U-shaped pipe type rope saw cutting machine

A cutting machine and wire saw technology, which is applied in the field of U-shaped pipe wire saw cutting machine, can solve the problems such as the inability to complete the internal bottom surface cutting of the object to be cut, and achieve the effect of good cutting effect, smooth incision, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

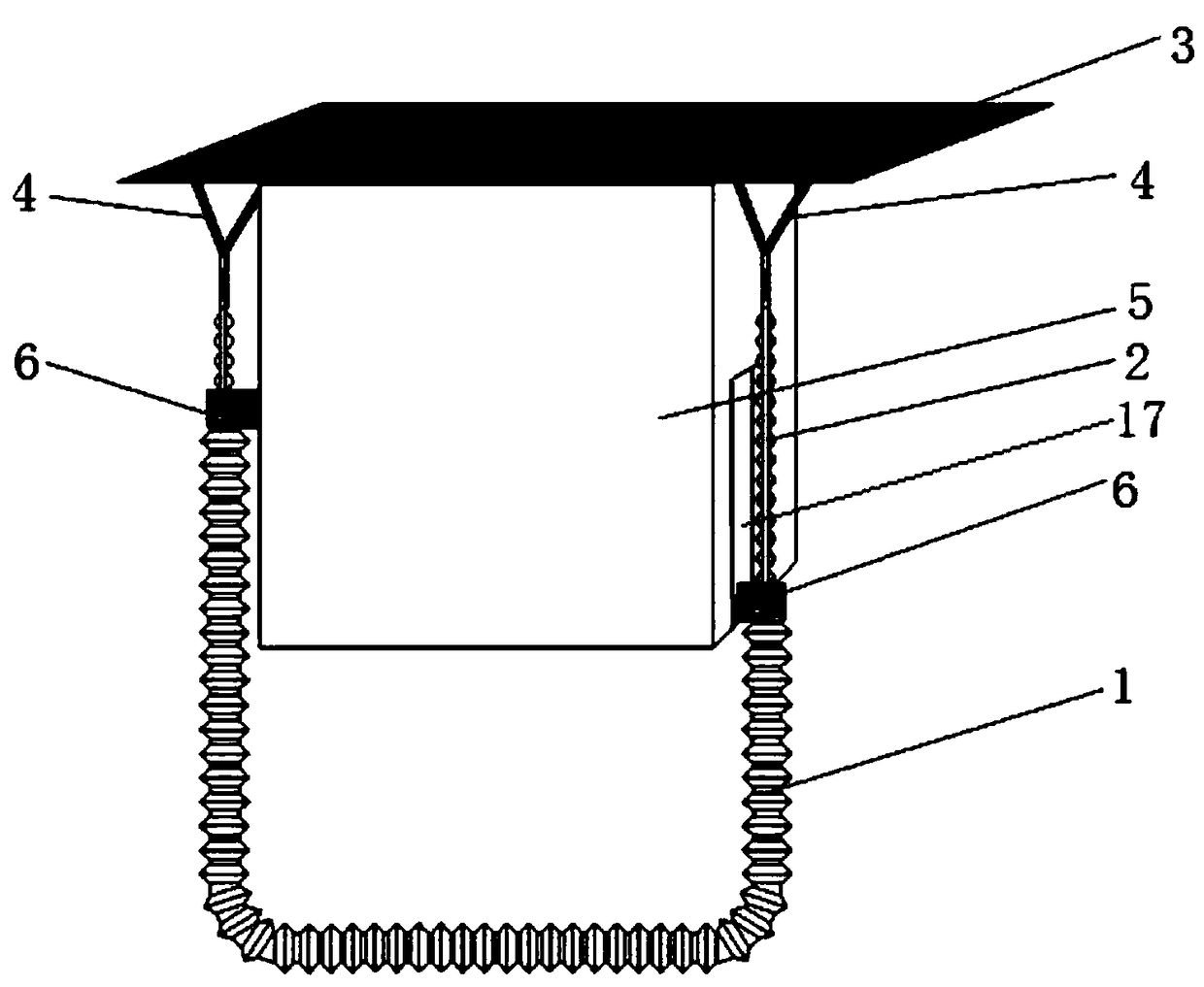

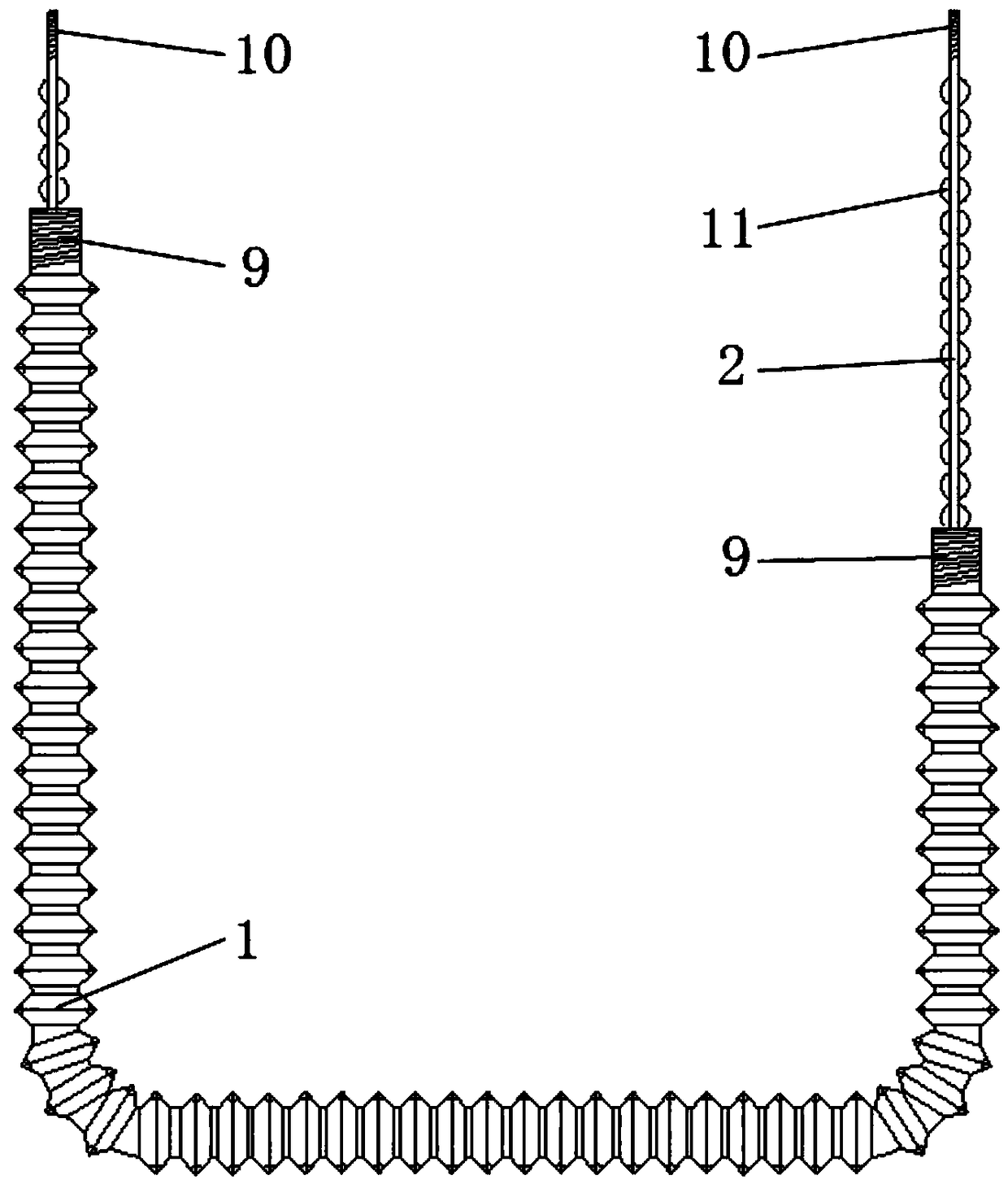

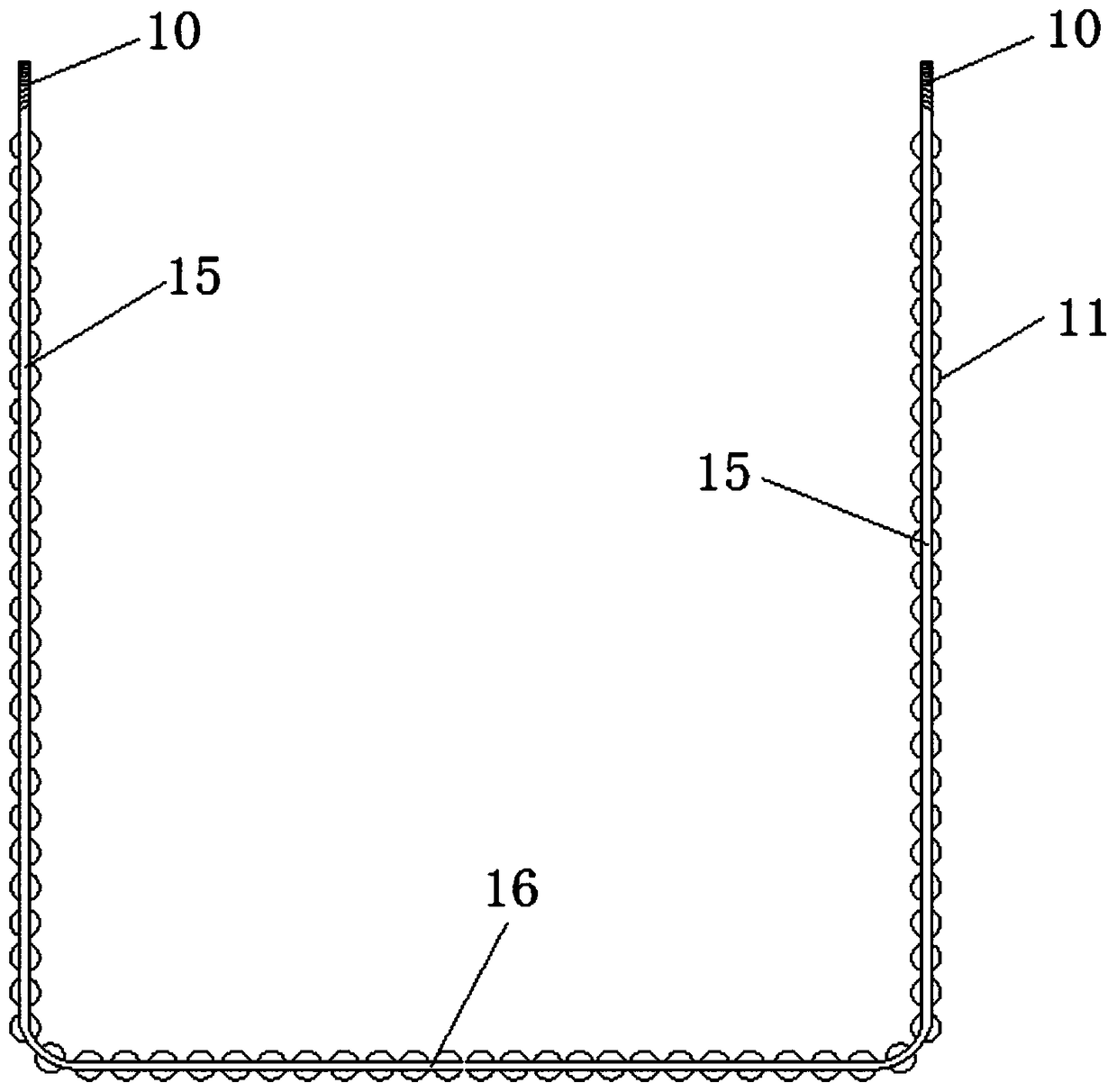

[0029] Such as figure 1 , 2 As shown in and 4, a U-shaped pipe type wire saw 1 cutting machine includes a wire saw combination device and a fixing and motor combination device. The saw 1 is set on the U-shaped roller-sliding fixed rod 2, and can slide freely along the U-shaped roller-sliding fixed rod 2. The pipe-type wire saw 1 can also be conveniently inserted or pulled out from a section of the U-shaped roller-sliding fixed rod 2, and the motor is fixed. The combined device includes a fixed plate 3, a fixed bracket 4 and a double-head reciprocating motor 5. There are two fixed brackets 4, which are respectively installed at both ends of the fixed plate 3. The distance between the two fixed brackets 4 is 210mm, and the double-head reciprocating motor The motor 5 is fixed on the lower surface of the fixed plate 3, the two ends of the U-shaped roller skating fixed rod 2 are respectively connected with the fixed bracket 4 at the corresponding position, and the side walls of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com