Variable valve timing device

A valve timing, variable technology, used in valve devices, non-mechanically actuated valves, engine components, etc., to solve problems such as oil leakage and difficult parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

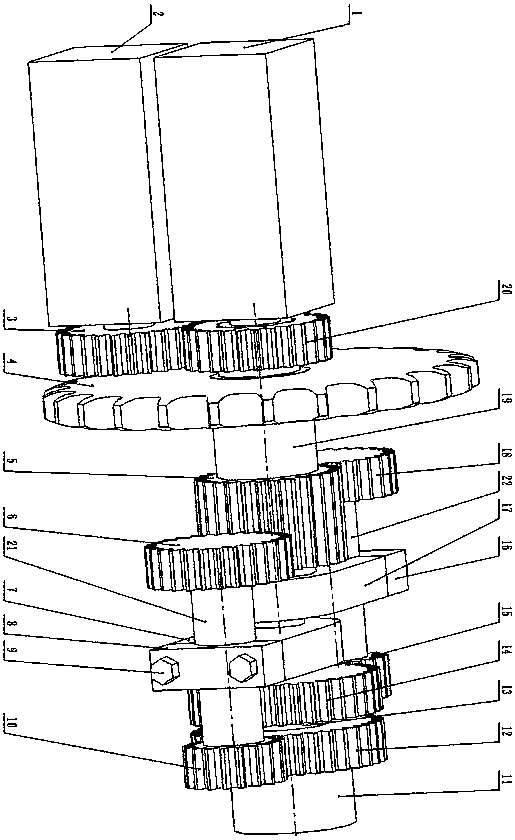

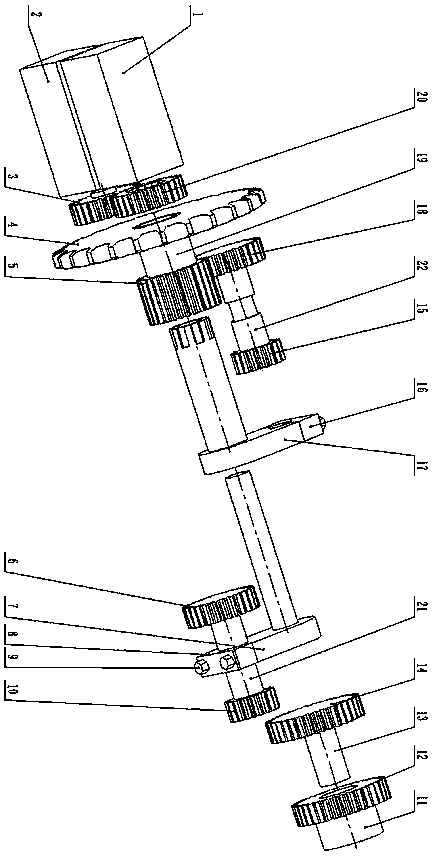

[0006] The upper sprocket (4), the driving gear (5), the connecting shaft (19) and the servo motor (1), the first arm, the first countershaft (21), the first countershaft gear (6, 10), the first countershaft The first set of control group consisting of a driven gear (12) can control the phase of the camshaft (11); add servo motor (2), gear shaft (3), gear (20), second arm, second middle The second set of control group composed of the shaft (22), the second countershaft gears (18, 15) and the second driven gear (14) can control the phase of the second shaft (13) rotating around the camshaft axis. The upper sprocket (4) and the driving gear (5) are fixed on the connecting shaft (19) or the upper sprocket (4) is integrally processed with the driving gear (5) and the connecting shaft (19); the connecting shaft (19) relies on the bearing It is positioned on the fixed mount and rotates around the axis of the camshaft (11); the axis of the connecting shaft (19) is drilled with a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com