Transmission method and transmission structure for circulating conveying trays

A transmission structure and cyclic conveying technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low transmission precision, complex transmission structure and high cost of construction, and achieve high transmission precision, simple transmission structure, Good load-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

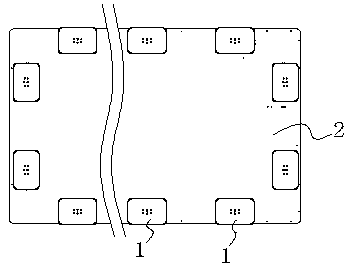

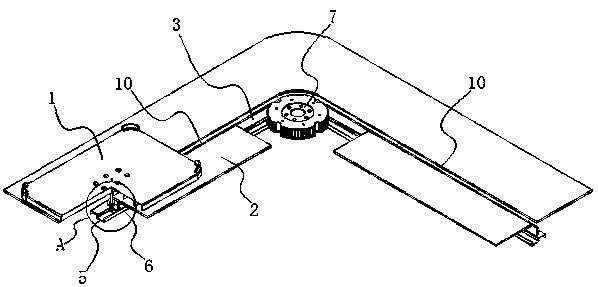

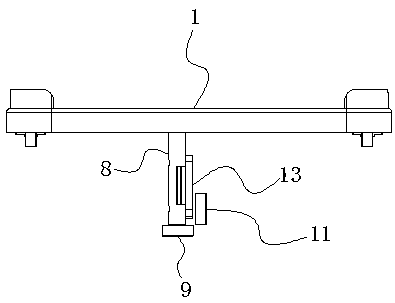

[0032]Embodiment 1: as figure 2 and Figure 5 As shown, a transmission method for circularly conveying pallets is to connect multiple pallets 1 with the timing belt 3 of the synchronous belt transmission mechanism. Driven by the synchronous belt transmission mechanism, multiple pallets 1 can move along the Circular rotation, a plurality of support wheels 4 are arranged on the bottom of each tray 1, and the plurality of support wheels 4 are in contact with the working platform 2 to carry out load bearing on the tray 1 and the distribution box frame placed on the tray 1; A guide rail mechanism 5 is set on the working platform 2, and a guide wheel mechanism 6 is arranged on the bottom of each tray 1, and the precise transmission of the tray 1 is realized through the contact and cooperation between the guide rail mechanism 5 and the guide wheel mechanism 6. This embodiment utilizes a plurality of supporting wheels to roll and support on the working platform for load-bearing duri...

Embodiment 2

[0039] Embodiment 2: as Figure 8 and Figure 9 As shown, compared with Embodiment 1, the difference is that a plurality of support wheels 4 in this embodiment are in contact with the top of the work platform 1, the guide rail mechanism 5 is arranged on the top of the work platform 1, and the guide wheel mechanism 6 Cooperate with the guide rail mechanism 5 on the top of the working platform.

[0040] The guide rail mechanism is 5 convex lines arranged on the working platform, and the convex lines include convex line 1 to convex line 4 (only convex line 1 513 and convex line 2 514 are drawn in the figure), and convex line 1 to convex line 4 are in the form of The rectangular shape is distributed on the working platform 2 and the ends of the adjacent two raised strips are disconnected (that is, at the four corners of the working platform, the two raised strips are disconnected instead of continuous); the guide wheel mechanism 6 includes a horizontal guide wheel 15 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com