Windscreen installation driving device

A drive and wiper technology, applied in the drive field, can solve problems such as huge installation space, and achieve the effects of reducing internal friction loss, reducing shaft offset, and large output angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

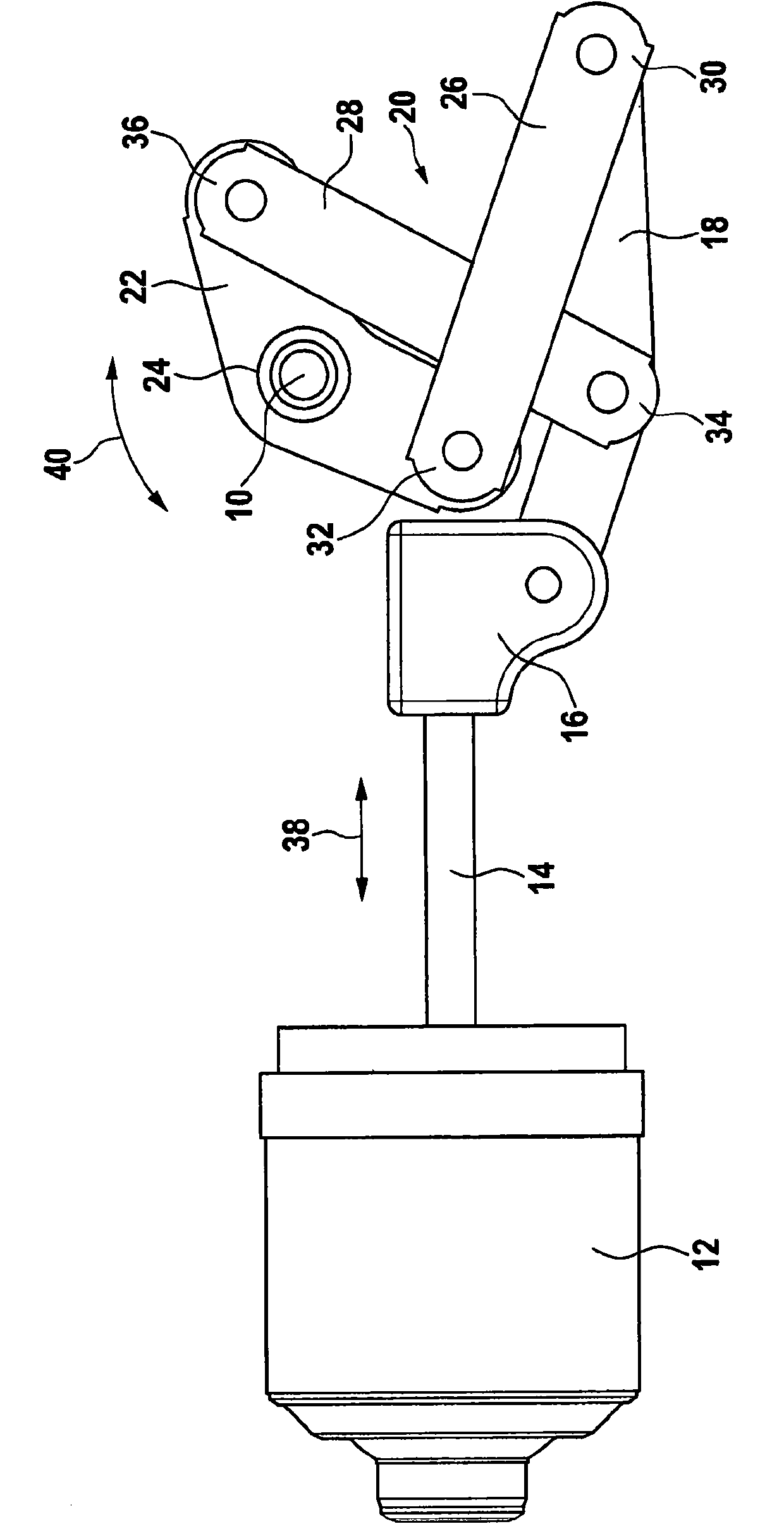

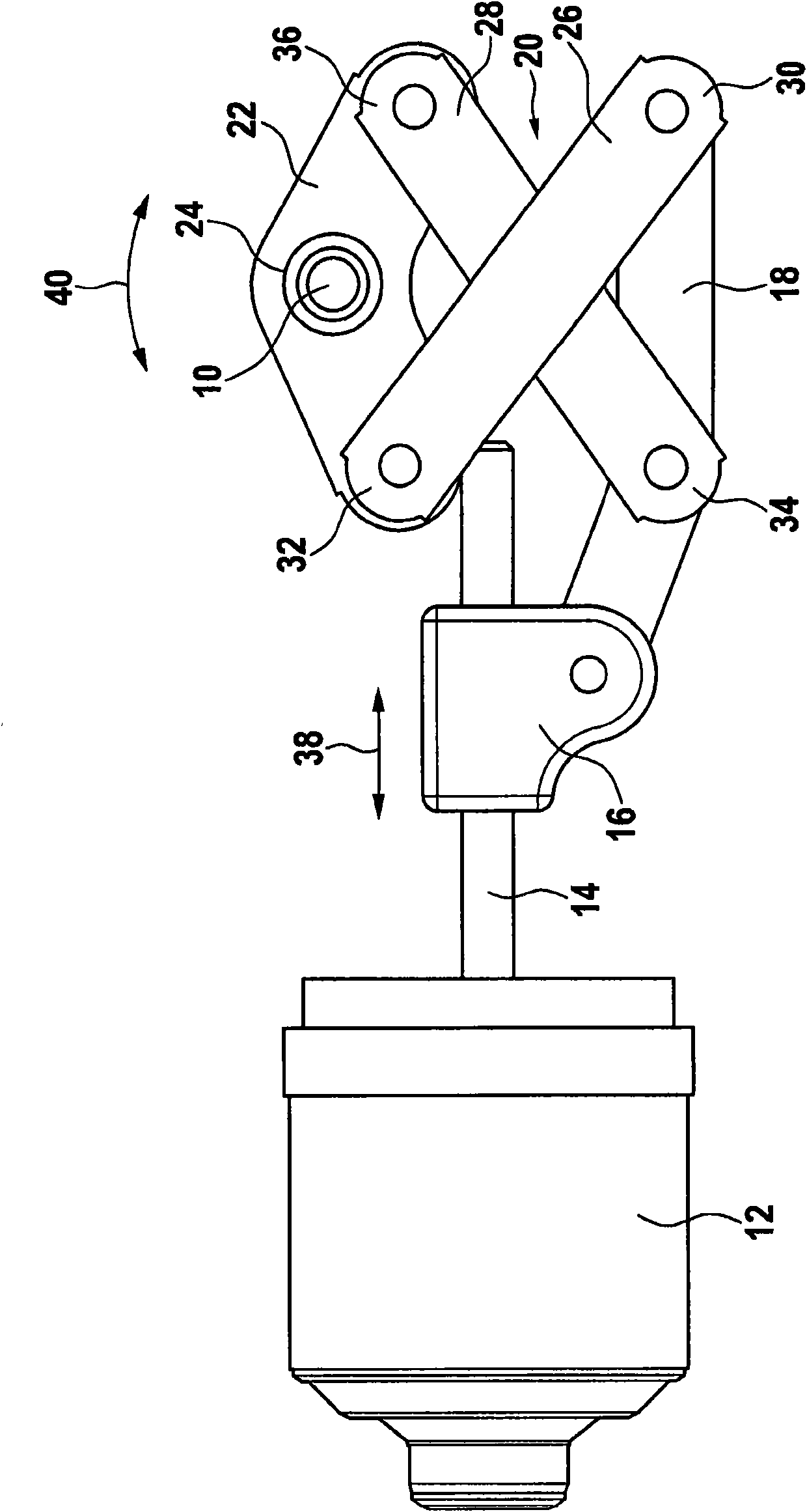

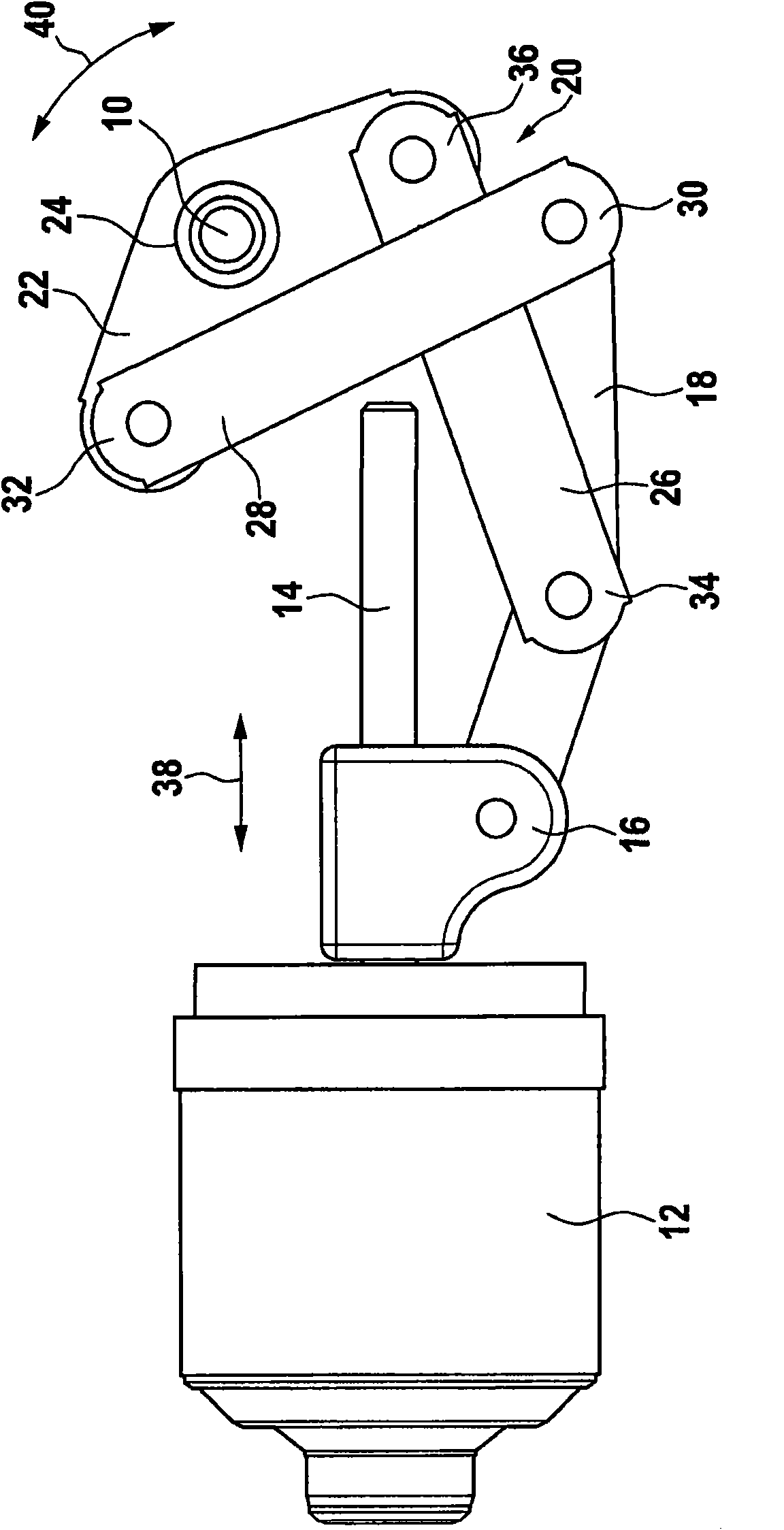

[0026] Figure 1 to 4 The drive for the wiper device according to the invention is shown for moving the output shaft 10. Here, the electric motor 12 is preferably a reversible motor driving a rotatably supported drive shaft 14 which is preferably designed as a screw thread or a worm thread. The drive shaft 14 is connected to the linear movement element 16 in a rotationally fixed manner, so that the rotational movement of the drive shaft 14 can be converted into the linear movement of the linear movement element 16. The linear movement element 16 is connected via a coupling piece 18 arranged on the linear movement element 16 in a fixed position, wherein the coupling piece 18 is articulated with the swing arm 22 via a fork guide 20, wherein the swing arm 22 is connected to the swing arm 22 via a hollow bore 24 The output shaft 10 is connected.

[0027] The fork-shaped guide device 20 has a first fork-shaped guide rod 26 and a second fork-shaped guide rod 28, wherein the first for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com