Plastic packaging material detection system constructed based on network technology

A technology of plastic packaging, network technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

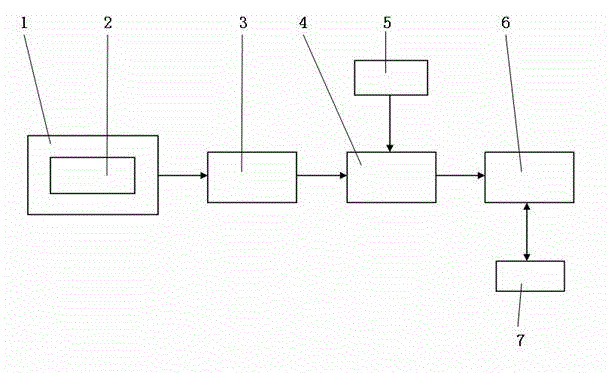

[0032] figure 1 Among them, the present invention includes four parts: a sample information collection unit, a sample detection unit, a storage unit 6 and a terminal device 7 . The sample information collection unit, the sample detection unit, the storage unit 6 and the terminal device 7 are connected through a network. The sample information collection unit includes a label collection device 3 and a label 2 set on the sample 1. The label 2 contains the material and manufacturing information of the sample 1. The label collection device 3 is an information collection device that matches the label 2 set on the sample 1. The device can collect the sample information in the label 2 and send the sample information to the sample detection unit through the network. The sample detection unit includes at least one detection device 4, the detection device 4 is connected to the corresponding energy monitoring device 5, and has an independent data sending and receiving device, the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com