top part of the grating base; the center of the upper end cap is equipped with a lifting ring; a bearing is sleeved on the upper part of the grating base; a reading head turntable is sleeved on the exterior of the bearing; the upper part and the side part of the reading head turntable are covered with cover caps; the reading head turntable employs an oil lubricated ring sliding surface for axial positioning; the inner side of the reading head turntable is provided with a grating reading head; and the radial inner side of the grating reading head is provided with a grating reflection ring which is sleeved on a conical step of the central part of the grating base, wherein the grating reading head presents a non-contact state with the grating reflection ring in a radial opposite direction, and the grating reflection ring is of annular structure of metallic material and has good resistance to mechanical impact.

Owner:CHONGQING MACHINE TOOL GROUP

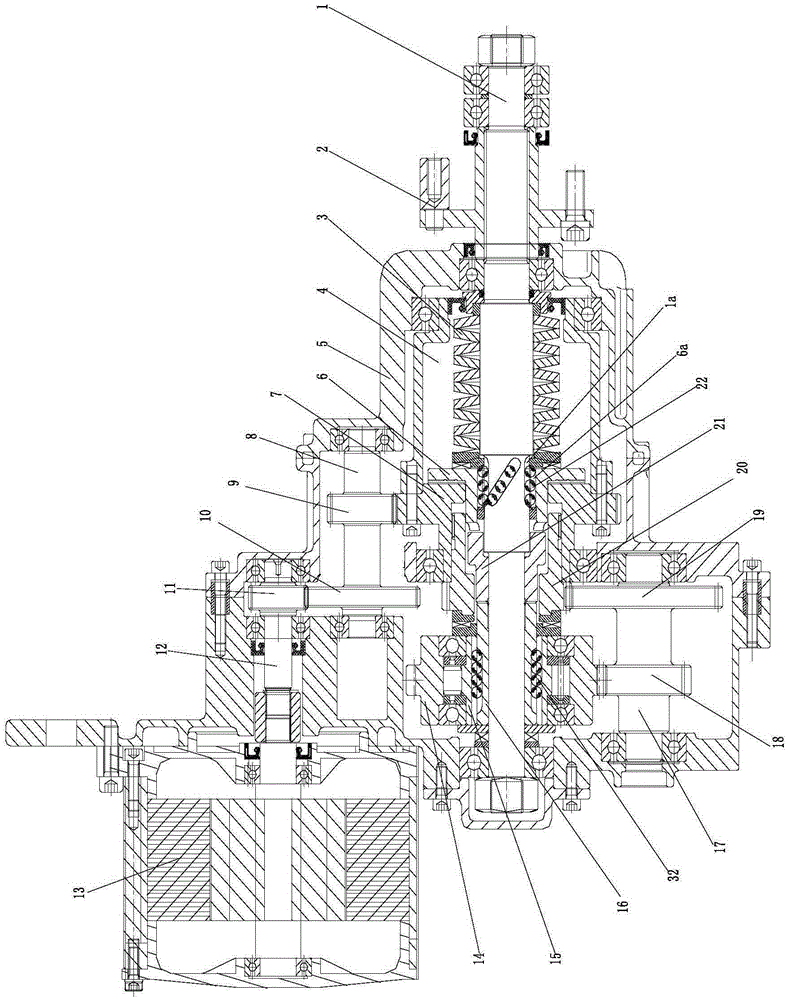

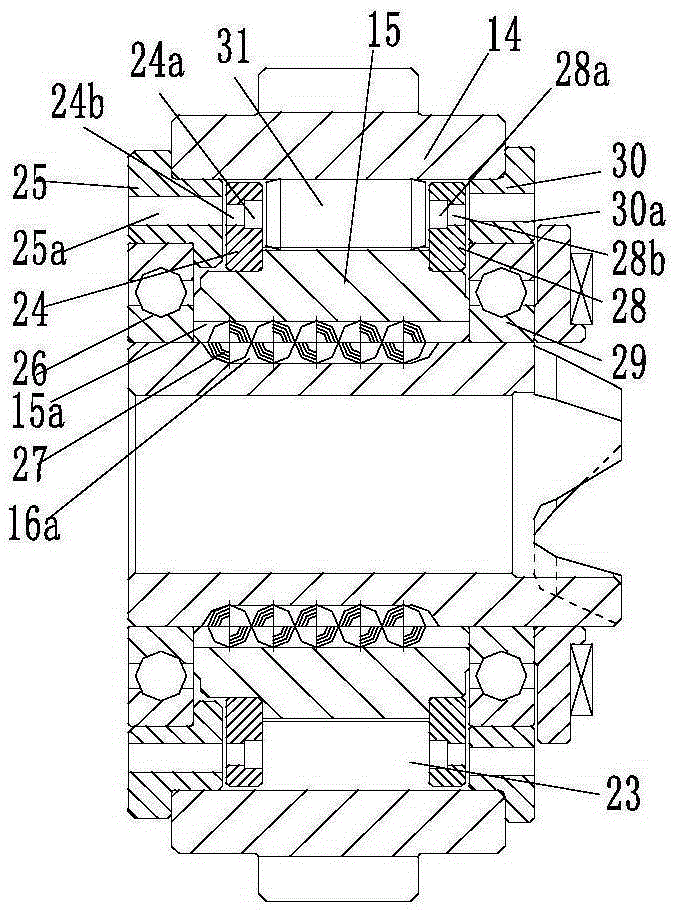

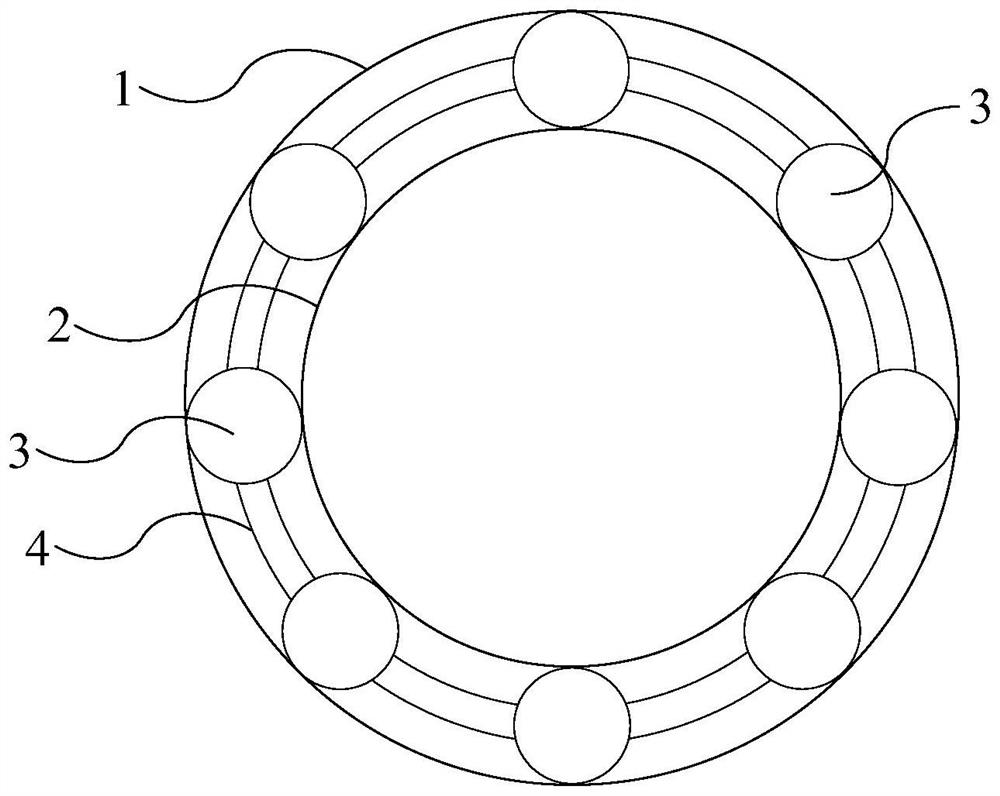

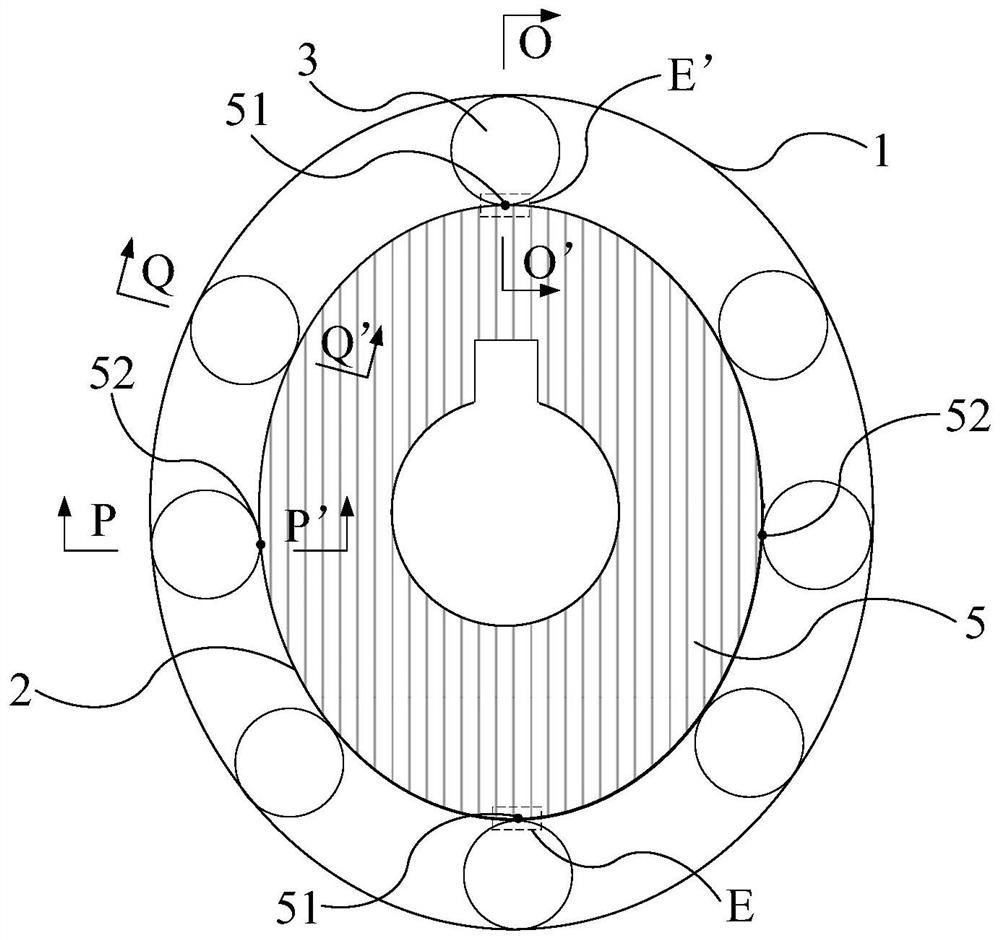

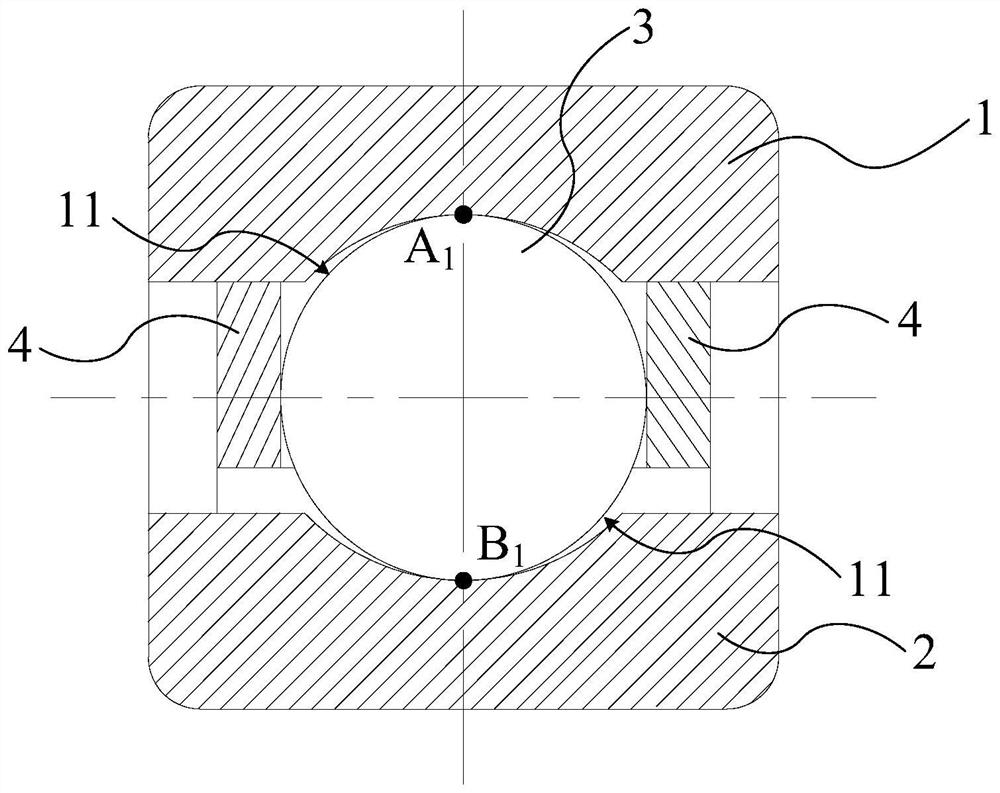

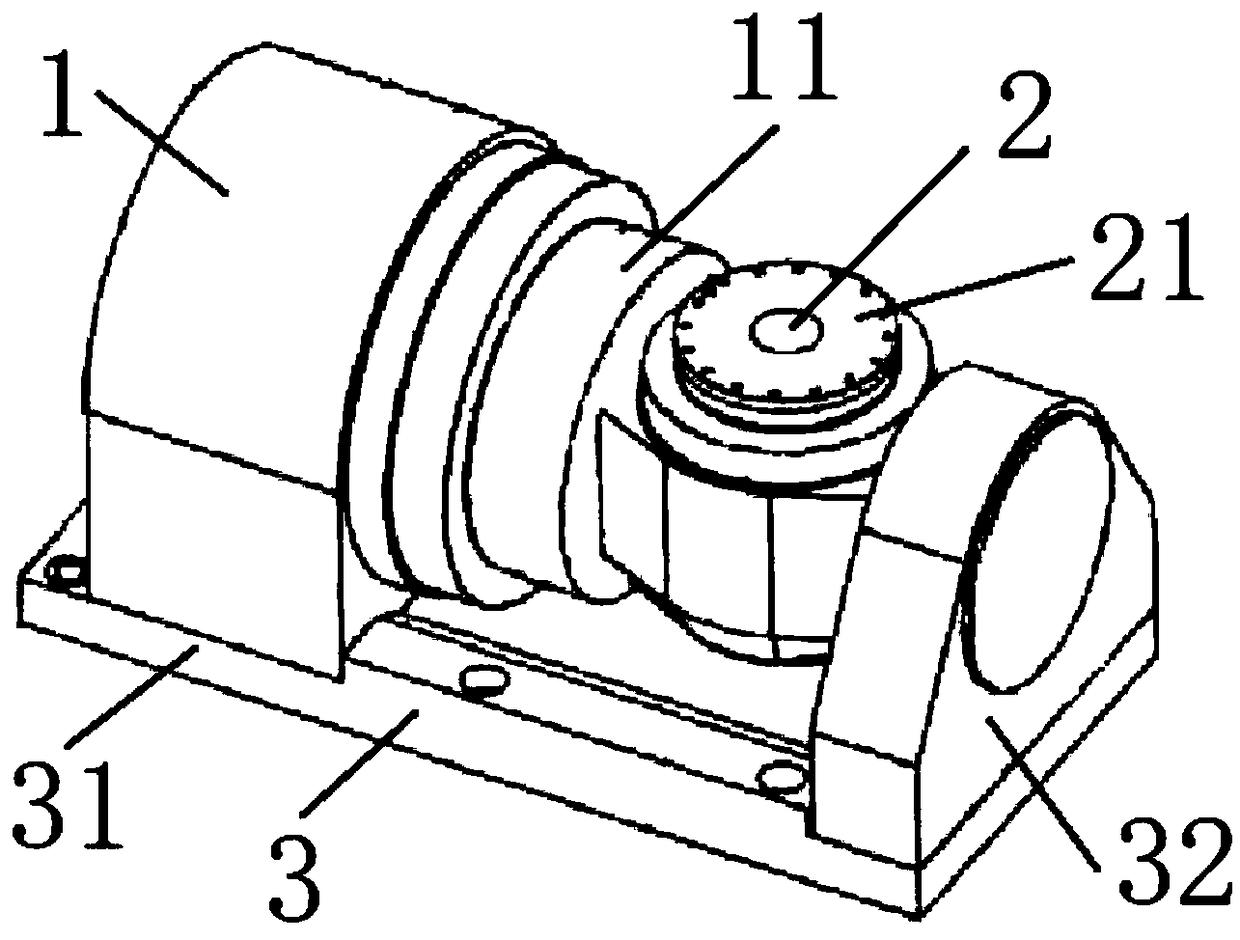

Flexible bearing for harmonic reducer and harmonic reducer

