Plastic injection lens mold

A mold and lens technology, which is applied in the field of plastic injection lens molds, can solve the problems of time-consuming and complicated operation, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

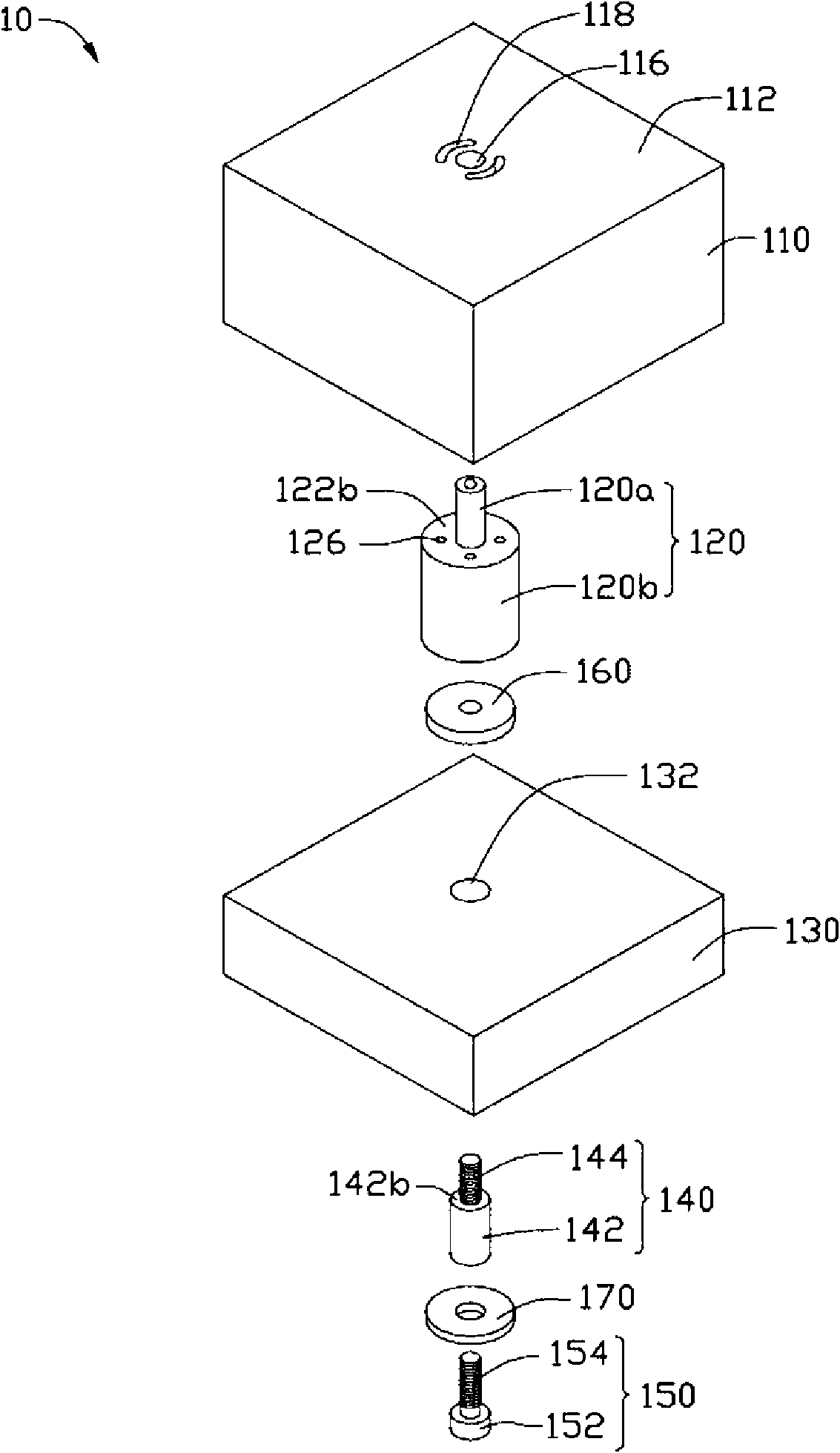

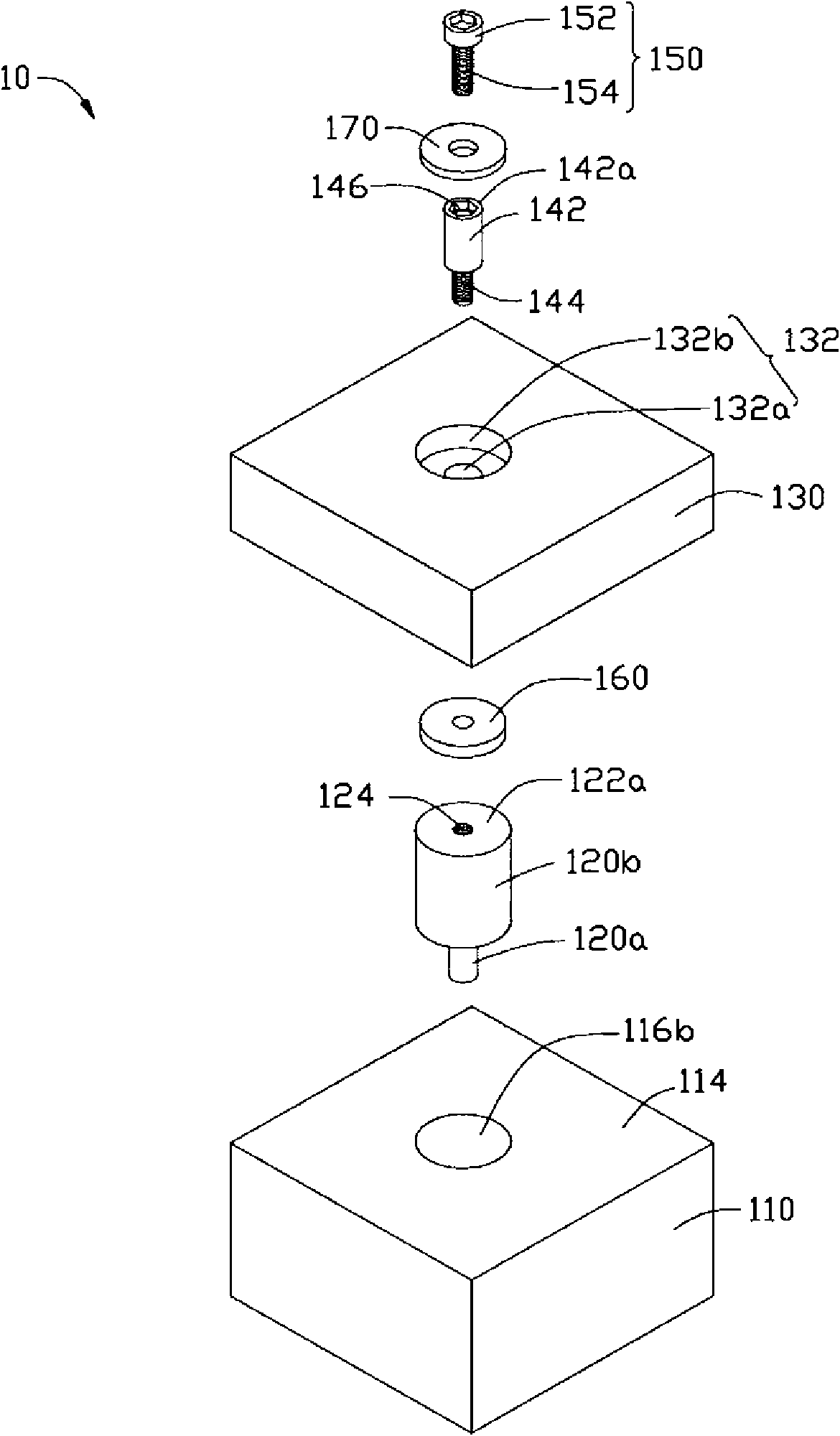

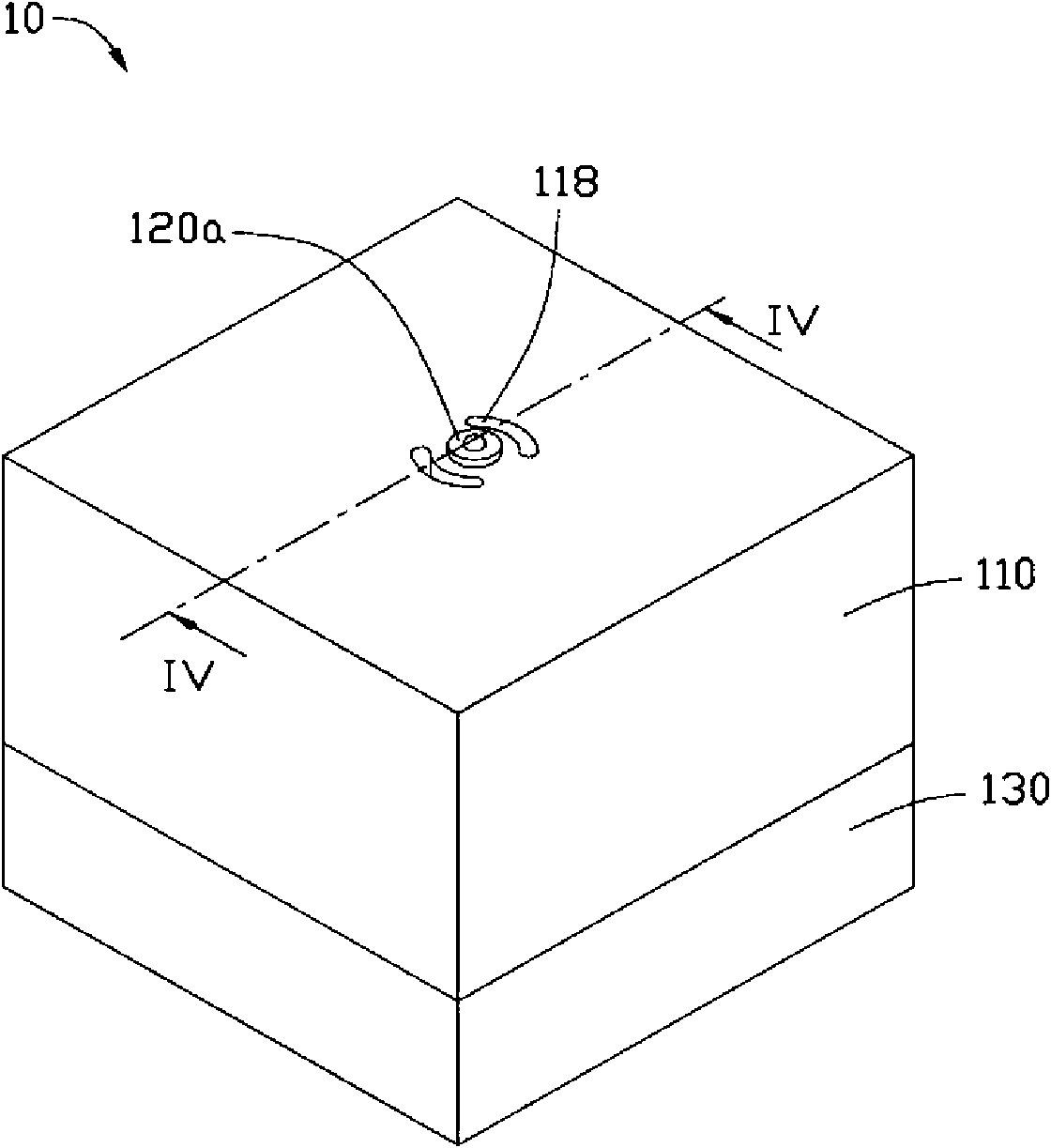

[0013] see figure 1 and figure 2 , a plastic injection lens mold 10 according to a preferred embodiment of the present invention, which includes a module 110 , a mold core 120 , a back plate 130 , a positioning member 140 and a fixing member 150 .

[0014] Please also refer to image 3 and Figure 4 The module 110 includes a parting surface 112 and a mounting surface 114 opposite to the parting surface 112 . In this embodiment, the shape of the module 110 is square. The module 110 defines a core hole 116 passing through the parting surface 112 and the mounting surface 114 . The core hole 116 is circular in shape and includes a core core hole 116a and a core core hole 116b. The core core hole 116a has a diameter smaller than that of the core core hole 116b. The parting surface 112 is also provided with two slots 118 surrounding the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com