Laser cutting machine

A laser cutting machine, laser technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of lack of rigidity of steel plates, inconvenience to cut steel plates separately, and inability to easily replace stencils, etc., to meet the requirements of cutting Operation, the effect of good transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

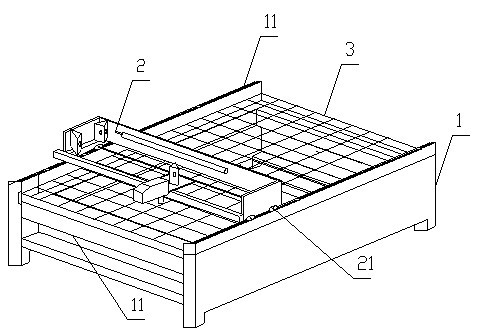

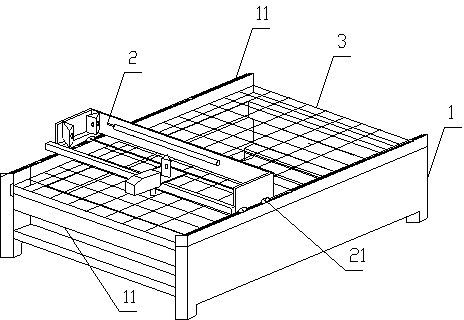

[0012] The laser cutting machine includes a frame 1, a laser horizontal frame 2 and a cutting screen 3, and the cutting screen 3 is slidably arranged on the frame 1 through slide rails arranged on the frame. The cutting screen 3 is a steel plate cutting screen or a cloth cutting screen. Wherein, support points (not shown in the figure) are provided at the grid nodes of the steel plate cutting stencil. Both sides of the frame 1 are provided with transmission racks 11, and the laser horizontal frame 2 is provided with a gear 21 meshing with the transmission racks. The middle part of the frame 1 is provided with a plurality of reinforcing rods 12 .

[0013] In the present invention, the cutting screen is slidably arranged on the frame, which is convenient for its extraction and replacement, thus meeting the different needs of cutting steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com