A zoom lens automatic image plane docking and optical axis runout detection system and method

A zoom lens and jump detection technology, which is applied in the field of aerospace full-spectrum zoom lens image plane debugging, can solve the problems of individual differences in optical axis jump detection, differences in image plane definition, and low efficiency, and achieve automatic image plane docking The effect of smooth process, consistent clarity and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

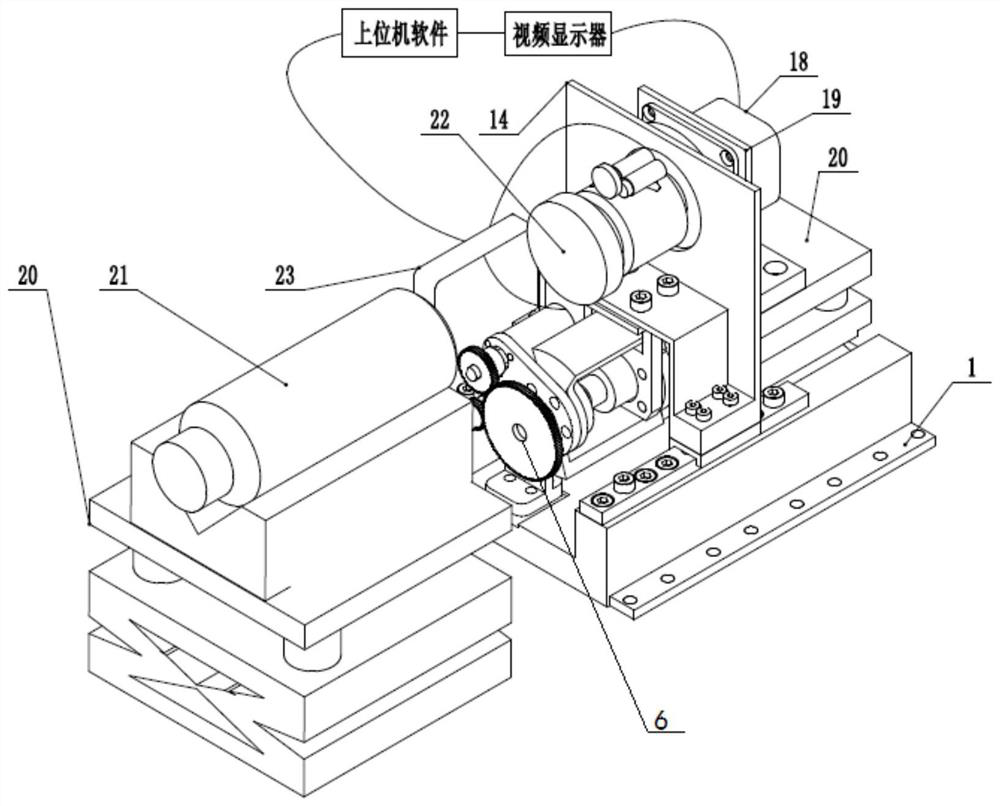

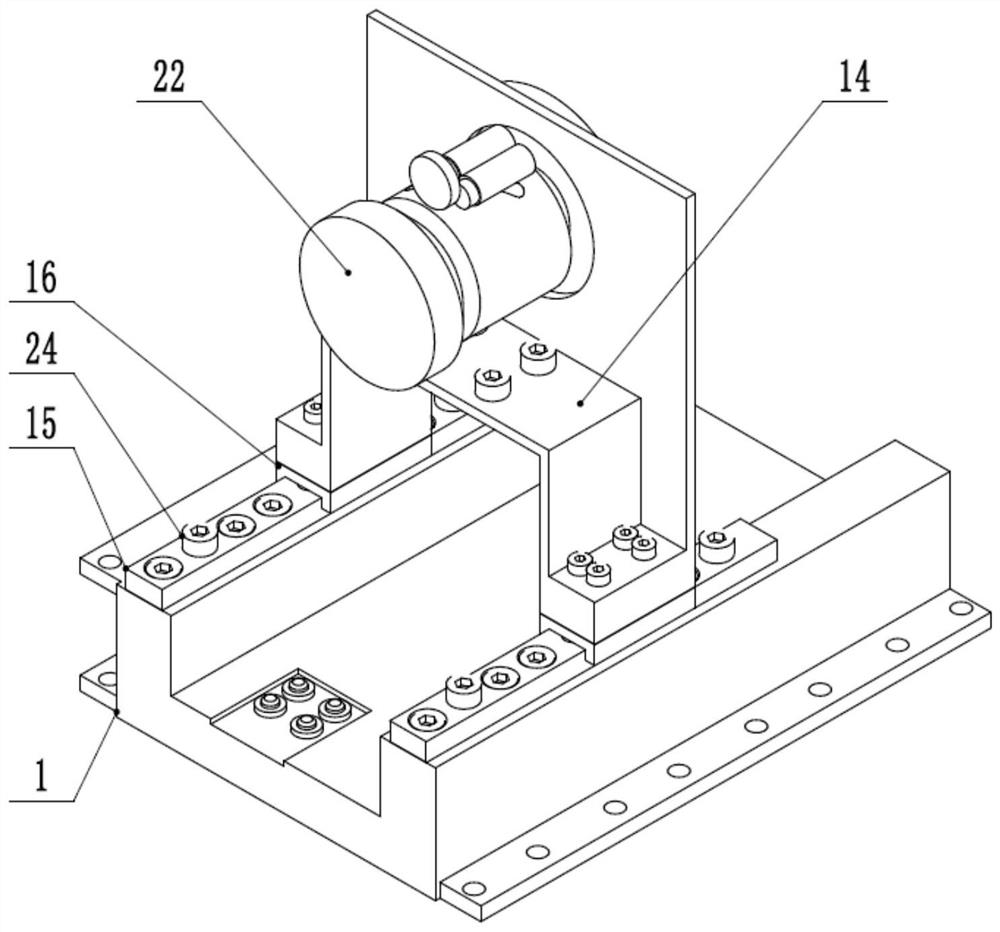

[0081] Such as figure 1 As shown, a zoom lens automatic image plane docking and optical axis runout detection system includes a system support bracket 1, a drive