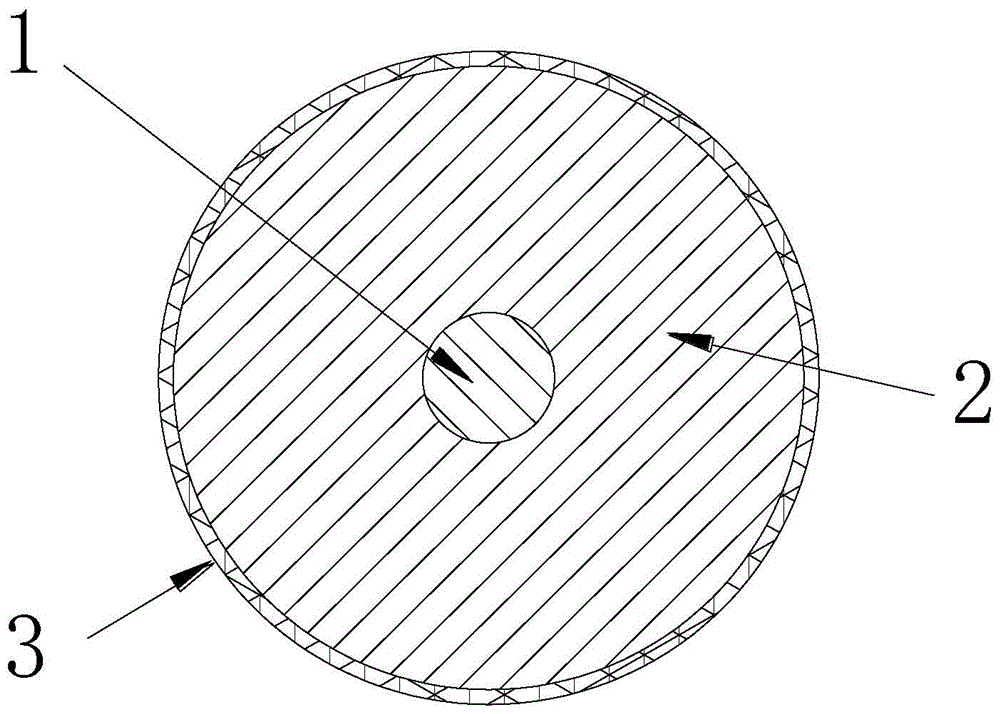

A fiber reinforced composite cable core

A composite material, fiber reinforced technology, applied in the field of electric power, can solve the problems of no signal transmission function, difficult dipping of the core, etc., and achieve the effects of excellent wettability, good load bearing, and improved anti-splitting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Taking the preparation of a fiber reinforced composite cable core with a tensile strength of more than 2100MPa and a diameter of 7.5mm as an example, the specific examples of manufacturing the present invention are as follows:

[0012] Under the traction of the tractor, 39 bundles of high-strength glass fibers (volume content 45%), 19 bundles of T700 carbon fibers (volume content 20%) and high-strength glass fiber tapes (volume content 1%) are dipped and passed through the inner layer of glass fibers , carbon fiber centered, glass fiber band outermost structural preforming mold, curing mold, post-curing box molding, wherein the volume content of the resin matrix is 34%, and then rolled into a coil.

Embodiment 2

[0014] Taking the preparation of a fiber reinforced composite cable core with a tensile strength of 2400MPa or more and a diameter of 7.5mm as an example, the specific examples of manufacturing the present invention are as follows:

[0015] Under the traction of the tractor, 5 bundles of high-strength glass fibers (volume content 5%), 55 bundles of T700 carbon fibers (volume content 60%) and glass fiber tapes (volume content 1%) are dipped and passed through the glass fiber inner layer, The structure preforming mold with carbon fiber in the center and glass fiber tape on the outermost layer, curing mold, and post-curing box are formed, wherein the volume content of the resin matrix is 34%, and then rolled into a coil.

Embodiment 3

[0017] Taking the preparation of a fiber reinforced composite cable core with a tensile strength of 2400MPa or more and a diameter of 7.5mm as an example, the specific examples of manufacturing the present invention are as follows:

[0018] Under the traction of the tractor, 9 bundles of high-strength glass fibers (volume content 10%), 40 bundles of T700 carbon fibers (volume content 40%) and glass fiber tapes (volume content 10%) are dipped and passed through the glass fiber inner layer, The structure preforming mold with carbon fiber in the center and glass fiber tape on the outermost layer, curing mold, and post-curing box are formed, wherein the volume content of the resin matrix is 40%, and then rolled into a coil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com