Portable aircraft skin drilling device

A technology for aircraft skin and drilling device, which is applied in portable drilling rigs, feeding devices, boring/drilling and other directions, can solve the problems that the assembly method cannot meet the requirements, the absolute positioning accuracy is low, the volume and weight are large, and the weight is reached. Light, compact and small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

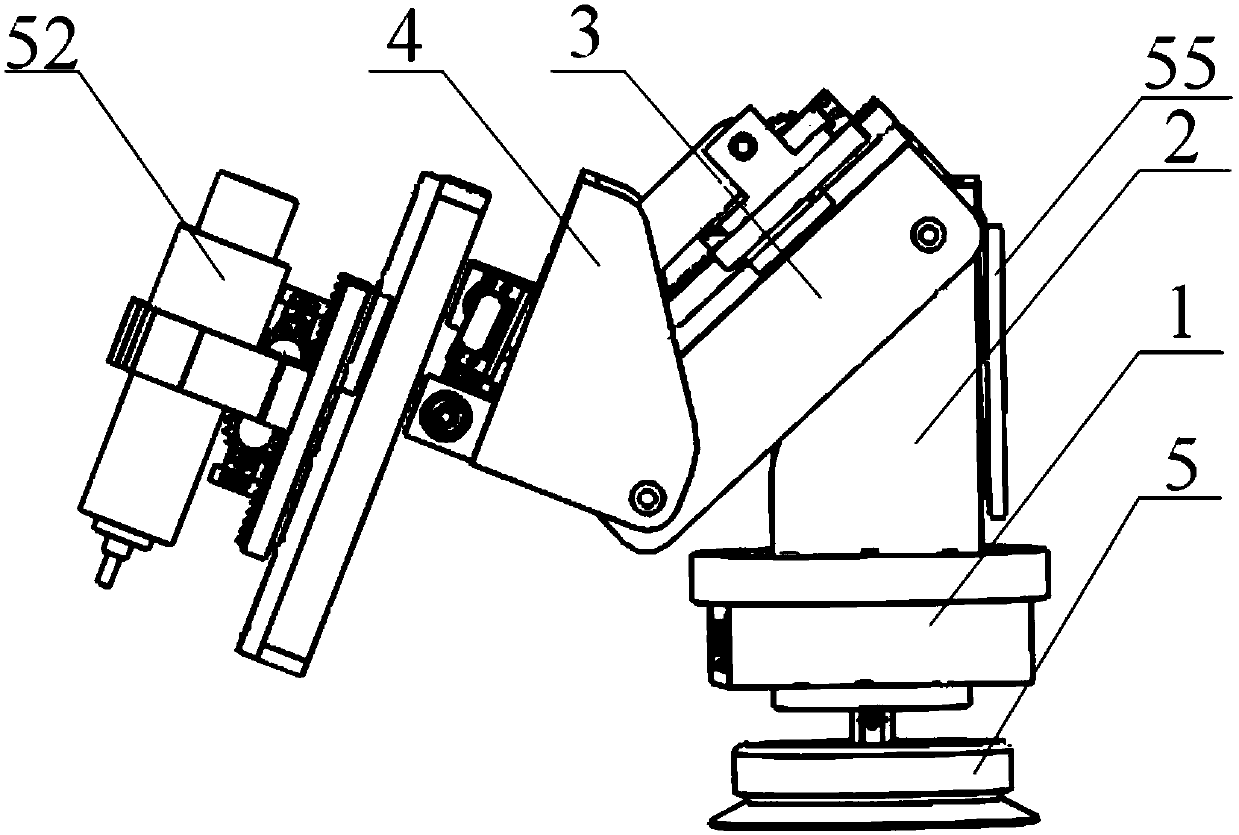

[0078] Such as figure 1 Shown: the present embodiment provides a kind of portable aircraft skin drilling device, and this device comprises:

[0079] Base 1, column 2, extension arm 3, rotating arm 4 and drilling mechanism 52;

[0080] The first end of the base 1 is provided with a suction cup 5 for fixing the portable aircraft skin drilling device. the first turntable 12;

[0081] The second end of the column 2 is movably connected with the first end of the extension arm 3; the second end of the extension arm 3 is movably connected with the first end of the rotating arm 4;

[0082] The second end of the rotating arm 4 is provided with a second turntable 41 , and the second turntable 41 is provided with a drilling mechanism, and the drilling mechanism 52 moves linearly on the second turntable 12 .