ActiveCN114278668AConvenient bindingExtended service lifeRolling contact bearingsGearingReduction driveEngineering

The invention provides a flexible bearing for a harmonic reducer and the harmonic reducer, the flexible bearing comprises an outer ring (1), an inner ring (2) and a rolling body (3) mounted between the outer ring (1) and the inner ring (2), and the outer ring (1) and the inner ring (2) are both provided with channels for accommodating the rolling body (3); the inner ring (2) is used for being arranged on the outer side of an oval cam (5) in a sleeving mode, and channels, located in the two ends of the oval cam (5) in the long axis direction, of the inner ring (2) and the rolling body (3) form a contact point. And two contact points are formed between the inner ring (2) and the rolling body (3), wherein the inner ring (2) is positioned in channels at other positions of the elliptical cam (5). According to the flexible bearing, the two ends in the long axis direction keep sufficient radial bearing capacity, meanwhile, the restraining capacity of the grooves of the flexible bearing on the balls is good, and the service life is longer.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Double-shaft numerical control rotary table

InactiveCN109494902AImprove reliabilityHigh transmission precisionMagnetic circuit rotating partsMagnetic circuit stationary partsNumerical controlEngineering

The invention discloses a double-shaft numerical control rotary table comprising a tilting shaft, a rotating shaft and a supporting mechanism. On the basis of combination of the cycloidal pin wheel reducer with the double-shaft numerical control rotary table, the transmission rigidity is guaranteed and the transmission precision is improved. The double-shaft numerical control rotary table has highpracticability.

