Cycloid planetary transmission gear based on line-plane conjugation

A technology of planetary transmission and cycloidal pinwheel, which is applied in transmission devices, gear transmission devices, belts/chains/gears, etc., can solve the problem of arc gear bearing capacity and transmission accuracy that cannot be used in precision transmission fields, shorten life, and generate heat and power loss issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

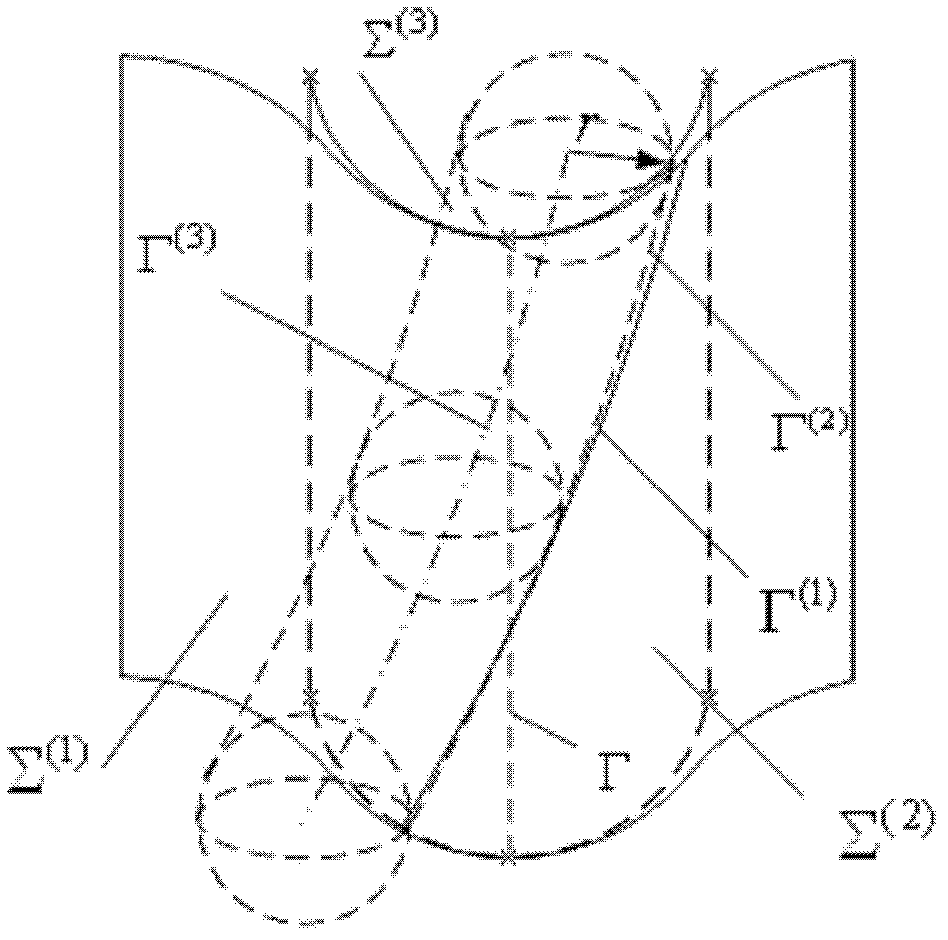

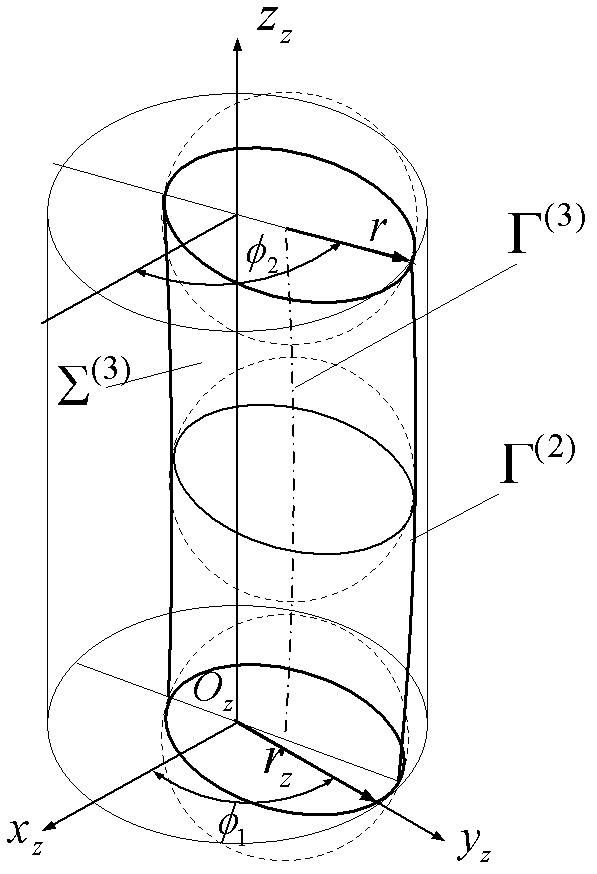

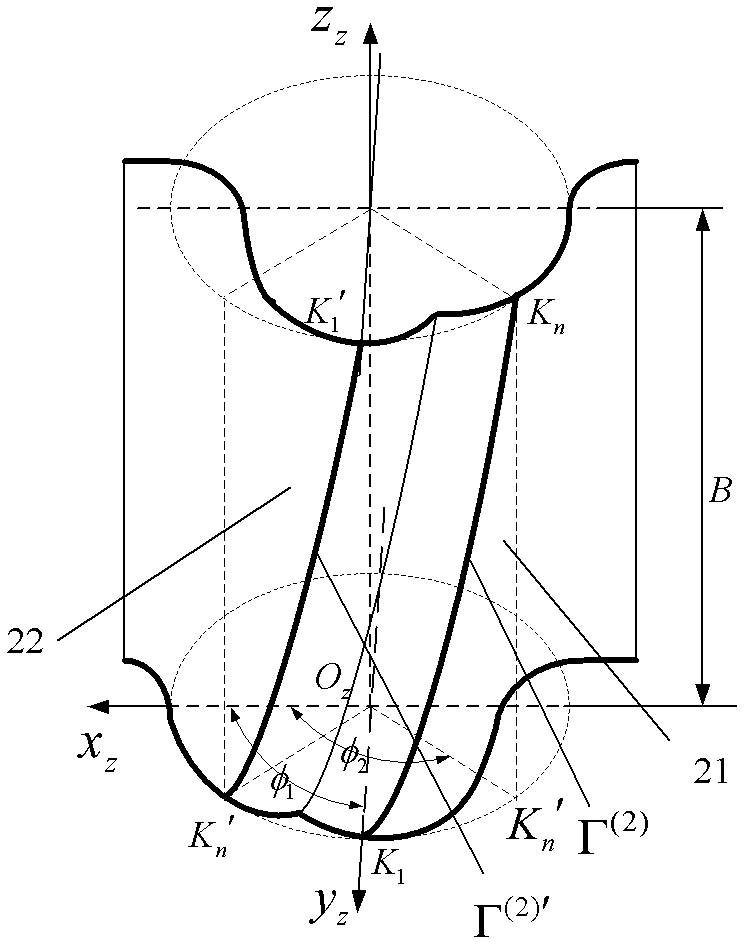

[0033] figure 1 It is a schematic diagram of line-plane conjugate cycloidal planetary transmission according to an embodiment of the present invention, figure 2 It is a schematic diagram of a cycloidal pin-tooth meshing tube according to an embodiment of the present invention; as shown in the figure: a cycloidal planetary transmission gear based on line-plane conjugation, including a cycloidal pinwheel planetary transmission meshing pair, is characterized in that: the cycloidal pinwheel The tooth profile of one gear in the meshing pair of planetary transmission remains unchanged, and the tooth surface of the other gear is a tubular meshing surface. The tubular meshing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com