Adjustable transformer core assembly table

An adjustable transformer core technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of increasing the difficulty and strength of the operation of the staff, falling and hurting people, and the collision of the workpiece iron core, etc., to achieve Increase quality stability and consistency, reduce production costs, and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

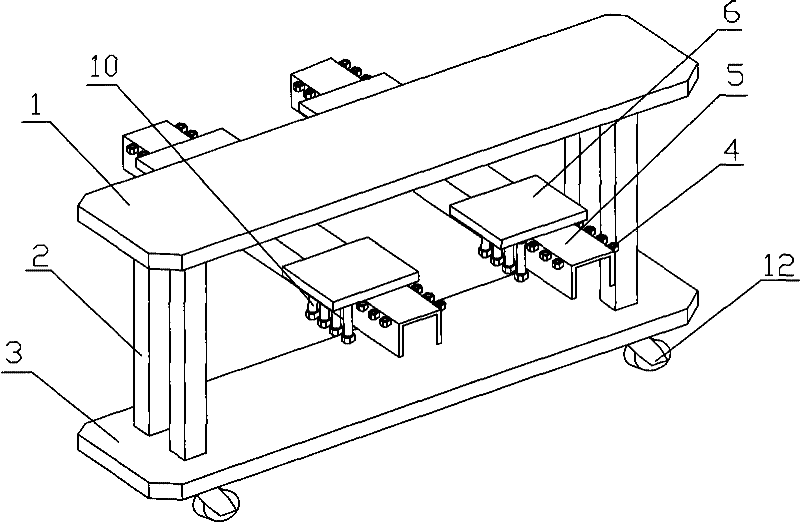

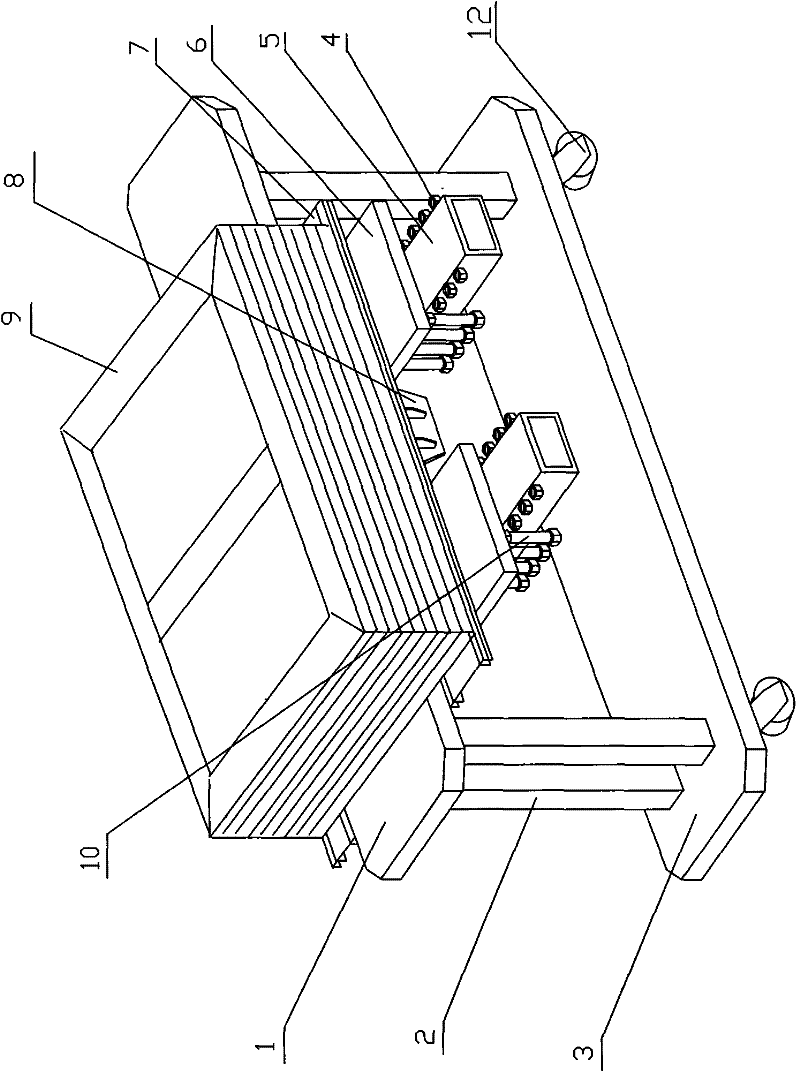

[0023] Such as figure 1 , 3 As shown, an adjustable transformer core assembly platform includes a platform 1 and a bottom plate 3 parallel to it. The lower surface is connected with two beams 5 arranged at intervals. The beams 5 run through the lower surface of the deck 1 and are parallel to each other and perpendicular to the deck 1 and the legs 2. One of the beams 5 is welded, riveted or screwed to the deck 1 The lower surface of the other crossbeam 5 is flexibly connected with the chute or positioning groove (not shown in the figure) provided in the platen 1 through fasteners, and the movement of the crossbeam 5 in the chute or positioning groove realizes its The lateral position is adjustable, and the crossbeam 5 protrudes from each outer end of the two sides of the platen 1 