Wheel assembly for motor vehicle

A wheel assembly and wheel technology, applied in the direction of wheels, wheel manufacturing, vehicle parts, etc., can solve problems such as high risk, deformation of rims, and difficulty in wheel replacement, and achieve the effects of simplifying maintenance operations, reducing weight, and avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

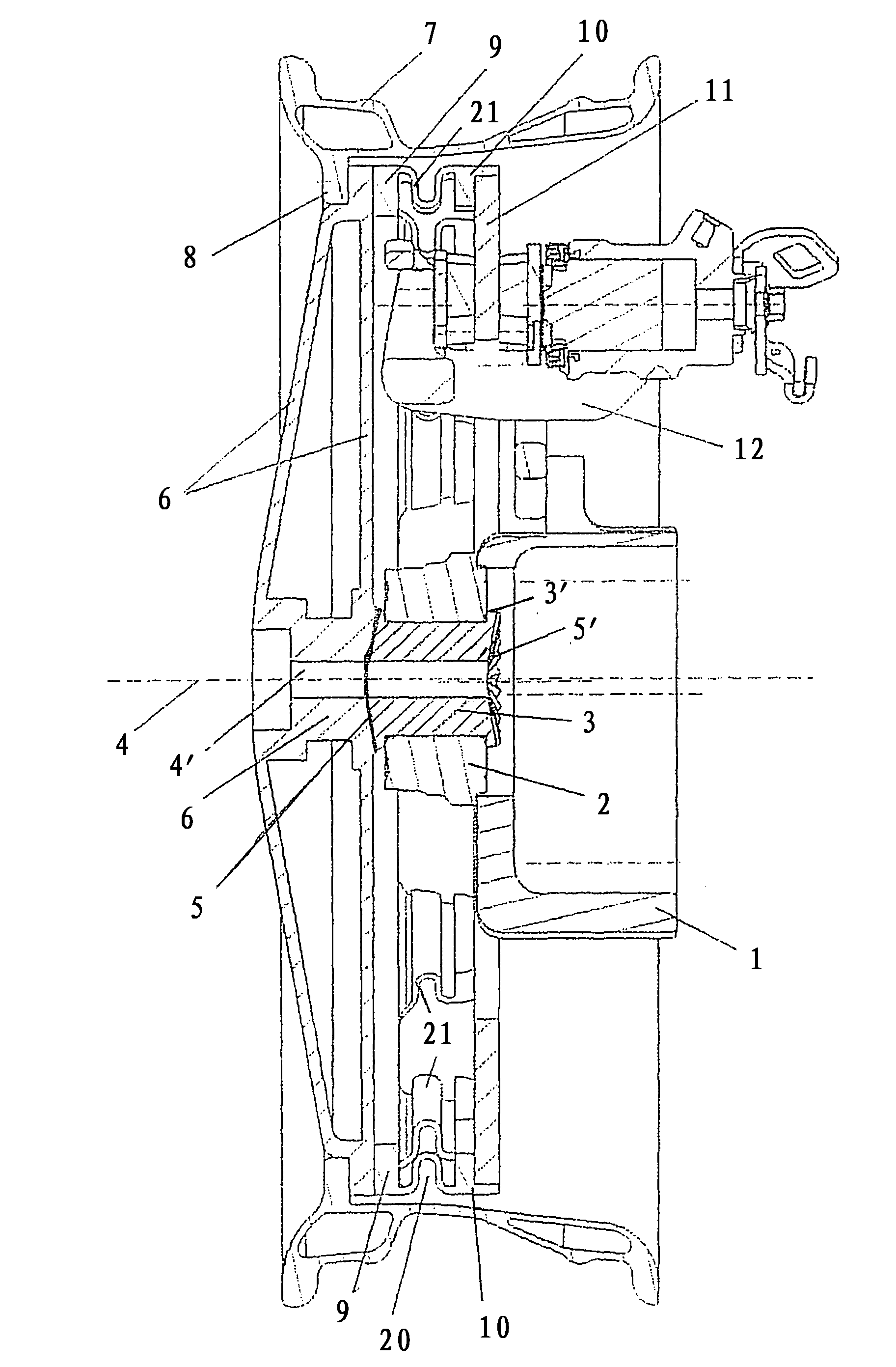

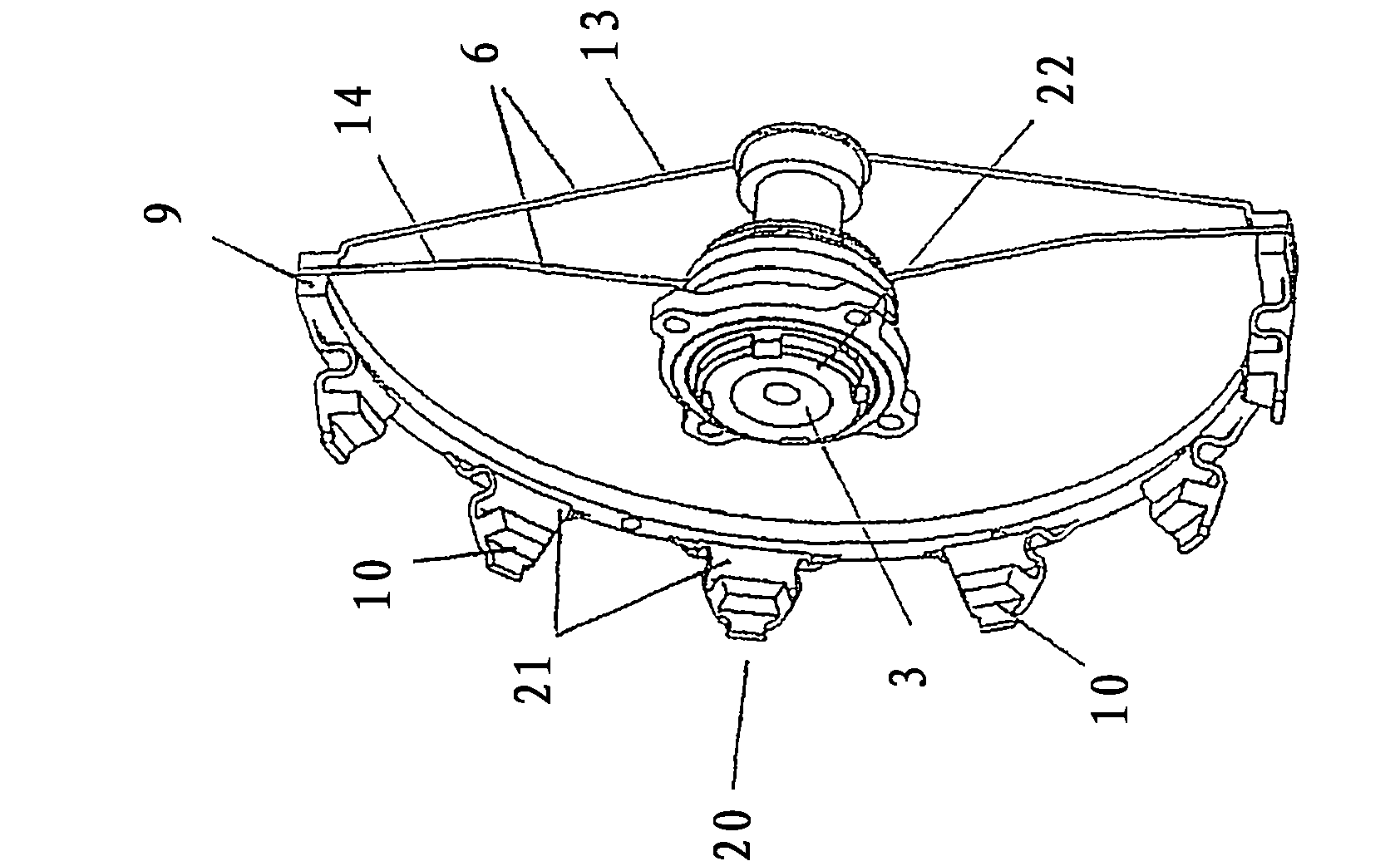

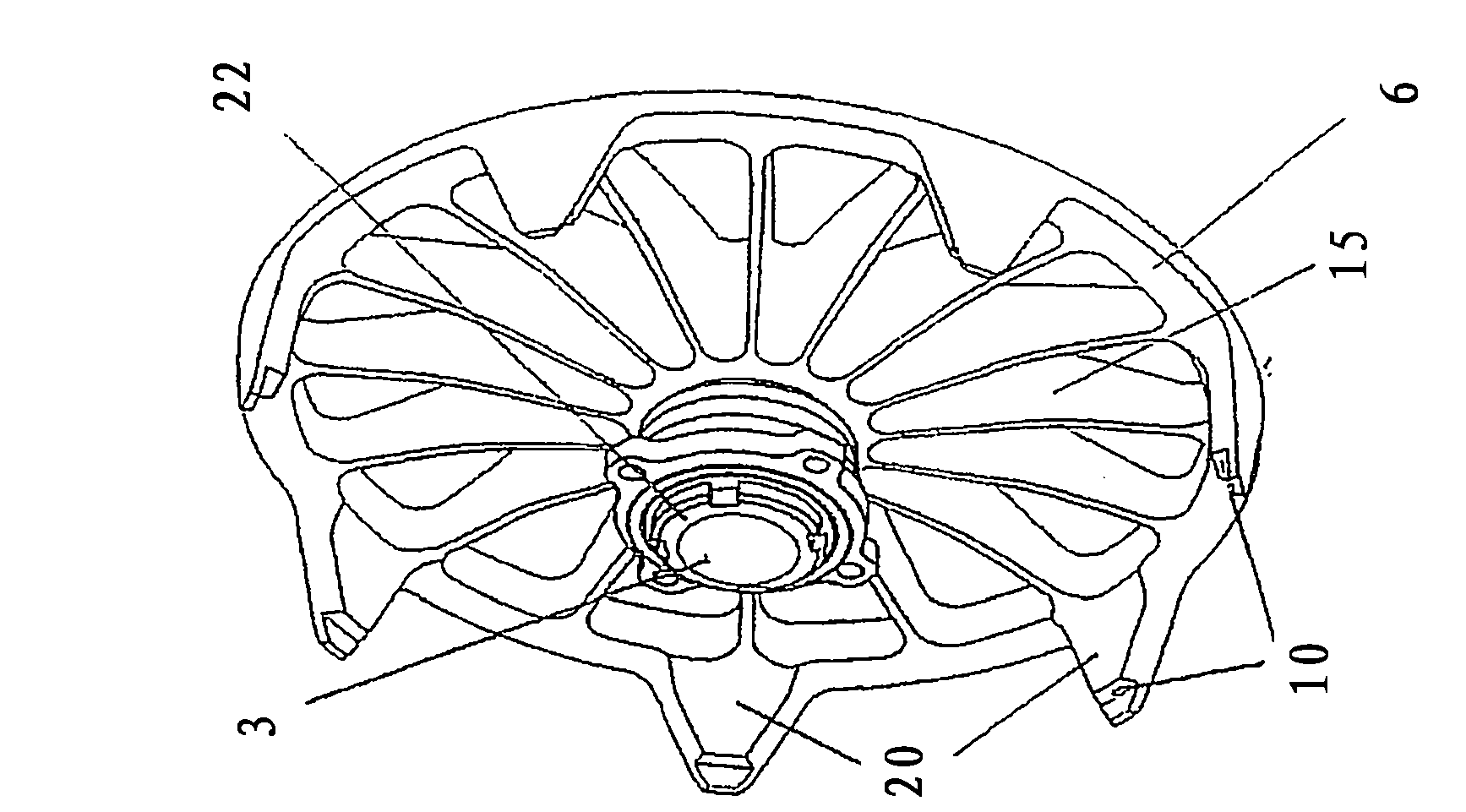

[0027] Wheel frame 1 is equipped with figure 1In the wheel assembly shown in , the wheel carrier fastens the outer ring of the wheel bearing 2 , which is only schematically shown. The inner ring of the wheel bearing 2 supports the hub 3 in a rotationally transmittable manner about an axis 4 drawn in dashed lines. The hub 3 is connected in a rotationally fixed and axially fixed manner to the wheel disk 6 via a flat-cut toothing 5 designed as a Voith face tooth. The wheel bearing 2 is fastened on the inner side of the wheel via its inner ring by means of the enlarged outer diameter 3' of the wheel hub 3 by means of flanges, wherein the enlarged outer diameter 3' is used to make the wheel hub 3 Another planar notched tooth groove 5' which is connected to the drive shaft not shown is made on the occasion. This is preferably done within the cutting process for the hub 3 by means of a cutting tool, not shown, preferably in one operation. The wheel hub 3 is thus connected on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com