Parallel double-input-shaft transmission system and gear-shifting control method thereof

A technology with dual input shafts and control methods, which is applied in the direction of controlling mechanical energy, vehicle gearboxes, collectors, etc., can solve the problems of inconvenient manufacturing and assembly, unreasonable structural design, and short service life of bearings, so as to facilitate manufacturing, processing, and assembly. Reasonable internal space layout, avoiding the effect of wasting electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

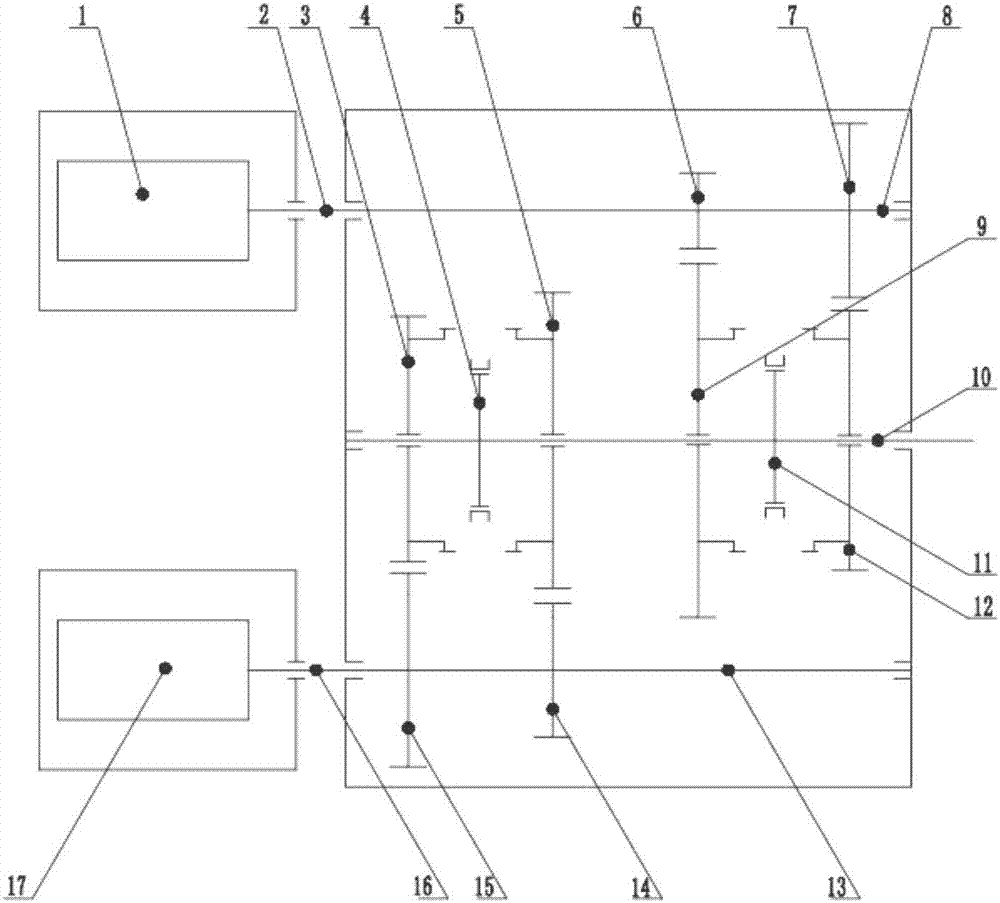

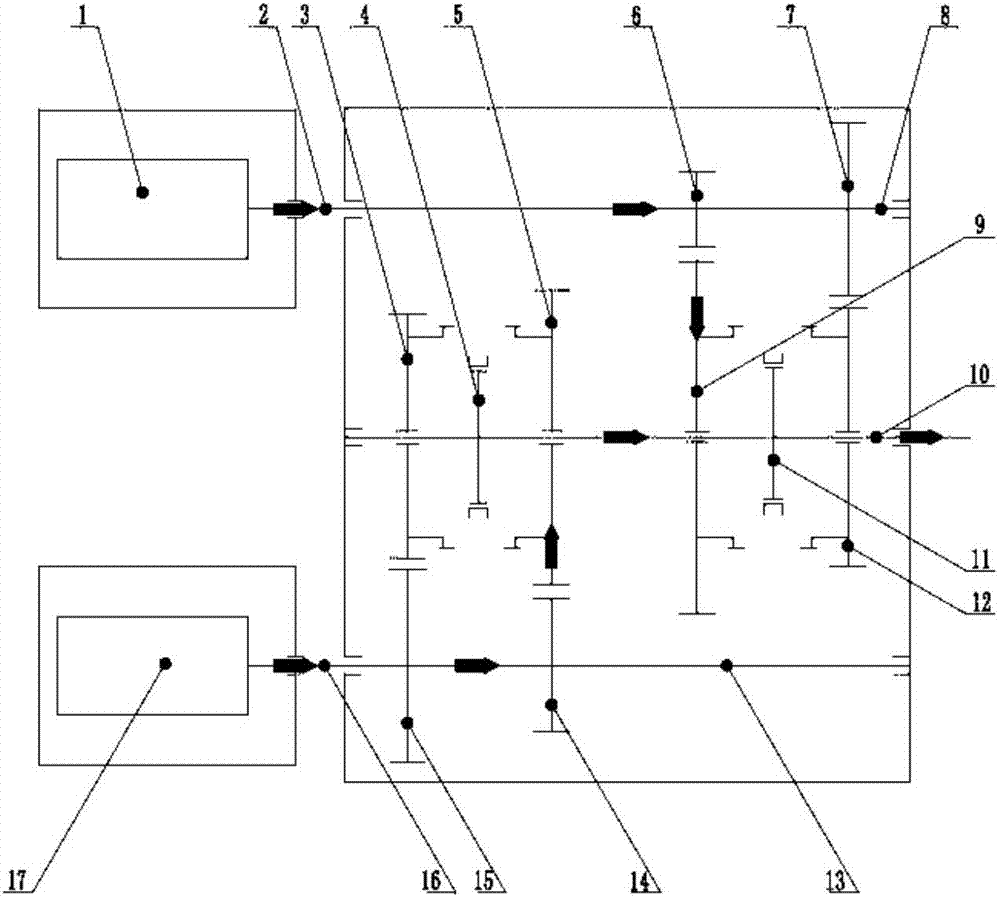

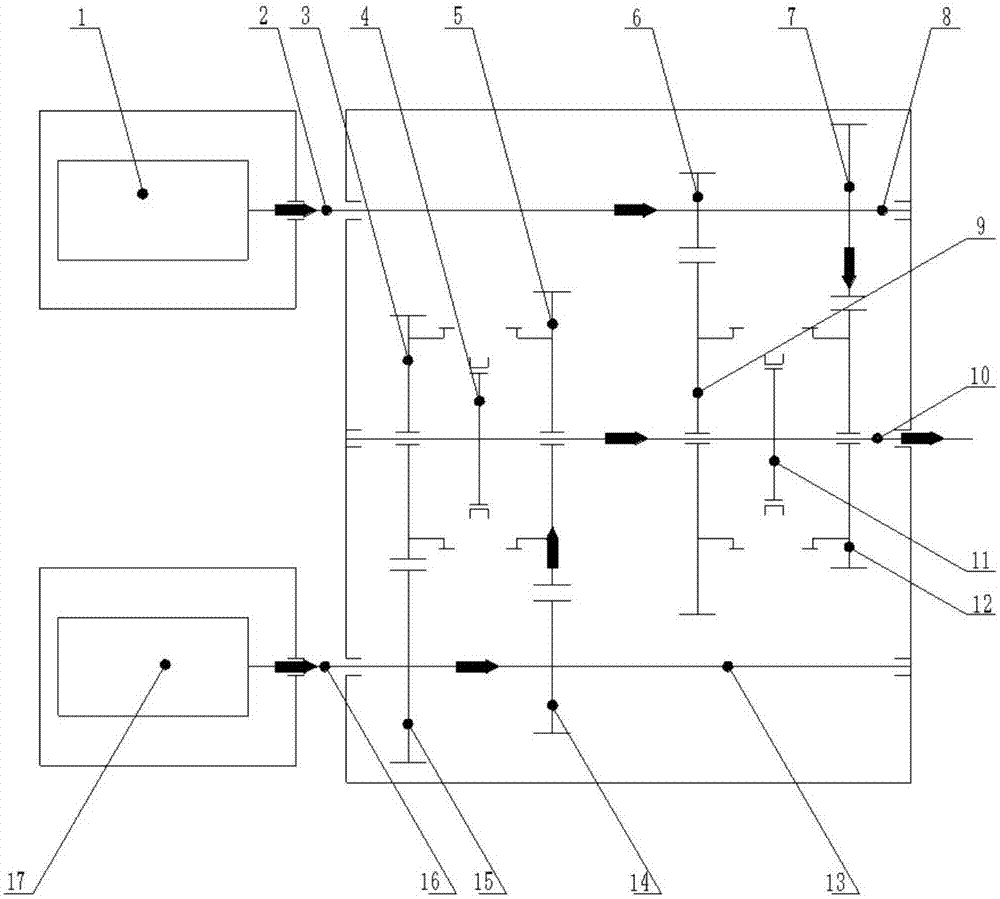

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] Such as figure 1 As shown, a parallel double input shaft transmission system includes: the first gear set consisting of gear I6 and gear III9, the second gear set consisting of gear V5 and gear VII14, and the third gear set consisting of gear II7 and gear IV12 Gear set, a four-speed gear set consisting of gear Ⅵ3 and gear Ⅷ15, transmission input shaft I8, transmission input shaft II13, transmission output shaft 10, sleeve I4, sleeve II11; wherein, the gear I6 and gear II7 are firmly connected On the transmission input shaft I8, the gear III9, the gear IV12, the gear V5 and the gear VI3 are idle sleeves on the transmission output shaft 10, the gear VII14 and the gear VIII15 are fixedly connected to the transmission input shaft II13, and the engagement sleeve I4 It is fixed on the transmission output shaft 10 and arranged between the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com