and is welded with 8 nuts 4, such as figure 1 , 3 As shown, only the adjusting bolt 10 is vertically screwed into the 2nd to 5th nut 4 near the side of the platen 1, the upper end of the adjusting b...

Embodiment 2

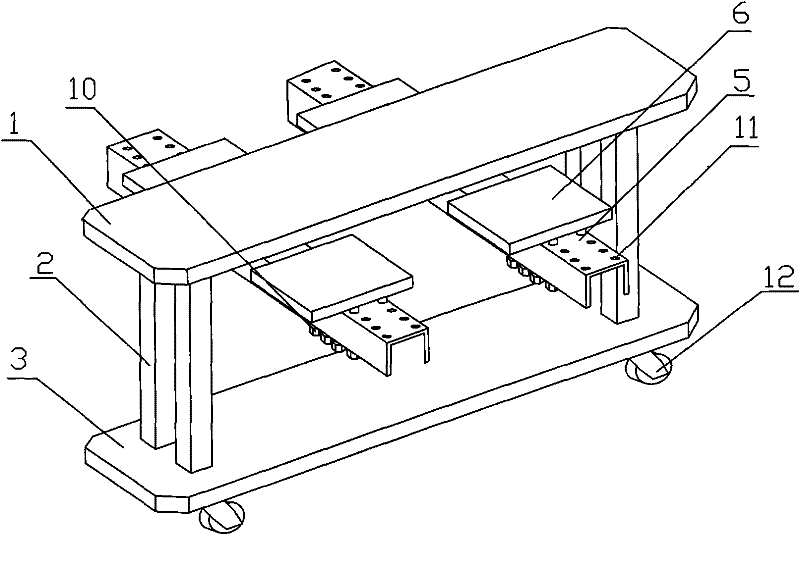

[0027] Such as figure 2 As shown, an adjustable transformer core assembly platform includes a platform 1 and a bottom plate 3 parallel to it. The lower surface is connected with two beams 5 arranged at intervals. The beams 5 run through the lower surface of the deck 1 and are parallel to each other and perpendicular to the deck 1 and the legs 2. One of the beams 5 is welded, riveted or screwed to the deck 1 The lower surface of the crossbeam 5 is movably connected with the chute or positioning groove (not shown in the figure) provided in the platen 1 through fasteners, and there are 8 through screw holes on the upper surface of the crossbeam 5. Connect the screw hole 11 of the adjusting bolt 10, because the adjusting bolt 10 needs to be installed in the screw hole 11, so the lower surface of the beam 5 cannot be closed, so the channel steel is used to make the beam 5, as figure 2 As shown, only the adjusting bolts 10 are vertically screwed into the 2-5 screw holes 11 near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com