Owner:华南智能机器人创新研究院

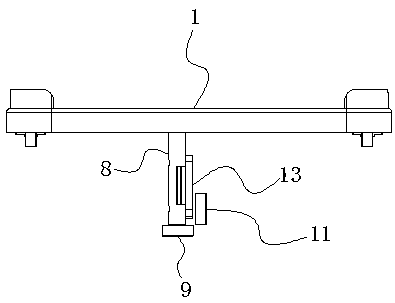

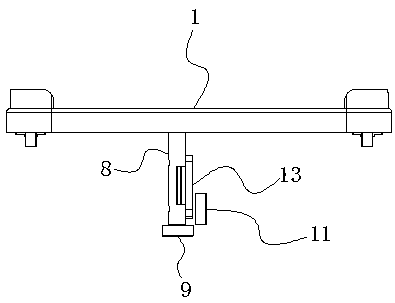

Truss manipulator for stamping carrying and material taking

PendingCN114833266AHigh strengthSimple and fast operationMetal-working feeding devicesPositioning devicesHuman–machine interfaceEngineering

The truss manipulator comprises a Z-axis aluminum alloy box body, a positioning installation connecting base is installed on the Z-axis aluminum alloy box body, a left organ plate is installed at one end of the positioning installation connecting base, and a right organ plate is installed at the other end of the positioning installation connecting base; a first X-axis main cross beam is installed at the rear end of the left organ plate. The truss manipulator for stamping carrying and material taking is special mechanical equipment designed for stamping carrying and material taking, the manipulator is divided into an upper shaft, a lower shaft, a left shaft and a right shaft, the front shaft and the rear shaft are driven by high-precision servo, vacuum negative-pressure adsorption materials are grabbed and can be replaced by electromagnets, advanced PLC control is applied, a touch screen is adopted as a human-computer interface, and the manipulator is high in automation degree. The machine body is bent and welded, the strength is high, the deformation is small, the sliding block is low in noise and good in stability, and the absolute value servo motor is matched with the planetary precision speed reducer, so that the transmission precision is good.

Owner:苏州大得机械科技有限公司

Cycloid planetary transmission gear based on line-plane conjugation

ActiveCN102252058BImprove rigidityGood transmission precisionPortable liftingToothed gearingsGear wheelEngineering

Owner:CHONGQING UNIV

A transmission structure for circularly conveying pallets

ActiveCN107934422BEasy to move around cornersIncreased load-bearing capacityMechanical conveyorsElectrical and Electronics engineering

Owner:LILING LVYUAN COMML & TRADING CO LTD

Transmission with adjustable transmission pitch

The invention discloses a transmission device capable of regulating the transmission distance, which comprises a section of driving cylinder shaft, at least one section of driving special-shaped shaft, a retainer and second transmission shafts; the driving cylinder shaft is connected with a power source by a power input mechanism; a first stepped shaft is sleeved on the driving special-shaped shaft, and the stepped shaft is connected with a load by a transmission mechanism; at least one of the second transmission shafts is connected with the driving special-shaped shaft by the transmission mechanism; the retainer is connected with the first stepped shaft and the second transmission shafts, so that the axis movement of the first stepped shaft is carried out along the driving special-shaped shaft along with the movement of the second transmission shafts; and the relative distance between the second transmission shafts and the power input mechanism is changed by changing the relative position of the first stepped shaft sleeved on the driving special-shaped shaft.

Owner:东台世恒机械科技有限公司

Built-in outer rotor motor direct drive lawn mower drive wheel and lawn mower

ActiveCN104079113BIncrease the moment of inertiaImprove stabilityLawn-mowersMotor depositionDrive wheelEngineering

The present invention provides a direct-drive lawnmower drive wheel and a lawnmower with an embedded external rotor motor, including a wheel side cover I, a wheel side cover II and a wheel sandwiched between the wheel side cover I and the wheel side cover II. The main body of the driving wheel assembled by the wheel body, the wheel side cover I, the wheel side cover II and the wheel body form a cavity, the outer rotor motor is installed in the cavity, and the outer rotor part of the outer rotor motor Relative to the main body of the driving wheel, the inner stator part of the outer rotor motor has a fixed shaft extending out of the main body of the driving wheel through the wheel side cover I. Shaft hole I. The invention installs the outer rotor motor inside the drive wheel, and directly drives the drive wheel of the lawnmower through the outer rotor motor, which has good transmission accuracy and reliability, and can make the inner space of the lawnmower more reasonable.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com