Hybrid coupling device based on mechanical automatic transmission

A technology of automatic transmission and coupling device, which is applied to the arrangement of multiple prime movers of power devices, pneumatic power devices, and general power devices, and can solve the problem of unbalanced technical complexity and power performance, power transmission chain, etc. Shafting torsional vibration, poor power output effect and other problems, to reduce the risk of shafting torsional vibration, reduce the size, and use the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

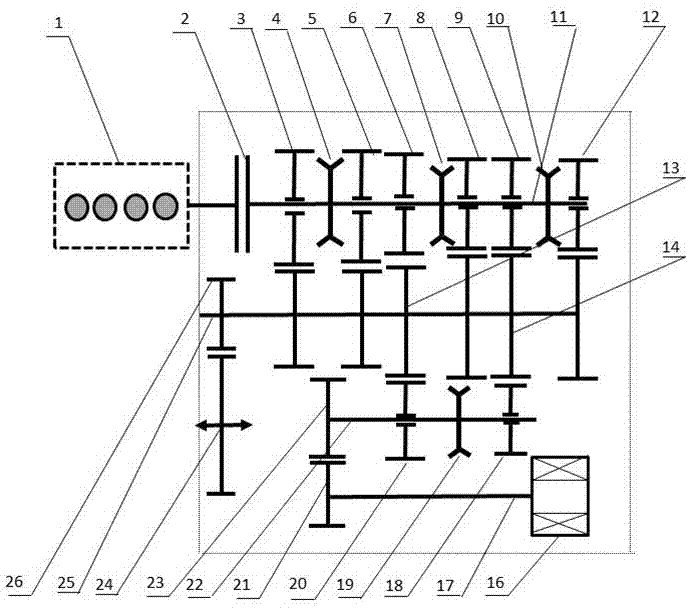

[0034] Embodiment one: see figure 1 , a hybrid coupling device based on a mechanical automatic transmission, including an engine 1, a drive motor 16, a differential 24, a synchronizer, an engine input shaft assembly, an output shaft assembly, a drive motor shift shaft assembly and The drive motor input shaft assembly, the engine 1 is connected to the engine input shaft assembly, the engine input shaft assembly receives the first power input by the engine 1 and outputs the first power to the output shaft assembly; the drive motor 16 is connected to the drive motor input The shaft assembly, the drive motor input shaft assembly is connected to the drive motor shift shaft assembly, the drive motor shift shaft assembly receives the second power input by the drive motor 16 and outputs the second power to the output shaft assembly; differential The output shaft assembly 24 is connected to the output shaft assembly, and the output shaft assembly receives the first power and / or the sec...

Embodiment 2

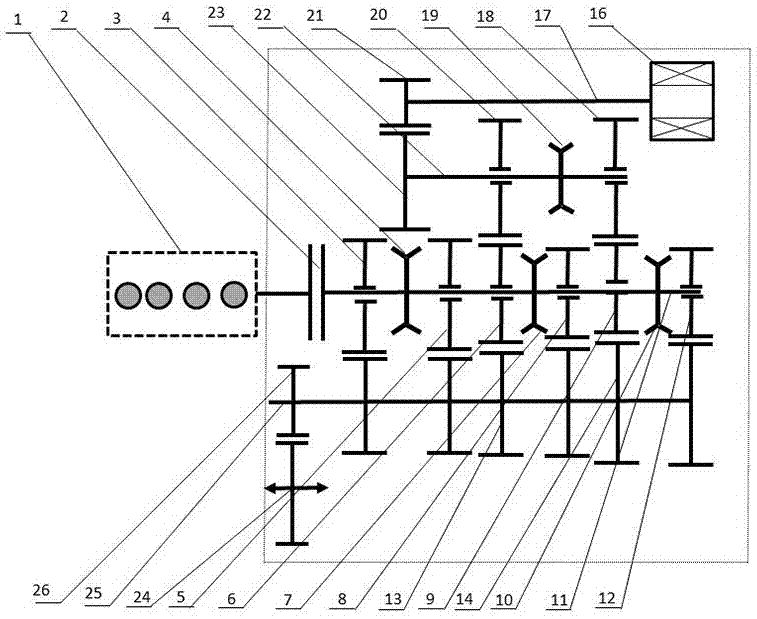

[0040] Embodiment two: see figure 2 The difference between this embodiment and the first embodiment is that the drive motor gear d is connected to the engine gear a correspondingly connected to the coupling gear c. i.e. contrast figure 1 Speaking, it is equivalent to moving the installation positions of the drive motor input shaft assembly and the drive motor shift shaft assembly from the bottom of the figure to the top of the figure. The function and performance of this embodiment are the same as those of Embodiment 1, and are figure 1 A more optimized way, the space structure is more conducive to the arrangement in the limited engine compartment.

Embodiment 3

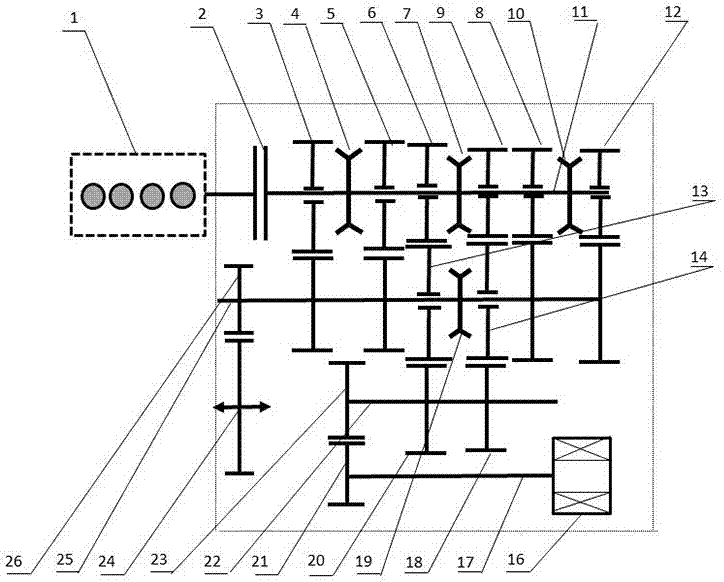

[0041] Embodiment three: see image 3 The difference between this embodiment and the first embodiment is that the synchronizers are installed on the engine input shaft 11 and the output shaft 25 respectively, and the synchronizers include the engine synchronizer e which is arranged on the engine input shaft 11 and the engine synchronizer e which is arranged on the output shaft 25 The drive motor synchronizer f on the top, the transmission gear pair can be two engine gears a or two coupling gears c, the transmission gear pair corresponding to a single engine synchronizer e is two engine gears a, and the single drive motor is synchronized The pair of transmission gears corresponding to device f is two coupling gears c.

[0042] image 3 Among them, there are three engine synchronizers e, numbered 4, 7, and 10; one drive motor synchronizer f, numbered 19; two drive motor gears d, numbered 18, 20; There are 2 coupling gears c, numbered 13, 14; 4 driven gears b; 6 engine gears a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com