Motorcycle accelerator handle structure and motorcycle

A motorcycle oil and door handle technology, which is applied to bicycle accessories, transportation and packaging, bicycle control systems, etc., can solve the problems of reduced zipper tightness, poor throttle handle feel, and inability to adjust the ratio, so as to facilitate layout and improve feel , increase the adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

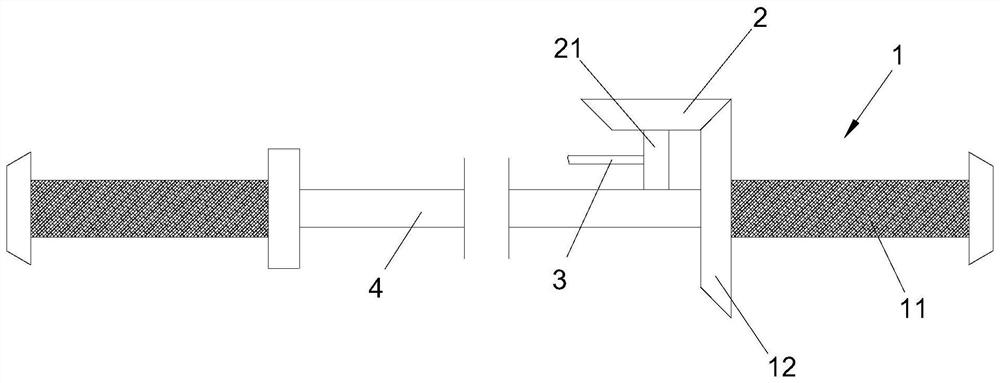

[0032] This embodiment relates to a motorcycle throttle handle structure, which is arranged on the body of the motorcycle, and includes a rotatable throttle coil 1 arranged on the vehicle body, and a transmission unit 2 connected with the throttle coil 1. The unit 2 can be driven by the rotation of the throttle coil 1 to pull the throttle zipper 3; the throttle coil 1 includes a rotatable bushing section 11 arranged on the vehicle body, and a first gear 12 fixed on the bushing section 11, The transmission unit 2 includes a second gear that is rotated on the vehicle body and meshes with the first gear 12. The above-mentioned bushing section 11 can be driven by an external force to drive the first gear 12 and the second gear to rotate. The rotation of the second gear can be Pull the throttle lock 3.

[0033] refer to figure 1 As shown, the first gear 12 of the present embodiment is fixed on one end of the casing section 11, specifically on an inner end of the casing section 11,...

