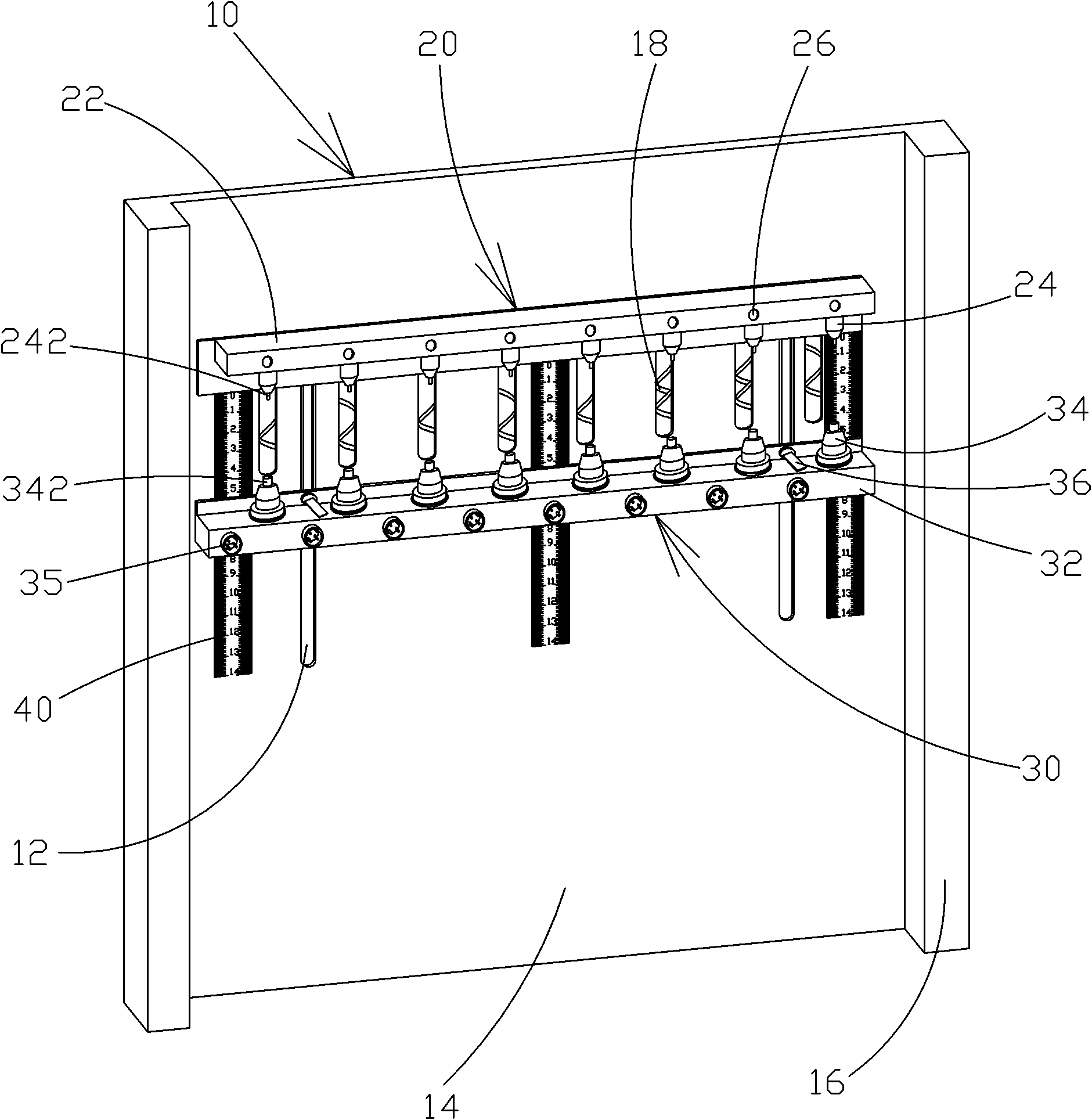

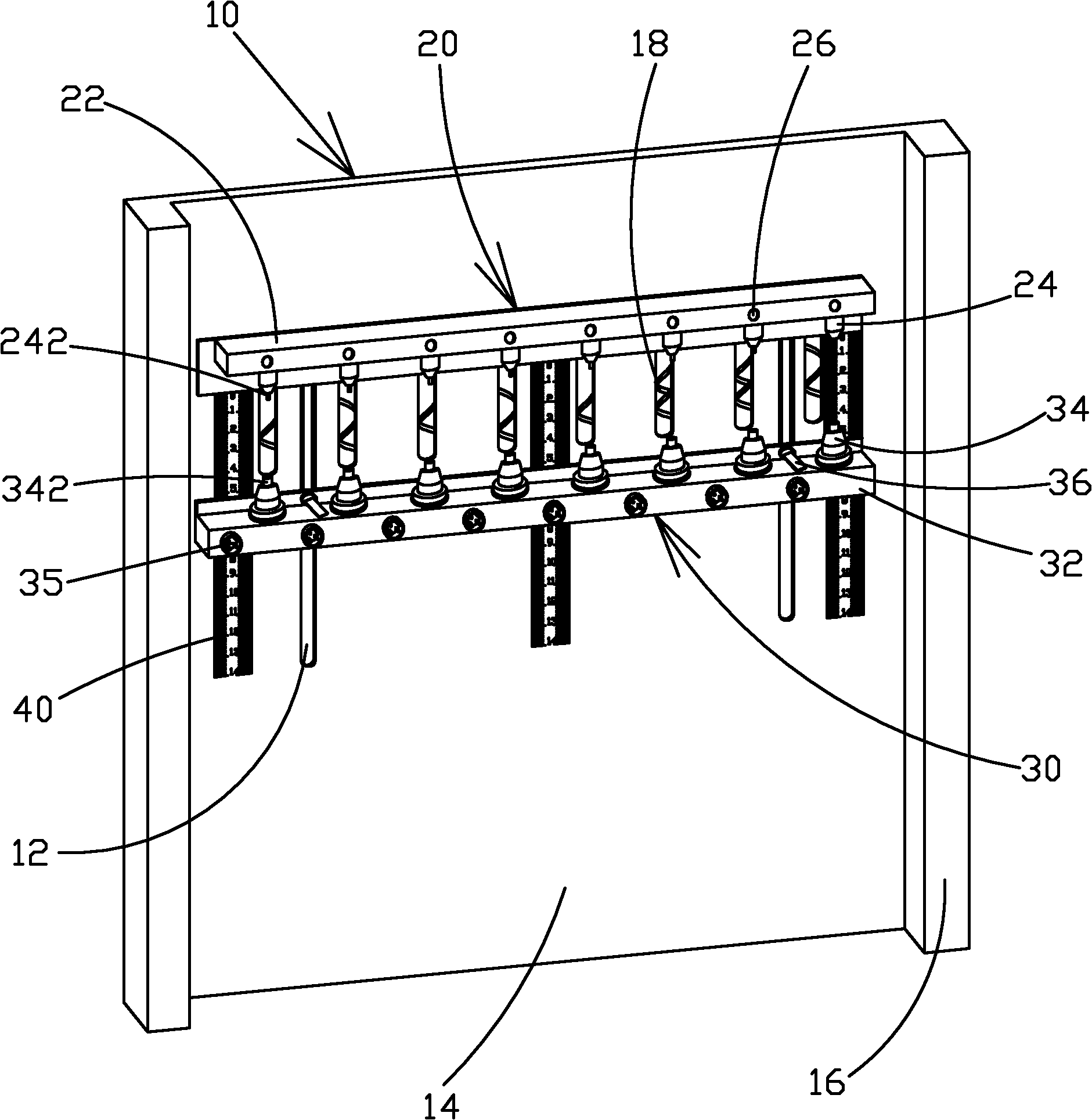

Battery test fixture with calibrations

A battery testing and fixture technology, applied in the field of mechatronics, can solve the problems of inconsistent adjustment distance between upper and lower fixtures, large error in test results, poor contact, etc., so as to reduce wages and maintenance funds, reduce the time required for testing, and prolong the service life of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0018] like figure 1 As shown, the present invention provides a battery test fixture with a scale, which includes: a base 10, an upper fixture 20 disposed on the base 10, and a lower fixture 30 corresponding to the upper fixture 20 disposed on the base 10 , and along the upper clamp 20 vertically downwardly arranged on several scales 40 with scales on the base 10; the two sides below the upper clamp 20 on the base 10 are respectively provided with a sliding track 12, the upper clamp 20 Including the upper splint 22 and several upper test contacts 24 arranged on the lower side of the upper splint 22, the lower fixture 30 includes the lower splint 32, several upper test contacts 24 corresponding to the upper test contacts 24 arranged on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com