Electromechanical controller and its control method for arc cam indexing mechanism

An indexing mechanism and electromechanical control technology, applied in the direction of electromechanical devices, DC motor speed/torque control, control systems, etc., can solve problems affecting the indexing and positioning accuracy of actuators, low transmission power, and unsatisfactory effects, etc., to achieve Improved positioning accuracy, reduced vibration, and reduced shock and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

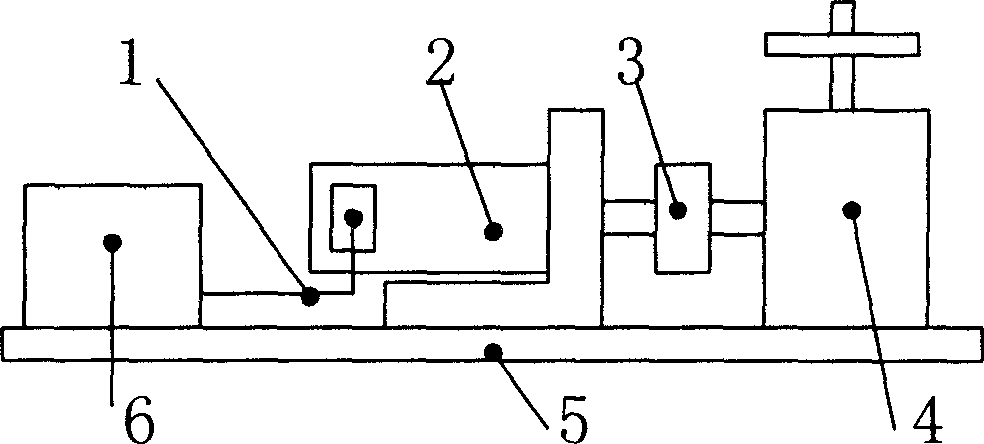

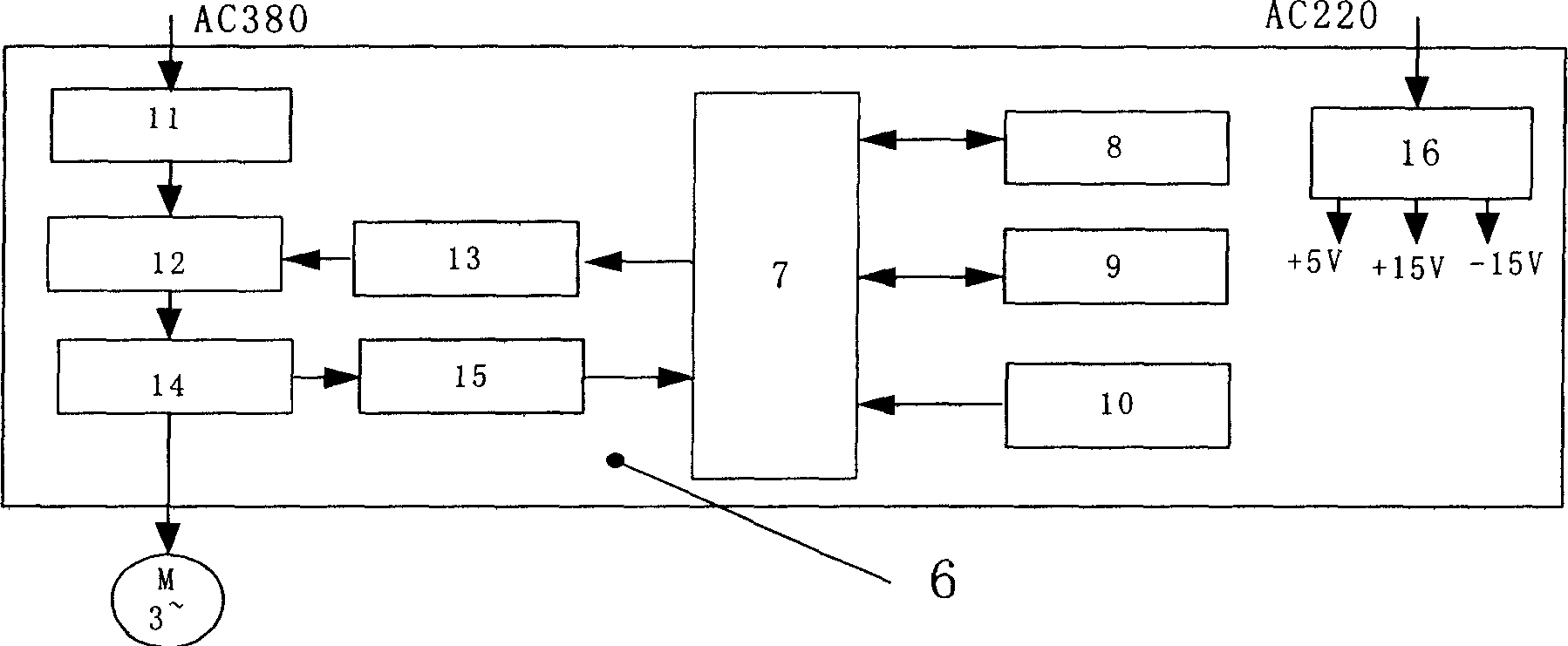

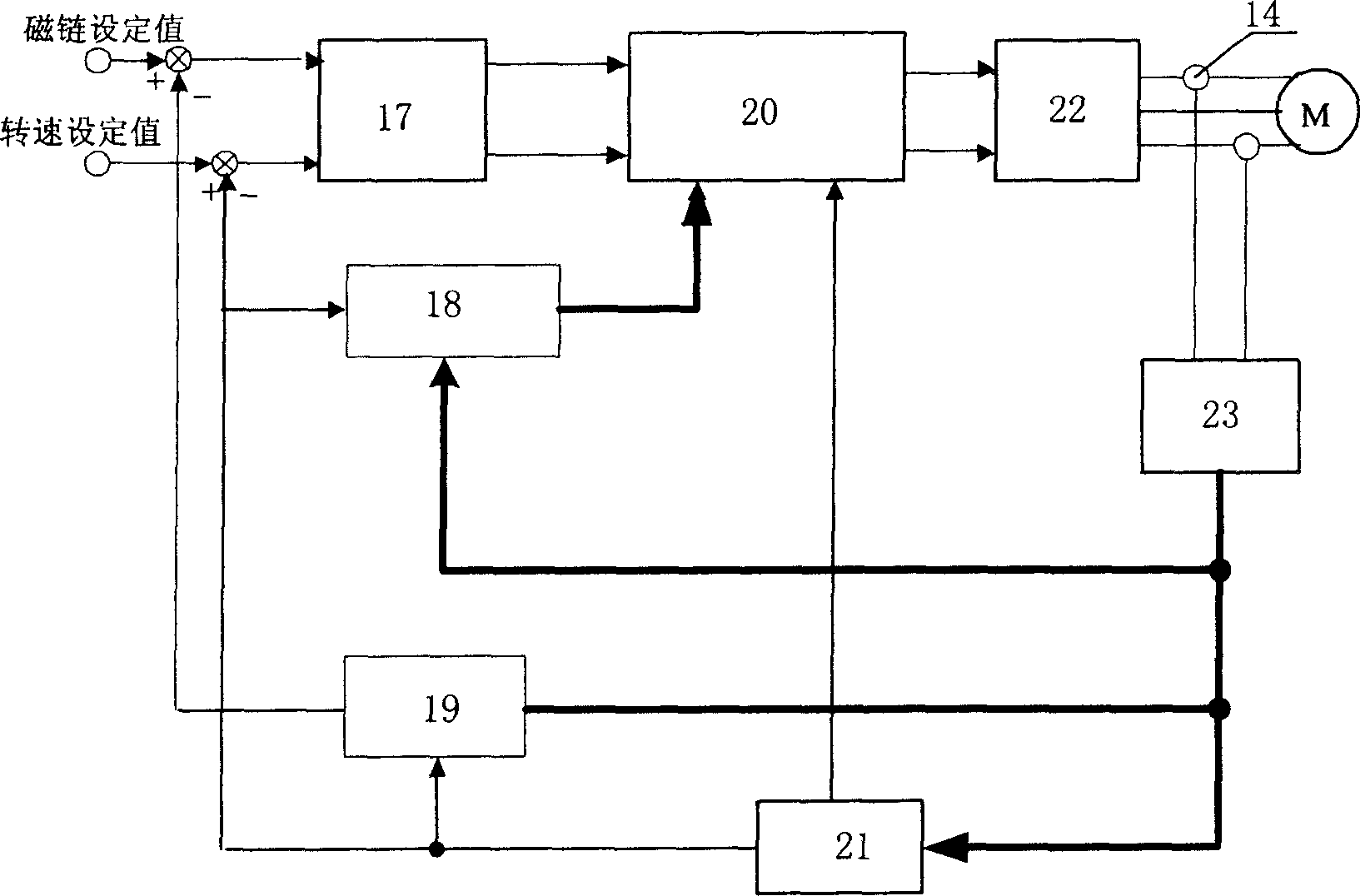

[0032] The structure of the present invention is as figure 1 and figure 2 As shown, the schematic diagram of the nonlinear disturbance compensation controller circuit in the present invention is as follows Figure 4 As shown, the control device includes a motor 2, an arc indexing cam box 4, a coupling 3, a base 5 and a nonlinear disturbance compensation controller 6, the motor 2 and the arc indexing cam box 5 are fixed on the base 5, The motor 2 is connected to the arc indexing cam box 4 through a coupling 3 , and the nonlinear disturbance compensation controller 6 is connected to the arc indexing cam box 4 through a connecting cable 1 .

[0033] The nonlinear disturbance compensation controller 6 is composed of a microprocessor 7, a memory 8, a peripheral interface circuit 9, a reset, a crystal oscillator and other auxiliary circuits 10, a rectifier circuit 11, a power inverter 12, a power drive circuit 13, a current sensor 14 and an electric circuit. Level conversion circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com