High temperature hot water pump

A technology of high-temperature hot water and cooling fins, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as reduced motor efficiency, shortened motor life, and dry-running damage to grease bearings, and achieves improved efficiency and better use The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

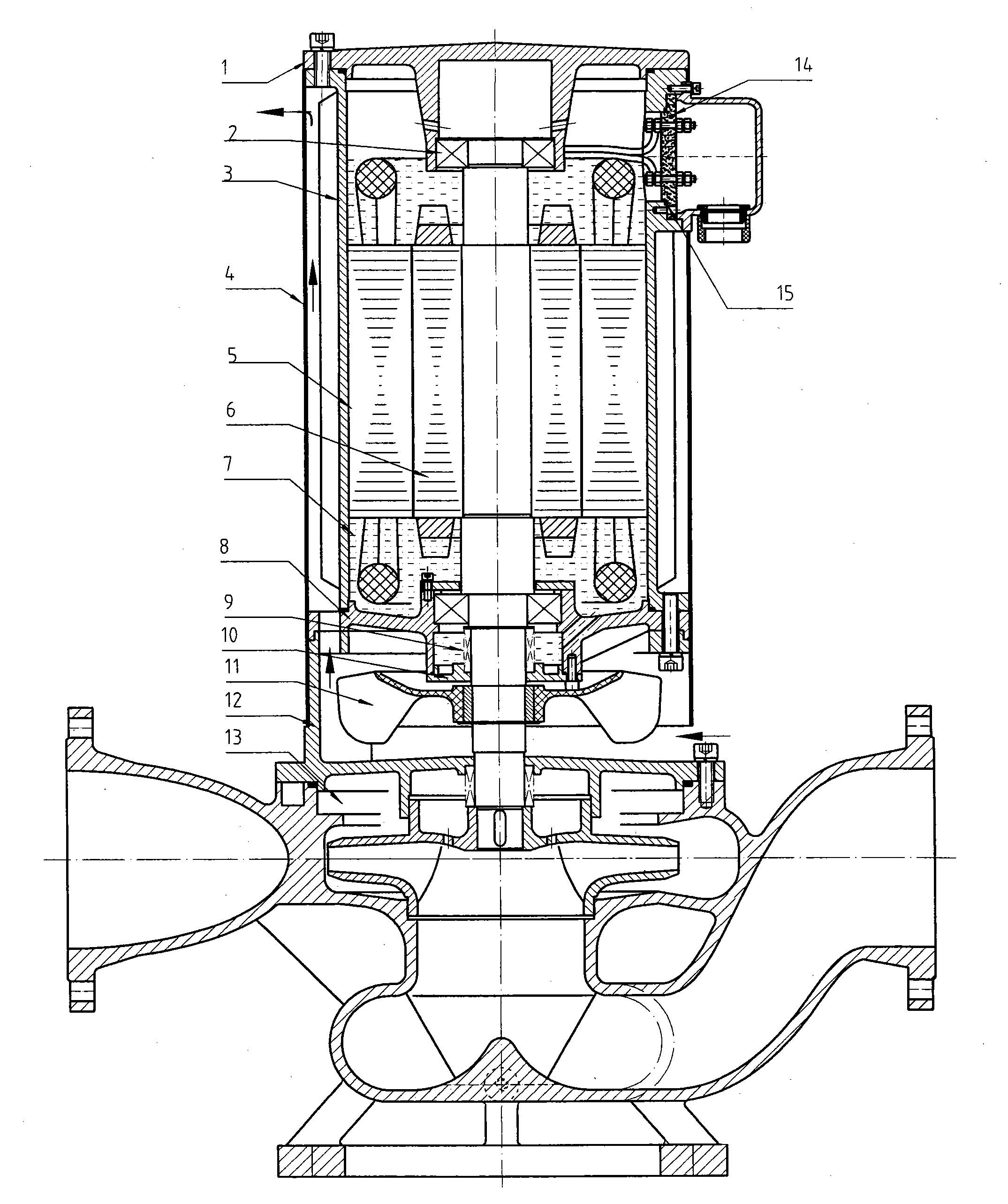

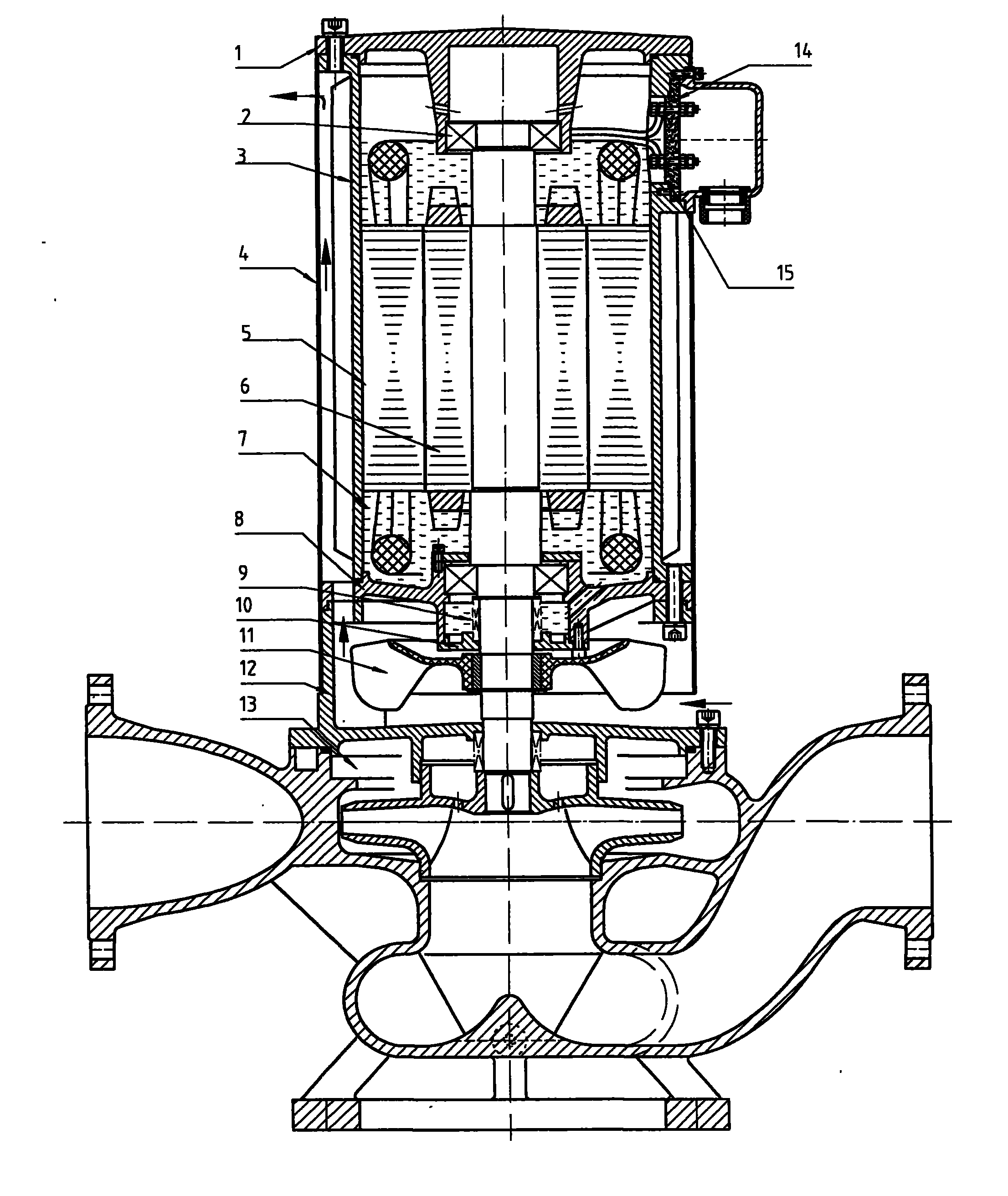

[0014] Such as figure 1 As shown in the high-temperature hot water pump of the present invention, a stator (5) and a rotor (6) are housed in the casing (3) with cooling fins, and the upper cover (1) and the lower bearing seat (8) are respectively connected with the casing (3) with cooling fins. ) are connected with bolts, the casing with heat sink (3) is equipped with an air guide sleeve (4), and the terminal block (14) is equipped with a sealing ring (15) and is fastened in the outlet hole of the casing with heat sink (3) with bolts. Bearing (2), mechanical seal (9), band seal mechanical seal gland (10) are housed in the lower bearing seat (8), and machine oil (7) is housed in the band cooling fin casing (3). Fan (11) is installed below the rotor (6) and the mechanical seal gland (10) with seal, the fan (11) periphery is equipped with pump cover (12), and water pump (13) is installed below the pump cover (12).

[0015] When the water pump is running, because the water delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com