Drive device

A driving device and drive shaft technology, which is applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve the problems of large installation space, flexible use and other problems, and achieve the effect of long output shaft length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

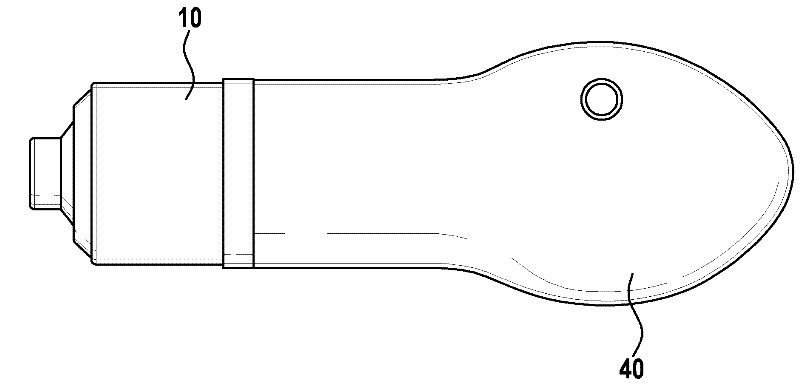

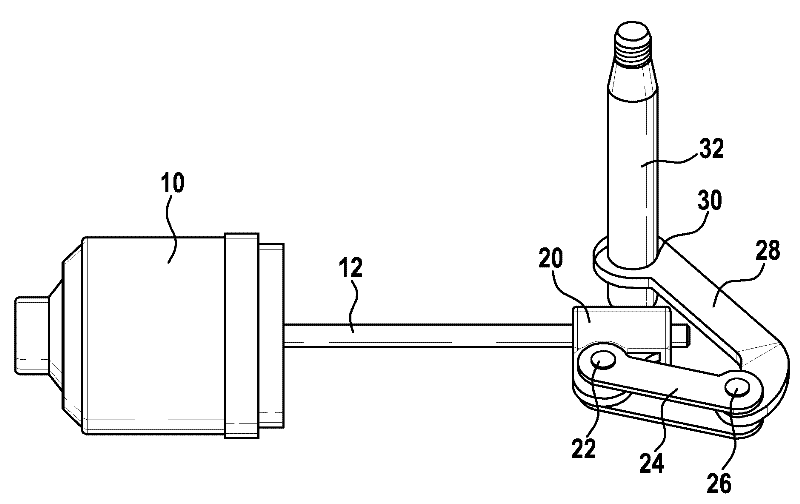

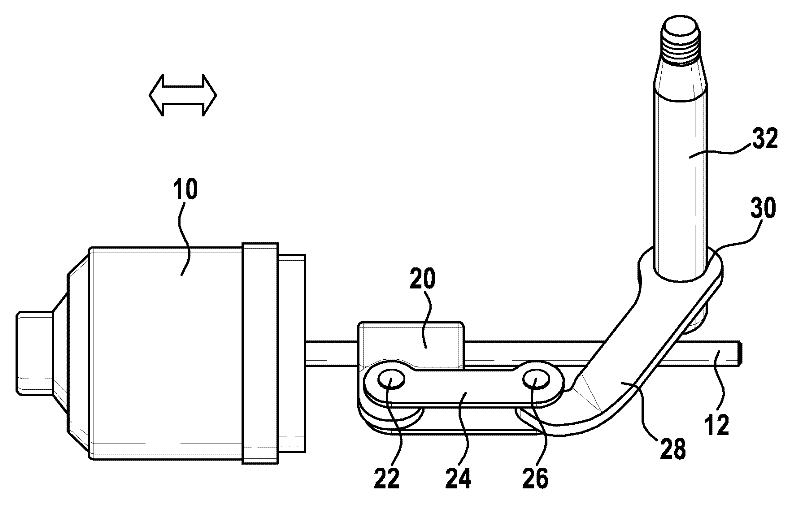

[0019] exist Figures 1a to 1c The drive according to the invention of the wiper device is shown for moving the output shaft 32 . In this case, the motor 10 preferably reversibly drives a rotatably mounted drive shaft 12 , which is preferably designed as a screw or worm thread. The drive shaft 12 is connected to the linear motion element 20 in a non-rotatable manner, so that the rotational motion of the drive shaft 12 can be converted into the linear motion of the linear motion element 20 . The linear movement element 20 is connected via a first hinge 22 to a connecting rod 24 , wherein the connecting rod 24 is connected via a second hinge 26 to a rocker arm 28 and the rocker arm 28 is connected non-rotatably to an output shaft 32 via a hollow hole 30 . The linear motion element 20 is driven by the motor 10 via the drive shaft 12 and moves back and forth on the drive shaft 12 between the motor 10 and the drive shaft 32 ( Figure 1a to Figure 1c ). In this case, the linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com