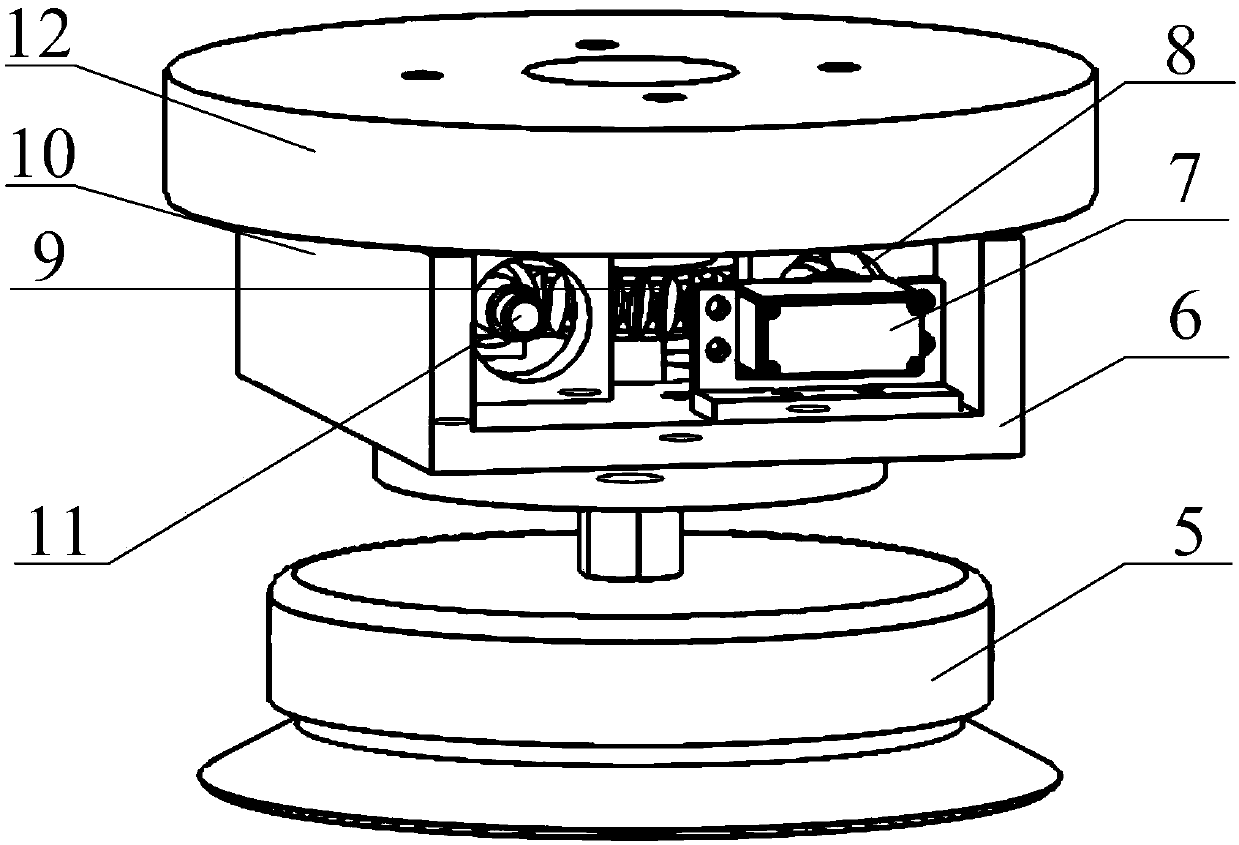

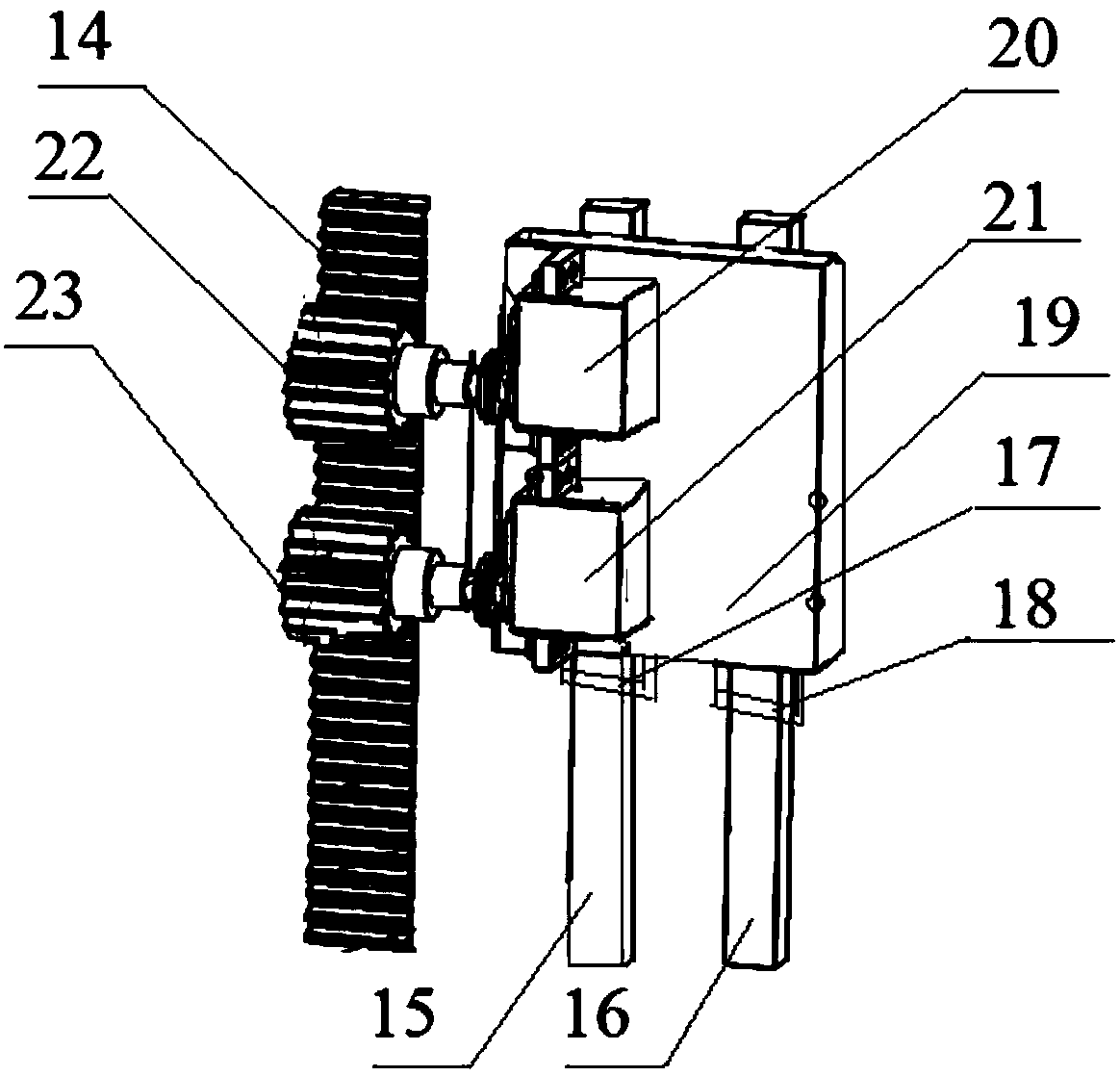

[0083] Optionally, base 1 also includes:

[0084] The first rotating mechanism and the base rotating shaft frame 6;

[0085] Wherein, the first rotating mechanism includes: a w...

Embodiment 2

[0125] In the specific implementation process, the mechanism of the device in this embodiment is as follows: figure 1 shown, refer to Figure 8 As shown, in this embodiment, the connecting flange 55 of the manipulator is fixedly connected to the second side 106 of the vertical column vertical plate perpendicular to the second turntable; the connecting flange 55 of the manipulator is connected to the manipulator;

[0126] For example, the manipulator can be a manipulator of any existing robot, which is not limited in this embodiment, and any manipulator that can perform mechanical actions can be the manipulator of this embodiment.

[0127] The working process of this embodiment is specifically as follows:

[0128] When drilling for high and far areas, the device of this embodiment can be connected with the manipulator through the connecting flange 55;

[0129]Before the drilling process, the present invention is first placed on the specified position of the aircraft skin with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com