Embodiment 2

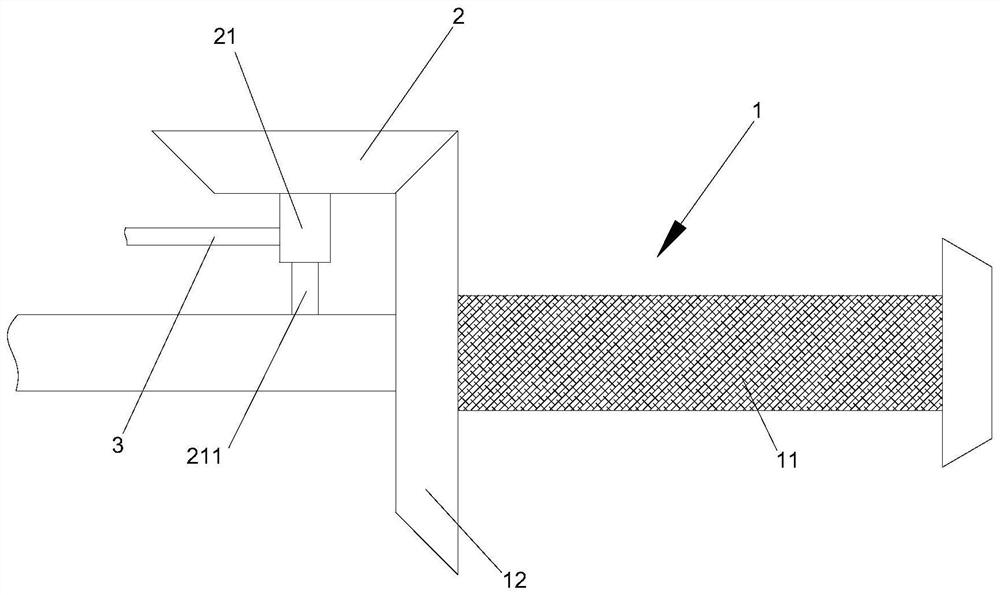

[0042] This embodiment relates to a motorcycle throttle handle structure, which has roughly the same structure as the motorcycle throttle handle structure described in Embodiment 1, the difference lies in: figure 2 As shown, the second gear shaft 21 of this embodiment includes several shaft sections 211 with different diameters connected in series, and the aforementioned throttle zipper 3 can be selectively connected with one of the shaft sections 211. It should be noted that the throttle zipper 3. For the way of connecting with each shaft section 211, please refer to the way of connecting the throttle zipper and the second gear shaft 21 in the first embodiment, so it will not be repeated here.

[0043] The motorcycle accelerator handle structure of the present embodiment, by setting the second gear shaft 21 to include shaft sections 211 with unequal diameters, when the throttle zipper 3 is connected with the shaft sections 211 of different diameters, when the throttle coil ro...

Embodiment 3

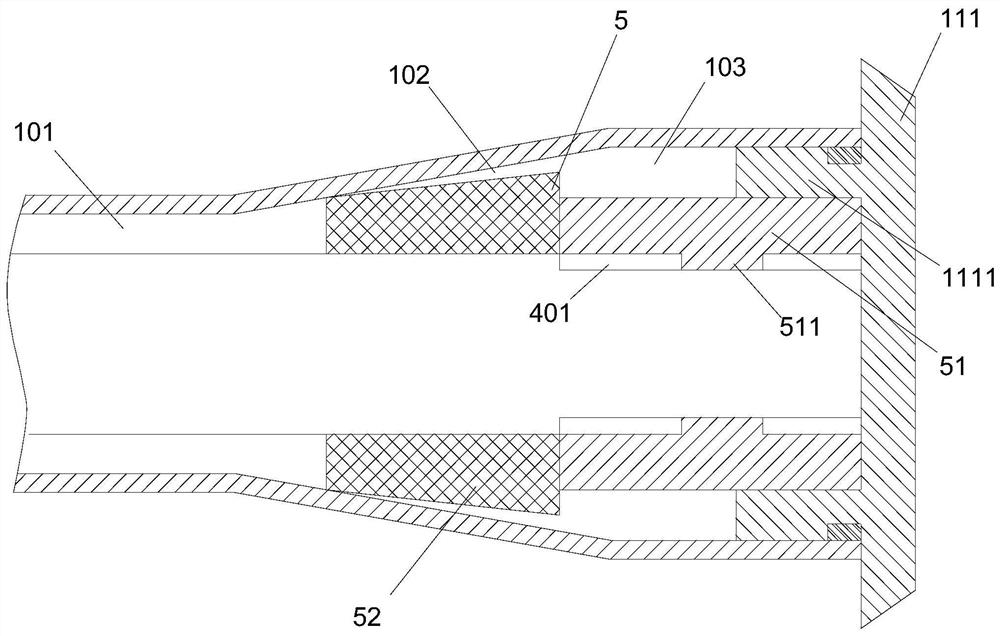

[0045] This embodiment relates to a motorcycle throttle handle structure, which has roughly the same structure as the motorcycle throttle handle structure of Embodiment 1 or Embodiment 2, the difference lies in: in this embodiment, the casing section 11 and the vehicle body A damping unit 5 is arranged therebetween for applying a damping force to the rotation of the bushing section 11 relative to the handle rod 4 . Preferably, the damping force provided by the damping unit 5 is set to be adjustable.

[0046] The sleeve section 11 of this embodiment specifically includes a sleeve body, and a rotatable knob 111 arranged on the sleeve body; , the above-mentioned damping unit 5 includes a rubber pad sandwiched between the side wall of the tapered hole and the handle rod 4 , and the rubber pad can be driven by the rotation of the knob 111 to move along the axial direction of the tapered hole.

[0047] For specific structure, refer to image 3 As shown, from one end of the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com