SCR (silicon controlled rectifier) denitration reactor of coal fuel gas

A denitration reactor, coal-fired flue gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of mixing uniformity, increase system pressure drop, shorten mixing distance, etc., to achieve good ammonia nitrogen Mixing effect, reducing adjustment difficulty, reducing the effect of the number of ammonia injection pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

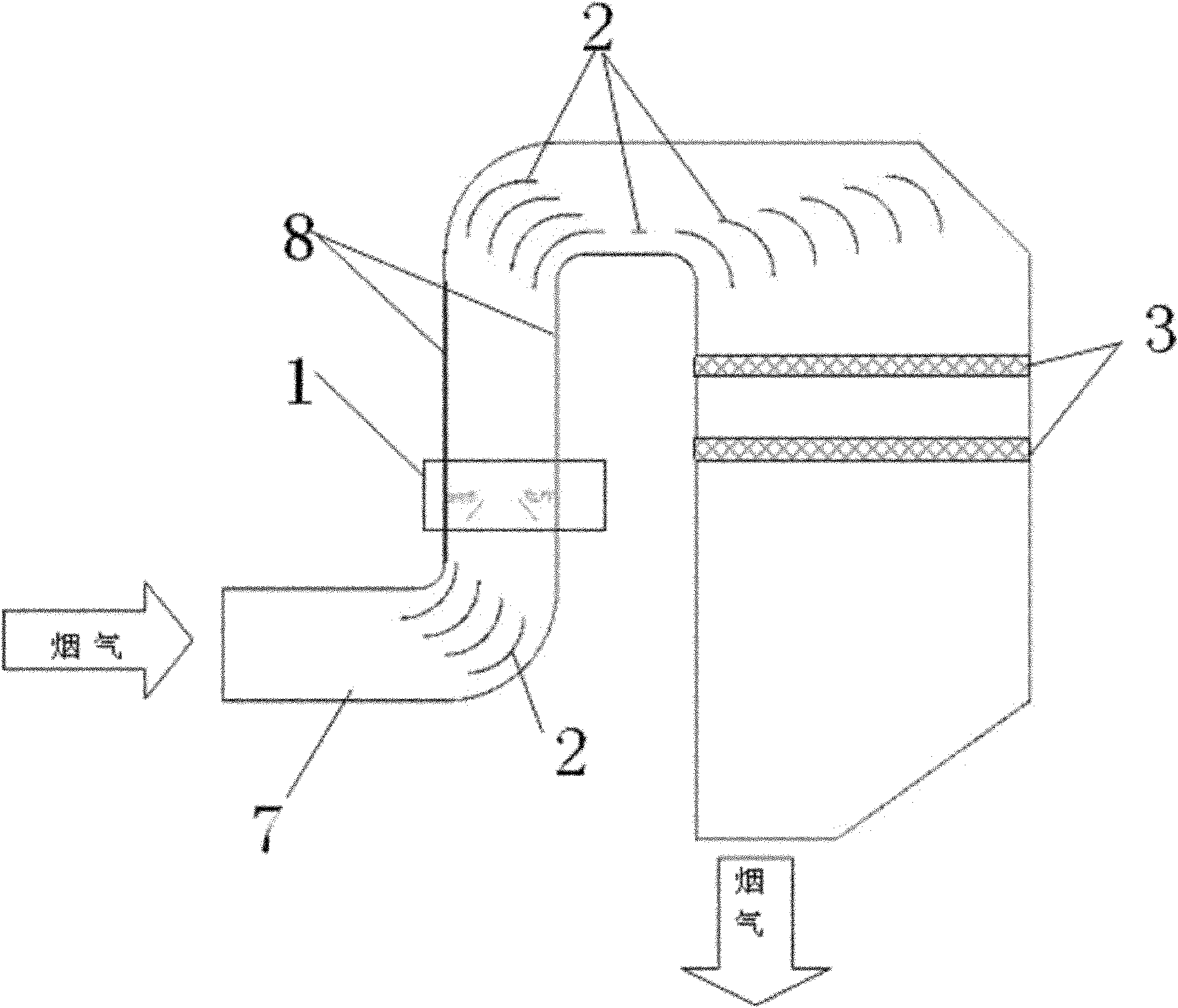

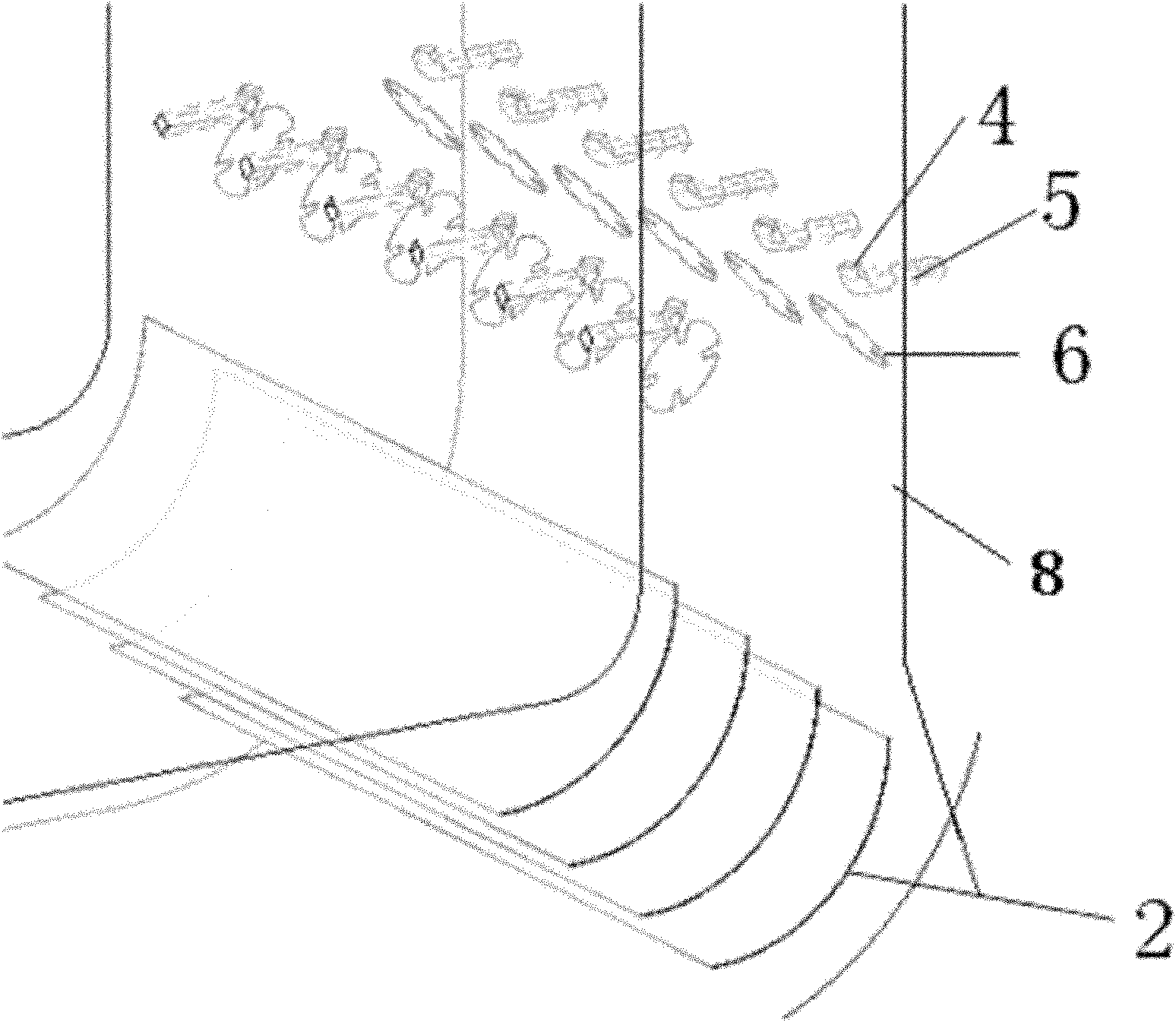

