Truss manipulator for stamping carrying and material taking

A technology of manipulators and trusses, applied in the field of truss manipulators, can solve problems such as poor stability, easy deformation, long travel time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

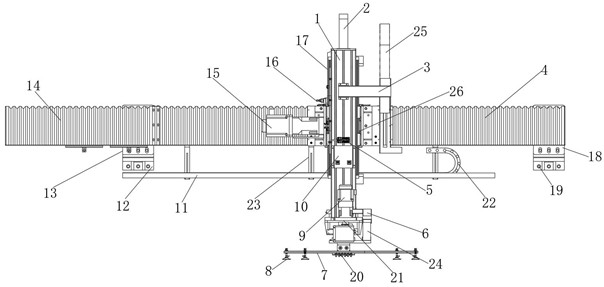

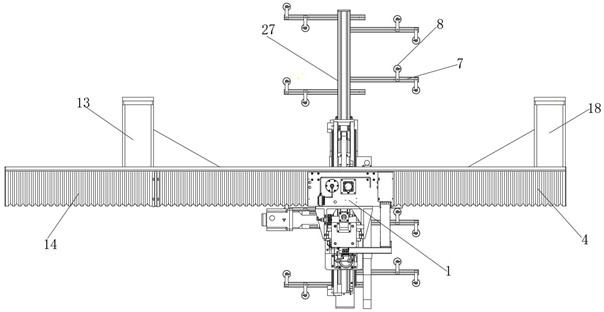

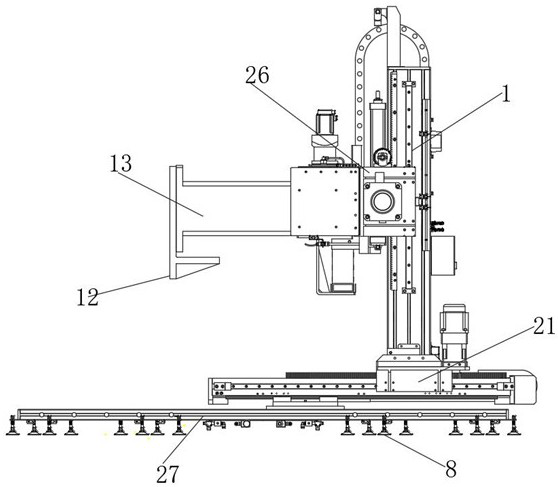

[0026] like Figure 1-4 As shown, a truss manipulator for punching, handling and reclaiming includes a Z-axis aluminum alloy box body 1, a positioning and mounting connection seat 26 is installed on the Z-axis aluminum alloy box body 1, and one end of the positioning and mounting connection seat 26 is installed with a left organ The plate 14, the other end of the positioning and installation connecting seat 26 is installed with the right organ plate 4, the rear end of the left organ plate 14 is installed with a No. X-axis main beam 13, and the rear end of the No. 1 X-axis main beam 13 is installed with a No. , the rear end of the right organ plate 4 is installed with the No. 2 X-axis main beam 18, the rear end of the No. 2 X-axis main beam 18 is installed with a No. 2 mounting plate 19, and the bottom front end of the Z-axis aluminum alloy box 1 is installed with a Y-axis Motor 9.

[0027] Further, the Z-axis aluminum alloy box 1 and the positioning and installation connectin...

Embodiment 2

[0029] On the basis of Example 1, as Figure 1-4 As shown, a truss manipulator for punching, handling and reclaiming includes a Z-axis aluminum alloy box body 1, a positioning and mounting connection seat 26 is installed on the Z-axis aluminum alloy box body 1, and one end of the positioning and mounting connection seat 26 is installed with a left organ The plate 14, the other end of the positioning and installation connecting seat 26 is installed with the right organ plate 4, the rear end of the left organ plate 14 is installed with a No. X-axis main beam 13, and the rear end of the No. 1 X-axis main beam 13 is installed with a No. , the rear end of the right organ plate 4 is installed with the No. 2 X-axis main beam 18, the rear end of the No. 2 X-axis main beam 18 is installed with a No. 2 mounting plate 19, and the bottom front end of the Z-axis aluminum alloy box 1 is installed with a Y-axis Motor 9.

[0030]Further, a Z-axis balance cylinder 2 is installed on the top po...

Embodiment 3

[0033] On the basis of Embodiment 1 and Embodiment 2, as Figure 1-4 As shown, a truss manipulator for punching, handling and reclaiming includes a Z-axis aluminum alloy box body 1, a positioning and mounting connection seat 26 is installed on the Z-axis aluminum alloy box body 1, and one end of the positioning and mounting connection seat 26 is installed with a left organ The plate 14, the other end of the positioning and installation connecting seat 26 is installed with the right organ plate 4, the rear end of the left organ plate 14 is installed with a No. X-axis main beam 13, and the rear end of the No. 1 X-axis main beam 13 is installed with a No. , the rear end of the right organ plate 4 is installed with the No. 2 X-axis main beam 18, the rear end of the No. 2 X-axis main beam 18 is installed with a No. 2 mounting plate 19, and the bottom front end of the Z-axis aluminum alloy box 1 is installed with a Y-axis Motor 9.

[0034] Further, an installation base 21 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com