Variable speed input and constant speed output device with double adjustment of hydraulic pressure and servo motor

A technology of servo motor and variable speed input, which is applied to the transmission device, transmission device control, fluid transmission device, etc. It can solve the problems of small hydraulic power split ratio, low efficiency, and inability to withstand the impact of sudden load changes. Effects of reducing inertial force and centrifugal force and optimizing transmission ratio of transmission gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation plan

[0039] Below in conjunction with accompanying drawing, the present invention is further introduced:

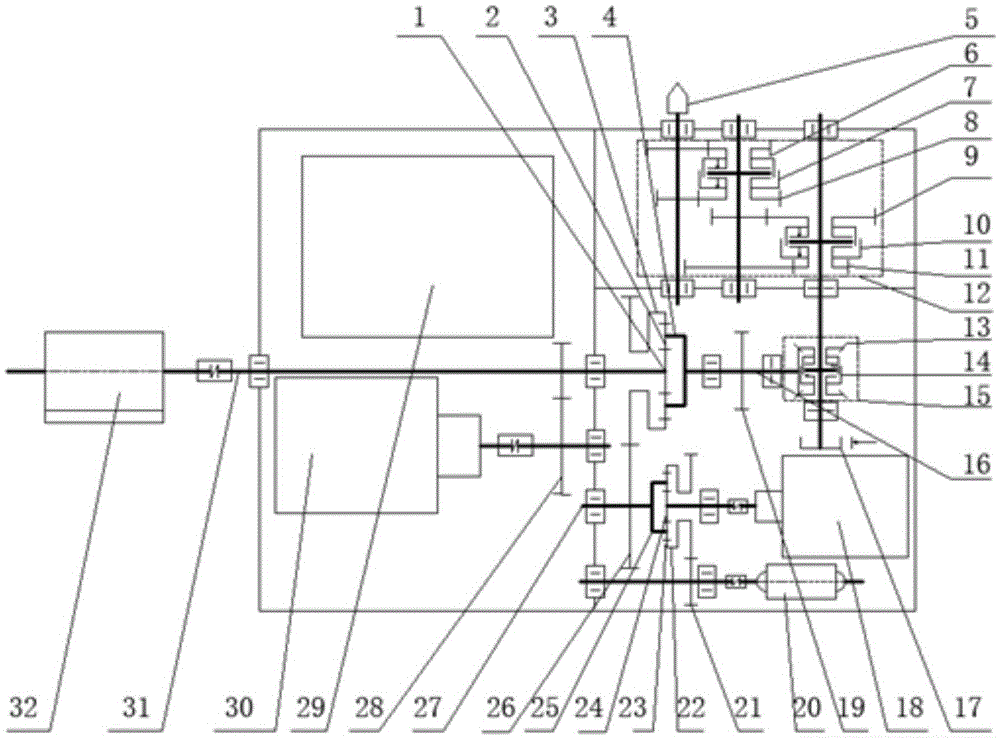

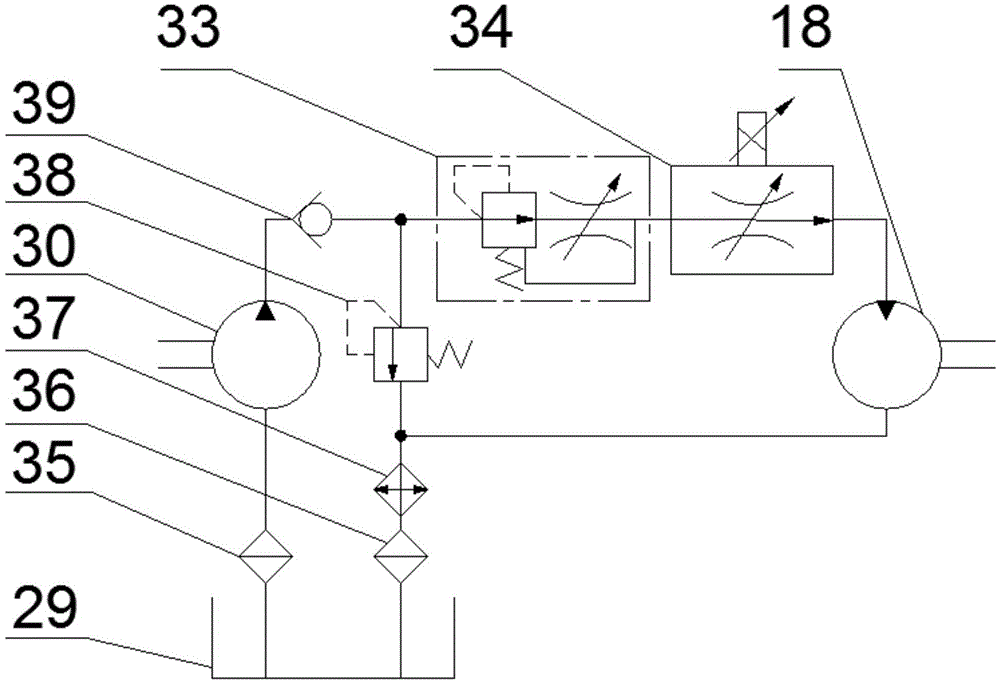

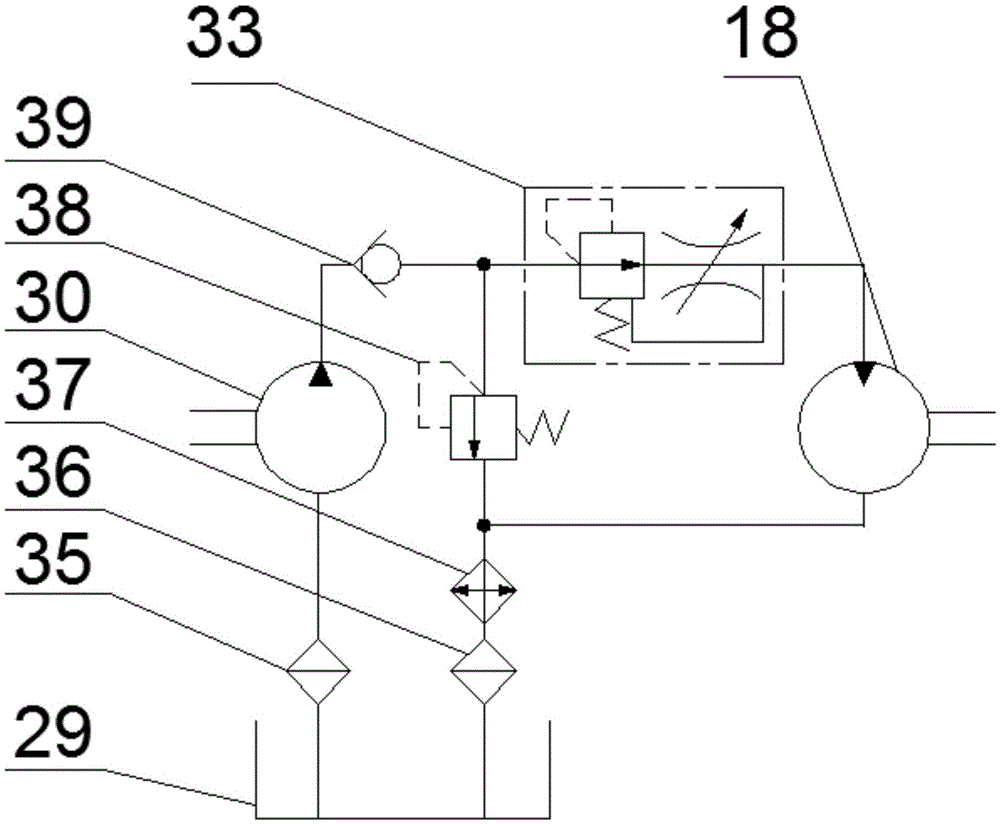

[0040] Such as figure 1 The variable-speed input and constant-speed output device with double adjustment of hydraulic pressure and servo motor includes a primary differential gear train, a secondary differential gear train, a hydraulic system, a servo motor, a speed sensor, a fixed-axis gear train stepped gearbox, and a reversing gear train. system;

[0041] The input of the speed change is provided by the power source 32, and the input power is transmitted to the primary differential gear sun gear 1 through the main input shaft 31, the primary differential gear sun gear 1 and the primary differential gear on the planet carrier 4 of the primary differential gear The planetary gear 2 meshes, and the first-stage differential gear train planetary carrier 4 is connected with the first-stage planetary carrier output shaft 16, and then communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com