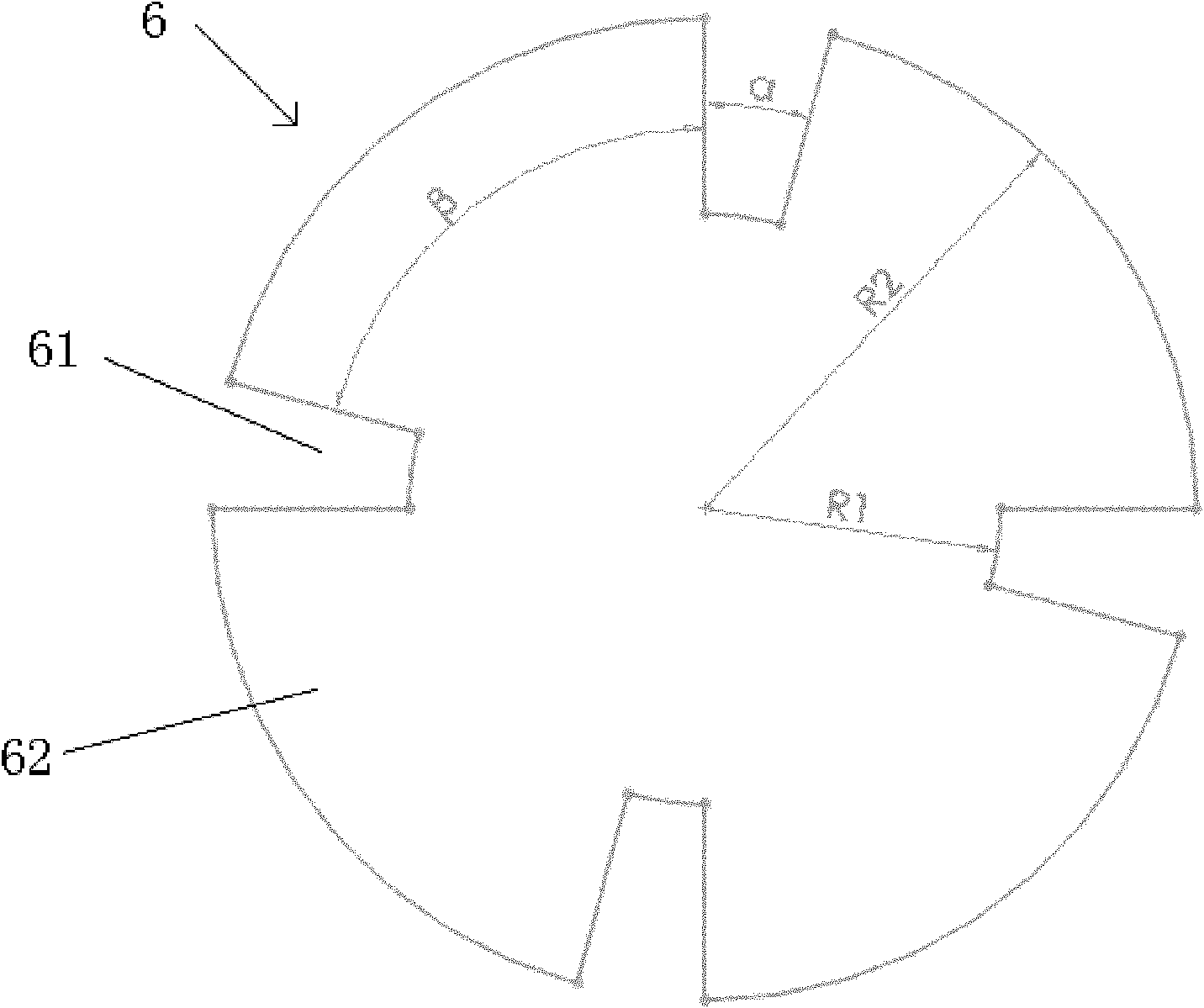

[0017] see figure 1 , figure 2 and Figure 4 As shown, a coal-fired flue gas SCR denitrification reactor includes a flue 7, a deflector 2 is provided at the corner of the flue 7, and a deflector 2 is provided in the flue 7 near the upper corner of the flue gas inlet. The strong vortex spray ammonia mixing device 1, the strong vortex spray ammonia mixing device 1 includes six to thirty reductant ammonia injection pipes 4, and ammonia nozzles 5 arranged at the ends of the reductant ammonia injection pipes 4, the reductant ammonia injection pipes The pipe 4 is symmetrically arranged on both sides of the flue 7, and the reducing agent ammonia is sprayed from the nozzle at the end of the injection pipe, and the injection direction is consistent with the direction of the flue gas flow; at the upstream of each reducing agent ammonia injection pipe 4, there is a Strong vortex generator 6, strong vortex generator 6 is fixedly connected with flue inner wall by support beam, each stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com