and feedback assembly for power supply and feedback for the mechanism, a guide assembly for ensuring the movement direction of the imaging assembly, an optical imaging assembly and control components.

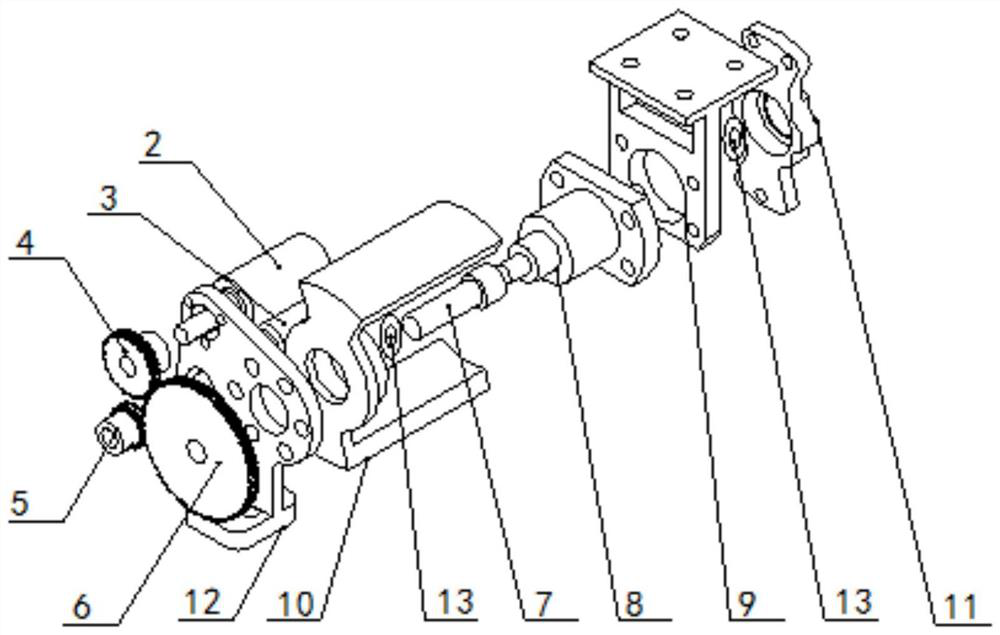

[0082] Such as figure 2 As shown, the drive and feedback components are set on the system support bracket 1, including potentiometer 2, motor 3, potentiometer gear 4, motor gear 5, transmission screw gear 6, coupling 7, ball screw nut 8 and nut Fixed bracket 9. Wherein, the output of the motor 3 is connected to the motor gear 5 for driving the rotation of the motor gear 5, the motor gear 5 meshes with the transmission screw gear 6, and is used to drive the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com