Built-in outer rotor motor direct drive lawn mower drive wheel and lawn mower

A technology of outer rotor motor and driving wheel, which is applied in the direction of lawn mowers, electric components, agricultural machinery and implements, etc., and can solve the problems of high speed of inner rotor motor, lower transmission accuracy and reliability, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

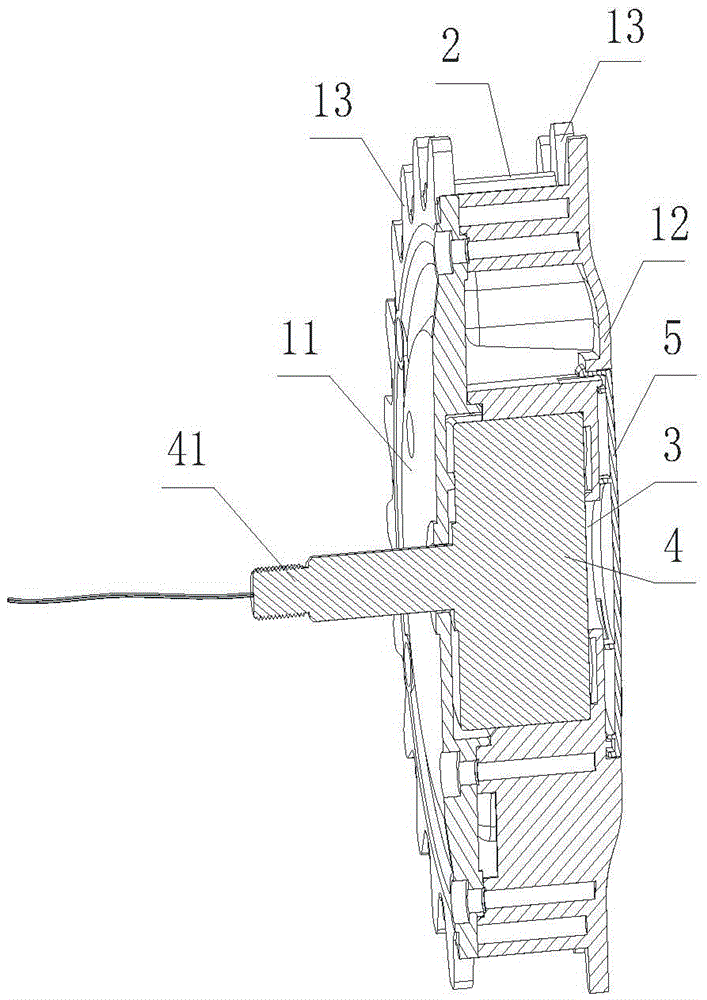

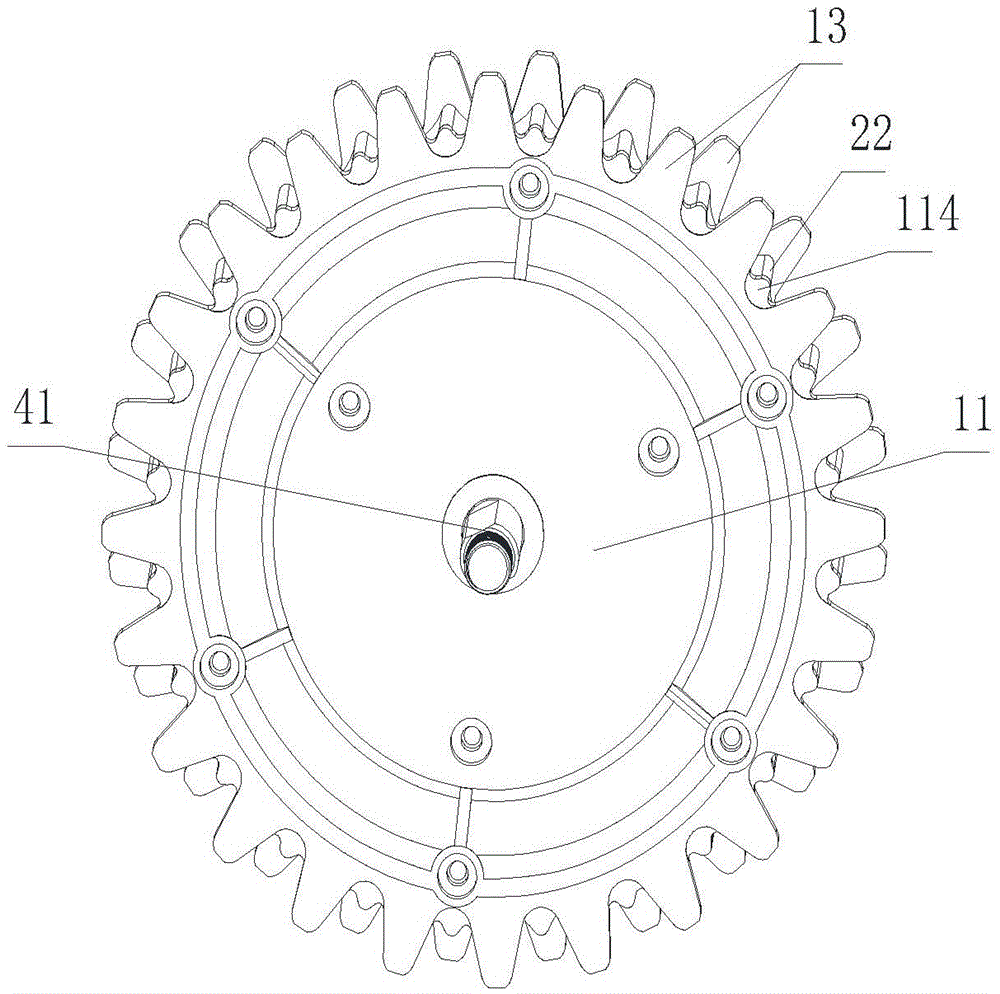

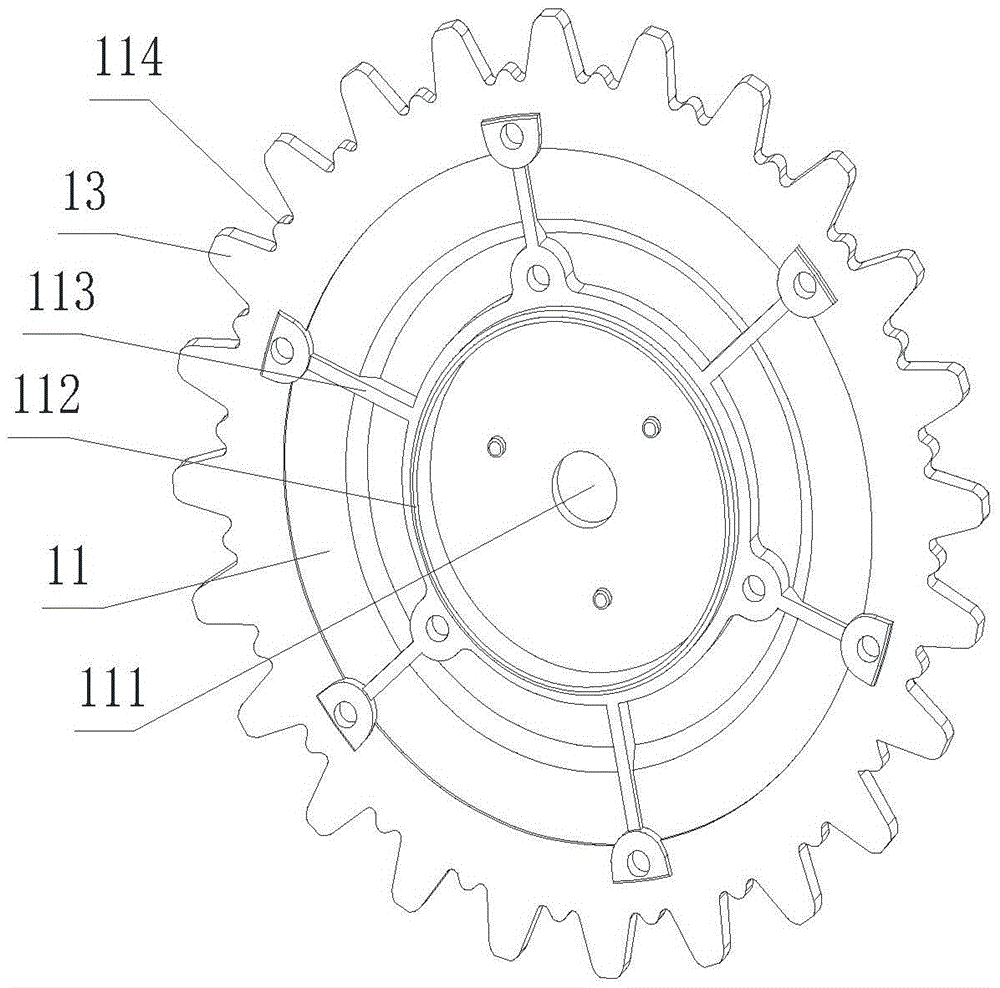

[0023] Such as Figures 1 to 5 As shown, the drive wheel of the built-in external rotor motor direct drive lawn mower is composed of the wheel side cover I11, the wheel side cover II12 and the wheel body 2 sandwiched between the wheel side cover I11 and the wheel side cover II12. The main body of the driving wheel, the wheel side cover II12 and the wheel body 2 are integrally formed. The wheel side cover I11, the wheel side cover II12 and the wheel body 2 form a cavity 3, and the outer rotor motor 4 is installed in the cavity 3. The outer rotor part of the outer rotor motor 4 is fixedly arranged relative to the main body of the driving wheel, and the stator part of the outer rotor motor 4 has a fixing part 41 protruding from the wheel side cover I11 to the outside of the driving wheel main body, and the fixing part 41 is a tubular or hollow cylinder Shaped structure, the hollow part is used to lead out the connecting wires of the outer rotor motor 4, and the wheel side cover I...

Embodiment 2

[0025] Such as Figure 6 As shown, the lawn mower includes a body 6, two universal wheels 8 are installed in front of the bottom of the body 6, and two driving wheels 9 are installed on both sides of the rear, wherein the driving wheels 9 are the embedded outer rotors in the first embodiment The motor directly drives the drive wheel of the lawn mower, wherein the fixing member 41 is fixedly connected to the body 6, and the body 6 has a control system electrically connected to the outer rotor motor; A cutterhead 72 is installed on the cutterhead 72, and a blade 73 is installed on the cutterhead 72. A plurality of guard columns 74 are arranged on the cutterhead frame 71. There is a distance between adjacent two guard columns 74. The cutterhead 72 and the blade 73 surround the guard column. In the middle of 74, the bottom surface of the body 6 is provided with some elongated ribs 61 around the cutter head frame 71. The extension direction of the ribs 61 is consistent with the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com