Driving shaft of electric switch

A technology for electrical switches and drive shafts, applied in switch lubrication, contact drive mechanism, contact vibration/shock damping, etc., and can solve problems such as non-installation of torsion springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings. The equi-orientation relationship only refers to the relative positional relationship of the components shown in the drawings, and does not represent their absolute position.

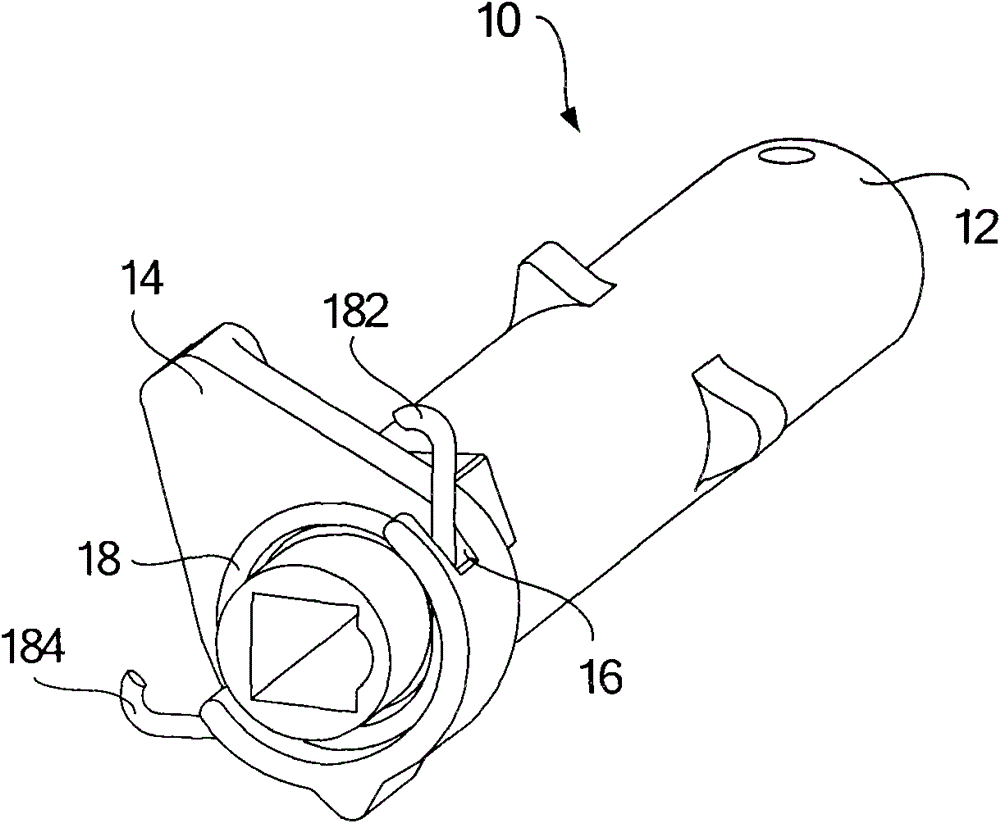

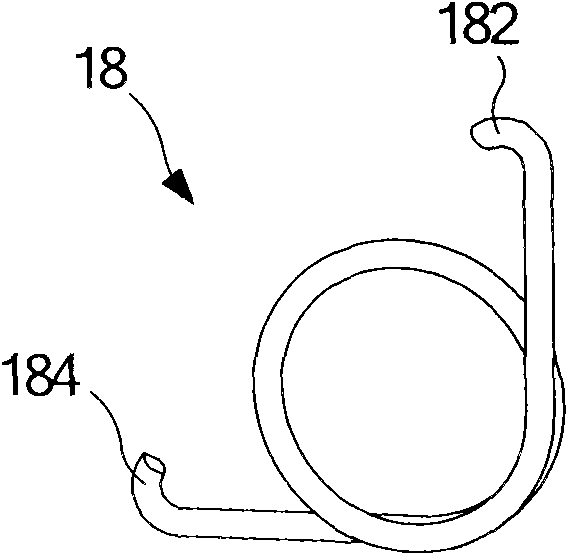

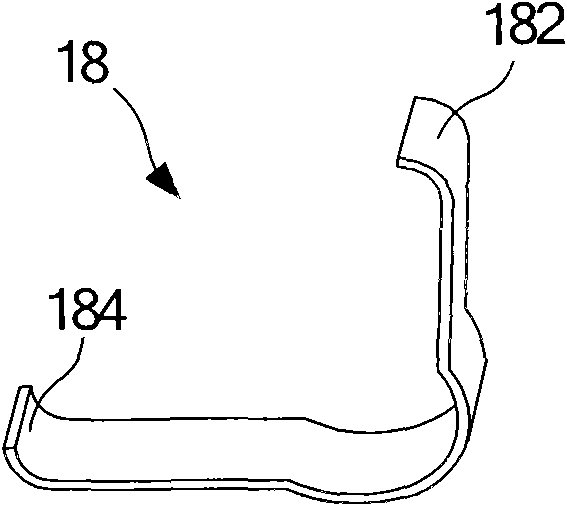

[0023] Such as figure 1 As shown, the drive shaft 10 has a shaft body 12 and a cam portion 14 located at the lower end of the shaft body 12. The cam portion 14 has a slot 16 perpendicular to the shaft body 12 and along the circumference of the cam portion 14. The spring 18 sleeved in the socket 16. The spring 18 has two ends protruding from the slot 16, one is the closing end 182 corresponding to the closing position of the drive shaft 10, and the other is the opening end 182 corresponding to the opening position of the drive shaft 10. Gate terminal 184 .

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com