Fail-safe tooling for engine crankshaft thrust washer

An engine and thrust plate technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of engine quality, engine crankshaft, cylinder block wear and other problems, and achieve the effects of simple production, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

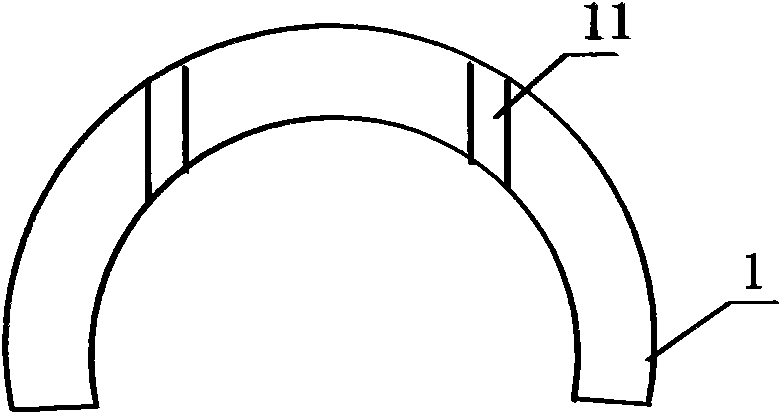

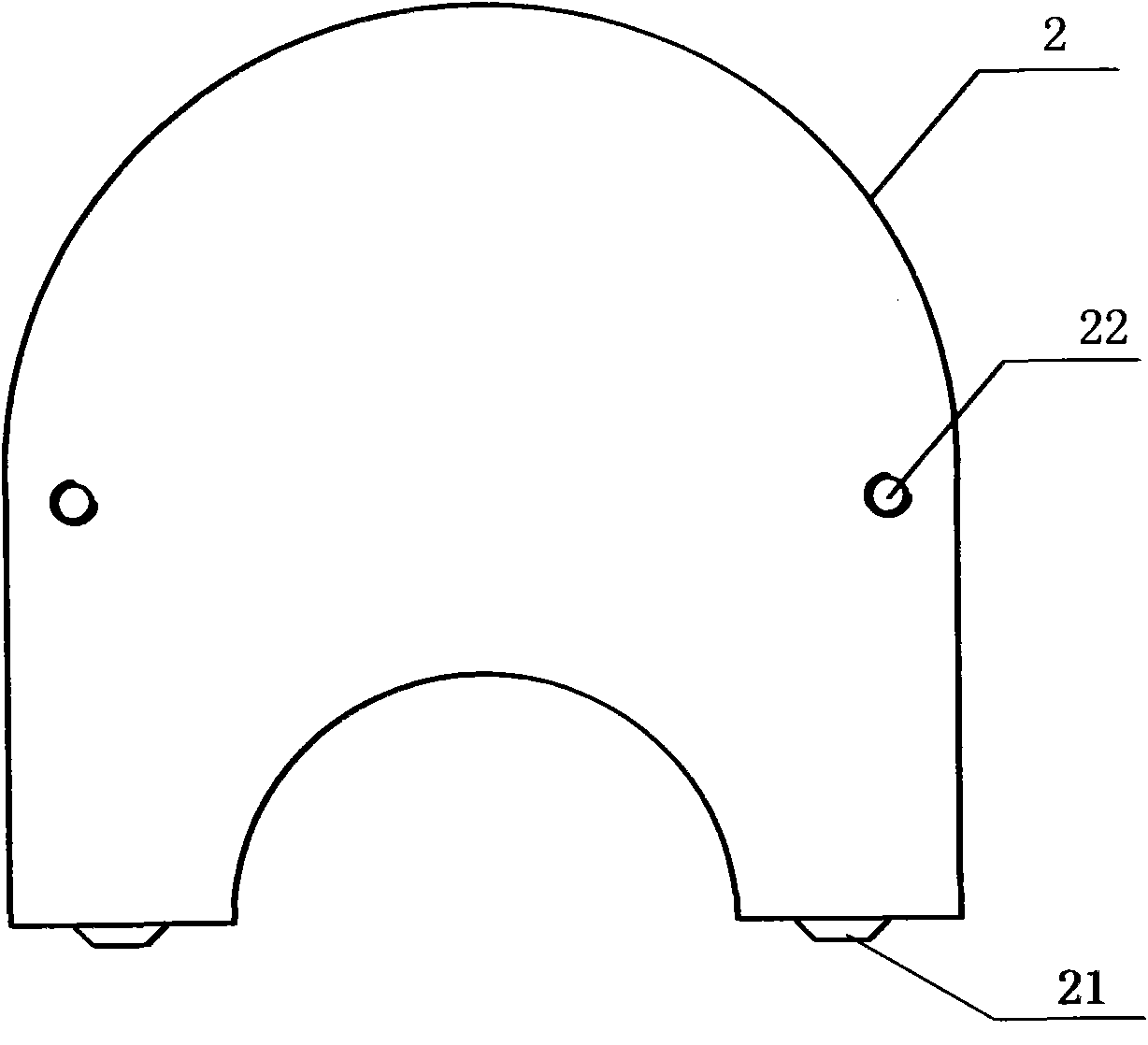

[0018] The invention includes a base body and an anti-error beam installed in the middle of the base body. See figure 2 , image 3 As shown, the cross-section of the middle part of the base body 2 is rectangular. The two ends of the bottom surface of the base body 2 are respectively provided with positioning pins 21; the middle part of the bottom surface of the base body forms an arc-shaped depression upward. The upper part of the base body is arc-shaped upwards. The substrate is provided with screw holes 22 to facilitate the installation of the error-proof beam through bolts.

[0019] See Figure 4 , Figure 5 As shown, on both sides of the central point of the side wall surface of the described anti-error beam 3, there are two protrusions 31 that match the oil groove on the engine crankshaft thrust plate symmetrically, and the distance between the two protrusions 31 is the same as The distance between the two oil grooves on the engine crankshaft thrust plate is equal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com