Oil pipe column cutting device with pressure balancer

A technology of cutting device and balancer, which is applied in wellbore/well components, earth-moving drilling, etc., can solve problems such as poor cutting effect, and achieve the effect of avoiding falling into the well, eliminating adverse effects and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

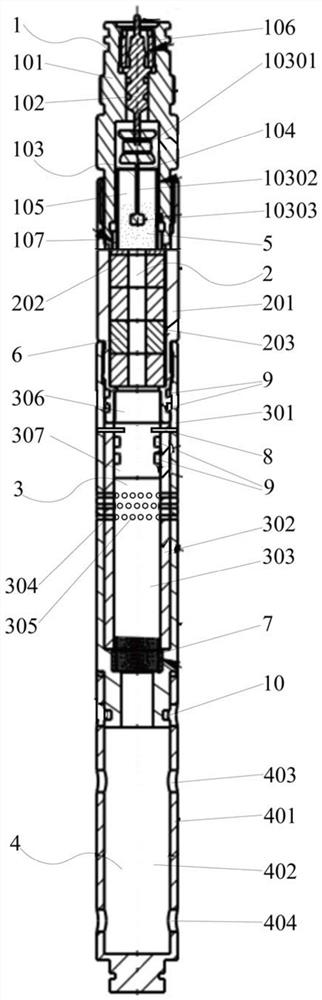

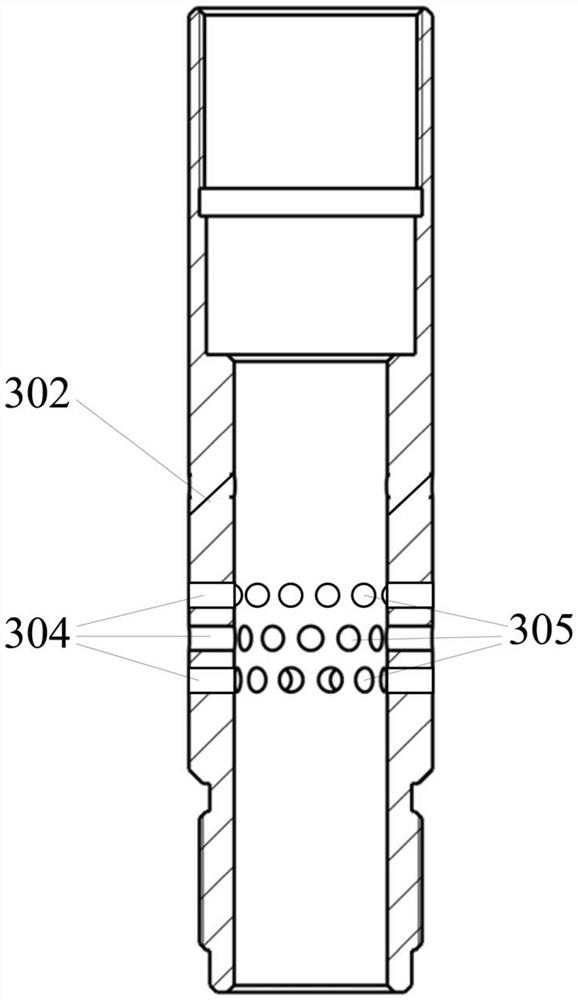

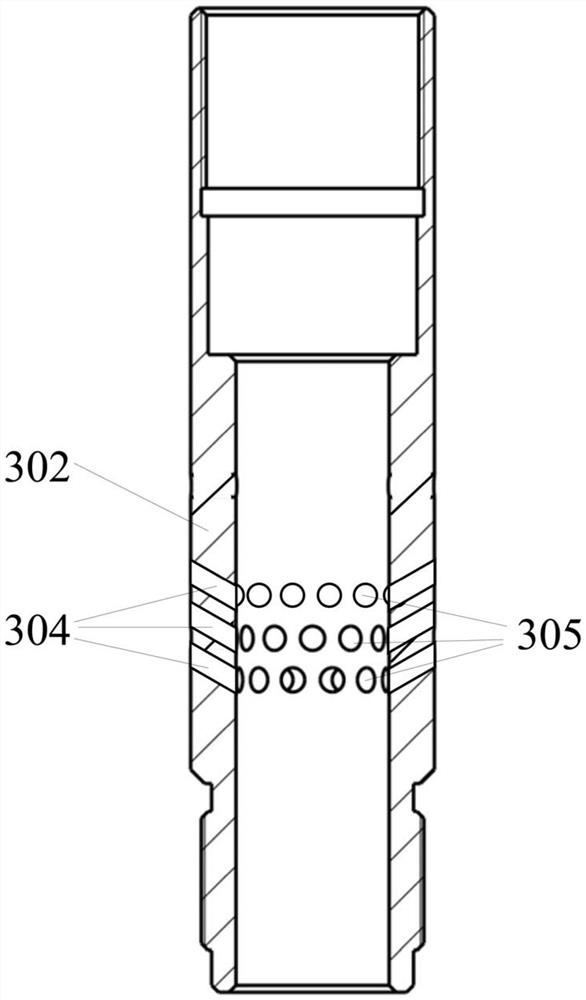

[0042] This embodiment provides a tubing string cutting device with a pressure balancer, such as Figure 1 to Figure 5 As shown, it includes an ignition joint 1, a power output part 2, a cutting part 3 and a pressure balancer 4 connected in sequence from top to bottom;

[0043] The ignition connector 1 includes an ignition connector housing 101 with open top and bottom ends, a sealed conductive pin 102 is installed in the top of the ignition connector housing 101, and the top of the sealed conductive pin 102 protrudes from the top of the ignition connector housing 101. The bottom end of the sealed conductive pin 102 is connected with a high-current ignition assembly 103; an ignition powder chamber housing 104 is arranged in the bottom of the ignition joint housing 101, and the space in the ignition powder chamber housing 104 is an ignition powder chamber 105, and the ignition powder chamber 105 is filled with igniting powder 5; the top of the high-current ignition assembly 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com